Automobile rear floor bearing structure

A load-bearing structure and automobile technology, which is applied to the upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems of complex structure, poor force on the rear floor, easy cracking, etc., and achieve good load-bearing performance and good manufacturability , the effect of strength draft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further illustrate the present invention below in conjunction with accompanying drawing:

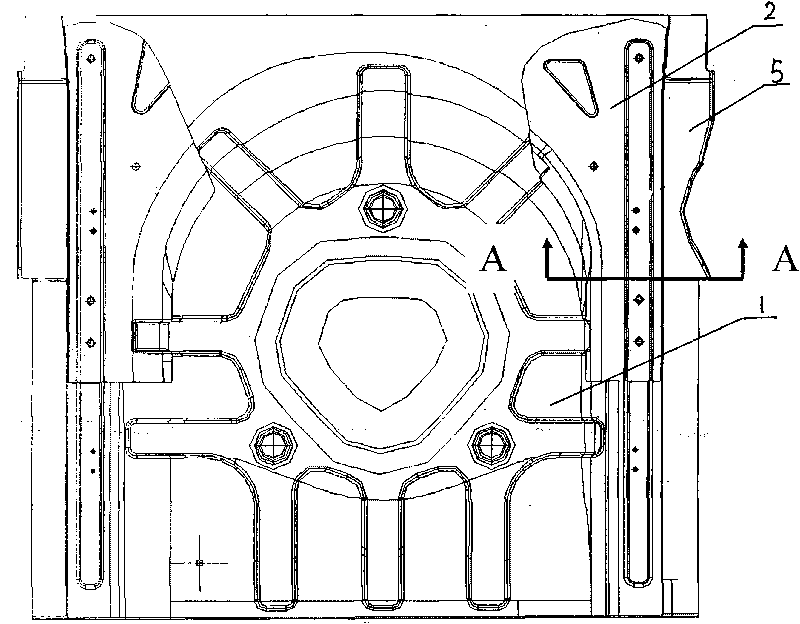

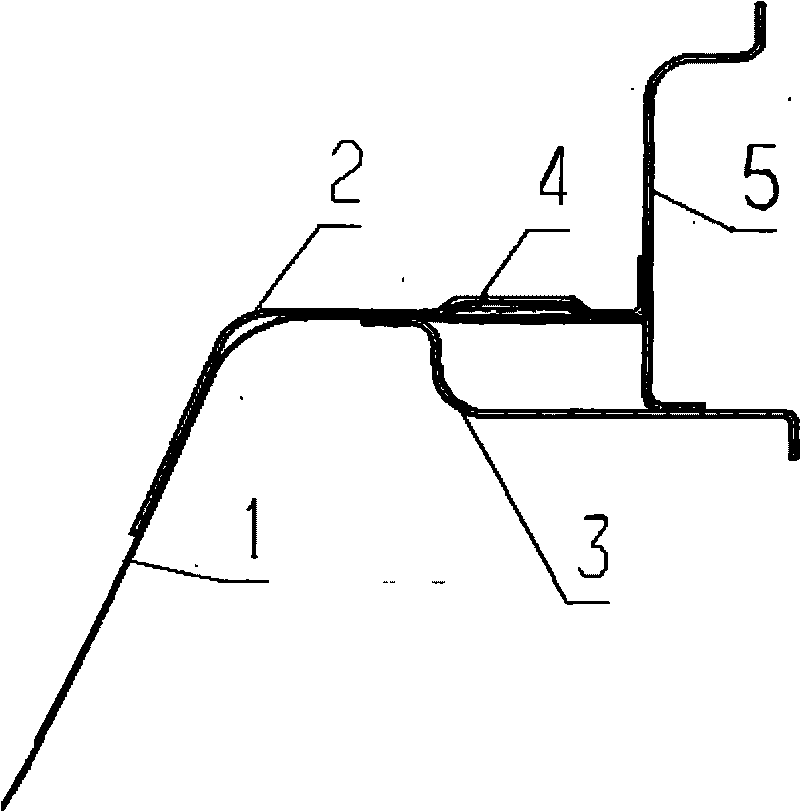

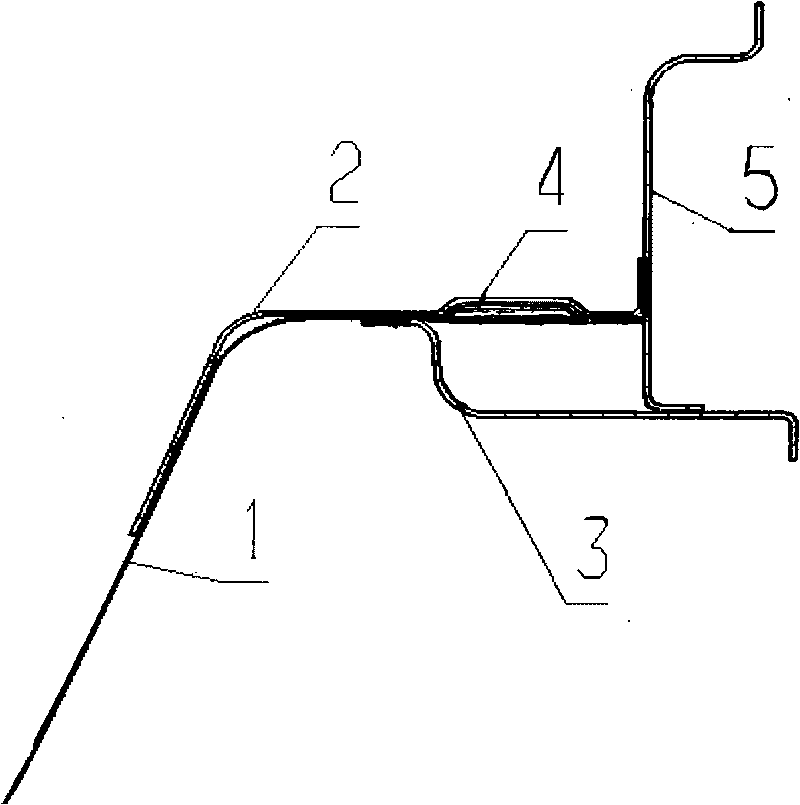

[0014] see figure 1 and figure 2 , The load-carrying structure at the rear of the floor includes a car rear floor 1 , a rear longitudinal beam 3 and a rear floor side panel 5 , a rear floor reinforcement 2 and a rear floor nut plate 4 . The left and right sides of the rear floor 1 are welded to the rear floor side panels 5 through flanging, and the rear longitudinal beam 3 is welded to the bottom surfaces of the left and right sides of the rear floor 1 . The cross-section of the rear longitudinal beam 3 is L-shaped, and its one side is welded with the bottom edge of the rear floor 1, and the other side is welded with the lower edge of the rear floor side plate 5, so that the back floor 1, the rear longitudinal beam 3 and the rear floor side plate The middle of 5 is surrounded to form a cavity-shaped structure, which has better bearing capacity.

[0015] The left and right side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com