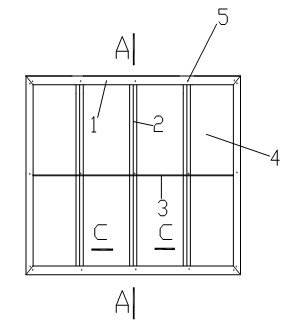

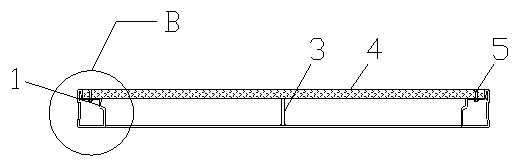

Light empty steel frame plywood formwork and assembling method

A technology of plywood and hollowing, applied in the field preparation of formwork/formwork components, building components, construction, etc., can solve the problems of poor stiffness and easy warping and deformation, and achieve easy welding and assembly, fewer welds, and high precision Create shaped effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

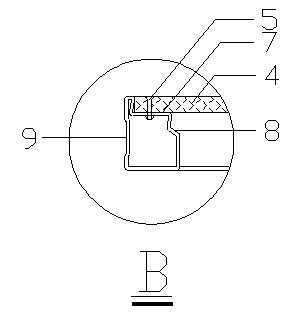

[0020] The height of the open web outer rib of the present invention matches the 15mm thickness wood plywood commonly used in construction sites and the flat 40×90mm or 50×100mm wood square size, that is, the height is 15mm+40mm=55mm or 15+50mm=65mm; Q235 steel or Q345 steel welded pipe or seamless steel pipe is drawn, or coiled steel is cold-formed and welded into the required size of outer rib hollow steel pipe, which solves the manufacturing problem of smaller size hollow special-shaped pipe; the outer peripheral hollow steel frame adopts a stepped section shape, the first One horizontal step can be used as a platform for shelving and installing wood plywood or bamboo plywood with a thickness of 9mm or 12mm. The second inclined step can be used as a platform for the clamping jaws of the fixing fixture between the steel frame plywood template blocks, and can also be used as a building Workers grasp the platform of the formwork block with their fingers when assembling and disas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com