Device for assembling and welding irradiation monitoring pipe

A technology for irradiating supervisory tubes and components, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of processing technology without irradiation supervisory tubes, and achieve the effect of good clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

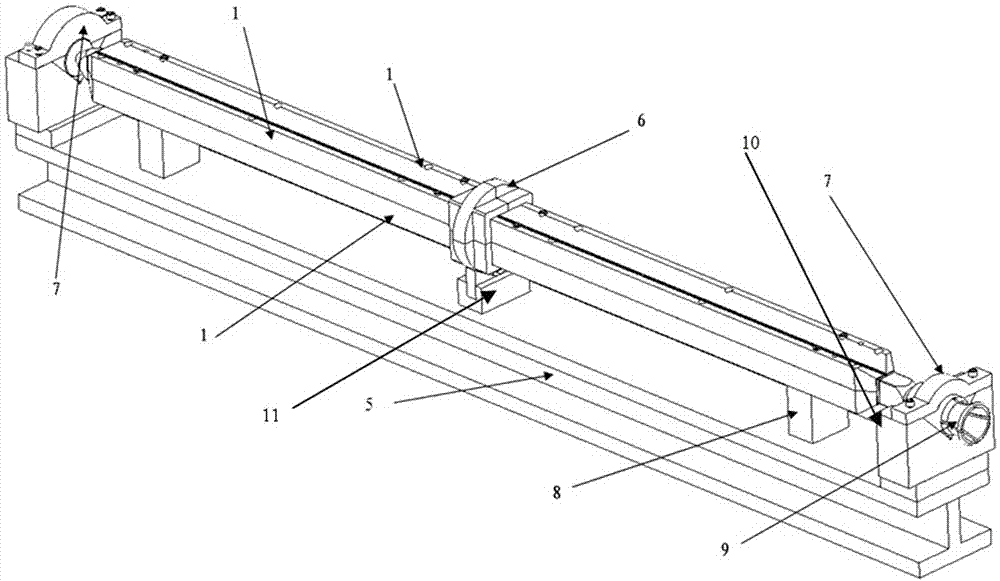

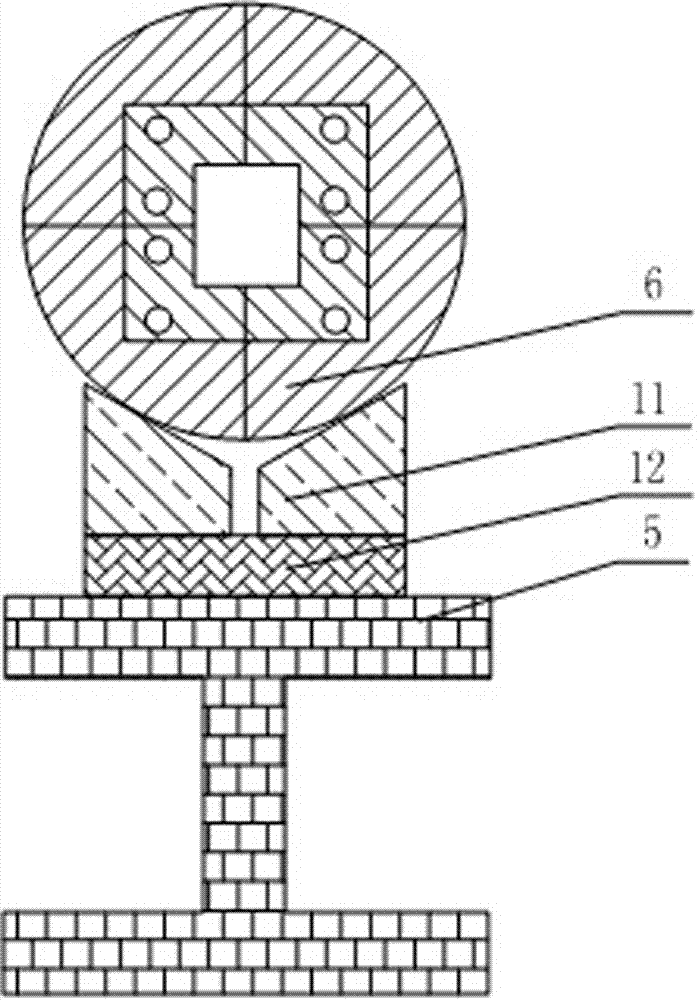

[0023] like figure 1 As shown, the present invention is a device for assembling and welding the radiation supervisory tube, comprising a base 5, the base 5 is made of cast iron, its cross section is I-shaped, and a concave hole is arranged in the middle of the base. The connector 12 of the groove is provided with a support seat 11 in the connector 12, and the support seat is provided with two slopes to form a V-shaped groove. Two neck support blocks 10 on the top, a limit reference block 8 is also provided between the support base 11 and the neck support block 10, the limit reference block 8 is used as a reference for defining length and height, and it is compatible with the neck support The block 10 and the base 5 are formed with an integrated structure, and also include a four-petal centering member 1 that wraps the radiation supervision tube 9. After the four-petal centering member 1 is wrapped on the outside of the radiation supervision tube 9, one end is fixed at the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com