Patents

Literature

53results about How to "High precision and efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

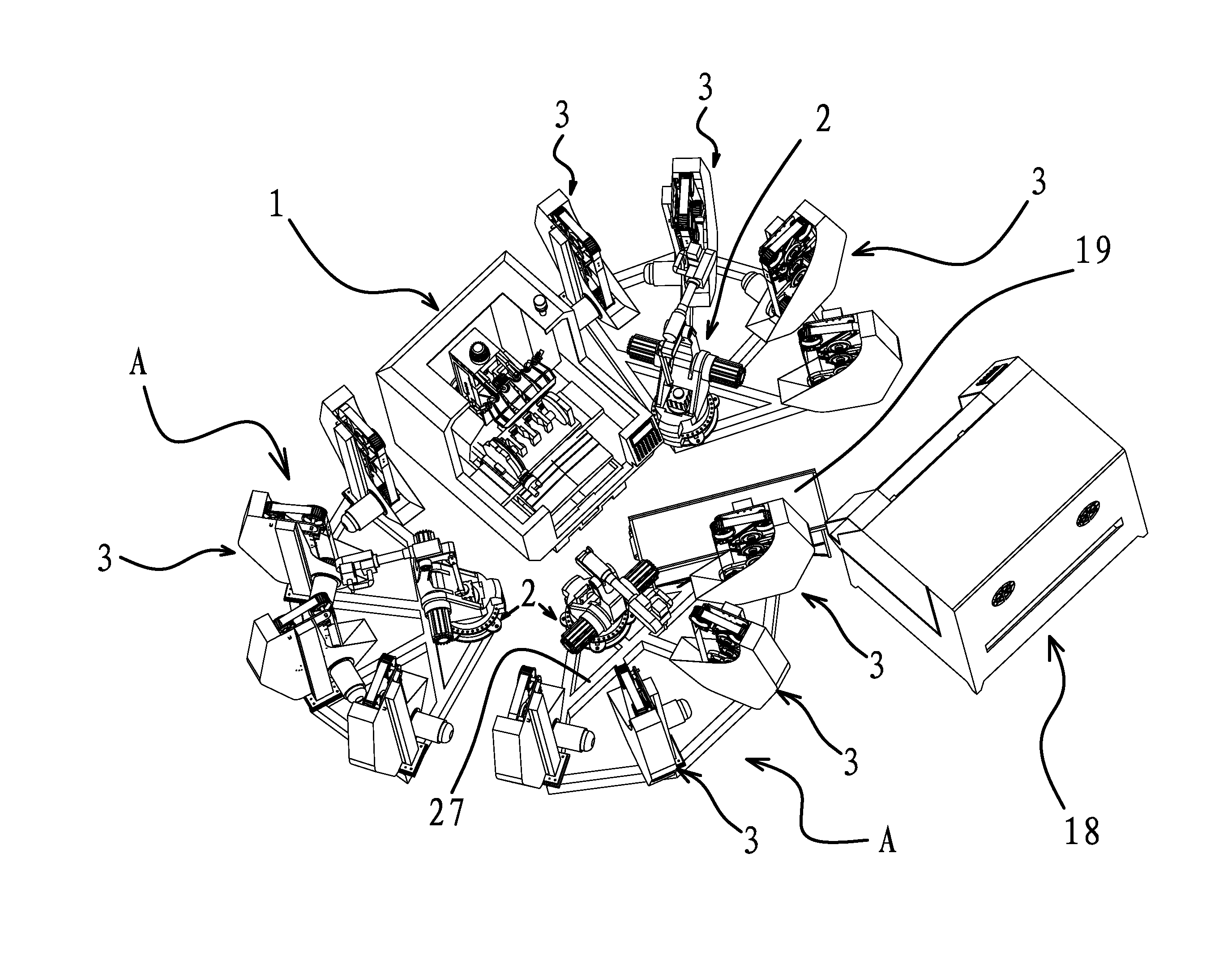

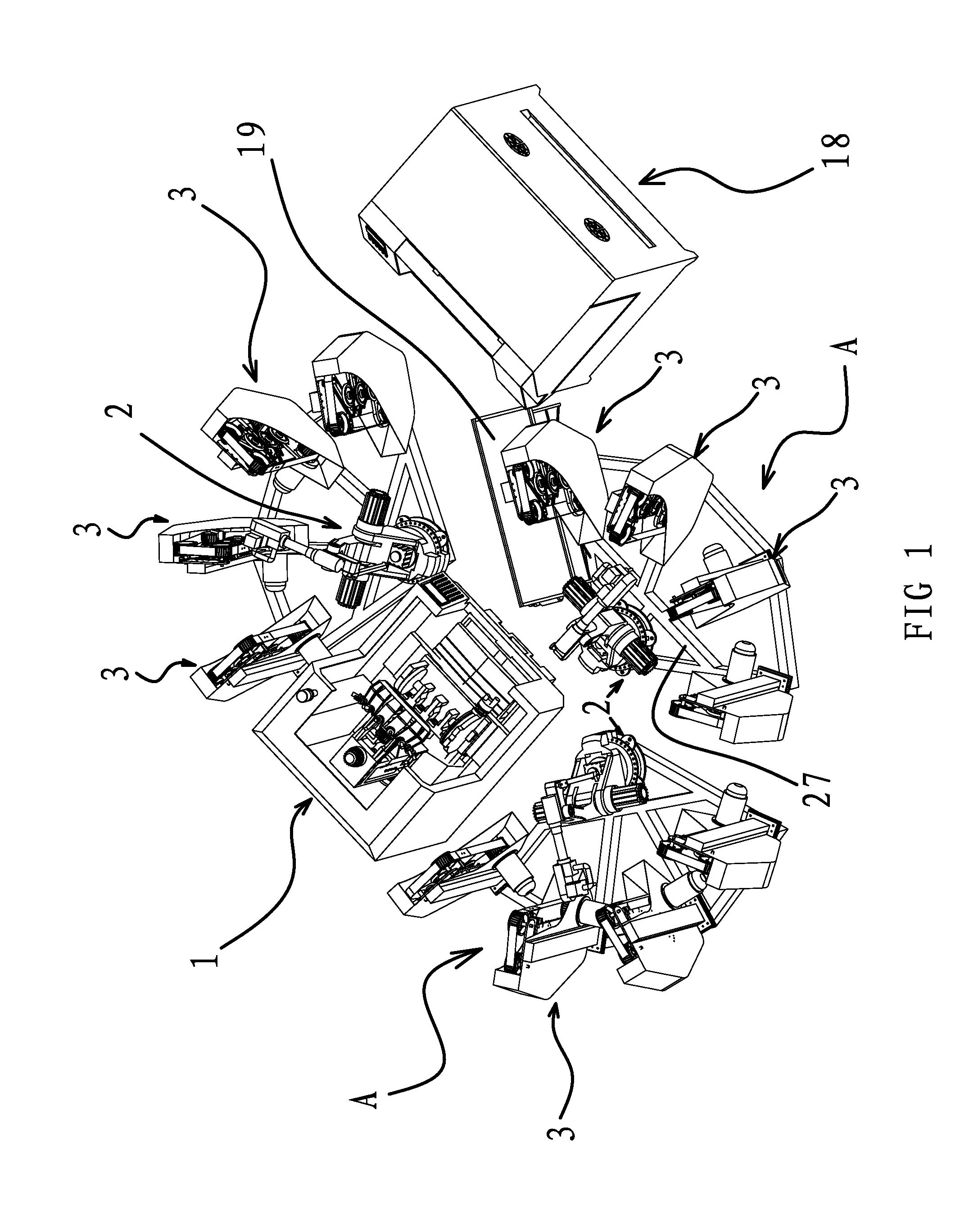

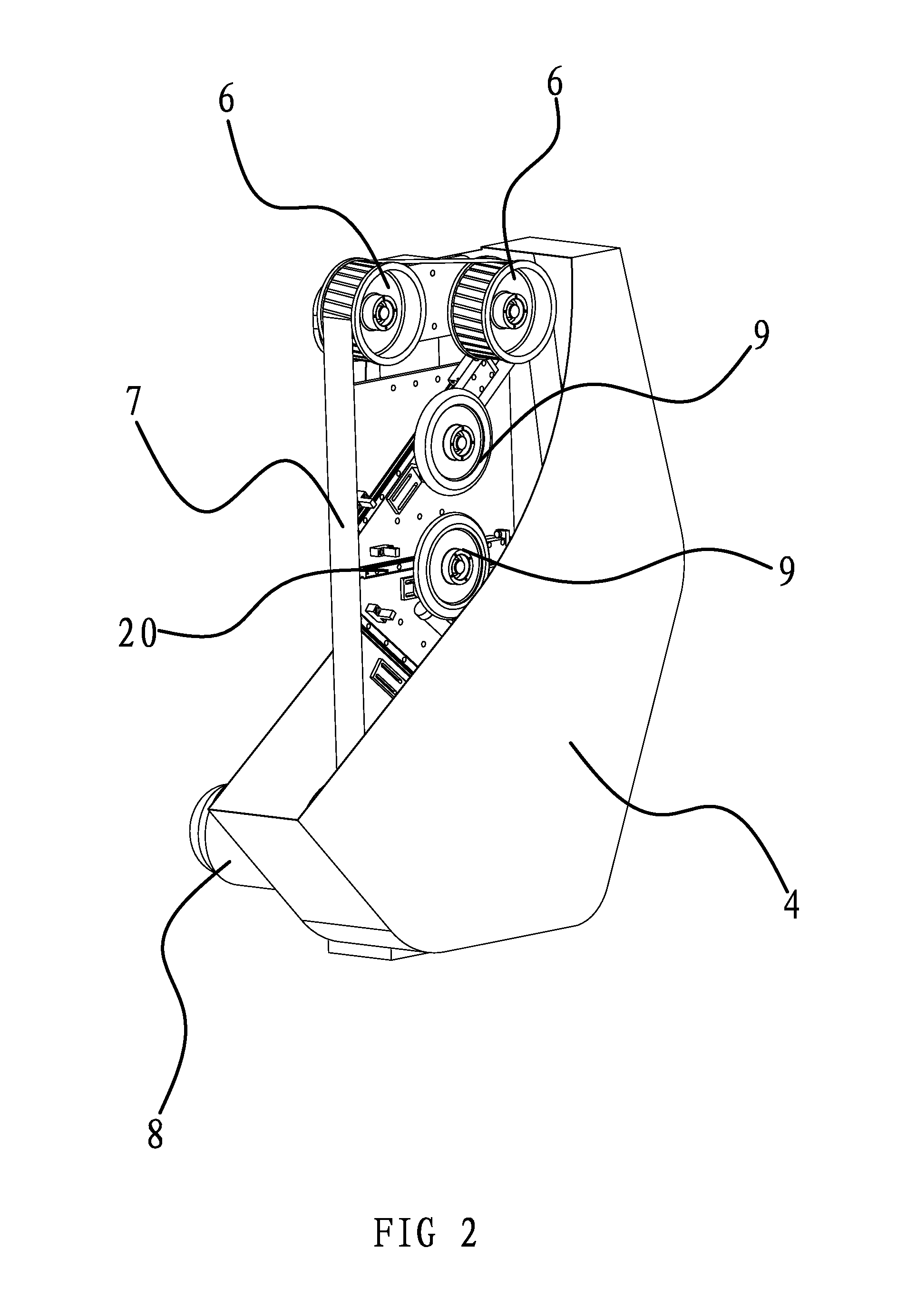

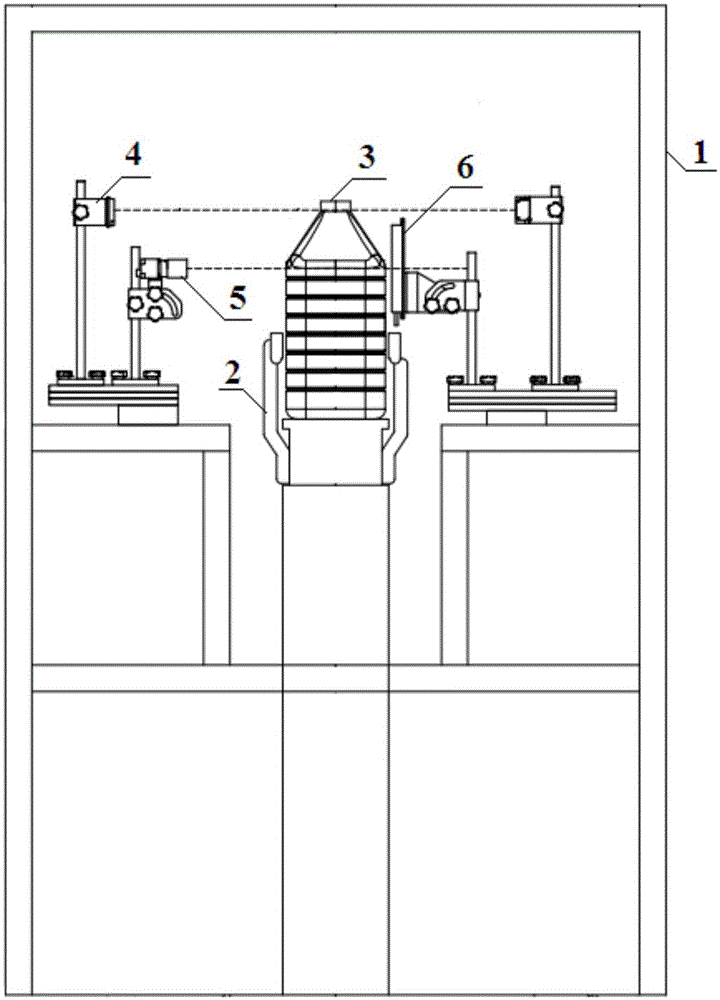

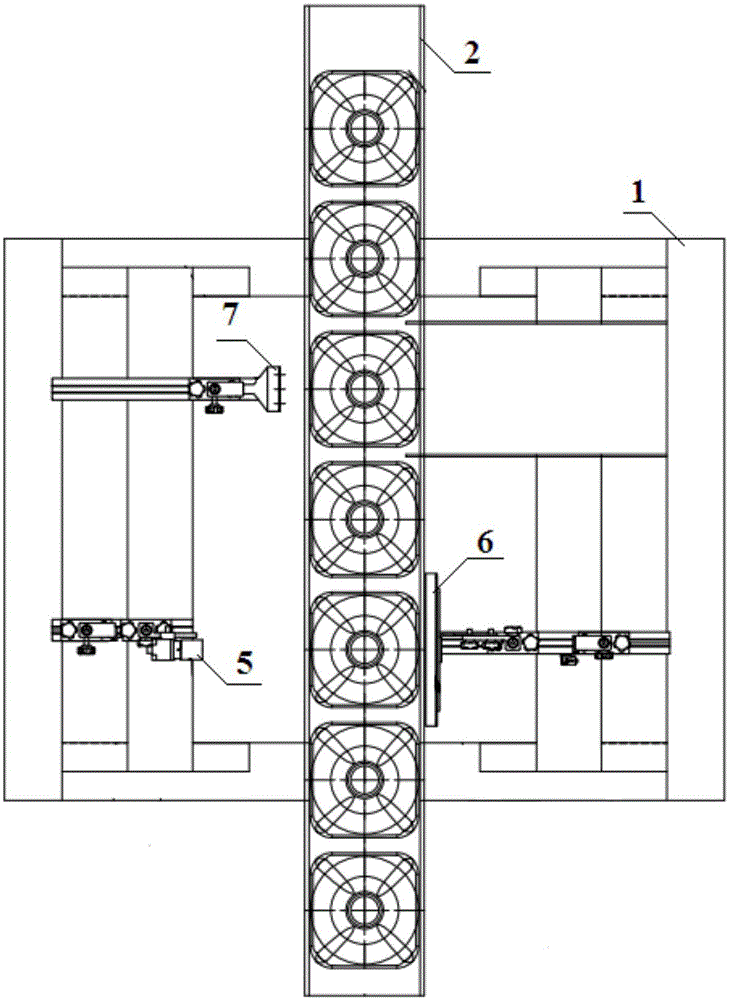

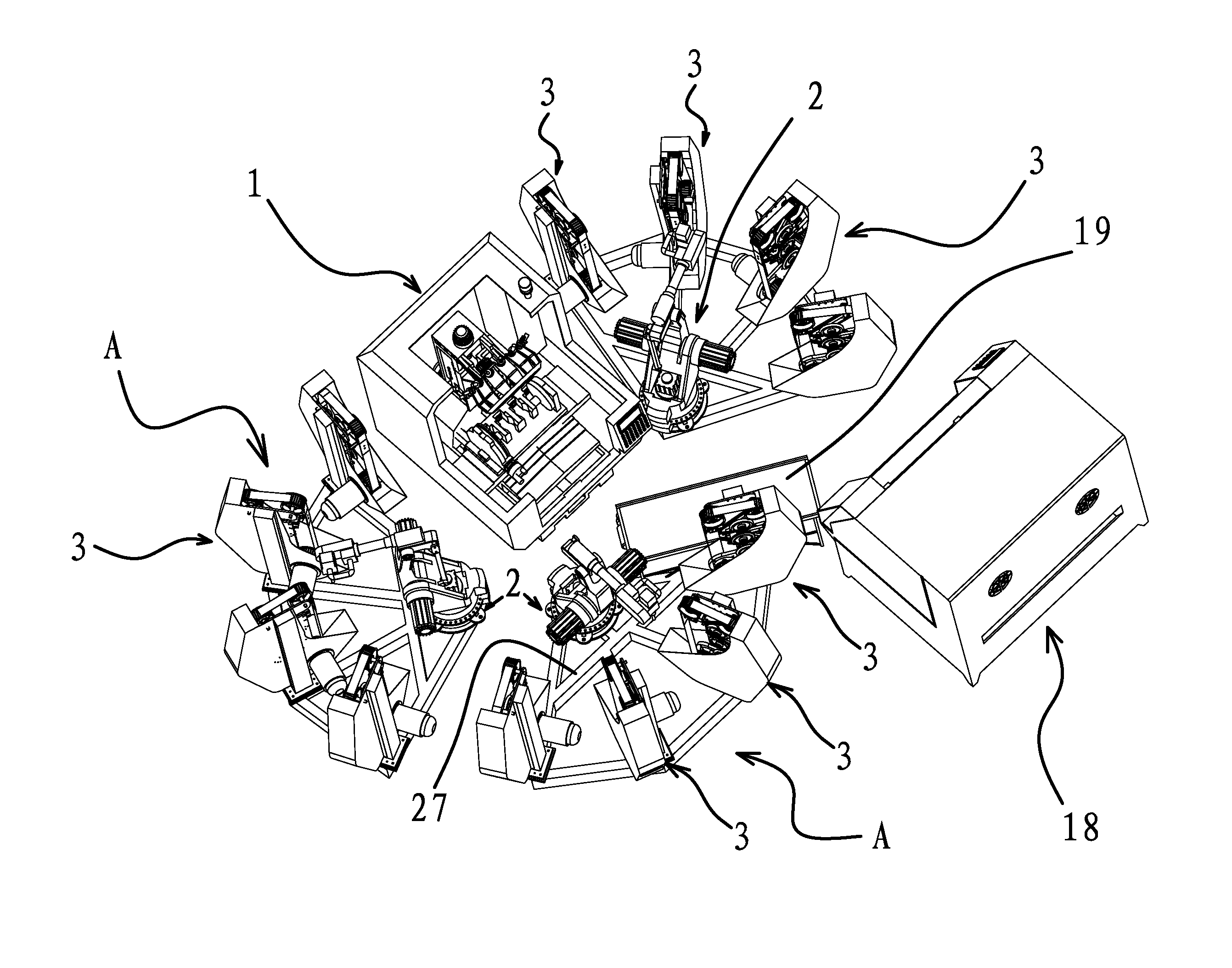

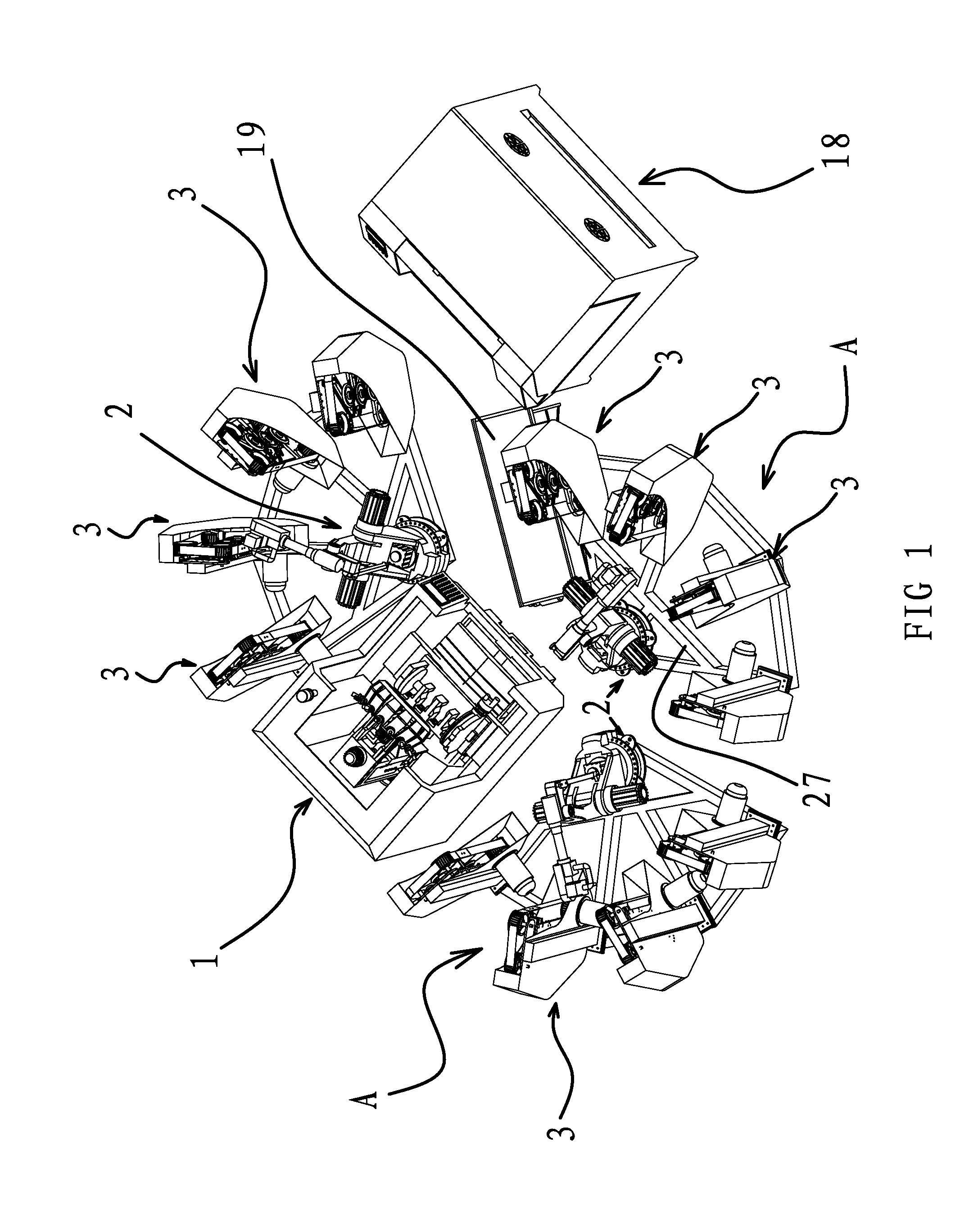

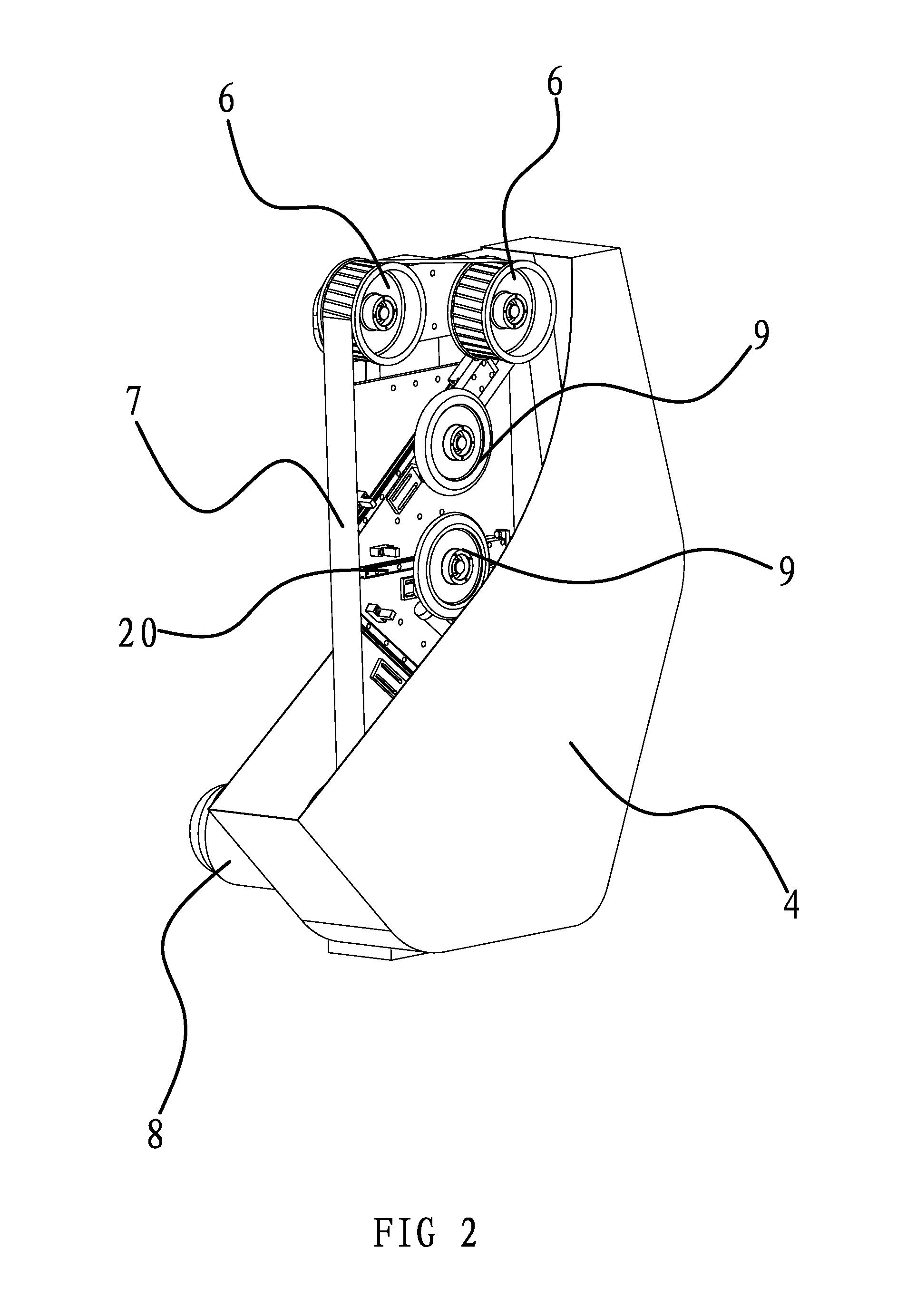

Surface Processing System for a Work Piece

InactiveUS20150044944A1Guaranteed to workImprove production efficiencyEdge grinding machinesBelt grinding machinesManipulatorMachining

