Assembling and welding clamp

A welding fixture and clamping unit technology, applied in the field of welding fixtures, can solve problems such as increased manufacturing cost, and achieve the effects of convenient welding operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

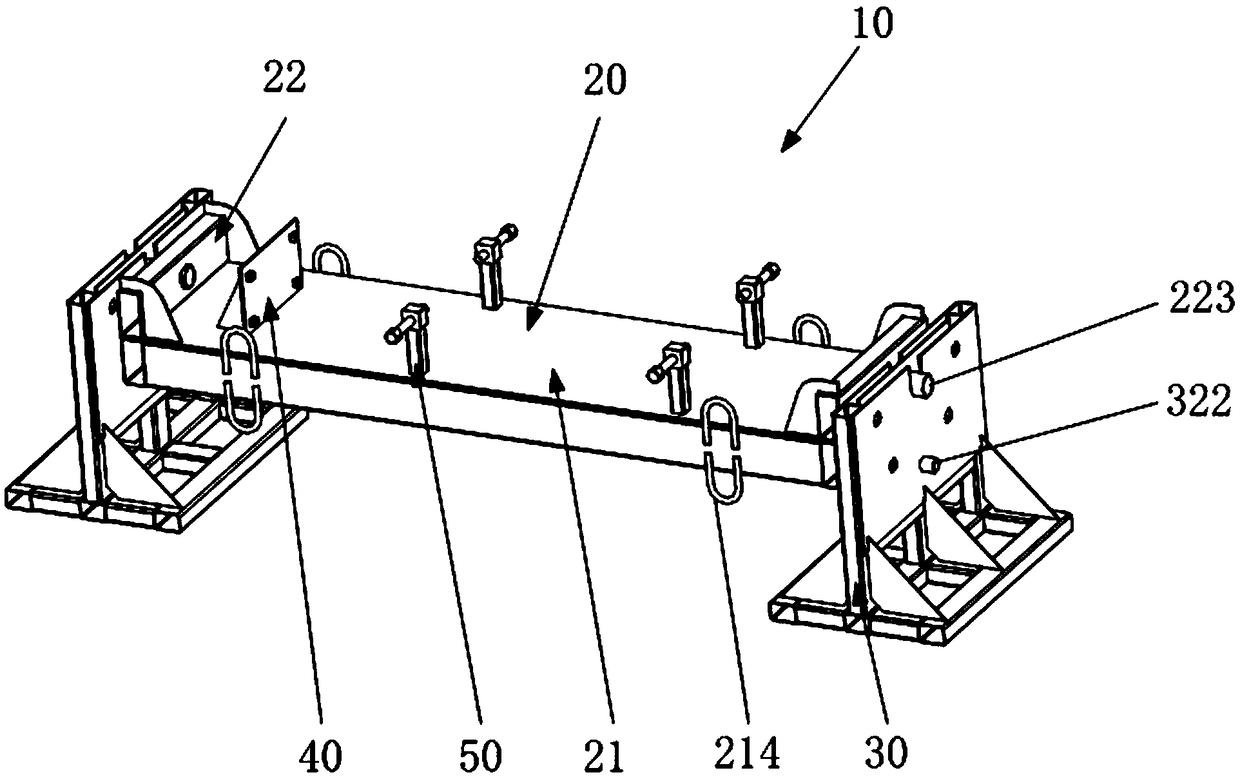

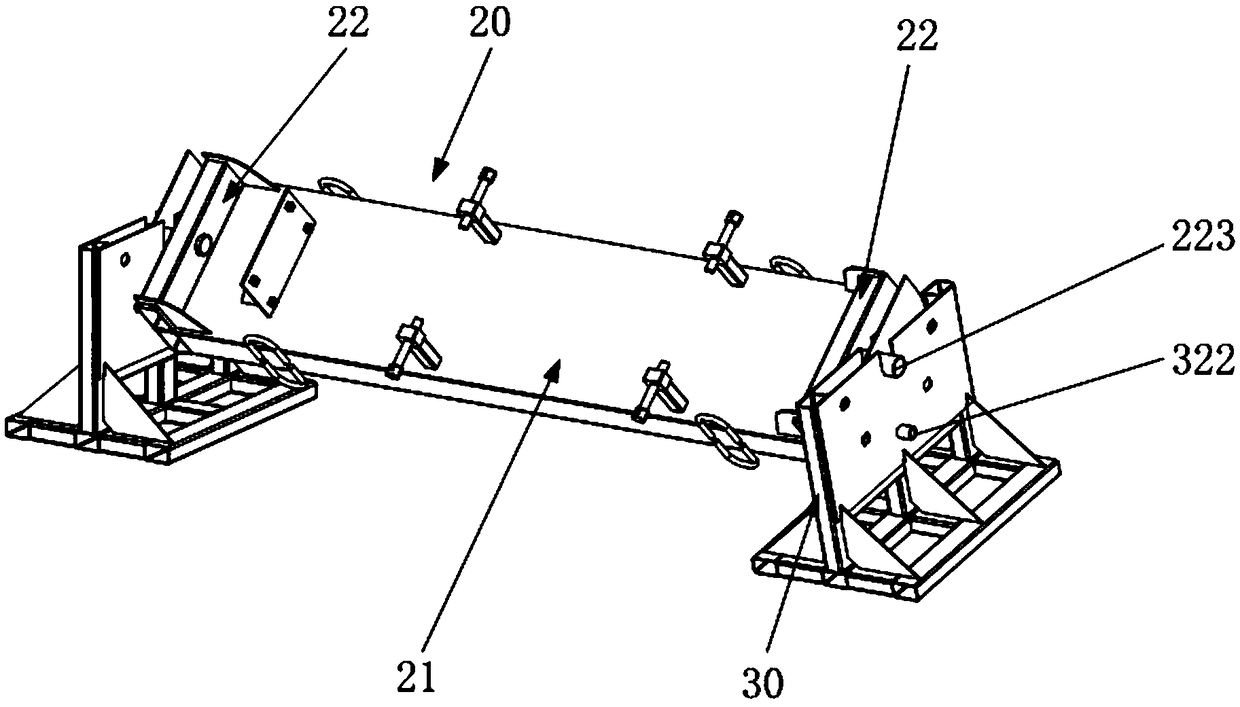

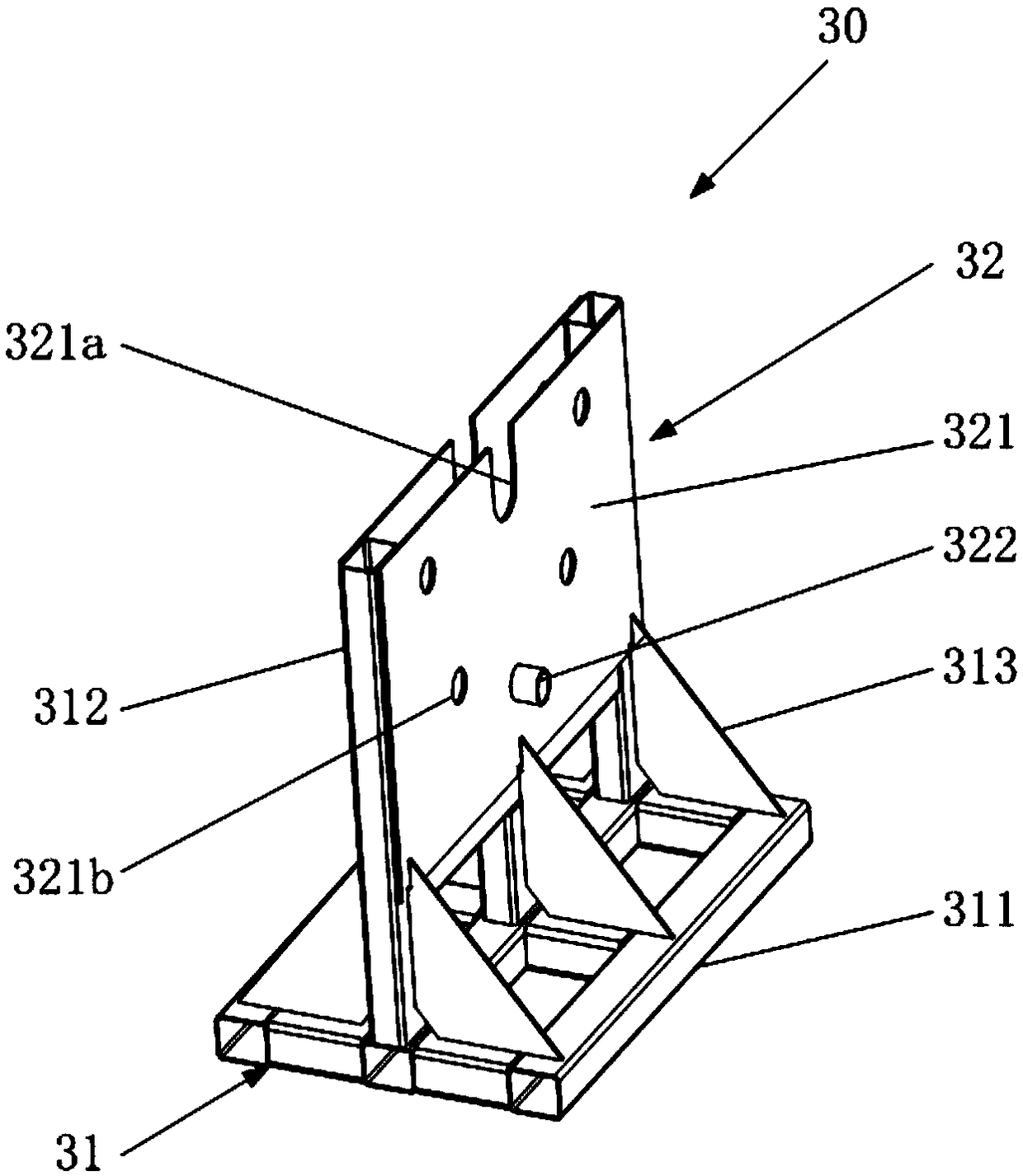

[0030] figure 1 It is an overall three-dimensional schematic diagram of the platform operation unit of the welding fixture of the present invention in a horizontal state. figure 2 It is an overall three-dimensional schematic diagram of the platform operation unit of the welding fixture of the present invention in an inclined state. Figure 4 It is a three-dimensional schematic diagram of the platform operation unit of the welding fixture of the present invention.

