A sheet metal box laser welding machine

A laser welding machine, sheet metal technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of inconvenient process, large consumption of welding tungsten needles, thermal deformation, etc., to achieve firm and beautiful welding seam, welding speed Faster and more efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

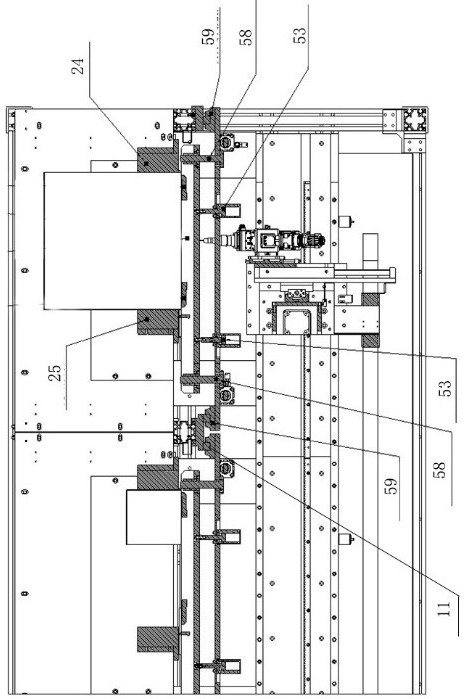

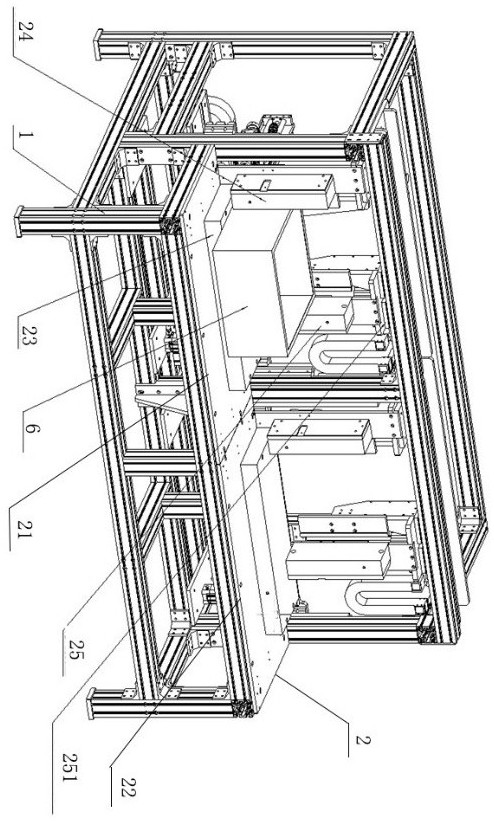

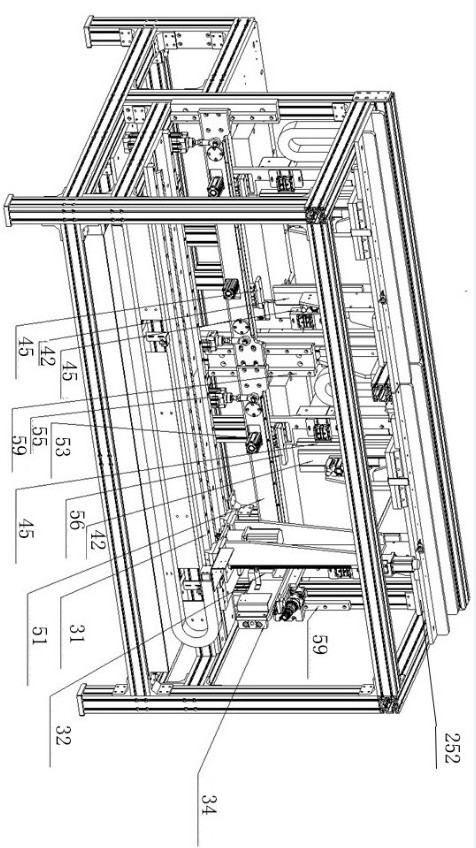

[0021] Combine now figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 To further illustrate the present invention, a sheet metal box laser welding machine includes a frame 1, and the frame 1 is provided with an operating platform 2 and a rear part of the operating platform 2 for pressing the box cover to ensure that the sheet metal The sheet metal positioning device and the welding mechanism 3 for the accuracy of the assembly and positioning of the gold box cover, the first station 21 and the second station 22 are provided on the operating platform 2, and the first station 21 and the second station The two stations 22 are equipped with suction cup assemblies, and the custom-made suction cups are used to fix the workpiece to ensure the flatness, perpendicularity and parallelism of each surface. 2-station design arrangement is adopted, when the workpiece of the 1st station is welded, the workpiece of the 2nd station is clamped, and when the welding of the workpiece of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com