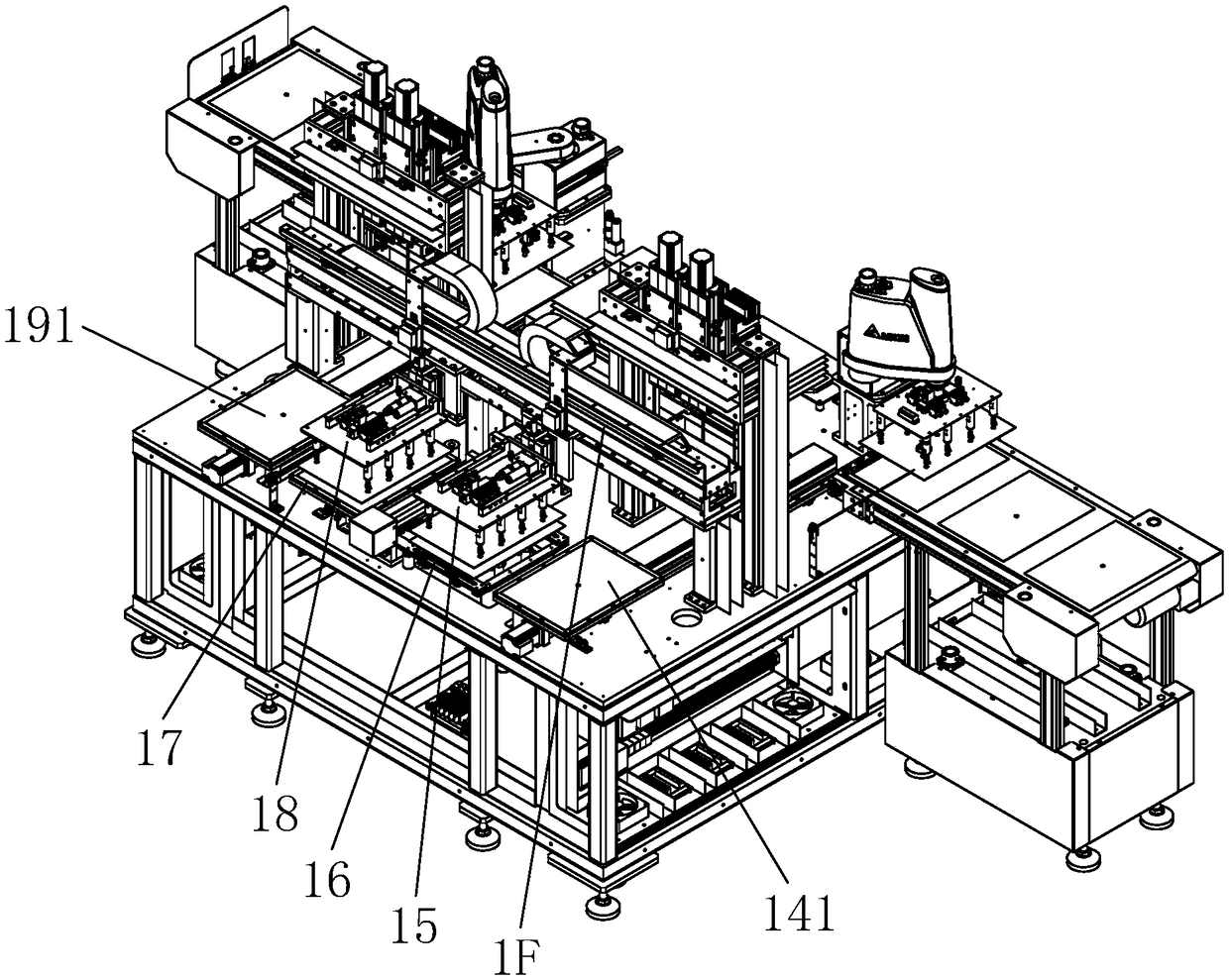

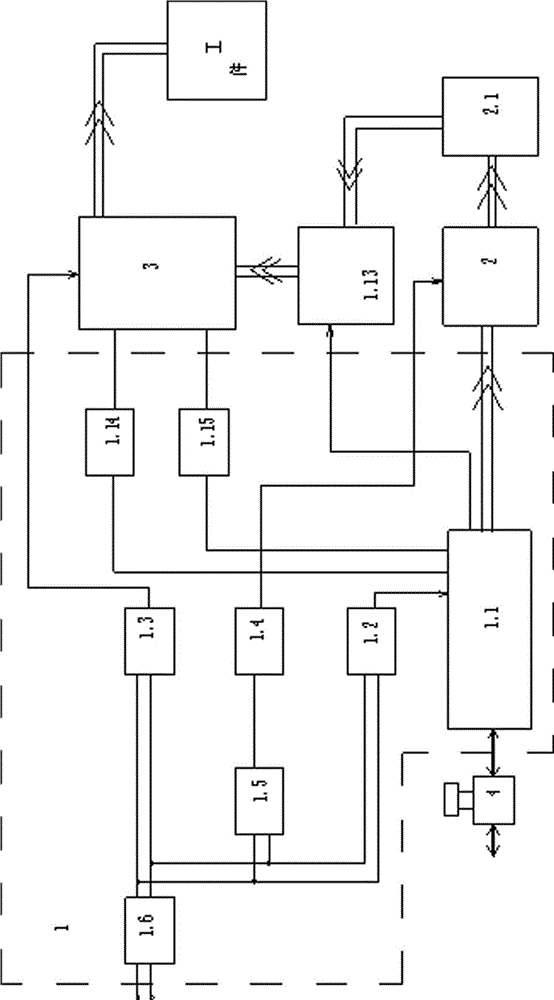

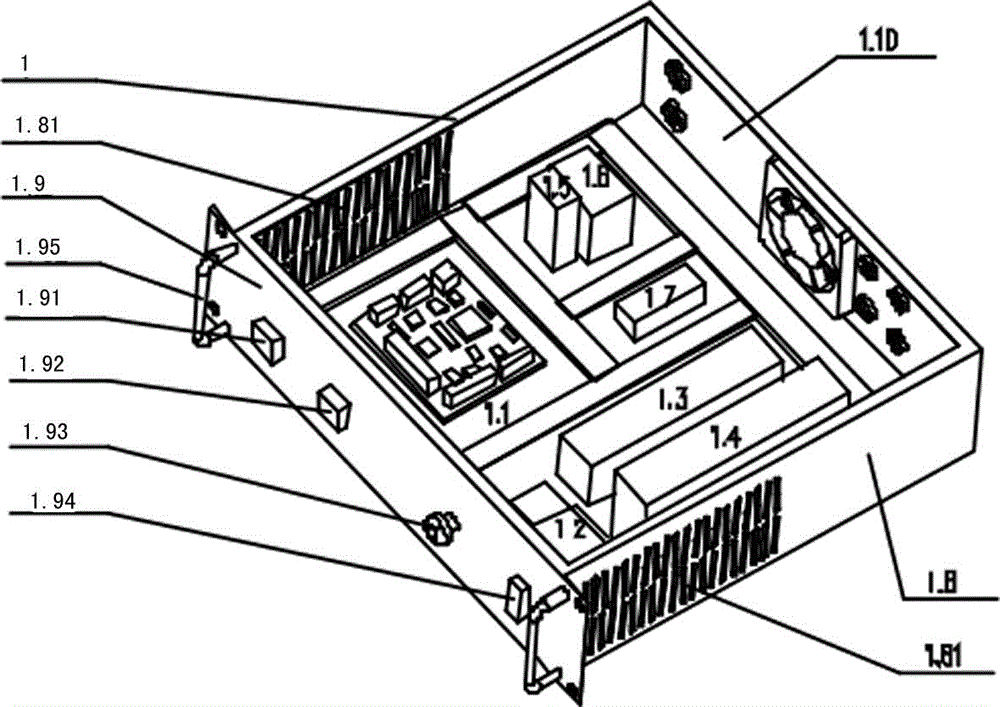

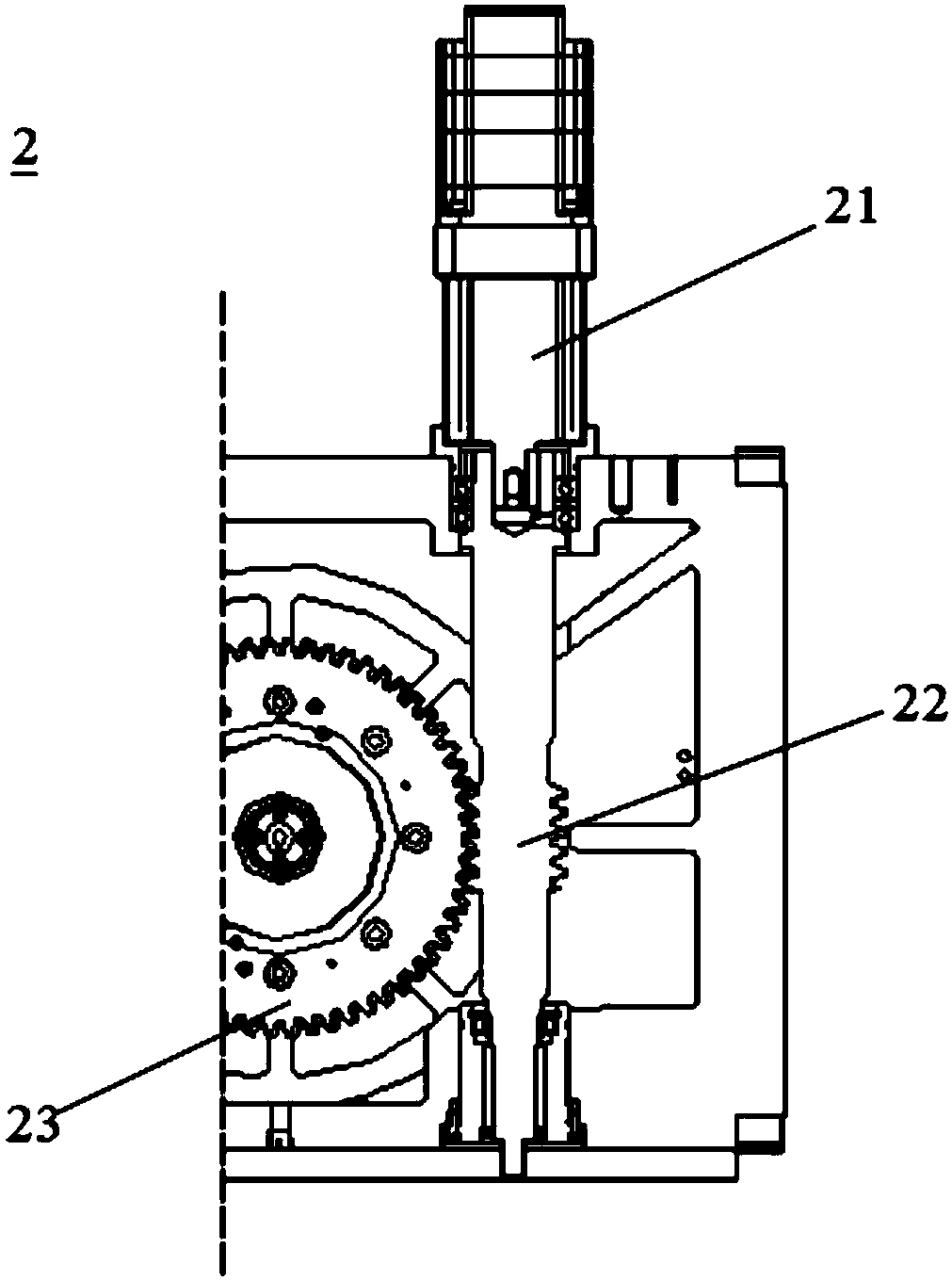

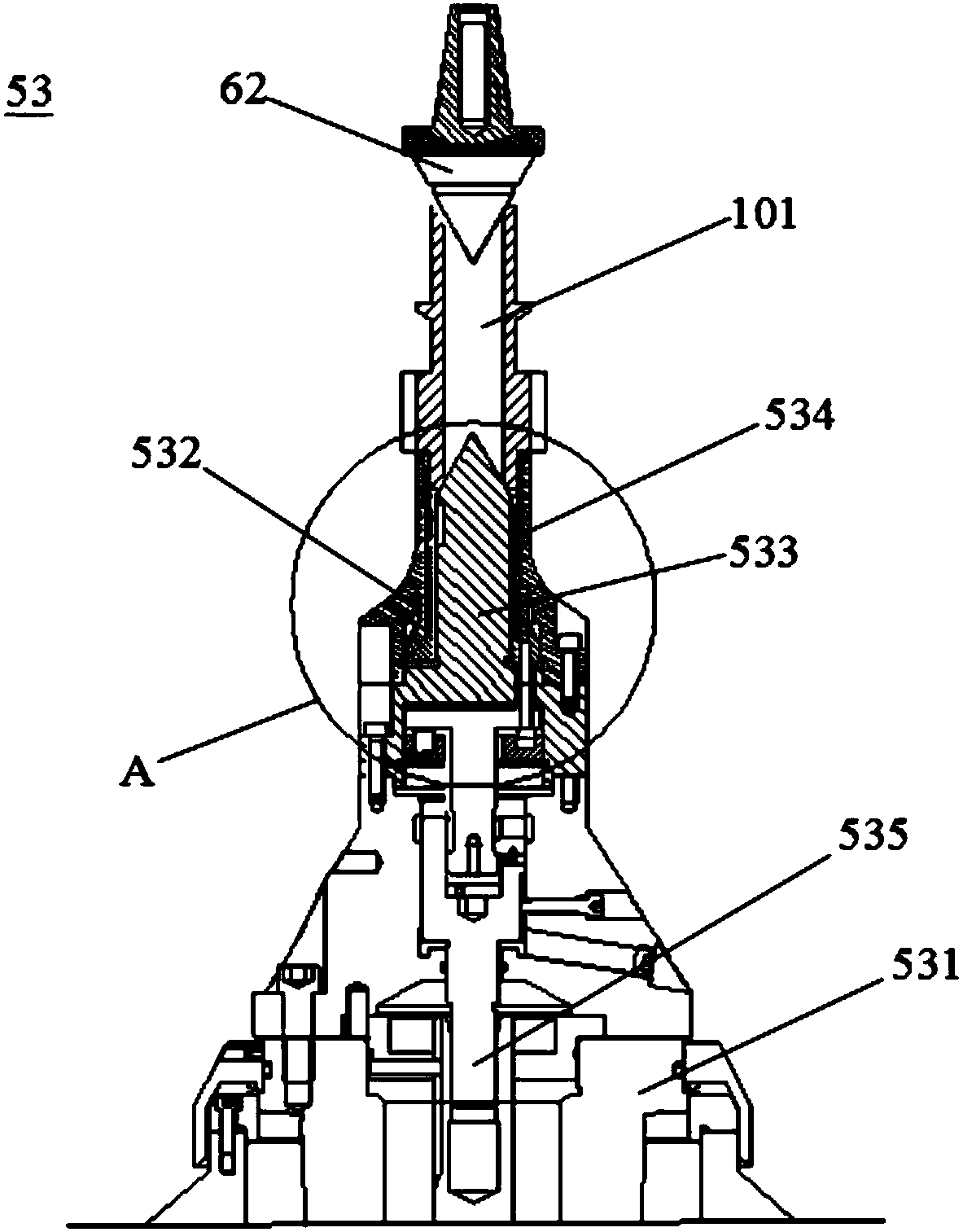

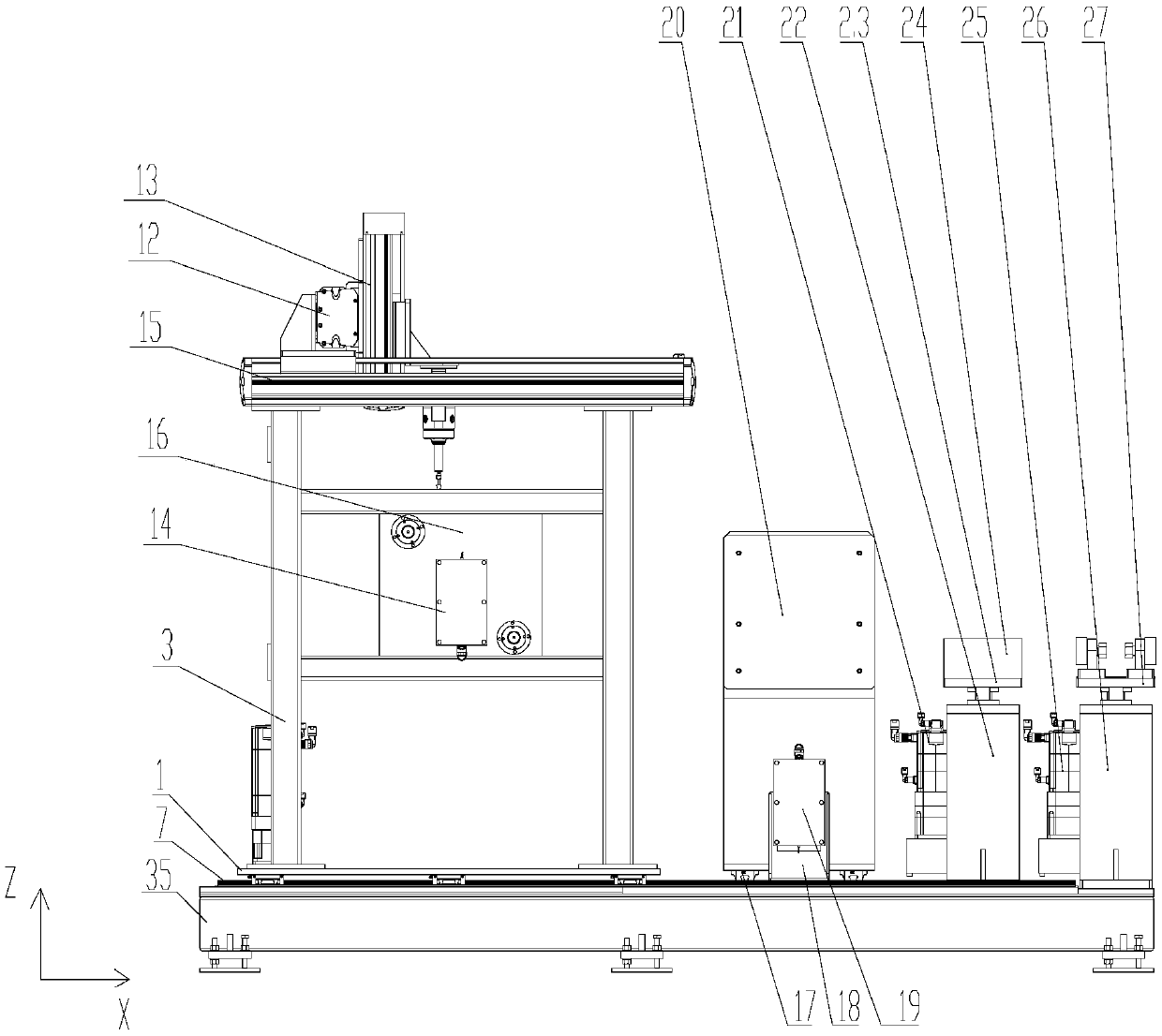

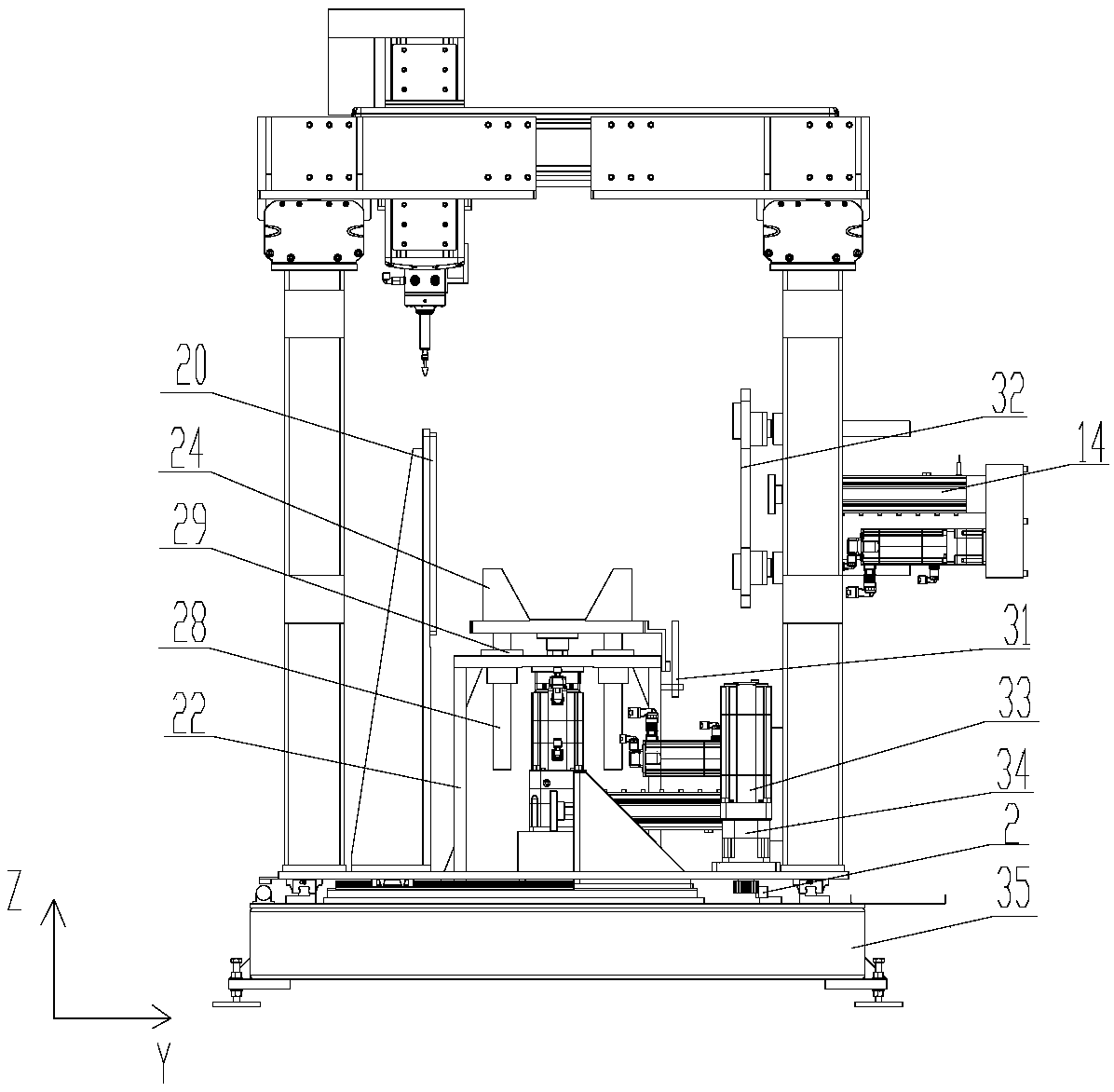

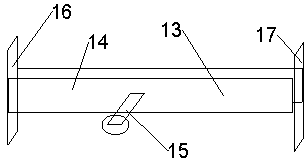

The present invention provides a surface processing system for a work piece in the mechanical technical field. The system comprises at least one group of polishing units. A manipulator and several polishers with different polishing precisions are provided on the polishing units. The polishers are arranged around the manipulator in turn. The work piece could be moved by the manipulator between the processing center and the polishing units. The machined work piece is loaded by the manipulator for one time when the manipulator is located at the processing center. When the manipulator is located at the polishing units, the manipulator keeps holding the work piece and transfers the work piece in a preset sequence to each polisher corresponding to the polishing unit where the manipulator is located. The surface of work pieces having different wall thicknesses and complex surfaces could be processed in a large batch with a high efficiency.

Owner:TAIZHOU FEDERAL ROBOT TECH

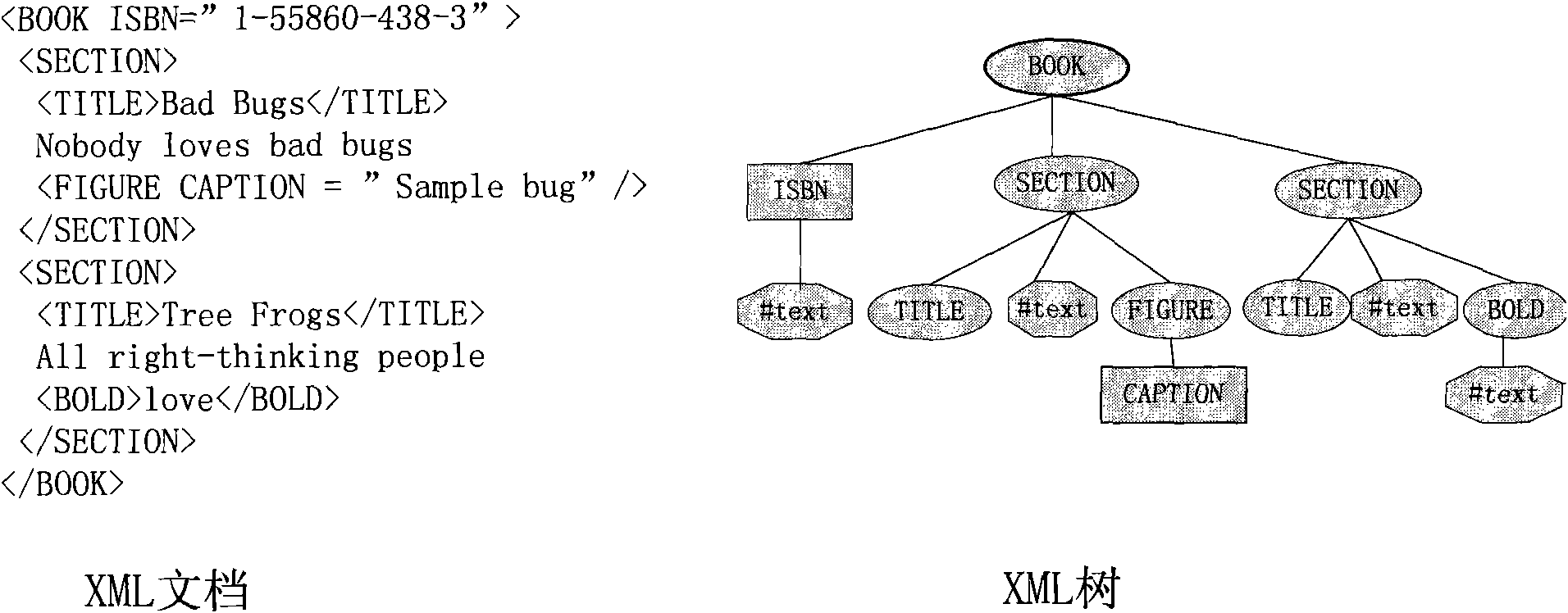

Method for calculating similarity of XML documents

InactiveCN101876995AExtract comprehensiveSimple measurement processSpecial data processing applicationsTheoretical computer scienceDegree of similarity

The invention belongs to the technical field of databases and aims to establish an XML document constraint model known as a bidirectional path constraint model. Based on the model, the invention discloses a new method for calculating the similarity of XML documents. The structural information of the XML documents is extracted more completely through the bidirectional path constraint of a node, so that the similarity of the XML documents is balanced more accurately. A very mature N-Gram thought in the field of natural languages is introduced and an N-Gram-based partition mode is applied in the similarity calculation of path constraint. The extraction and operation of N-Gram information are simplified by making skillful use of positive integers and weight numbers. The method can be used in the fields of XML document classification, clustering, mode extraction and the like.

Owner:NANKAI UNIV

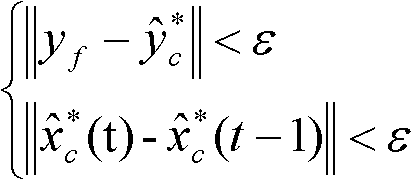

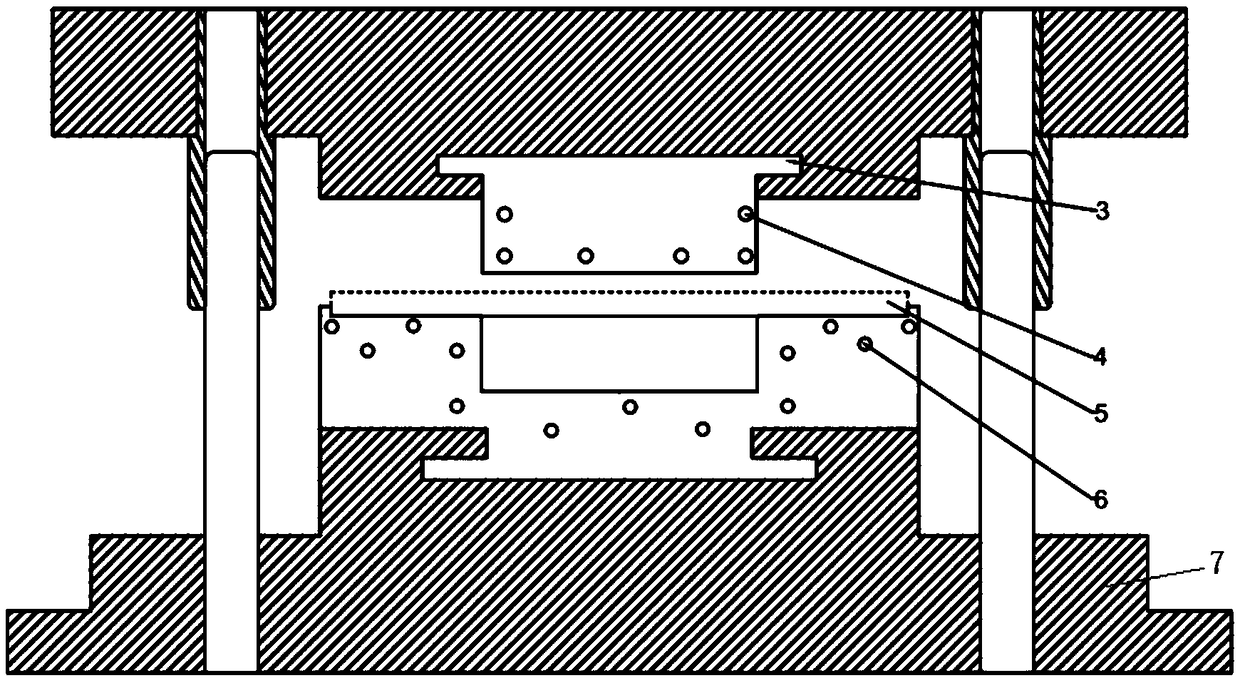

Optimization method of stamping based on space mapping of response function

InactiveCN101908090APrevent extractionPrecise spatial mappingSpecial data processing applicationsElement modelSpace mapping

The invention relates to an optimization method of stamping based on space mapping of a response function. The method comprises the following steps: (1) establishing fine and rough finite element models of a forming system to be optimized; (2) preliminarily establishing an initial space mapping relation Pr between the fine and rough finite element models; (3) determining an initial solution in a response space of the fine finite element model at random, and determining a corresponding response in the rough finite element model through the space mapping relation Pr; (4) entering into an iteration step: when an approximate model based on the rough finite element model meets precision requirements, obtaining an optimal solution of the rough finite element model through reverse; (5) using the optimal solution of the rough finite element model as the initial solution of the fine finite element model to obtain corresponding yf; and (6) when the approximate model based on the rough finite element model meets conditions of convergence, finishing the iteration step to obtain an optimized result, and using the fine finite element model to check the calculation result. The invention has a simple principle, can ensure solution precision and can improve the efficiency of an approximate model optimization algorithm in a large scale.

Owner:HUNAN UNIV

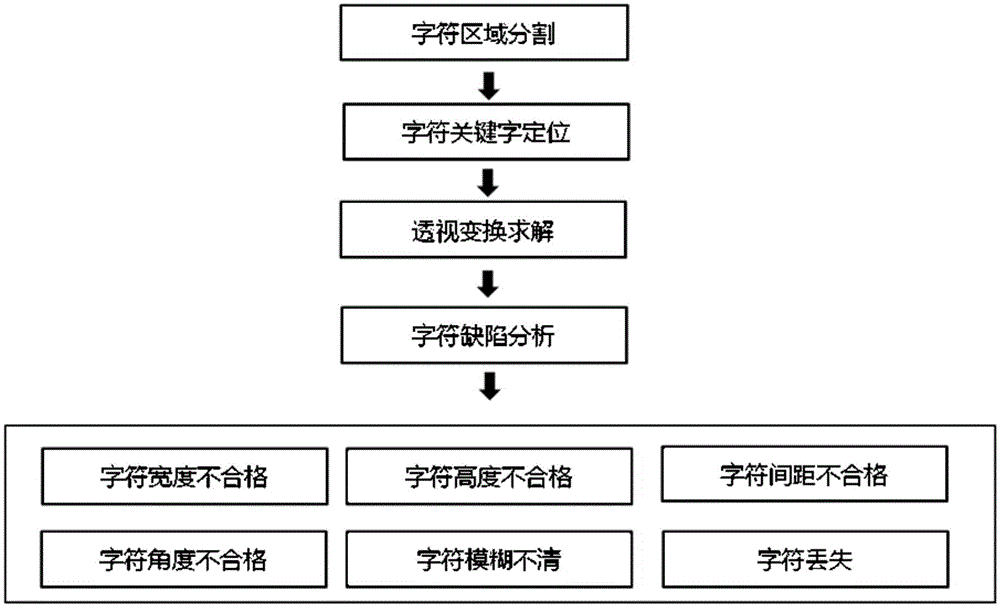

Jet code detection method and system

InactiveCN105023018APrecise positioningAccurate readingCharacter and pattern recognitionAlgorithmEngineering

The invention belongs to the technical field of jet printing and discloses a jet code detection method. The method comprises: setting a character template; and carrying out character region partitioning, character keyword positioning, perspective transformation and solving and character defect analysis, wherein character defects comprise unqualified character width, unqualified character height, unqualified character separation distances, unqualified character angle, blurring characters and loss of the characters; a jet code comprises a keyword and a variable character. According to the method and system disclosed by the invention, the jet code detection efficiency and reliability are enhanced through efficient automatic detection method and system.

