Connecting structure for underframe edge beam and side wall of straddle-type monorail vehicle body

A straddle-type monorail and connecting structure technology, applied in the direction of the chassis, railway car body, monorail system, etc., can solve the problems of complicated manufacturing process of side beams, difficult welding, large amount of arc welding, etc., to reduce work Difficulty, reducing the amount of arc welding, simplifying the effect of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

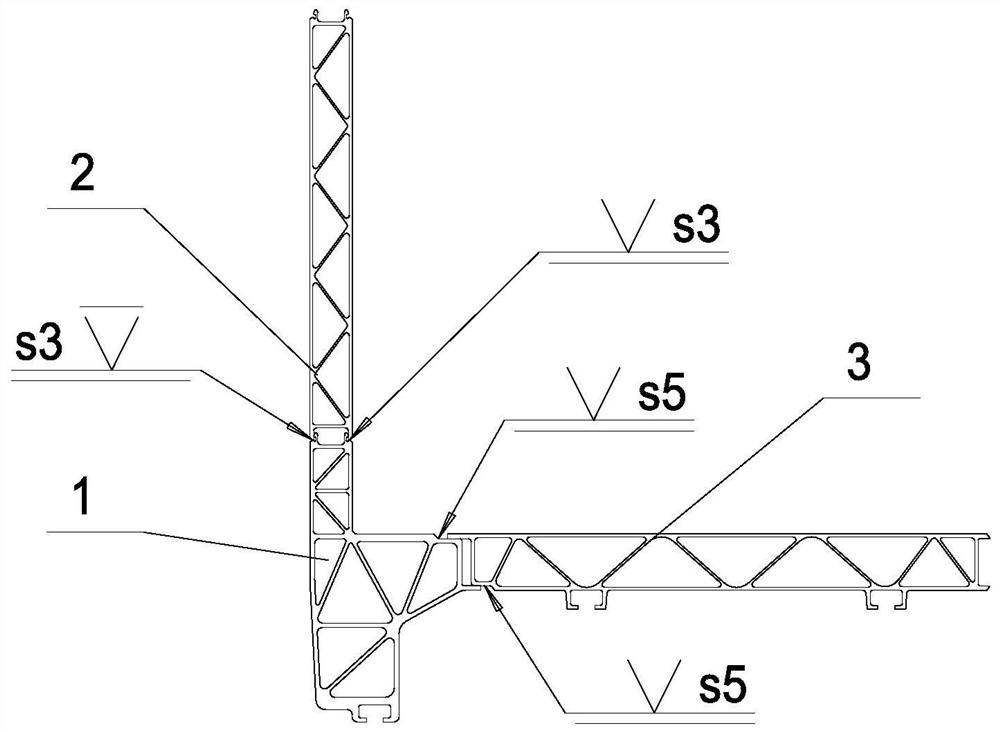

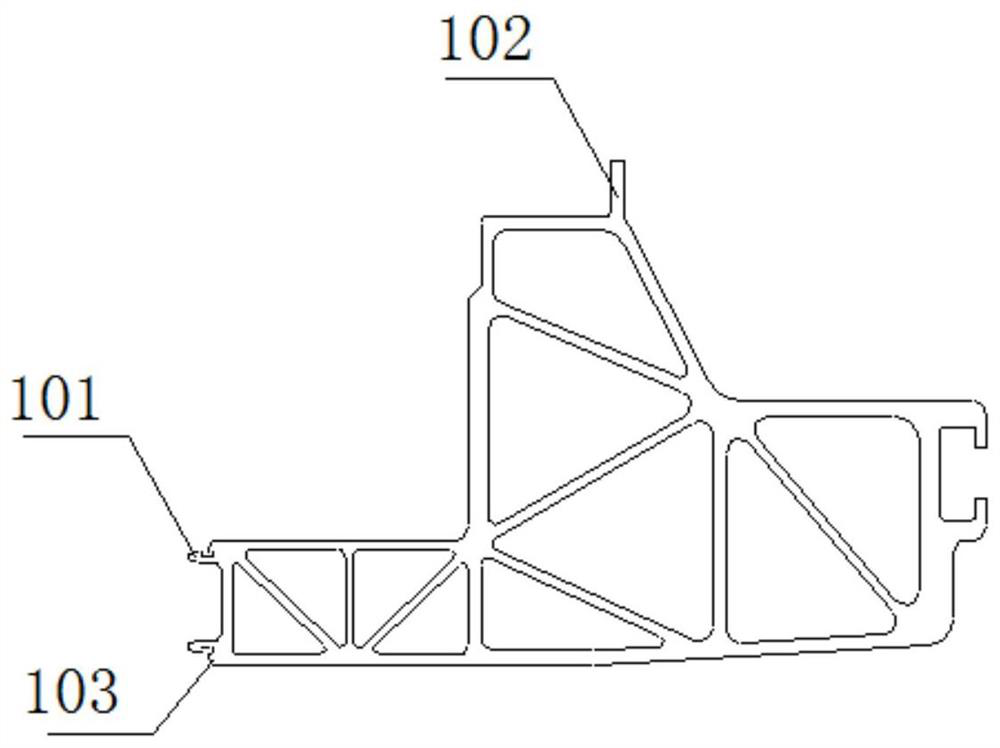

[0013] refer to figure 1 , figure 2 , the large part of the underframe of the straddle-type monorail train body of the present invention adopts the plug-in structure of aluminum alloy closed-end profiles. The aluminum alloy profile of the full-length underframe side beam of this section is obtained by the aluminum alloy extrusion molding process. The connection between the side beam profile and the side wall of the bottom frame is designed with a plug interface 101. This structure simplifies the connection form between the side wall and the bottom frame, improves the assembly accuracy of the side wall and the bottom frame, reduces the difficulty of assembly, and reduces the number of side walls. The number of welds at the connection with the chassis improves the overall quality and precision. The upper end of the side beam structure of the underframe is designed with a socket interface 101 for arc welding connection with the side wall panel, which reduces the difficulty of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com