High-capacity pallet transport boxcar

A large-volume, pallet-based technology, which is applied in the railway transport boxcar structure and the field of railway freight car manufacturing, can solve the problems of poor loading environment of goods in the car, the inability to load pallet goods, and increase the volume of the vehicle, so as to reduce the weight of the vehicle and avoid partial Crushing phenomenon, the effect of enlarging the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]Below in conjunction with embodiment the present invention is further described.

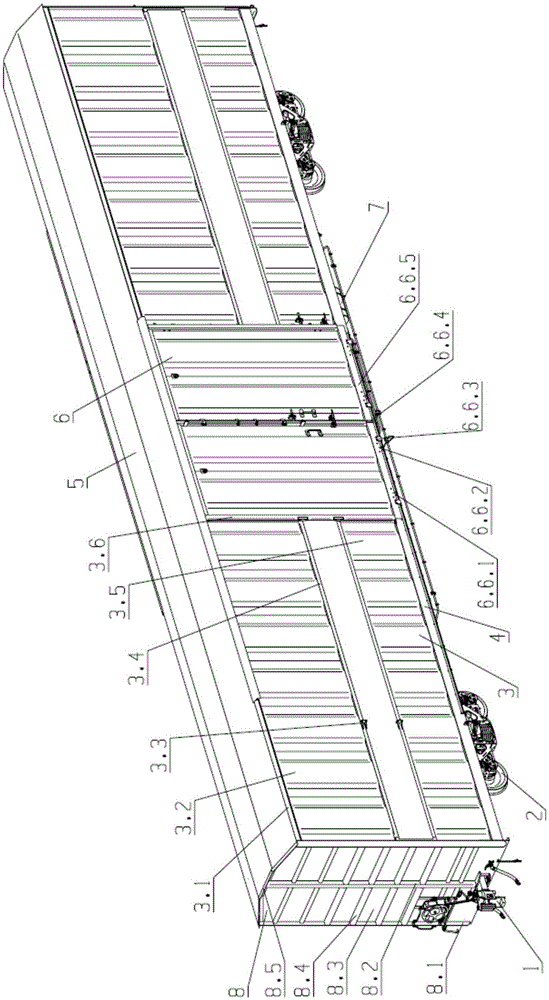

[0048] refer to figure 1 — Figure 9 As shown, the present invention provides a large-volume pallet transport boxcar, which includes a coupler buffer device 1, a bogie 2, a side wall 3, an underframe 4, a roof 5, a door 6, an air brake device 7 and an end wall 8; The roof 5 is a grid beam structure, the side wall 3 is a corrugated plate structure that can be installed with pallets, the underframe 4 is a fish-belly beam structure, the door 6 is a structure with a container locking device, and the end wall 8 is a broken line shape beam structure.

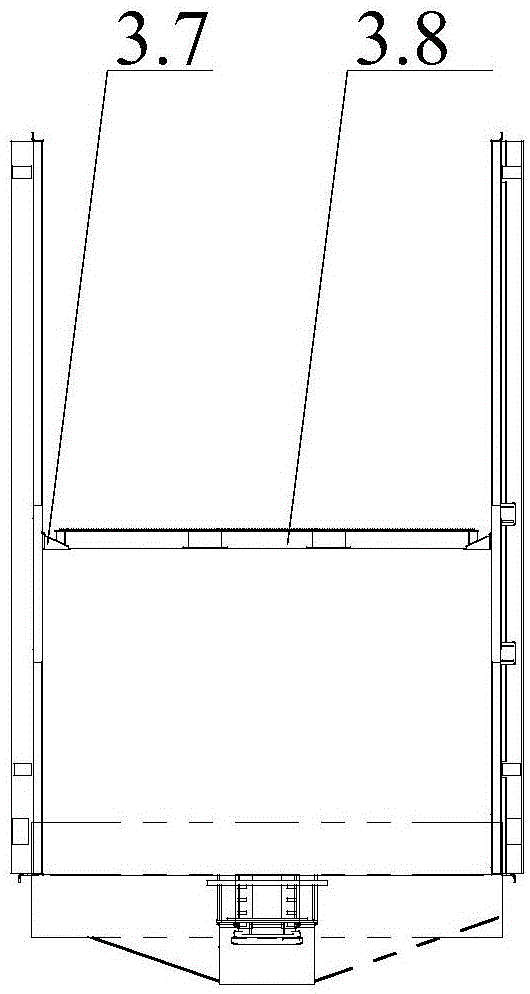

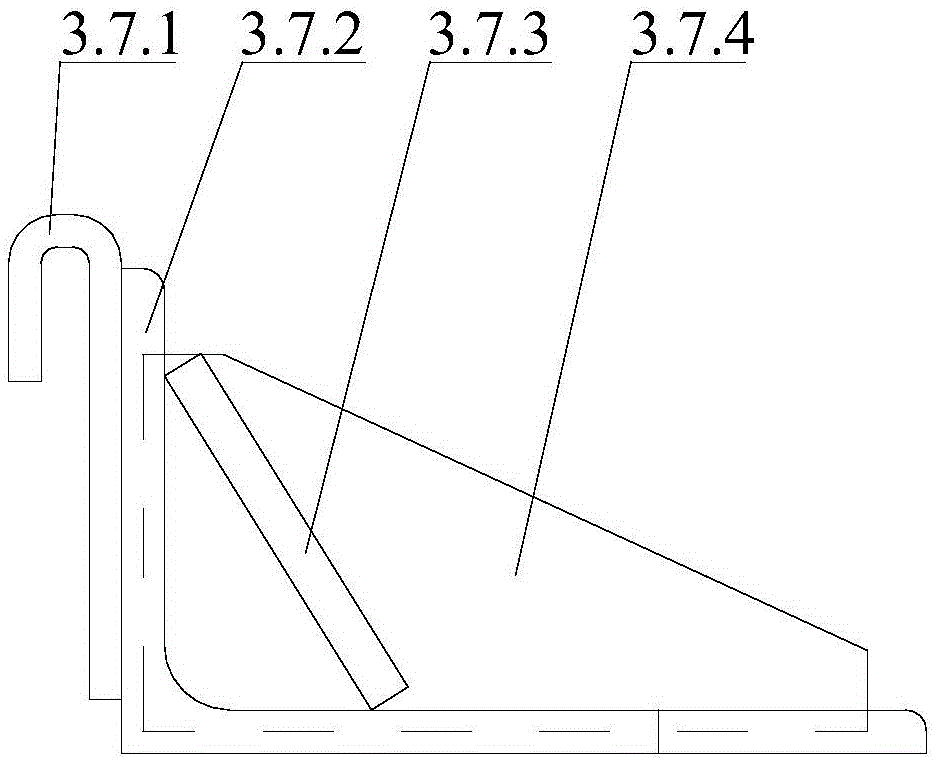

[0049] The side wall 3 includes an upper side beam 3.1, an upper side wall panel 3.2, a door stop 3.3, a bracket, a horizontal belt 3.4, a lower side wall panel 3.5, a door post 3.6, a chain ring, a hook composition 3.7 and a tray 3.8. The upper side wall panel 3.2 and the lower side wall panel 3.5 adopt a corrugated structure, cancel the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com