Owner:武汉楚锐视觉检测科技有限公司

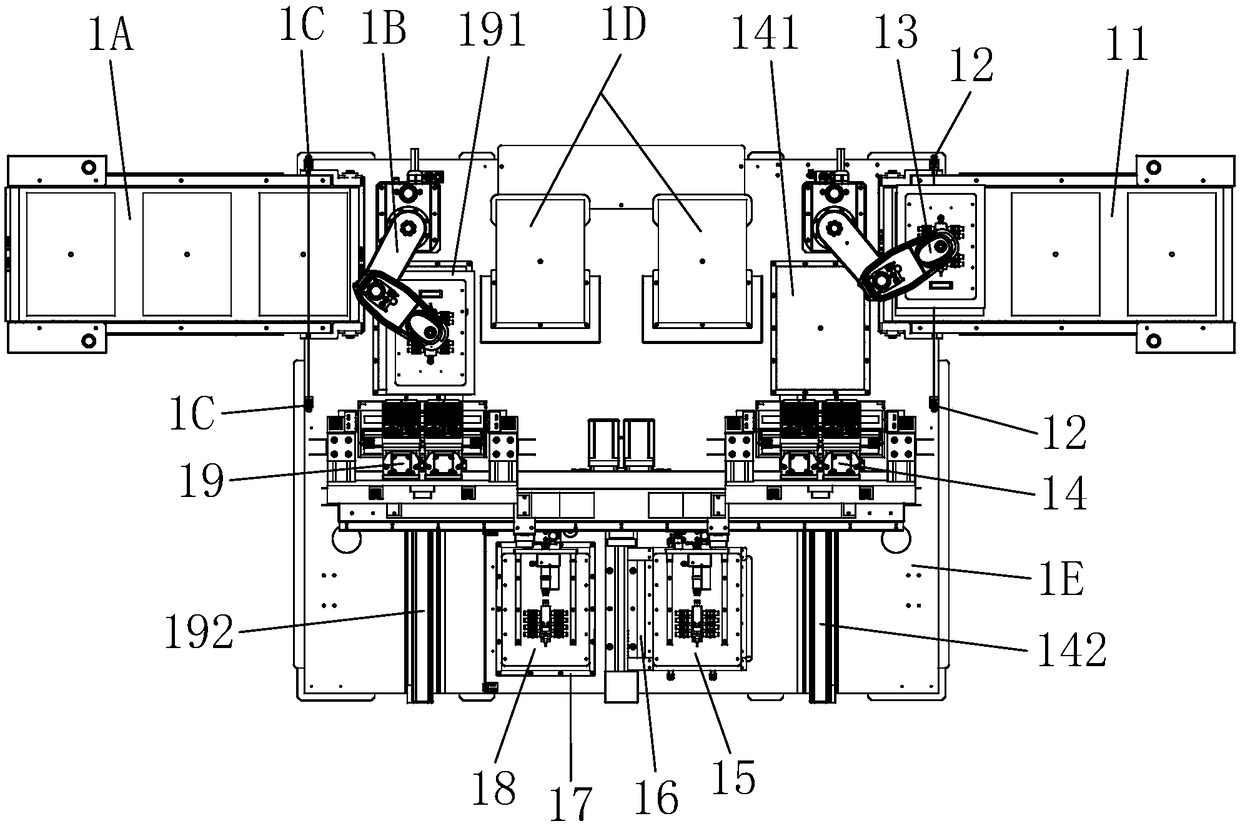

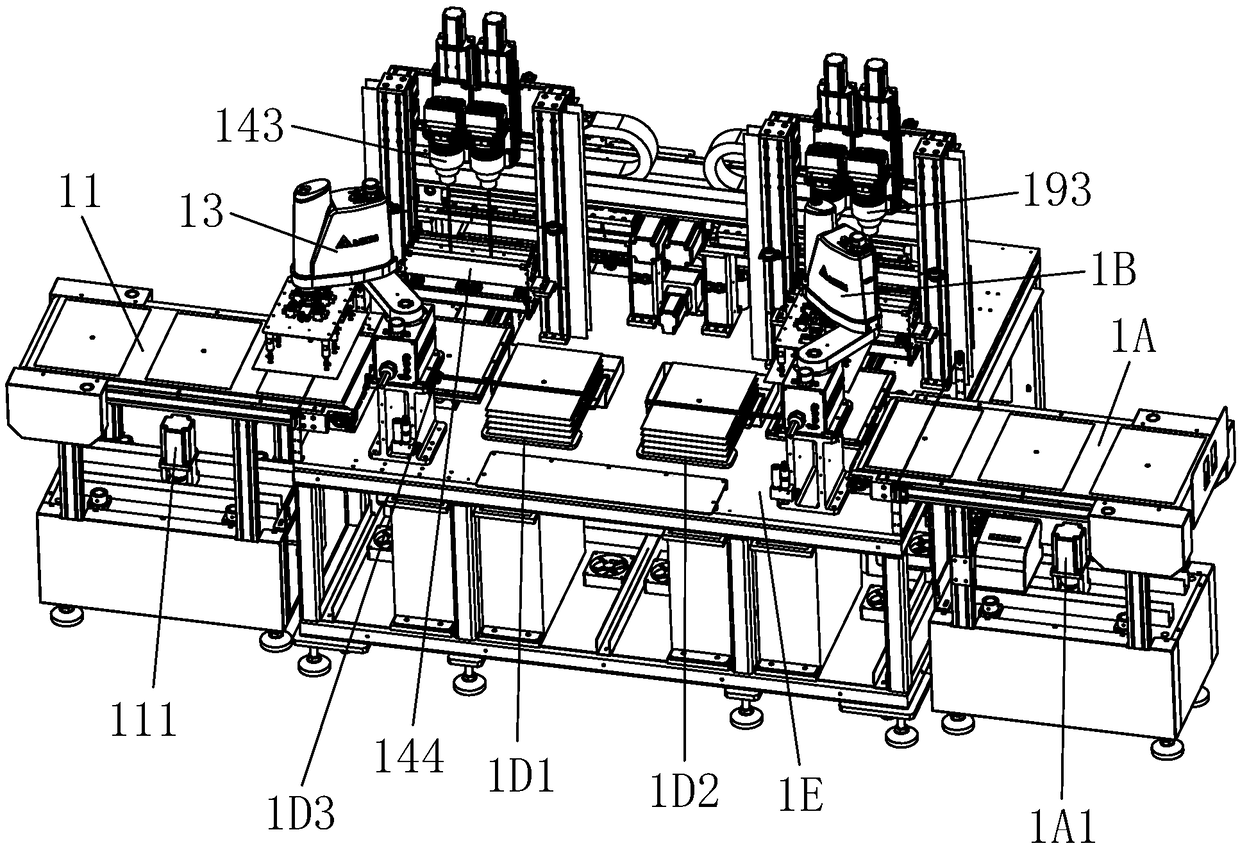

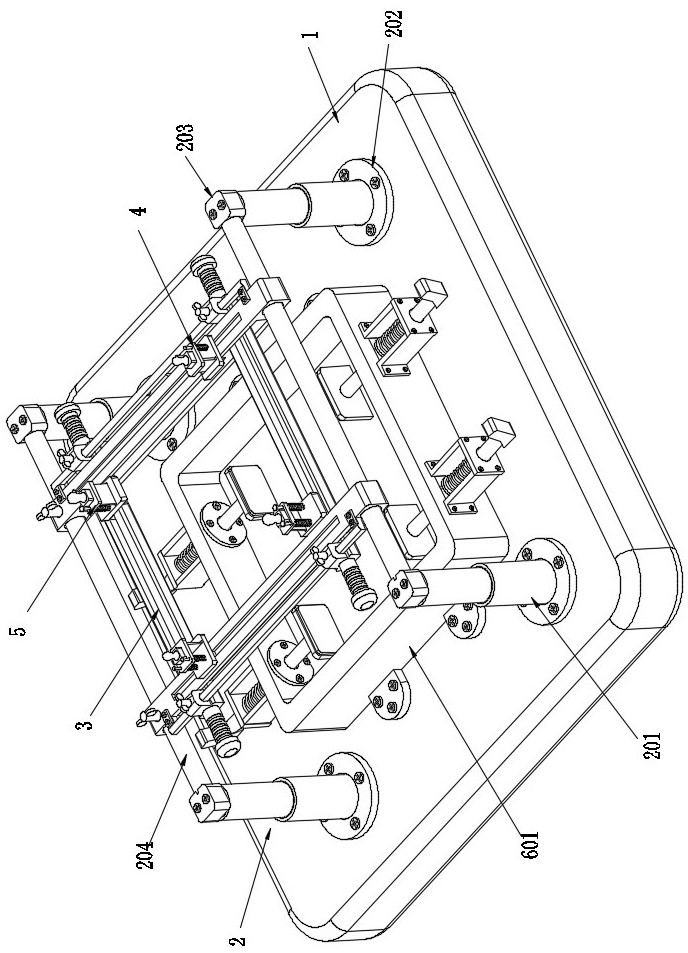

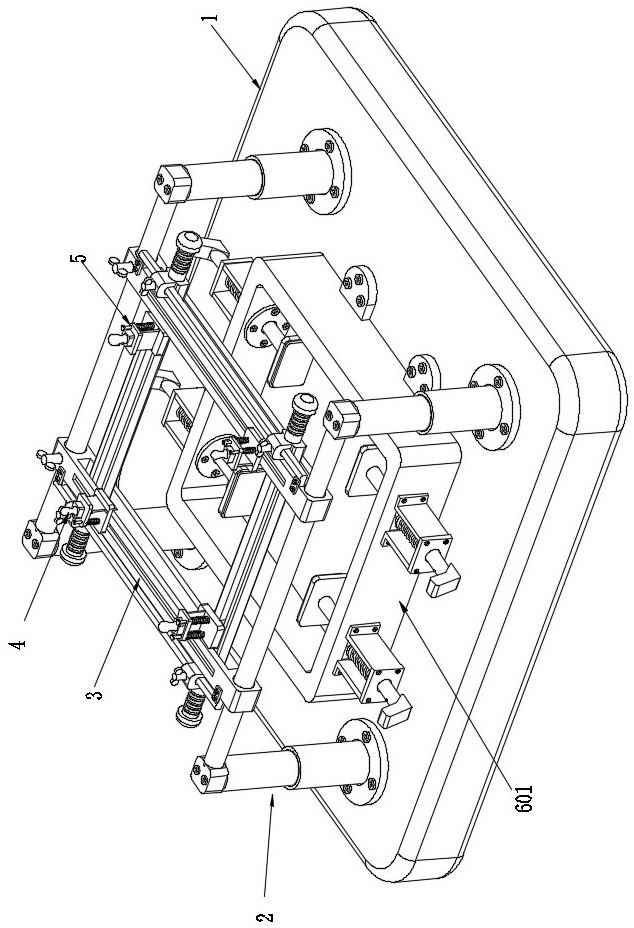

Full-automatic FPC (flexible printed circuit) board appearance test unit and corresponding appearance test method

PendingCN109406546AImprove detection efficiencyAccurate placementMaterial analysis by optical meansConveyorsEngineeringManipulator

The invention provides a full-automatic FPC (flexible printed circuit) board appearance test unit and a corresponding appearance test method. The full-automatic FPC board appearance test unit includesa first appearance test device, a second appearance test device, a feeding platform, a discharging platform, a transfer system, a feeding manipulator and a discharging manipulator. The full-automaticFPC board appearance test unit has the advantages that the feeding manipulator positions and grips an FPC board on the feeding platform to the first appearance test device to carry out photographic appearance test on one side, the transfer system then turns over the FPC board tested by the first appearance test device, corrects the FPC board and transfers the FPC board to the second appearance test device so that photographic appearance test is performed on the other side, the FPC board is finally gripped and discharged to the discharging platform by the discharging manipulator, testing is automated, and testing efficiency is high.

Owner:深圳宜美智科技股份有限公司

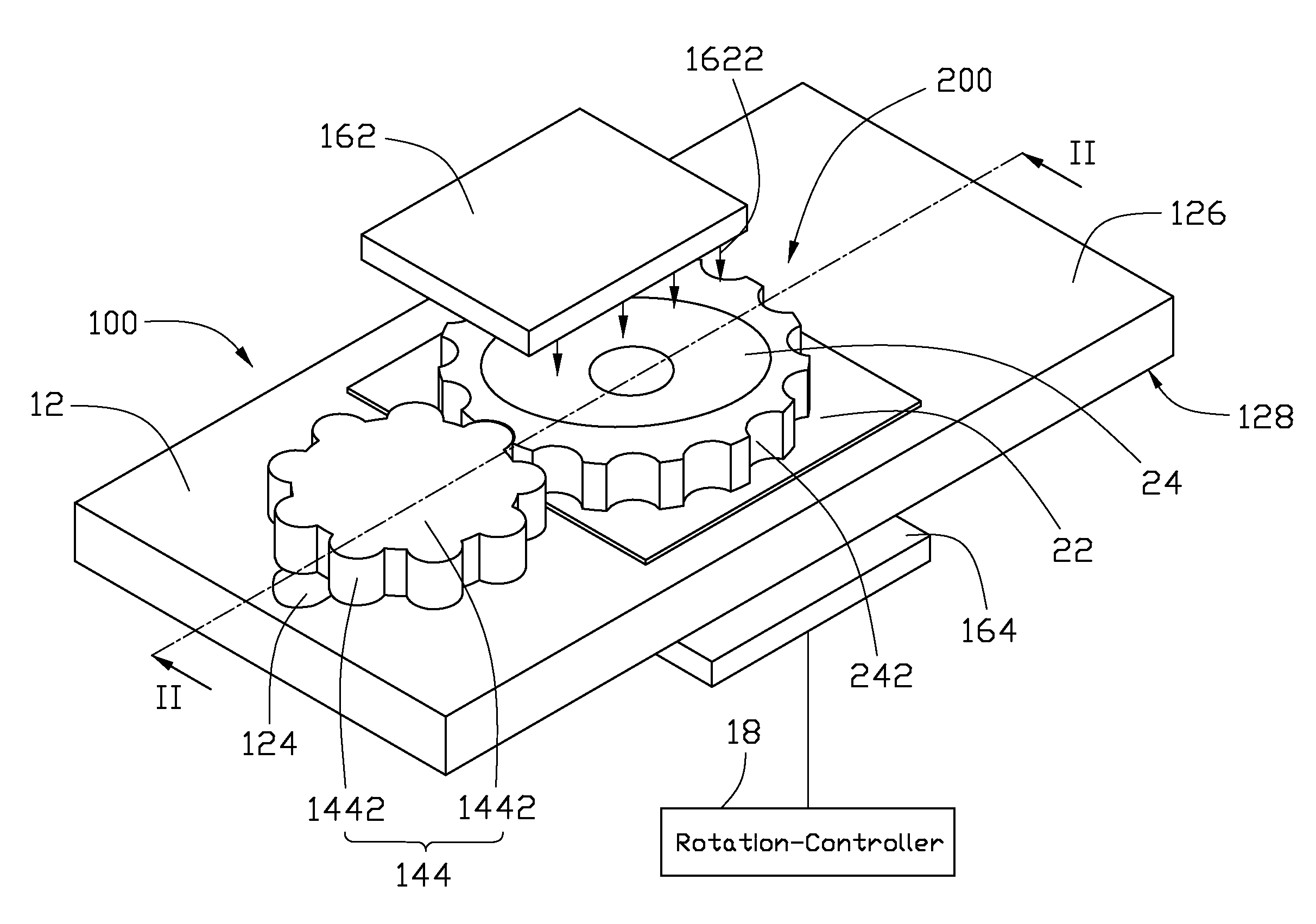

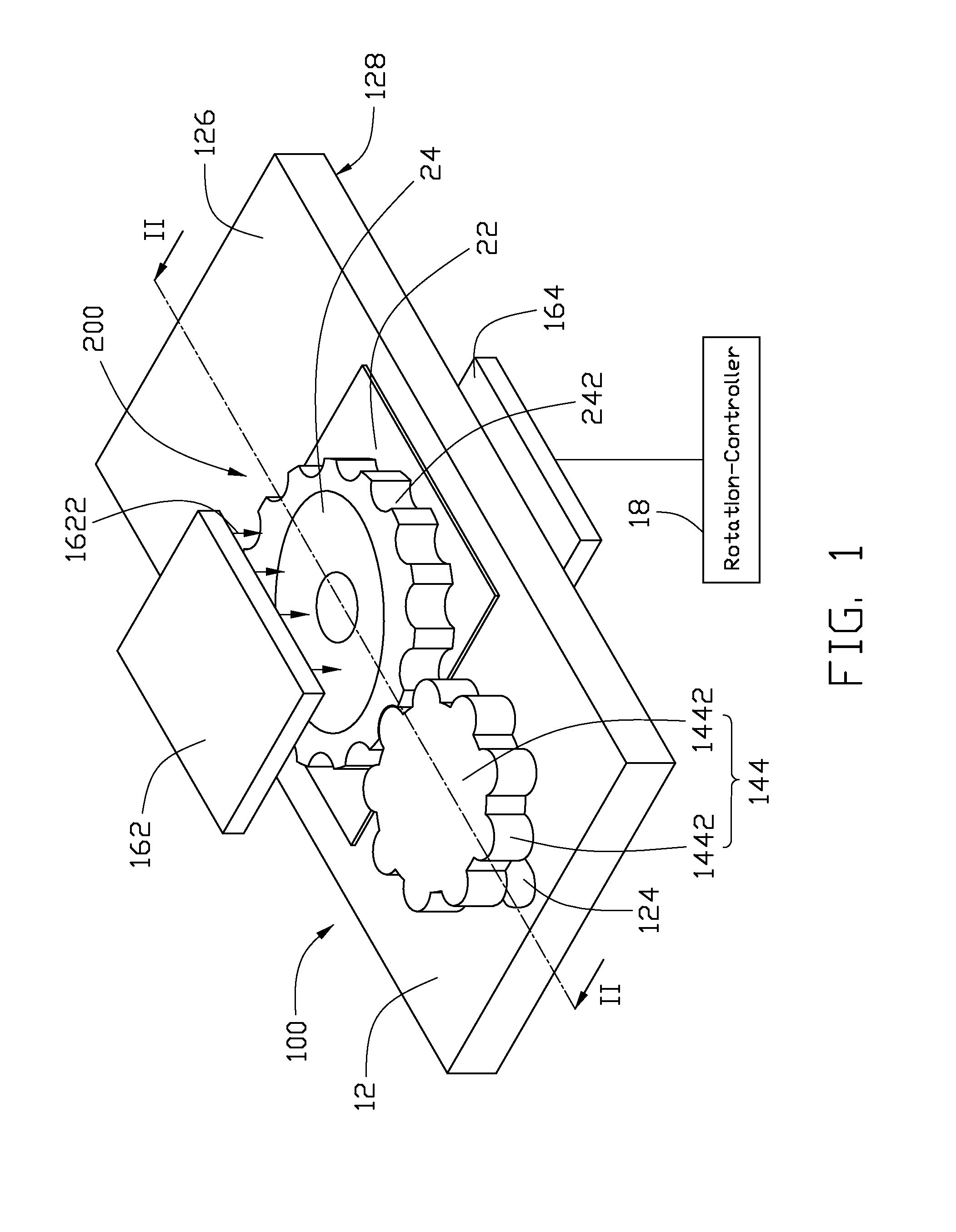

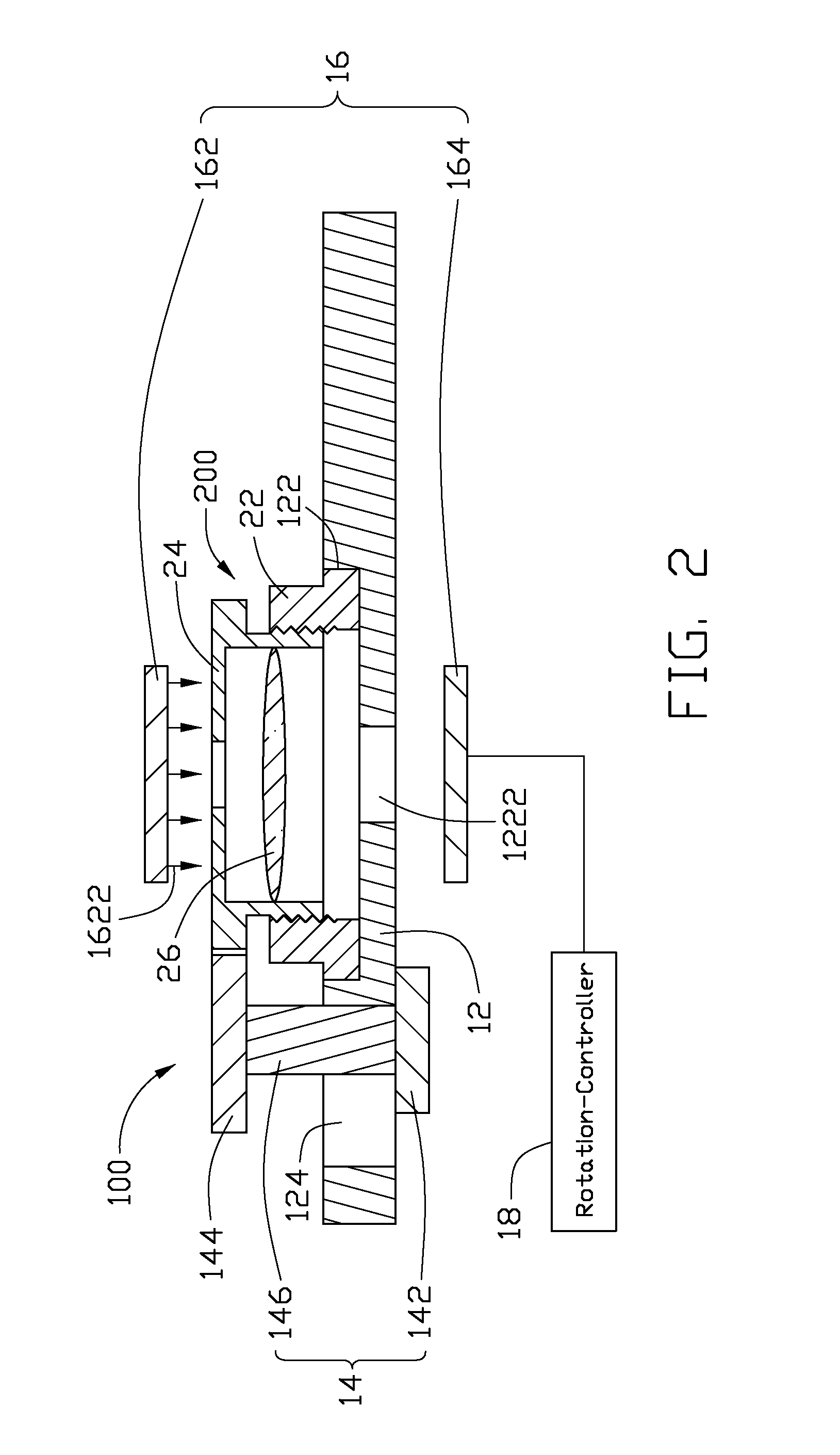

Apparatus for checking concentricity between lens barrel and barrel holder

InactiveUS20080180669A1High precision and efficiencyUsing optical meansMountingsImage sensorEngineering

An apparatus for checking concentricity between a barrel holder and a lens barrel rotatably engaging with the barrel holder is provided. The lens barrel includes at least one lens coaxially received therein. The apparatus includes a barrel holder retaining member, a rotating member, a driving unit, a light source, and an image sensor. The barrel holder retaining member is used for fixedly retaining the barrel holder in position. The rotating member is structured for meshing with the lens barrel. The driving unit is used for driving the rotating member to rotate, thereby rotates the lens barrel. The light source is configured for emitting light toward a first end of the lens barrel. The image sensor is arranged to face toward an opposite second end of the lens barrel. The image sensor is configured for sensing the light emitted from the light source.

