Four-arm helical antenna of novel feed structure

A four-armed helix, a new type of technology, applied in the direction of the radiating element structure and the connection of the antenna grounding switch structure, can solve the problems of reducing the size of the antenna, restricting the application, etc., to reduce the overall size, improve the qualification rate, and achieve excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

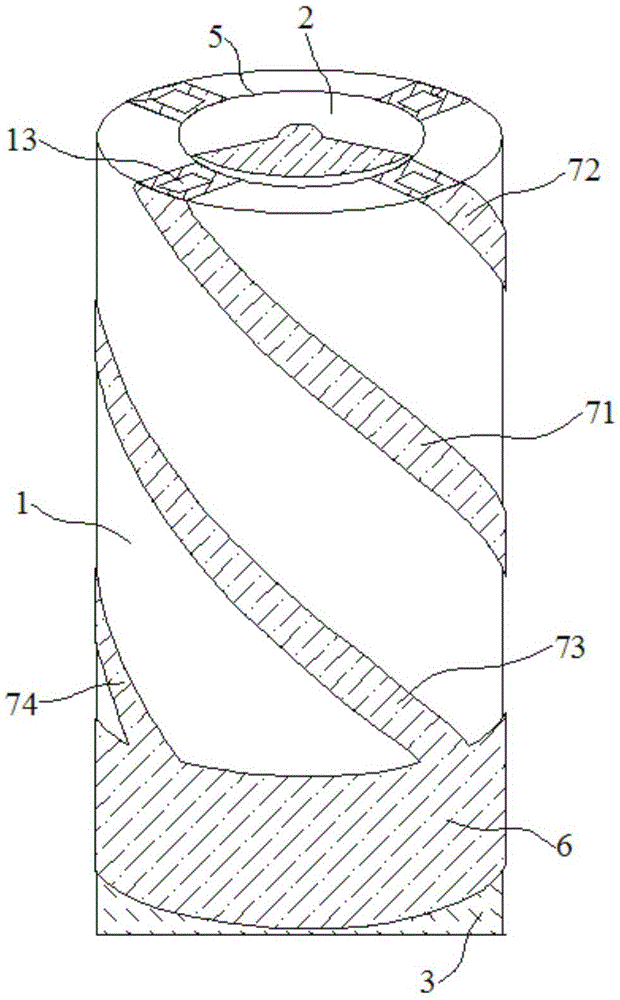

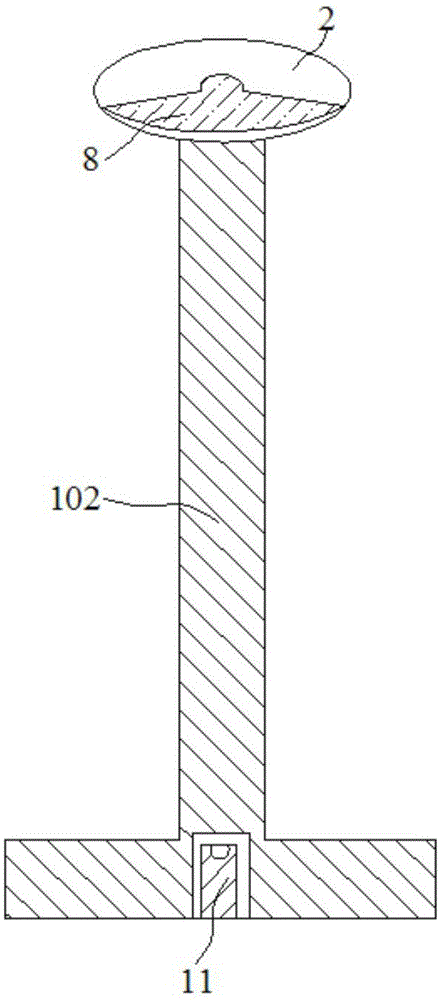

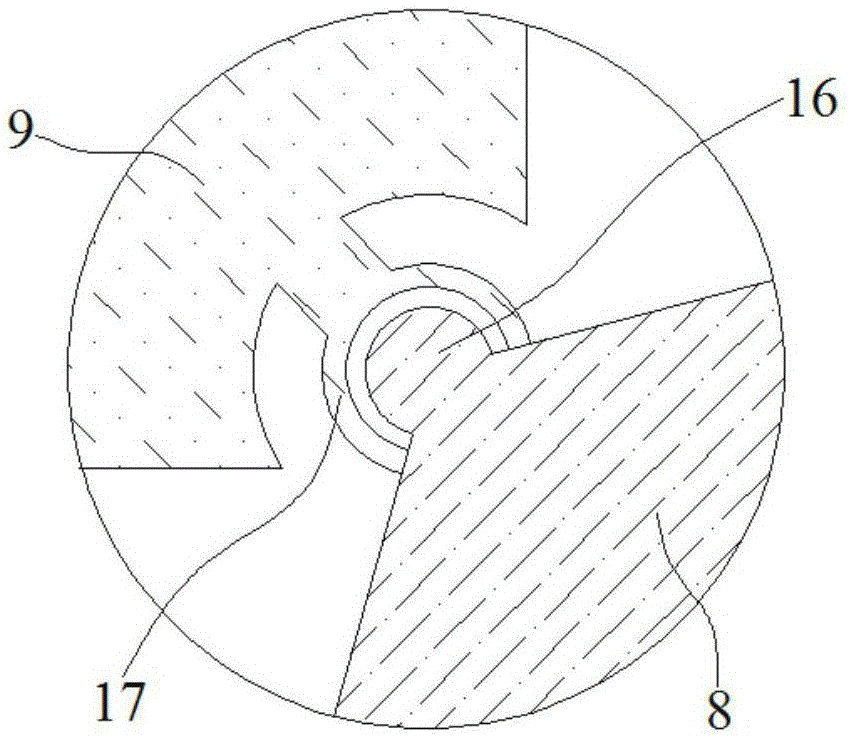

[0035] Embodiment 1: A four-arm helical antenna with a new feed structure, including a ceramic cylinder 1 with a through hole 5 at the axis, an upper PCB printed circuit board 2, a lower PCB printed circuit board 3 and a PCB printed connection board 4, The upper PCB printed circuit board 2 and the lower PCB printed circuit board 3 are respectively located in the upper opening and the lower part of the through hole 5, and the PCB printed connection board 4 is located in the through hole 5 of the ceramic cylinder 1 and is located on the upper PCB printed circuit board. 2. Between the lower PCB printed circuit board 3;

