A process for assembling and welding of radiation supervisory tube

A technology of radiation supervision tube and radiation supervision, which is applied in the field of assembly and welding of radiation supervision tube, to achieve the effect of improving the efficiency of assembly and welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

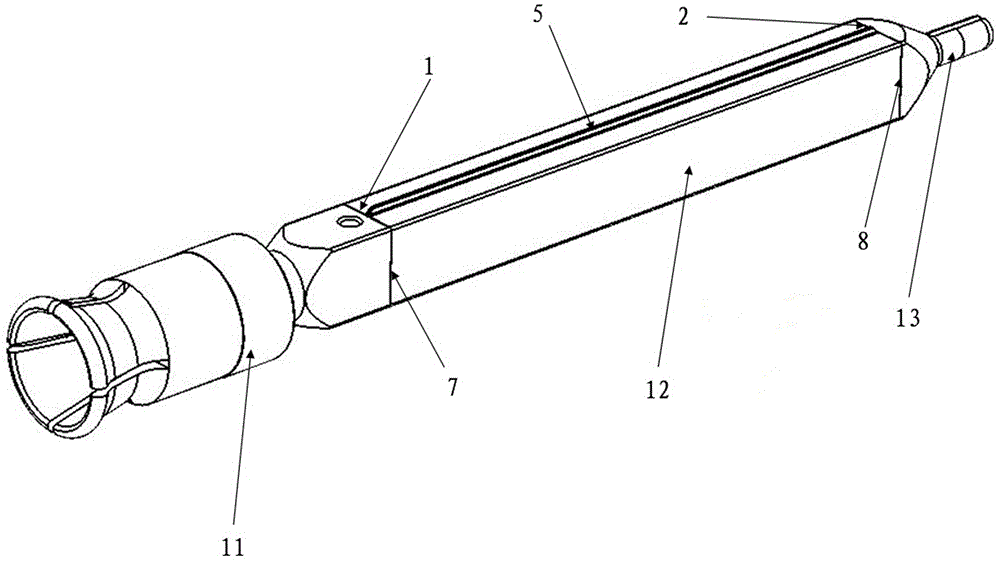

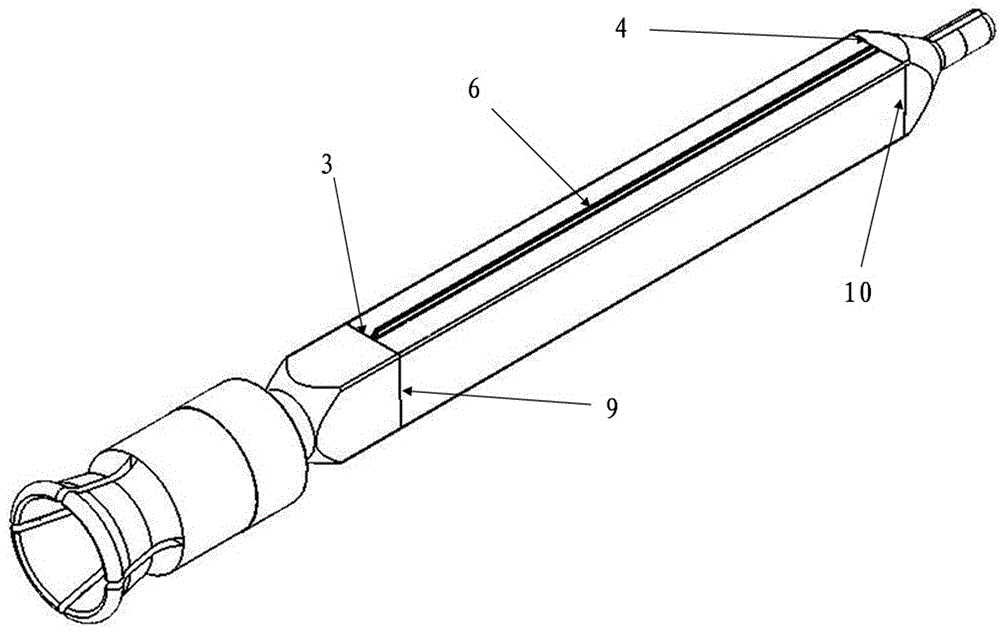

[0029] Such as figure 1 As shown, a process for assembling and welding the irradiation supervisory tube in the present invention is carried out on the welding tool. The tooling includes a base made of cast iron with an I-shaped cross section. A connecting piece with a groove is provided in the middle of the connecting piece, and a supporting seat is provided in the connecting piece, and two slopes are arranged on the supporting seat to form a V-shaped groove. Two neck support blocks on a straight line are also provided with a limit reference block between the support base and the neck support block. Formed with an integrated structure, it also includes a four-petal centering member that wraps the irradiation supervision tube. After the four-petal centering member is wrapped on the outside of the irradiation supervision tube, one end is a bottom plug fixed in the rolling assembly on the support seat, and the other end is For the top plug to be placed on the limit reference blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com