Owner:HON HAI PRECISION IND CO LTD

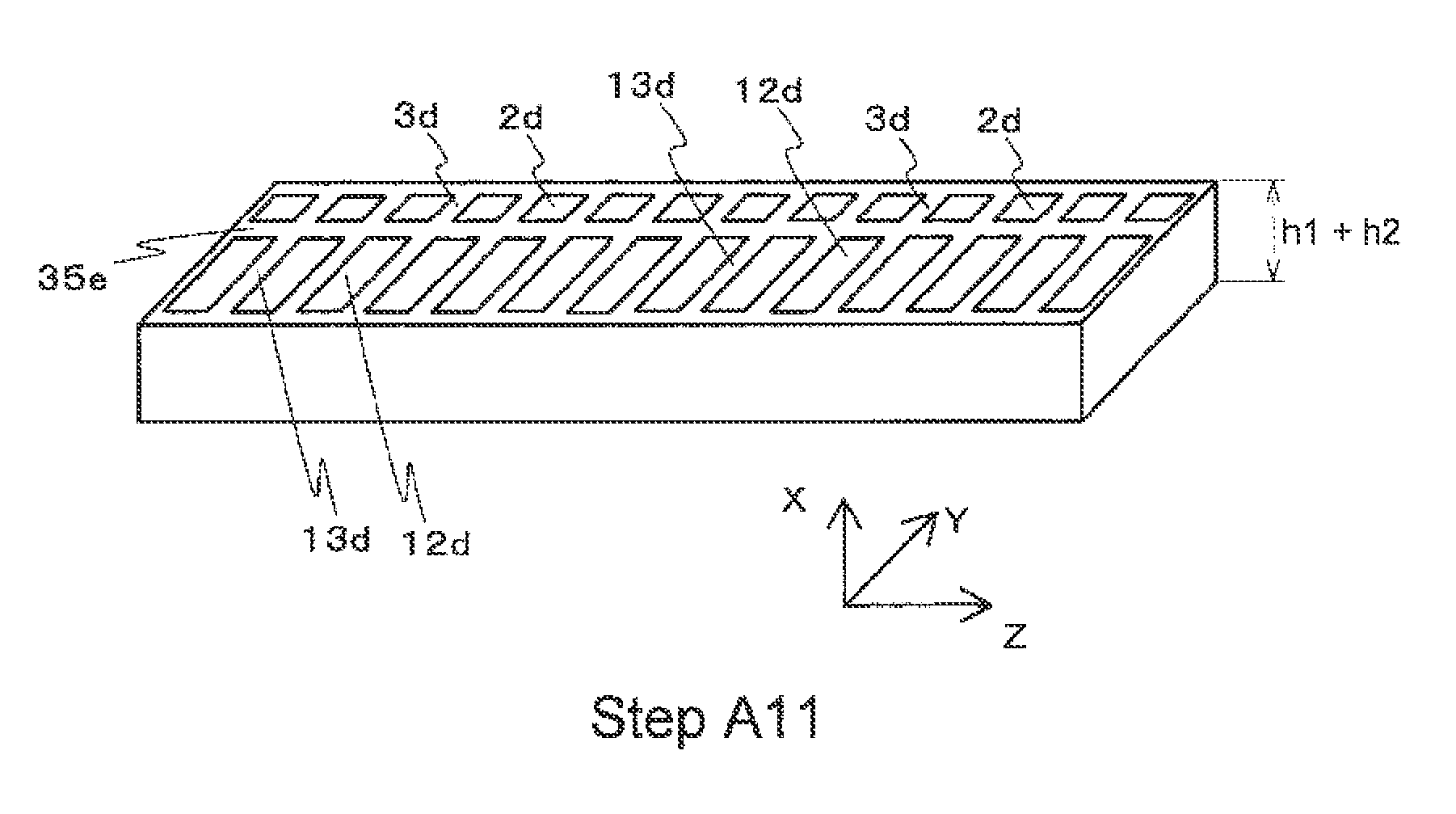

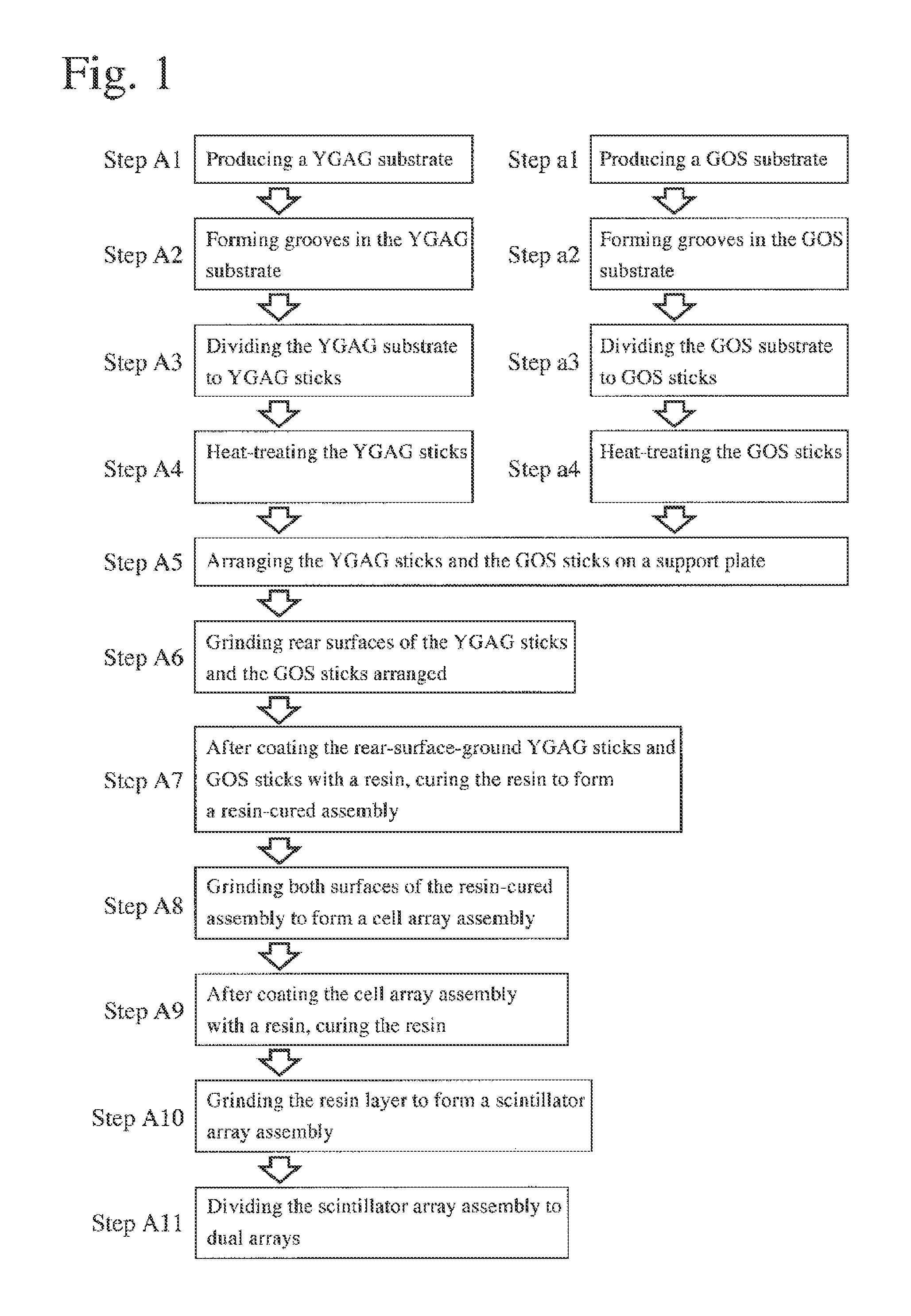

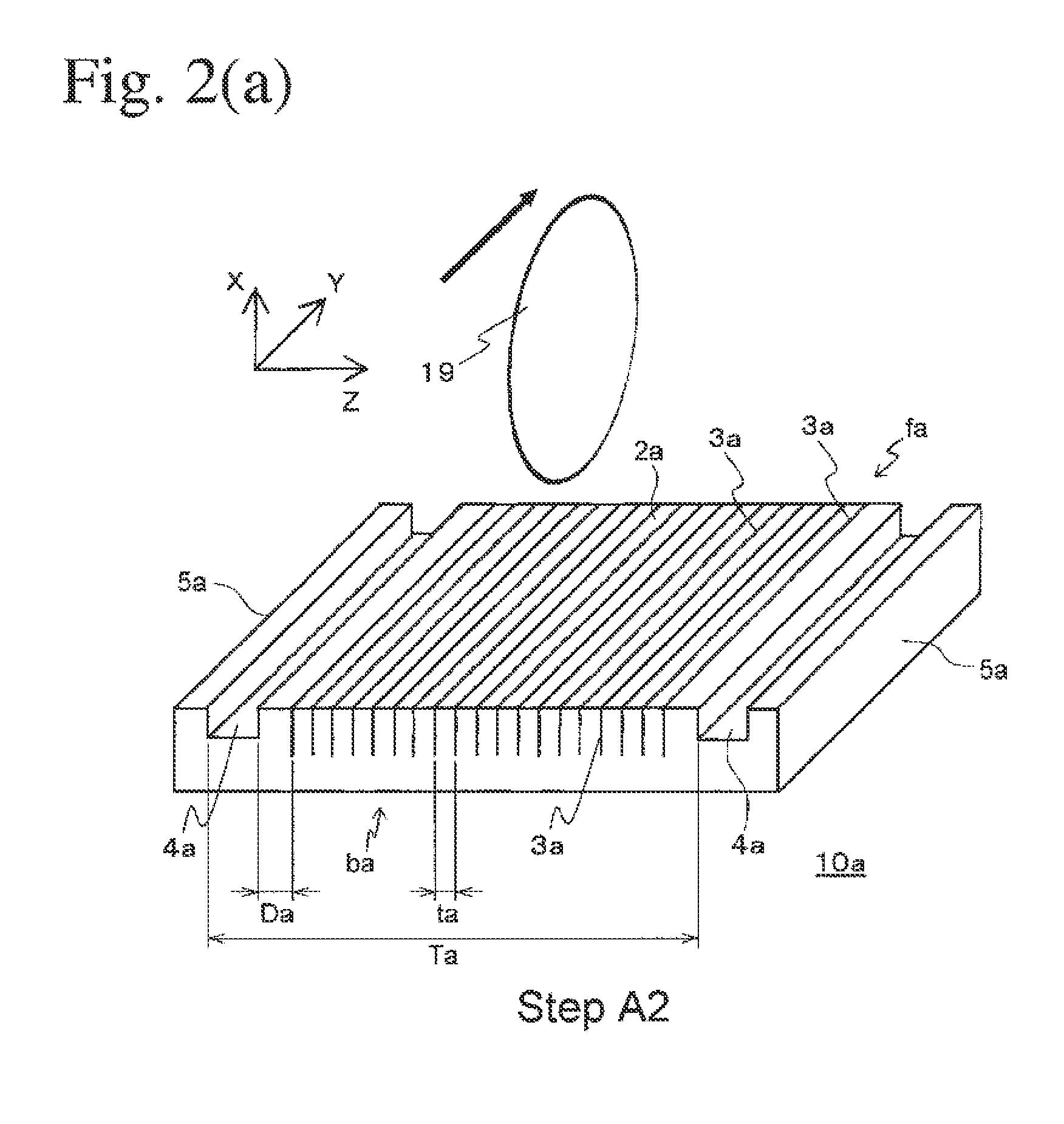

Production method of scintillator array

ActiveUS20130125385A1High precision and efficiencyHigh detection sensitivityWave amplification devicesRadiation intensity measurementElectrical and Electronics engineeringScintillator

A method for producing a dual-array-type scintillator array, comprising forming first and second scintillator sticks having cell portions by providing first and second scintillator substrates with pluralities of grooves and cutting them in directions perpendicular to the grooves; arranging and fixing plural sets of the first and second scintillator sticks with the cell portions downward on a support plate via spacers; removing base portions from the first and second scintillator sticks by grinding to form first and second cell arrays comprising the first and second cells each arranged in line; forming an integral resin-cured assembly by filling the grooves and gaps of the first and second cell arrays with a resin for a reflector, curing the resin, and then removing the support plate; and cutting a resin layer between the first and second cell arrays in adjacent sets to divide the resin-cured assembly to sets of the first and second cell arrays.

Owner:HITACHI METALS LTD

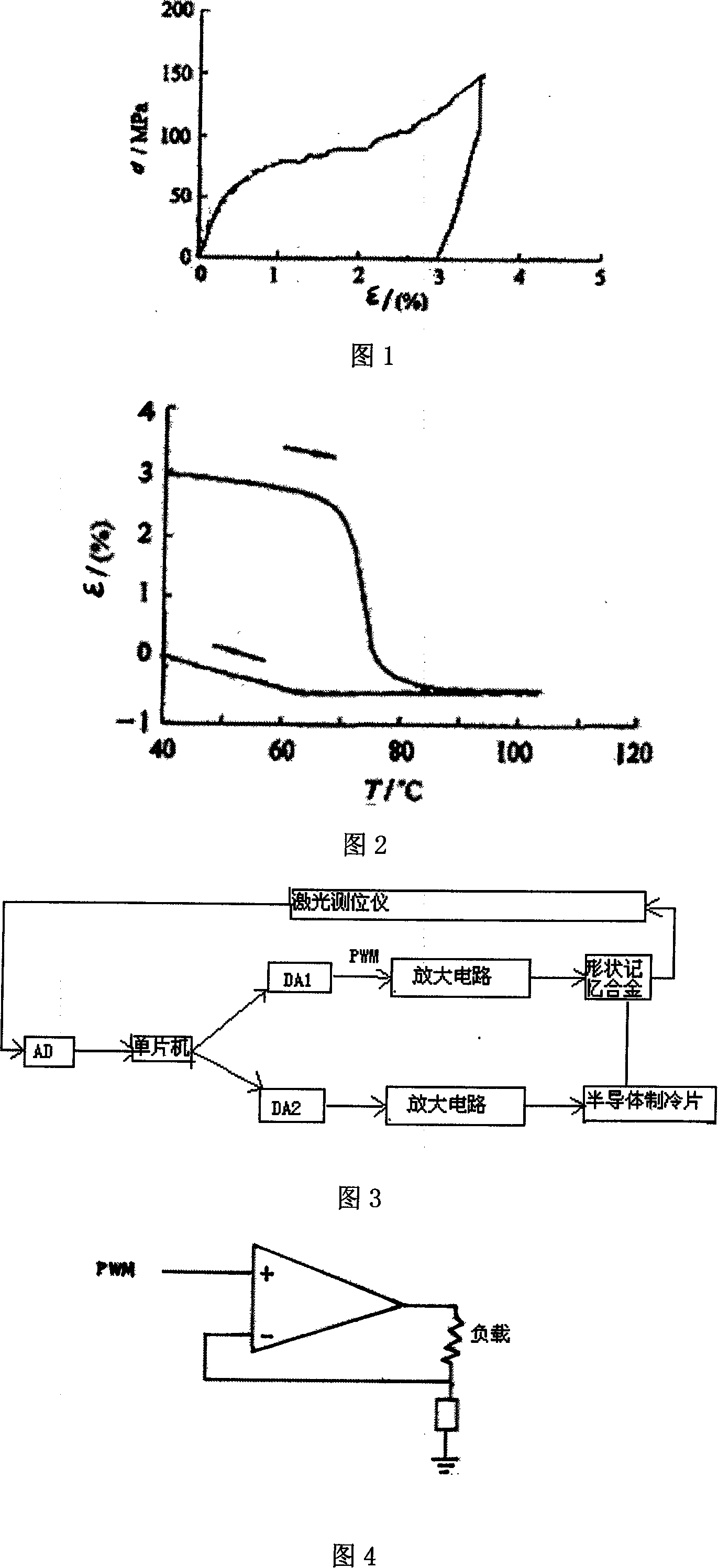

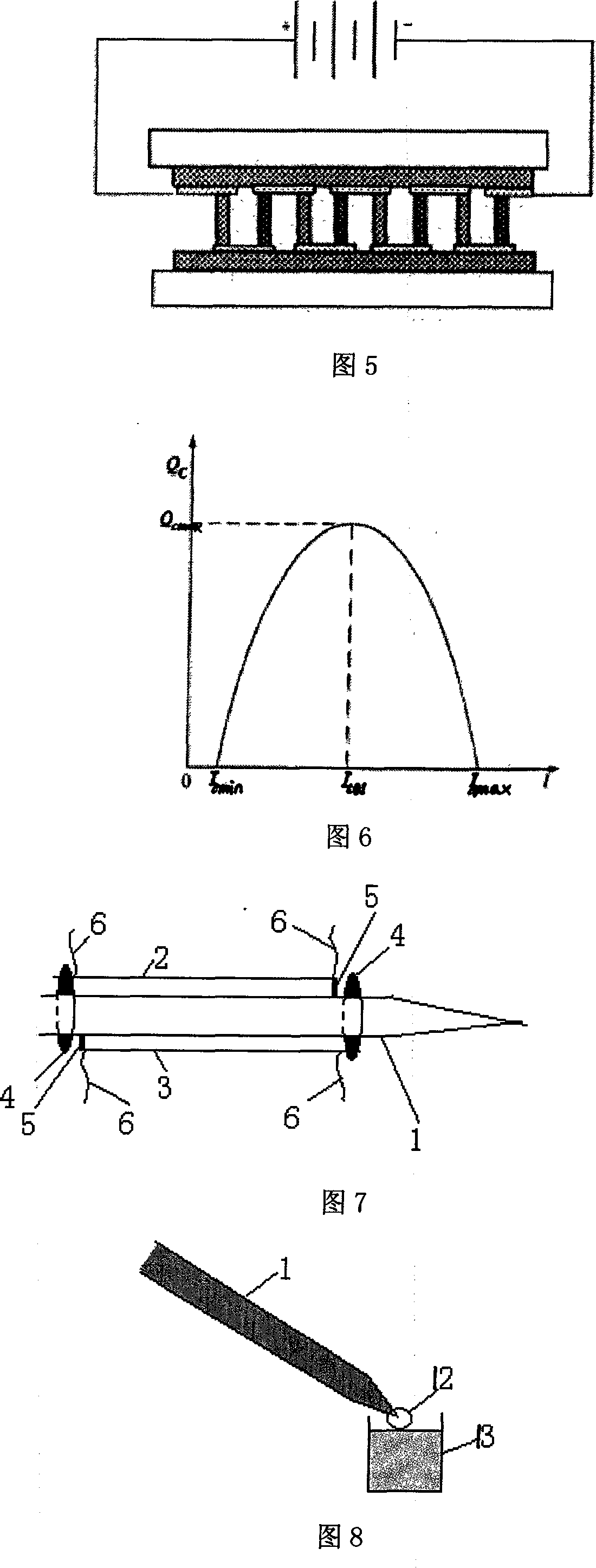

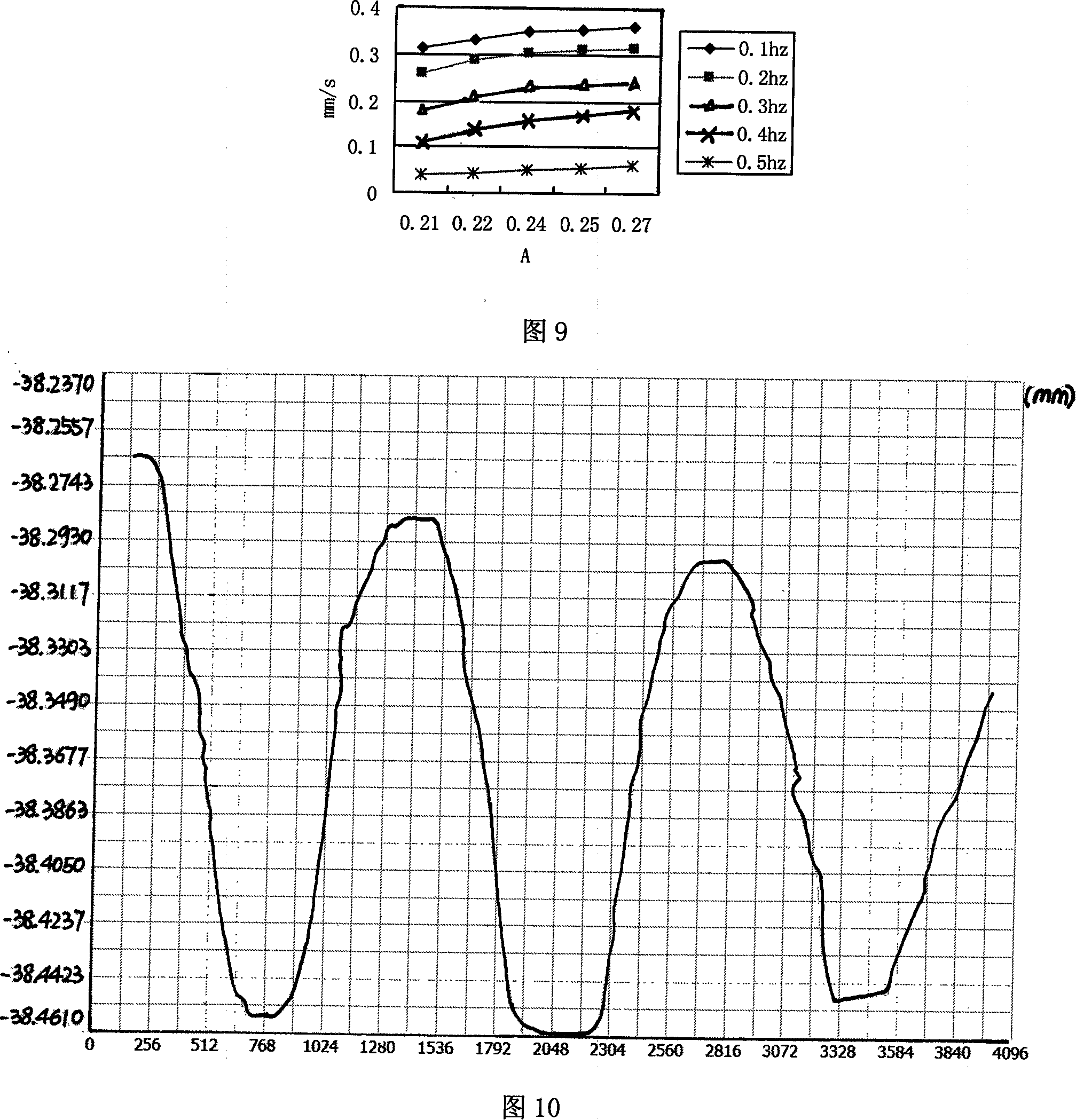

Micromanipulation device used for microoperation

InactiveCN101082548AHigh precision and efficiencyReduce the driving voltageMicrobiological testing/measurementPreparing sample for investigationMicro-operationDisplacement reactions

The invention provides a kind of micro-operation micromanipulation equipment which includes a control unit and a micromanipulation hand. The control unit includes a controller, an A / D switching circuit of connection controller, and the displacement collect unit and the micromanipulation hand includes two-strip shape memory alloy, micro-operation pin and the fixed section and the two-strip shape memory alloy sets up at the two side of the micromanipulation pin by the fixed section and the two-strip shape memory alloy connects with the control unit. The micromanipulation pin can work at the condition of low-frequency alternate current it has the merits like the fast response speed and the simple structure. By the experiment we can get that: the closed loop system can get the well displacement reaction driving at the frequency of 0.2 Hz and the displacement can continue to increase with the increase of the current in the consent rang.