[0036] The lower part of the outer surface of the ceramic cylinder 1 has a Balun line 6 along the circumferential direction, and four metal spiral arms 7 are wound on the outer surface of the ceramic cylinder 1 at intervals, and the upper ends of the four metal spiral arms 7 extend to the ceramic cylinder 1. On the upper end surface of the ceramic cylinder 1, a m...

Embodiment 2

[0045] Embodiment 2: A four-arm helical antenna with a new feeding structure, including a ceramic cylinder 1 with a through hole 5 at the axis, an upper PCB printed circuit board 2, a lower PCB printed circuit board 3 and a PCB printed connection board 4, The upper PCB printed circuit board 2 and the lower PCB printed circuit board 3 are respectively located in the upper opening and the lower part of the through hole 5, and the PCB printed connection board 4 is located in the through hole 5 of the ceramic cylinder 1 and is located on the upper PCB printed circuit board. 2. Between the lower PCB printed circuit board 3;

[0046] The lower part of the outer surface of the ceramic cylinder 1 has a Balun line 6 along the circumferential direction, and four metal spiral arms 7 are wound on the outer surface of the ceramic cylinder 1 at intervals, and the upper ends of the four metal spiral arms 7 extend to the ceramic cylinder 1. On the upper end surface of the ceramic cylinder 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com