[0031] Such as figure 1 As shown, the welding jig 10 is used for assembling and welding small and medium-sized steel structures. unit.

[0032] The platform operation unit 20 is supported by the rotation support unit 30 in a manner of being erected on the left and right rotation support units 30 , and there is a space for the platform operation unit 20 to rotate on the lower side of the platform operation unit 20 . The platform working unit 20 has a working platform 21 for performing welding work, and left and ...

Embodiment 2

[0044] Except for the following technical content, all the other conditions are the same as in Embodiment 1: the disposition angular interval of the support plate positioning holes 224b of the rotating support plate 224 is set corresponding to the positioning plate positioning holes 321b of the rotating positioning plate 321, and the plurality of support plate positioning holes 221b of the rotating support plate 224 The arrangement angular intervals of the plate positioning holes 224b are 30°, and the arrangement angular intervals of the plurality of positioning plate positioning holes 321b of the rotation positioning plate 321 are 30°.

Embodiment 3

[0046] Except for the following technical content, all the other conditions are the same as in Embodiment 1: the disposition angular interval of the support plate positioning hole 224b of the rotating support plate 224 does not correspond to the positioning plate positioning hole 321b of the rotating positioning plate 321, and the plurality of support plate positioning holes 321b of the rotating support plate 224 The arrangement angular interval of the plate positioning holes 224b is 30°, and the arrangement angular interval of the plurality of positioning plate positioning holes 321b of the rotation positioning plate 321 is 45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com