Owner:HARBIN ENG UNIV

Surface processing system for a work piece

InactiveUS9193024B2High precision and efficiencyAccurate and stable mannerBelt grinding machinesGrinding feedersEngineeringManipulator

Owner:TAIZHOU FEDERAL ROBOT TECH

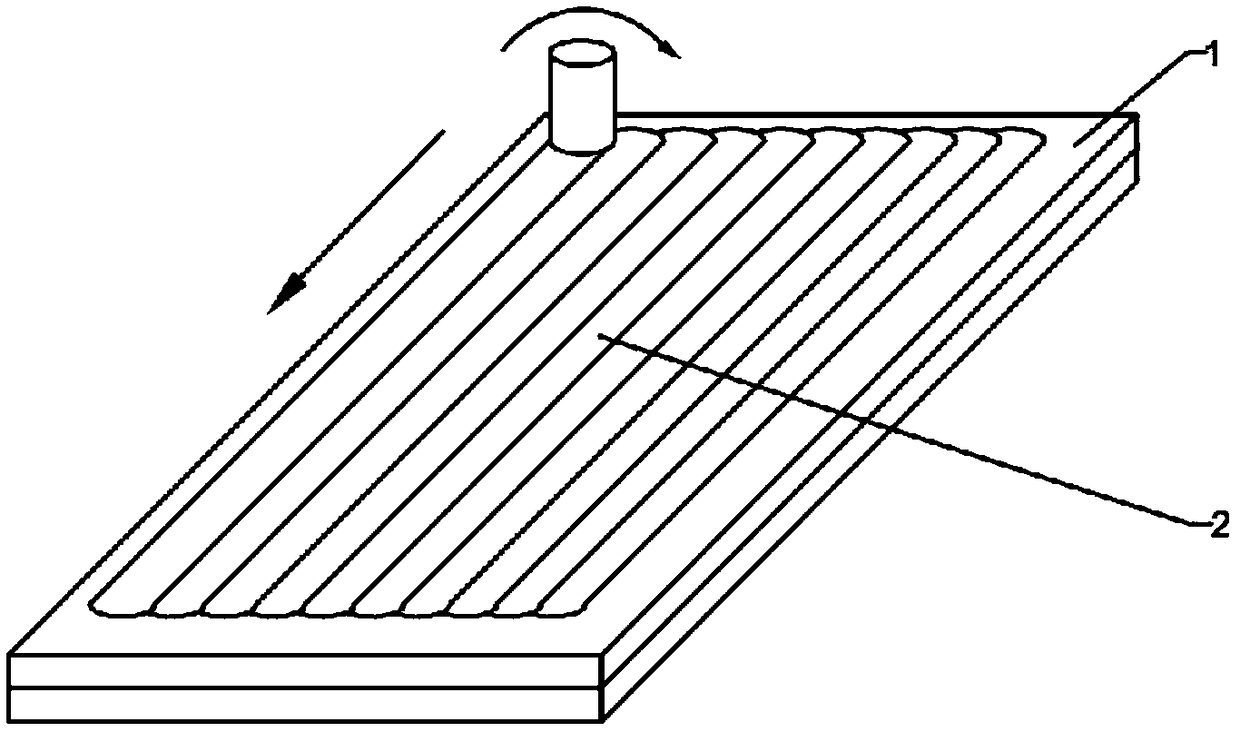

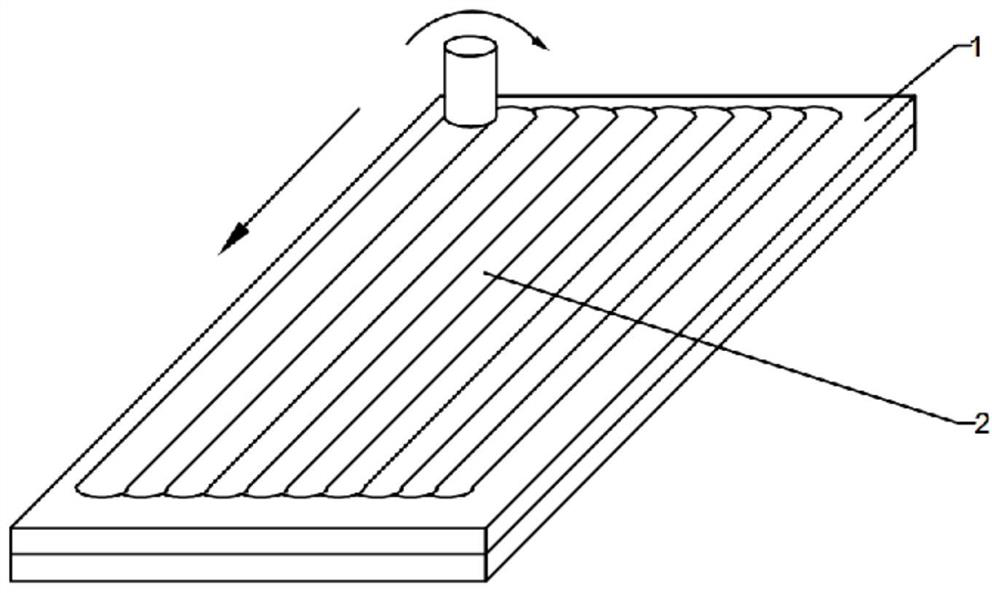

Forming method for foam aluminum part with complex curved face

The invention discloses a forming method for a foam aluminum part with a complex curved face. The forming method includes that steps that S1, a stamping die is provided, and the stamping die includesa convex die, a concave die, and a heating assembly; S2, two stacked metal plates are provided, a foaming agent and a stabilizer are evenly distributed between the two metal plates, and stirring friction welding is adopted to conduct multi-pass welding treatment on the two stacked metal plates to obtain a foam aluminum prefabricated body; S3, a heating mechanism or the heating assembly using the stamping die is provided to heat and insulate the foam aluminum prefabricated body in the S2; and S4, the heated foam aluminum prefabricated body is transferred to the stamping die, die closing is carried out, the foam aluminum prefabricated body is subjected to stamping and forming, die opening is carried out, the convex die is moved to be at a distance from the concave die, and the heating assembly is started to heat the foam aluminum prefabricated body, so that the foam aluminum prefabricated body completes remaining foaming action to obtain the foam aluminum part with the complex curved face. According to the forming method for the foam aluminum part with the complex curved face, not only can any desired curved face forming parts be formed, but also the whole process has short durationand low cost.

Owner:WUHAN UNIV OF TECH

Following management system for laser marking and product quality assurance based on network communication

InactiveCN102717605APrevent cross-sellingPut an end to fake and shoddyPrintingStructure of Management InformationInterface standard

Owner:湖北百一科技发展有限公司

Method for precisely balancing Z-axis weight in real time

The invention relates to a method for precisely balancing Z-axis weight in real time. The method comprises the steps that: a linear motor module drives a Z-axis movement module to move a certain distance; after the Z-axis movement module is stabilized, a grating ruler reading head reads first position data of a grating ruler and records the first position data into adjustment software, and the Z-axis movement module continues to fall; the adjustment software gives a pressure increase signal to a precision electric proportional valve, a rodless cylinder body is slowly filled with gas, and a rodless cylinder slider drives the Z-axis movement module to move up; the grating ruler reading head reads second position data of the grating ruler and compares the second position data and the first position data, and the second position data and the first position data are the same, the adjustment software reads pressure data of the precision electric proportional valve and records the pressure data when the position is stable; in the next time of equipment starting and operation, the adjustment software increases the pressure of the rodless cylinder body according to the automatically measured pressure data so as to balance gravity. According to the method, the judgment and adjustment are automatic, shutdown is not needed, and the Z-axis movement module reaches a balanced state.

Owner:BOZHON PRECISION IND TECH CO LTD +1

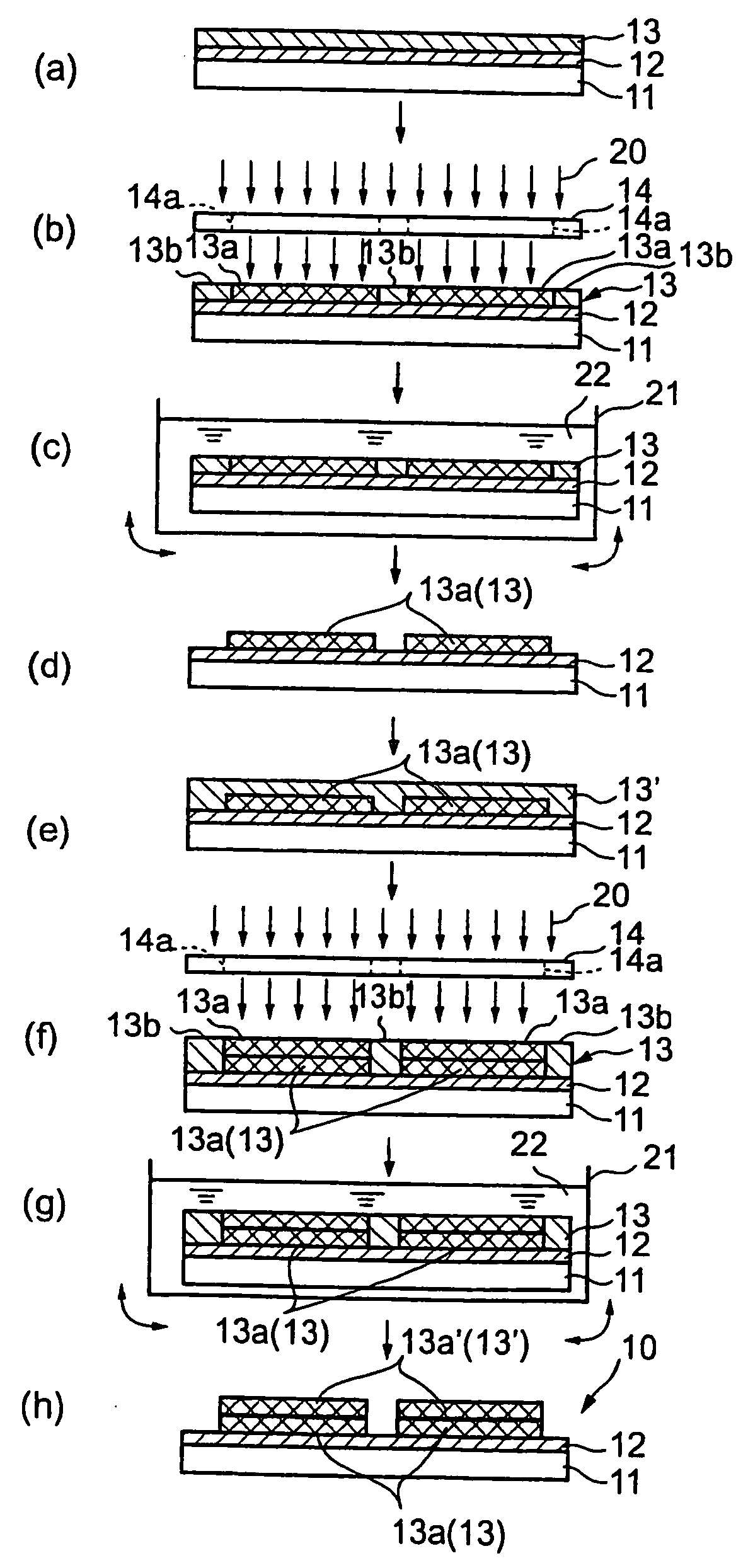

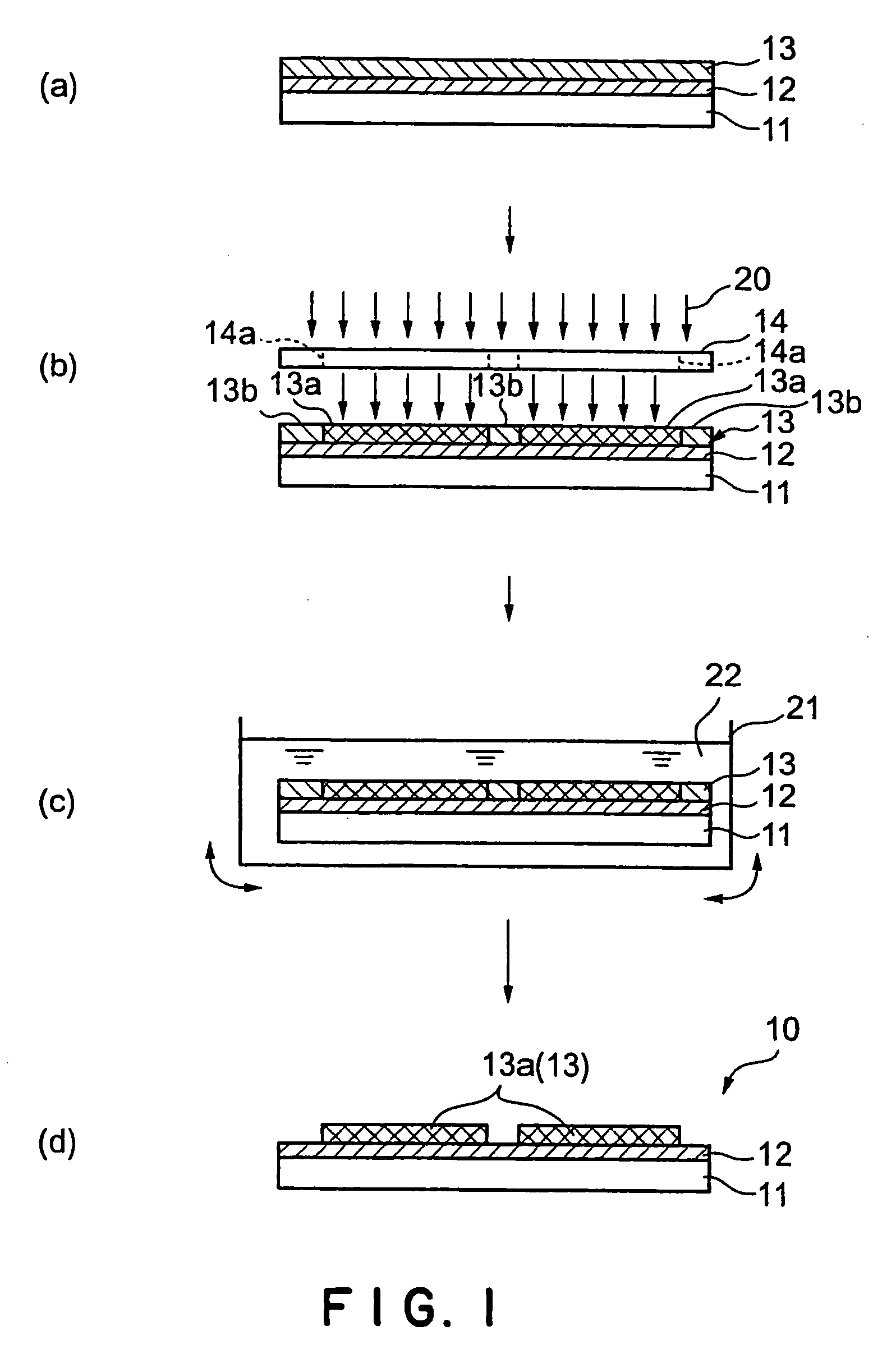

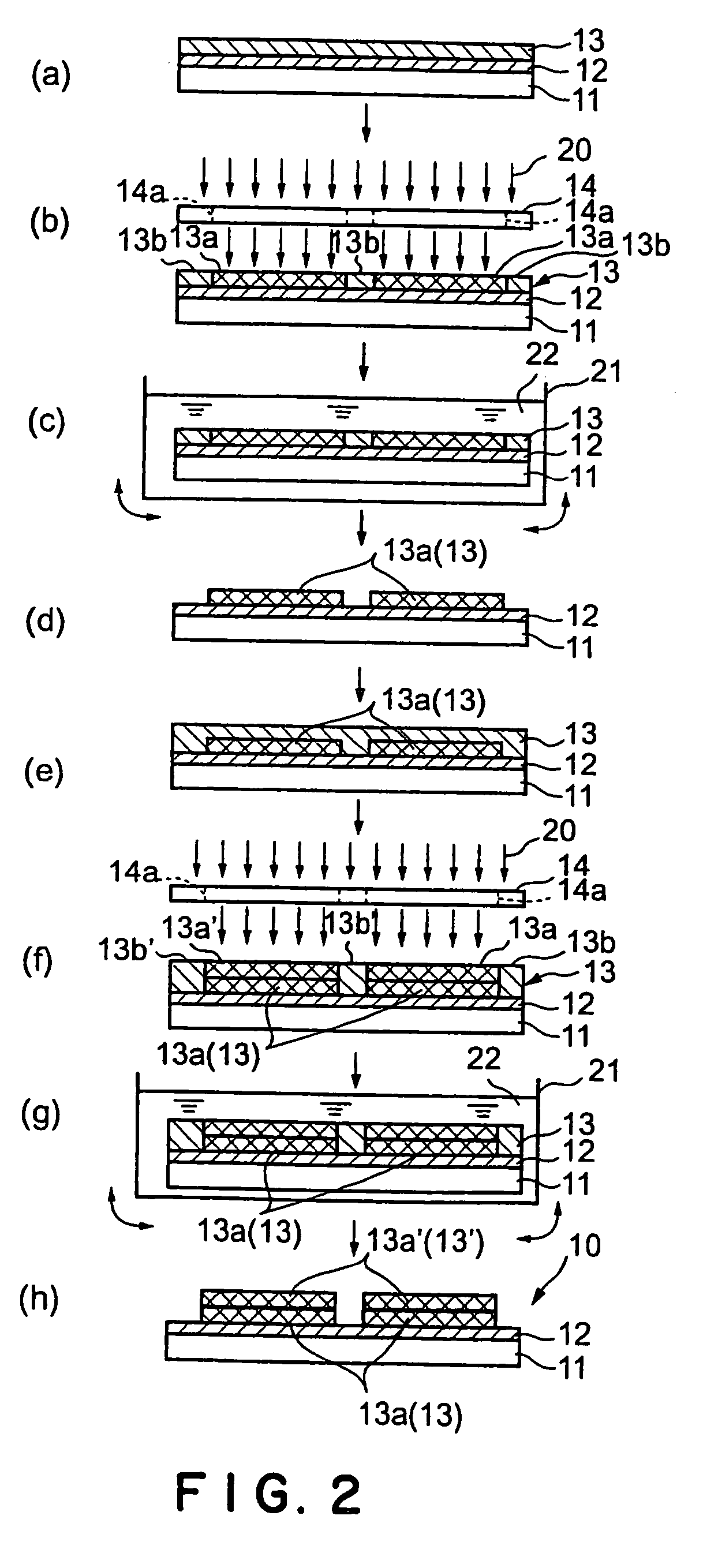

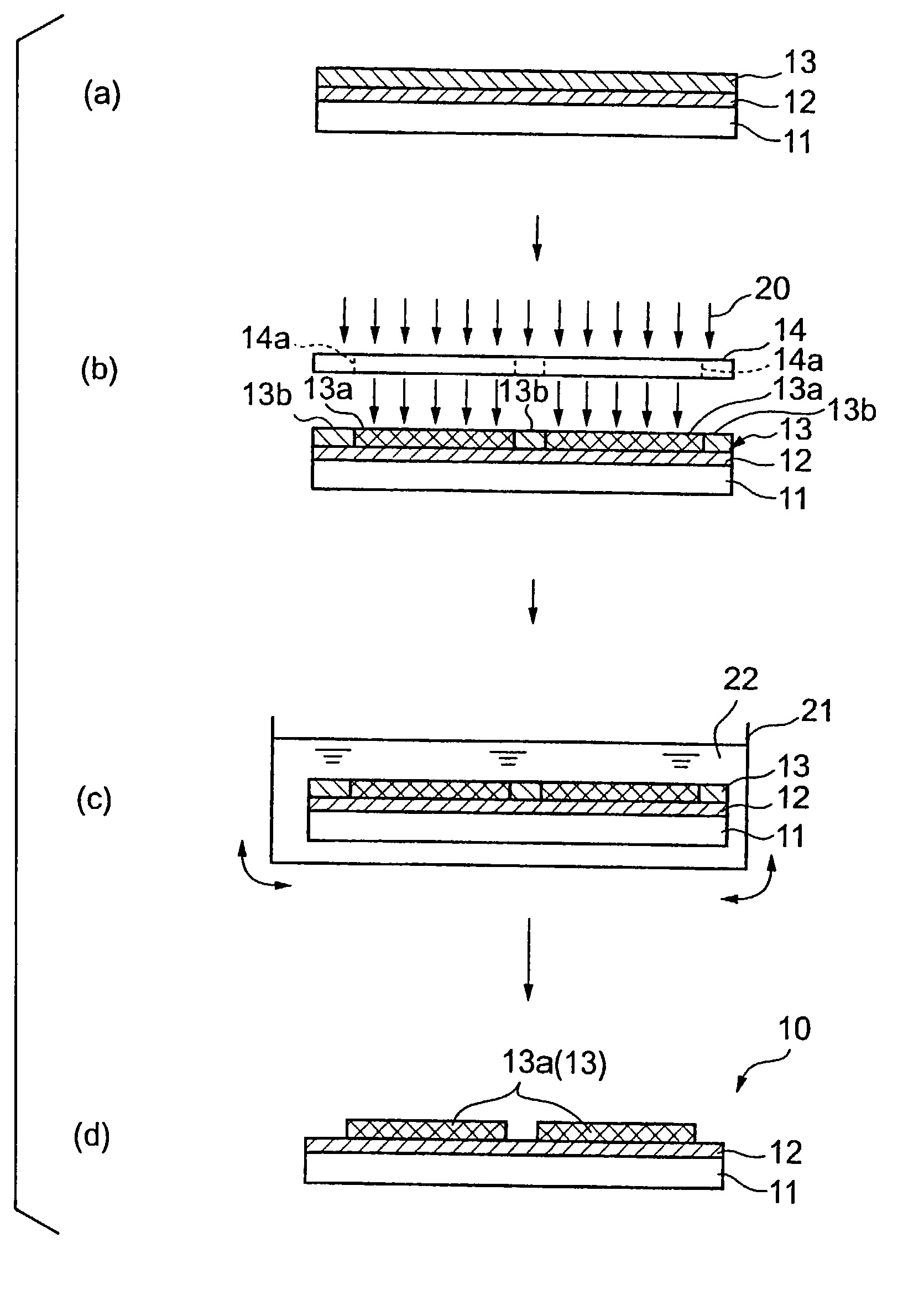

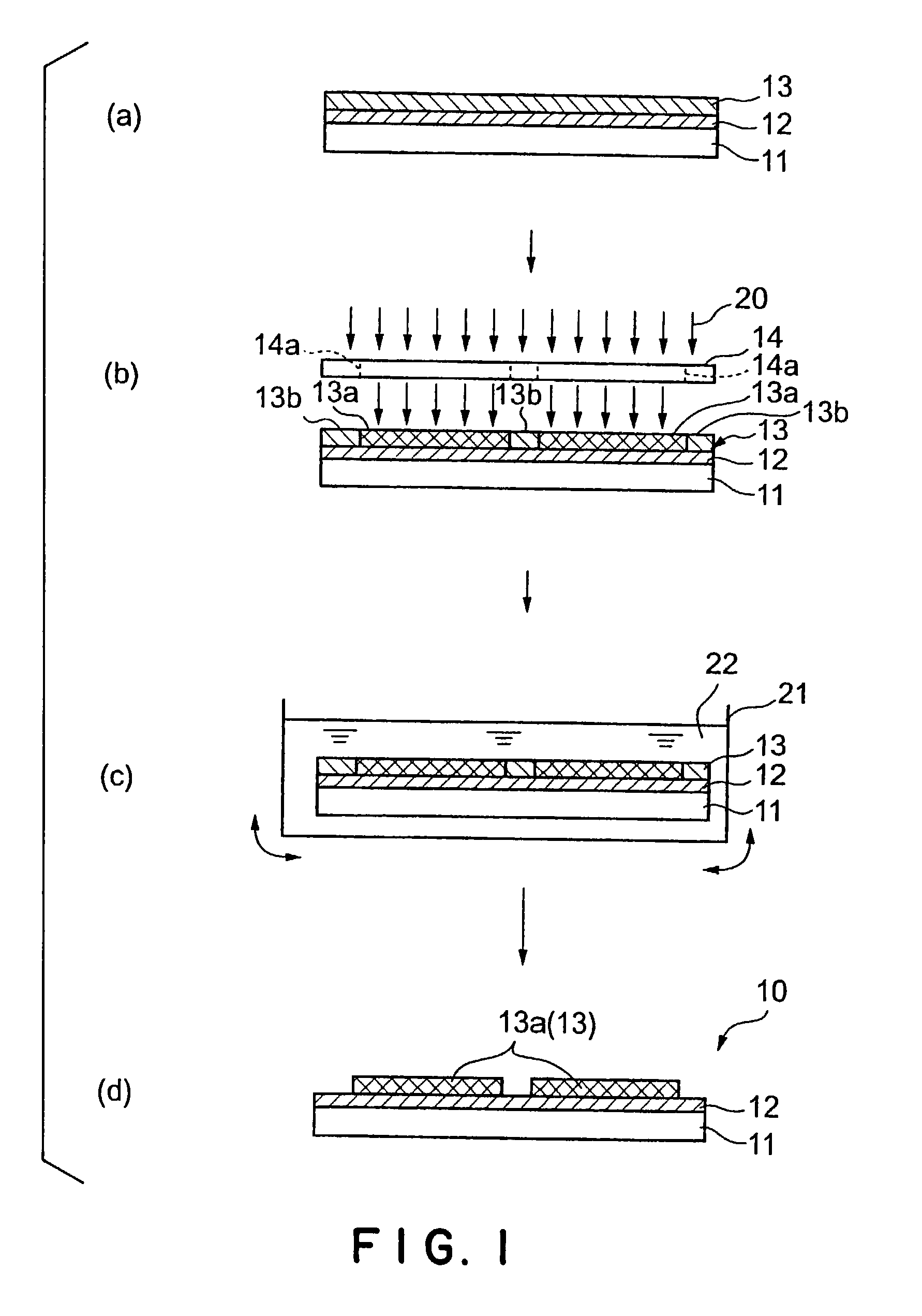

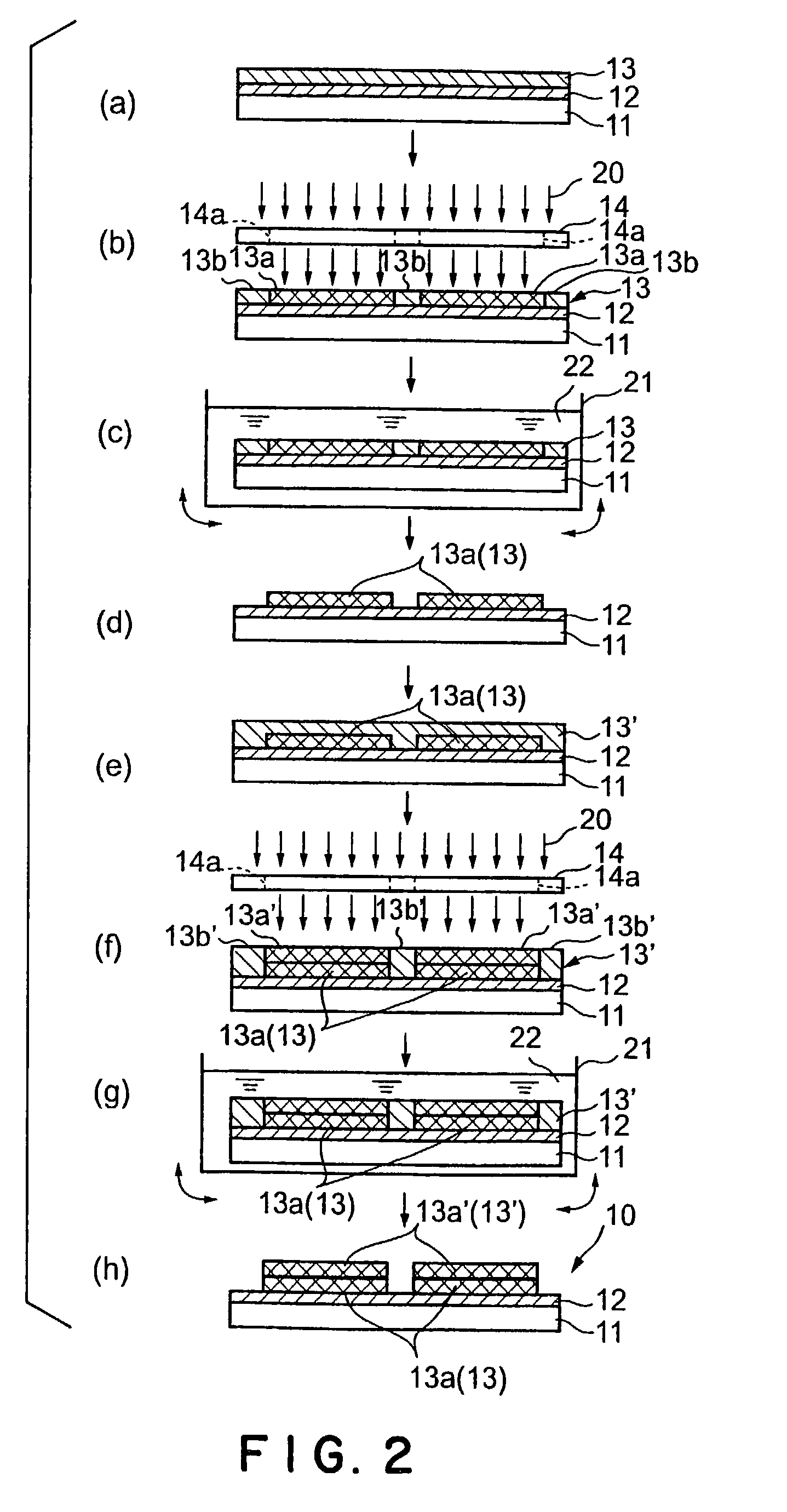

Method of producing optical element by patterning liquid crystal films

InactiveUS20060082720A1Good optical performanceHigh precision and efficiencyLiquid crystal compositionsPolarising elementsOrganic solventPhotomask

A radiation-curing liquid crystal having cholesteric regularity is applied to a glass substrate 11 provided with an alignment layer 12 to form a first cholesteric liquid crystal film 13 in the uncured state (FIG. 2(a)). Radiation 20 is then selectively applied, through a photomask 14, to the desired portions of the first cholesteric liquid crystal film 13 to partially cure it (FIG. 2(b)); thereafter, the first cholesteric liquid crystal film 13 is immersed in an organic solvent 22 to remove the uncured portions 13b thereof (FIG. 2(c)), thereby forming the first cholesteric liquid crystal film 13 in a desired pattern (FIG. 2(d)). Then, in the same manner as described above, a radiation-curing liquid crystal having cholesteric regularity is applied to the surface of the formed first cholesteric liquid crystal film 13 and the alignment layer 12 to form a second cholesteric liquid crystal film 13′ in the uncured state (FIG. 2(e)). To the second cholesteric liquid crystal film 13′, application of radiation 20 (FIG. 2(f)) and immersion in an organic solvent 22 (FIG. 2(g)) are carried out to remove the uncured portions 13b′ thereof (FIG. 2(e)), thereby producing an optical element 10 having the cholesteric liquid crystal films 13 and 13′ in desired patterns (FIG. 2(h)).

Owner:DAI NIPPON PRINTING CO LTD

Method of producing optical element by patterning liquid crystal films

InactiveUS7002662B2Good optical performanceHigh precision and efficiencyLiquid crystal compositionsPolarising elementsLiquid-crystal displayOrganic solvent

A method for making an optical element from patterned liquid crystal films by placing a radiation-curing liquid crystal on an aligning function substrate surface, radiating selectively a portion of the liquid crystal film partially to cure it, contacting the partially cured film with an organic solvent to remove the uncured portion of the film and form a pattern in the film, and applying another radiation-curing liquid crystal to a surface of the first film exposed by removing the uncured portion, thereby forming and patterning the second liquid crystal film. The solvent does not dissolve the substrate surface.

Owner:DAI NIPPON PRINTING CO LTD

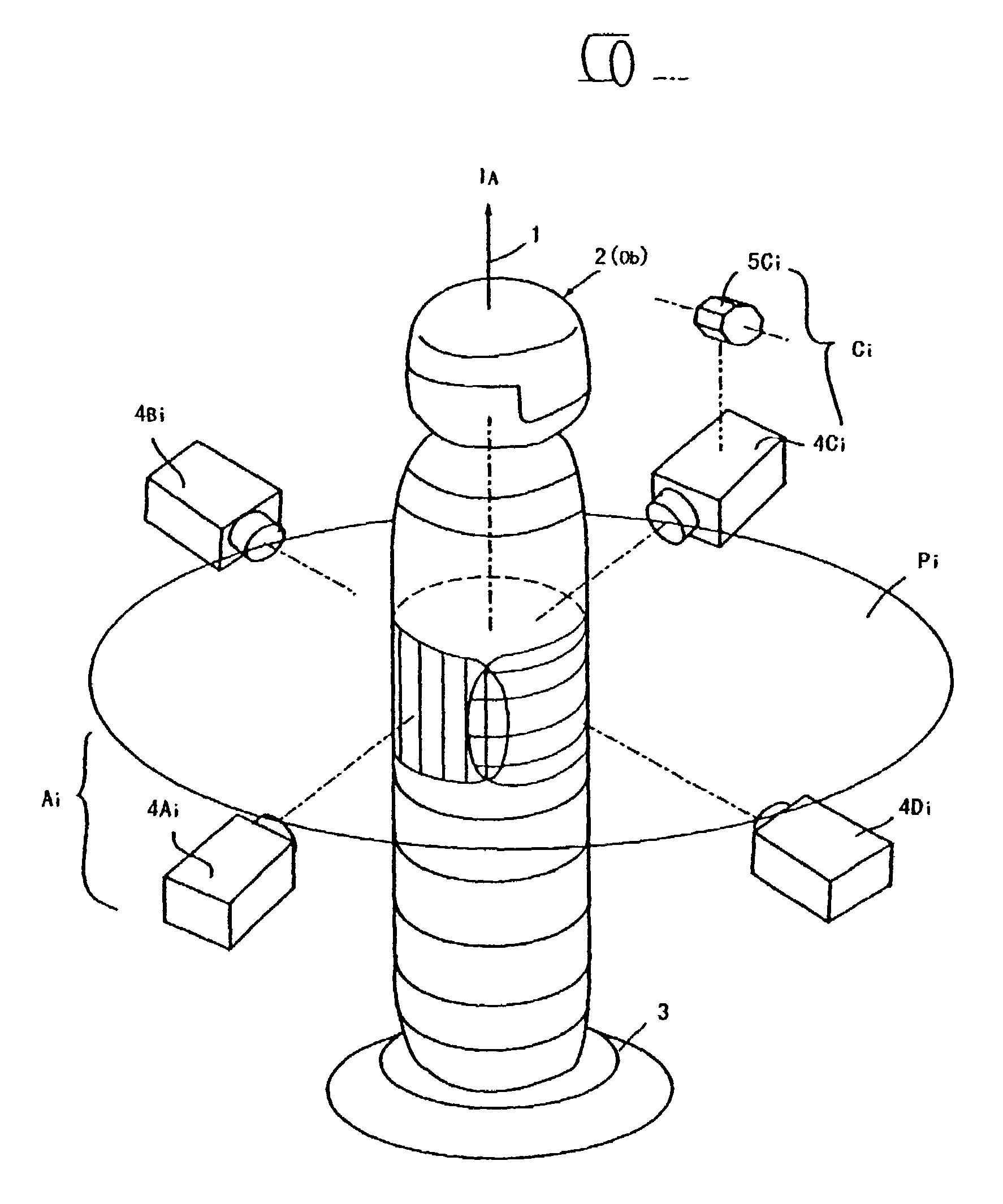

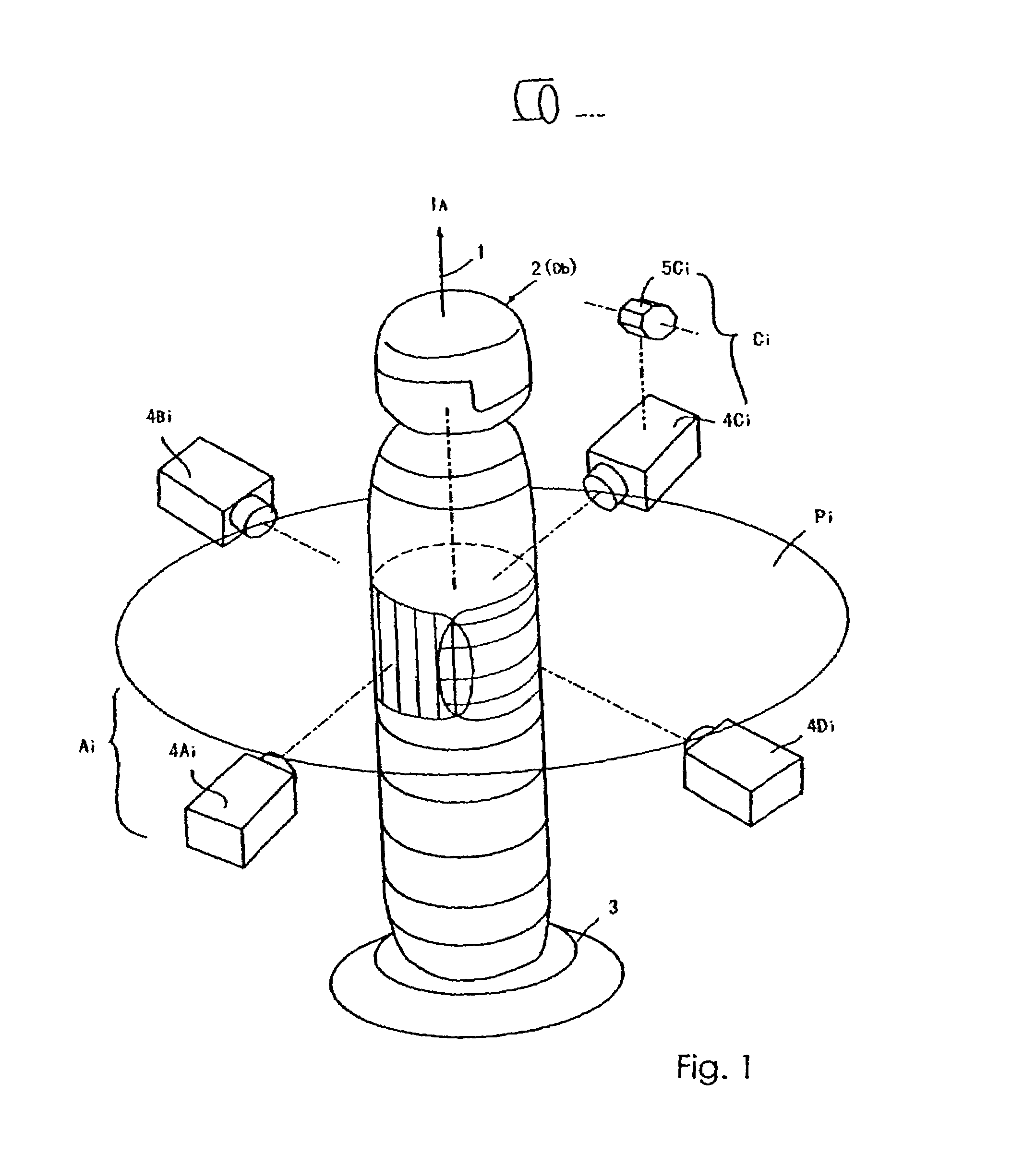

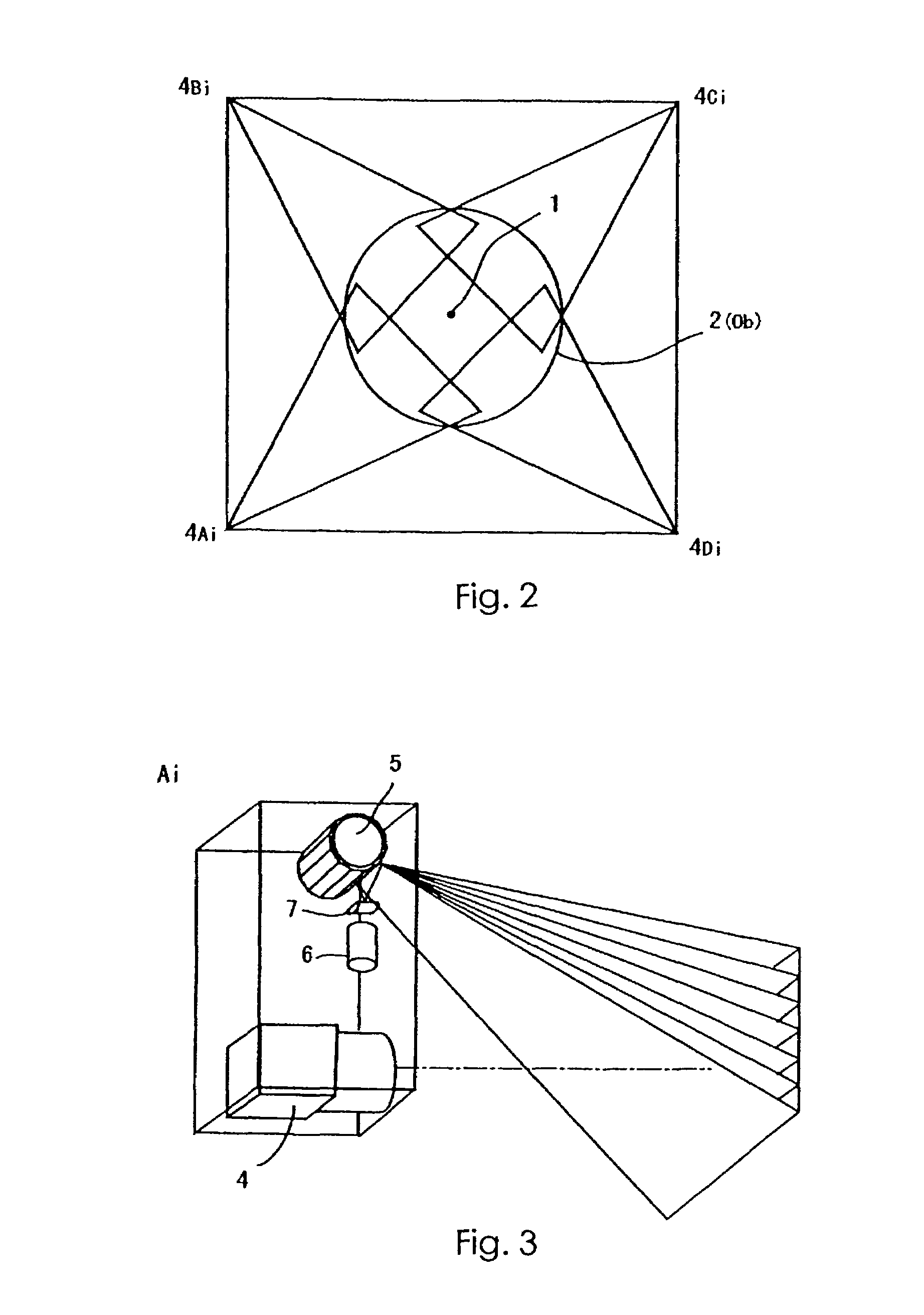

Method and apparatus for three-dimensional surface morphometry

InactiveUS6980301B2High precision and efficiencyImprove efficiencyRadiation/particle handlingCharacter and pattern recognitionThree dimensional dataOptical axis

The present invention provides a method and apparatus for non-contacting morphomtry of three-dimensional surface of an object such as a human body in a shorter time period and with higher precision, wherein the present non-contacting morphometry of three-dimensional surface of an object involves a plurality of measuring video heads, Ai, Bi, Ci and Di and a controlling unit for controlling the measuring time of the measuring heads and for processing and storing the obtained data from the measurements. The present method comprises the steps of: placing the object to be measured so that one axis thereof lies along and with an imaginary central axis; placing the object to be measured so that the measuring heads are arranged on each of n (n≧1) planes intersecting the imaginary central axis where the optical axis of each measuring head faces the imaginary central axis and each annular slice of the surface of the object is covered by the sight fields of the m (m≧3) measuring heads; operating simultaneously one group of a plurality of measuring video heads, the sight field of each of which does not substantially overlap with the sight field of the other in the group, and thereafter, operating other group of a plurality of measuring video heads, the sight field of each of which does not substantially overlap with the sight field of the other in the group. The n×m sets of data thus obtained in the foregoing steps are processed to obtain three-dimensional data.

Owner:CUBIC INC +2

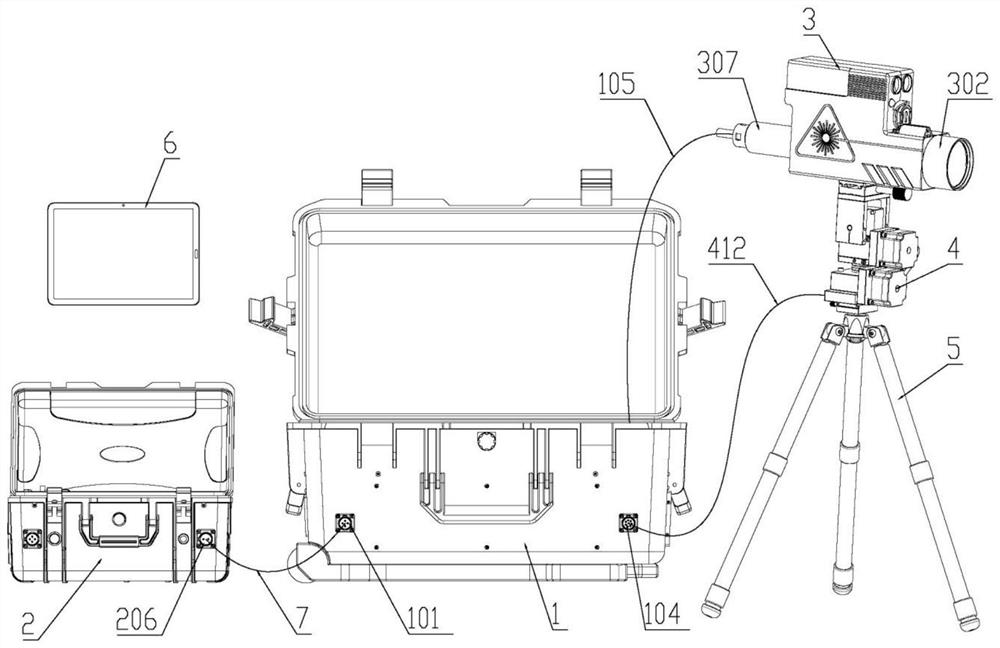

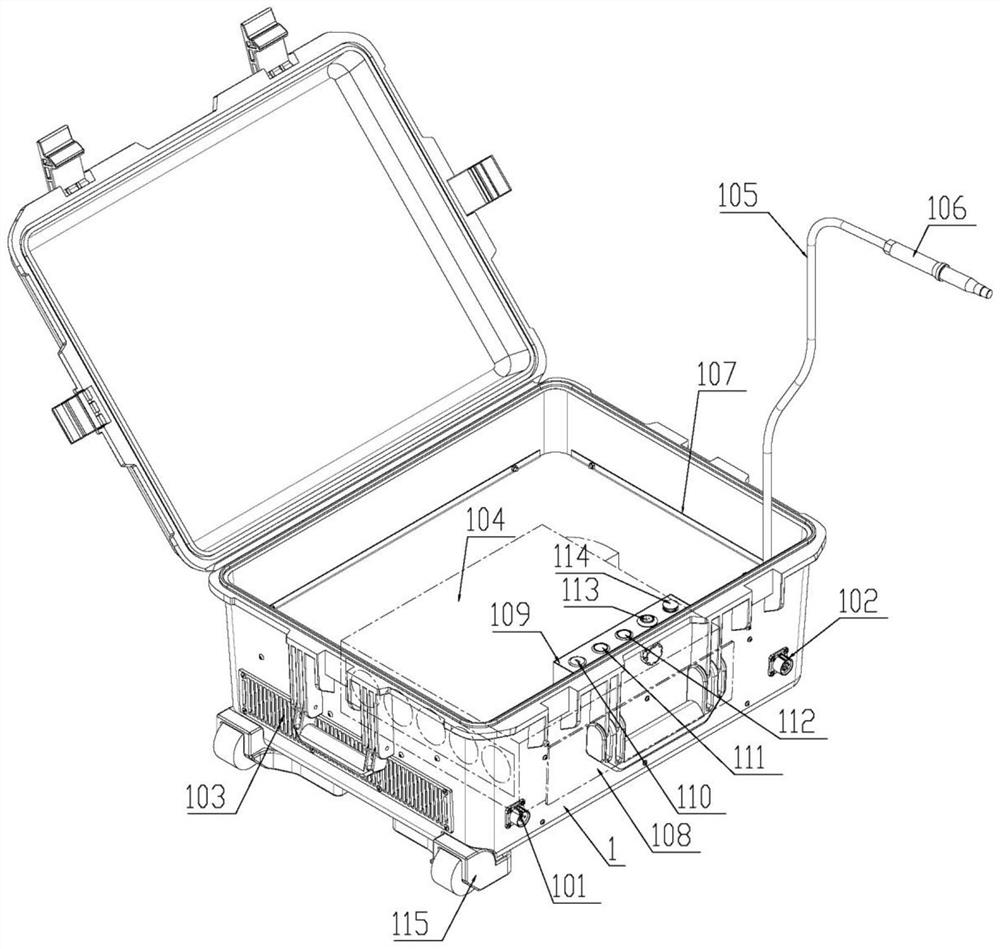

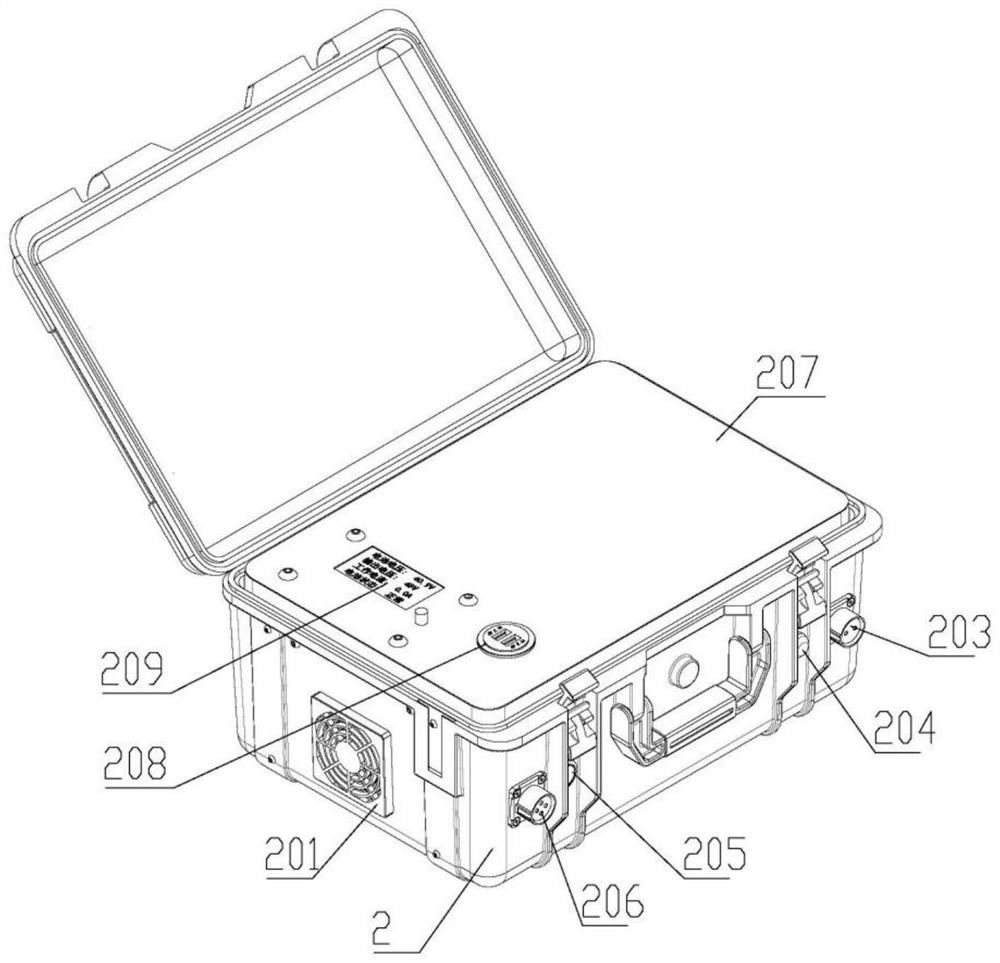

Intelligent laser destructor for unexploded ordnance

PendingCN114413702AImprove securityAvoid accidentsCircuit monitoring/indicationDifferent batteries chargingElectrical batteryResidual charge

The invention discloses an intelligent unexploded ordnance laser destructor which comprises a mainframe box, a mobile power box, an aiming launching device, an electric cradle head, a tripod and a handheld manipulator, the electric cradle head is fixedly installed at the top end of the tripod, and the aiming launching device is installed at the top end of the electric cradle head; the mobile power box provides power support for the main case, the aiming launching device and the electric holder, the aiming launching device, the electric holder and the tripod can be stored in the main case, and control software is installed in the handheld controller. The battery voltage, the output voltage, the working current, the battery state, the residual electric quantity and the fault reason when the power supply works can be displayed on the screen through the scram button and the battery state display screen of the mobile power box, and meanwhile, the mobile power box has an alarm function when the mobile power supply is under-voltage, over-voltage and over-high in temperature.

Owner:NANTONG SIPAITE LASER TECH

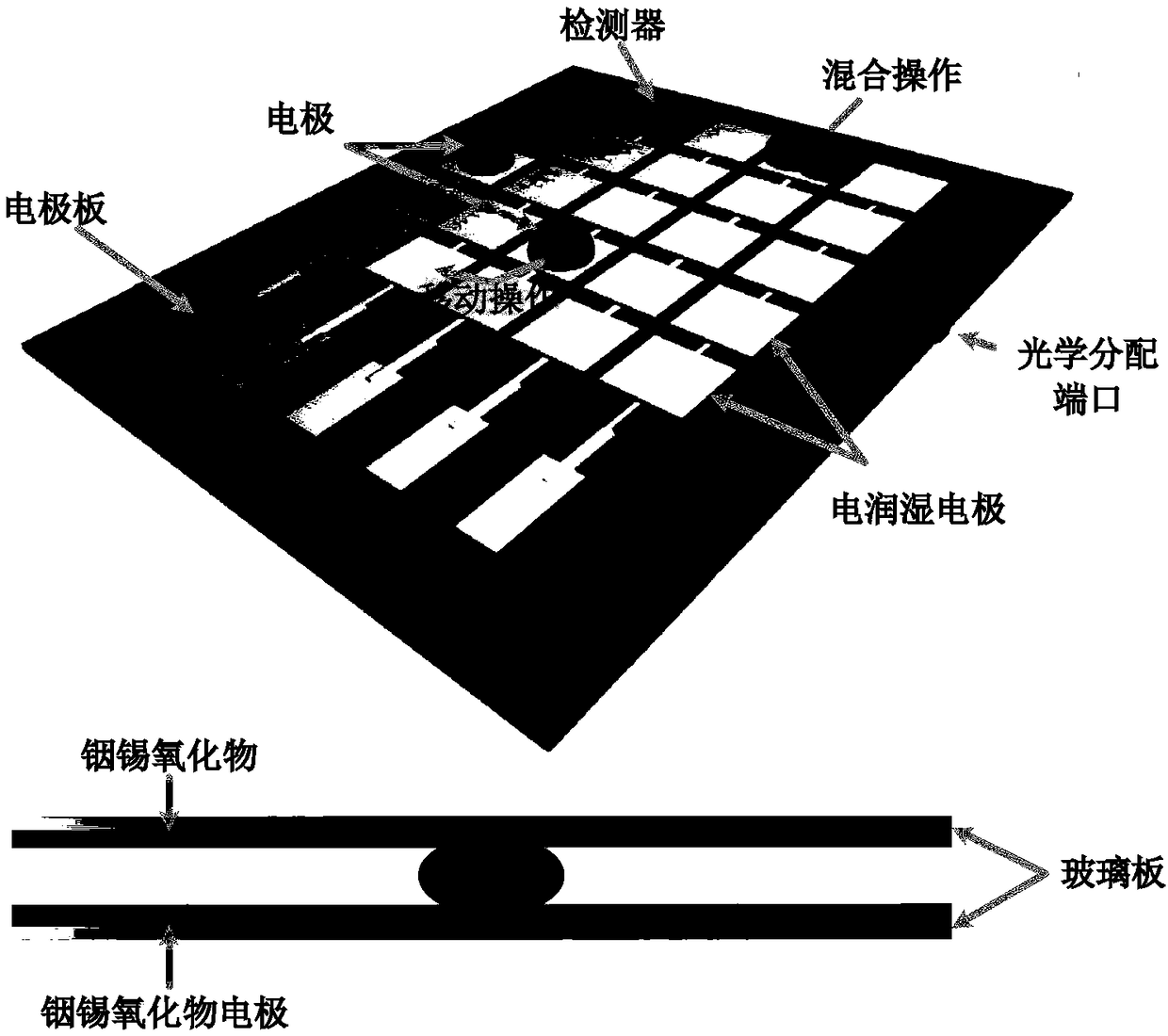

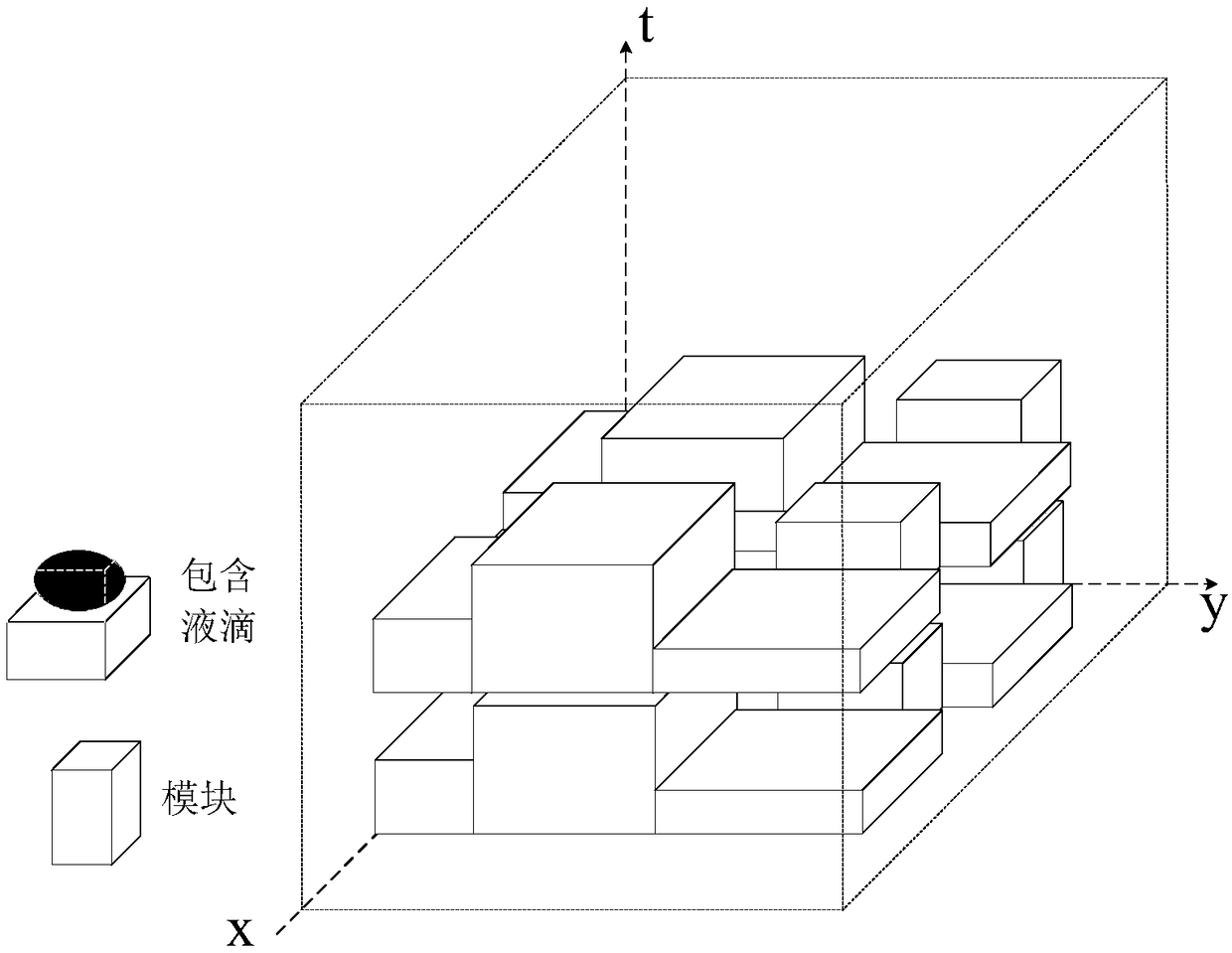

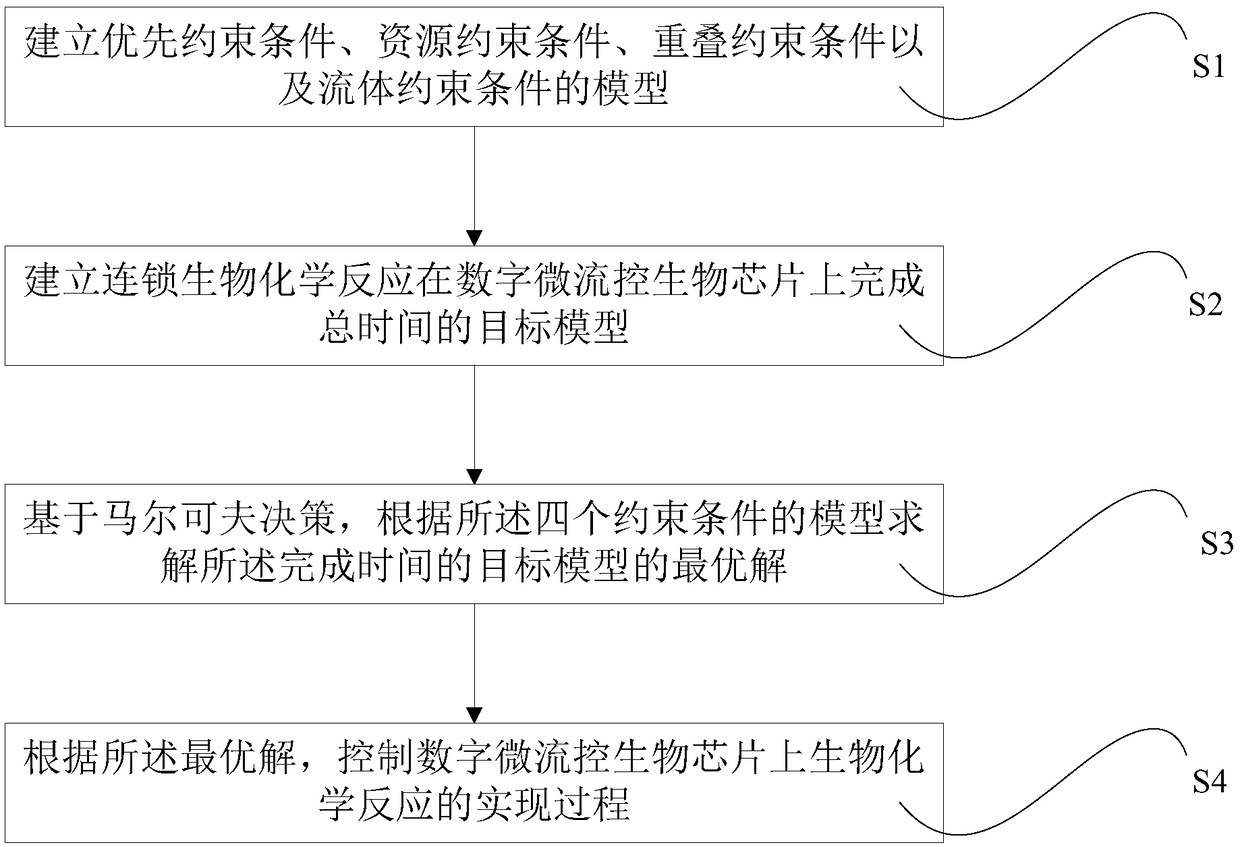

Time optimization method for computer-aided layout design of digital microfluidic biochips

ActiveCN109117497ALow costHigh precision and efficiencySpecial data processing applicationsComputer-aidedObjective model

The invention discloses a time optimization method for computer-aided design layout of a digital microfluidic biochip, which comprises the following steps: establishing a model of four constraint conditions of priority constraint, resource constraint, overlap constraint and fluid constraint; establishing a target model of the total time of interlocking biochemical reactions on digital microfluidicbiochip; solving an optimal solution of the target model of the completion time according to the model of the four constraint conditions based on a Markov decision; according to the optimal solution,the realization process of the biochemical reaction on the digital microfluidic biochip being controlled. The invention can minimize the biochemical reaction time in the digital microfluidic biochip,and has the advantages of low cost, high precision and high efficiency.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

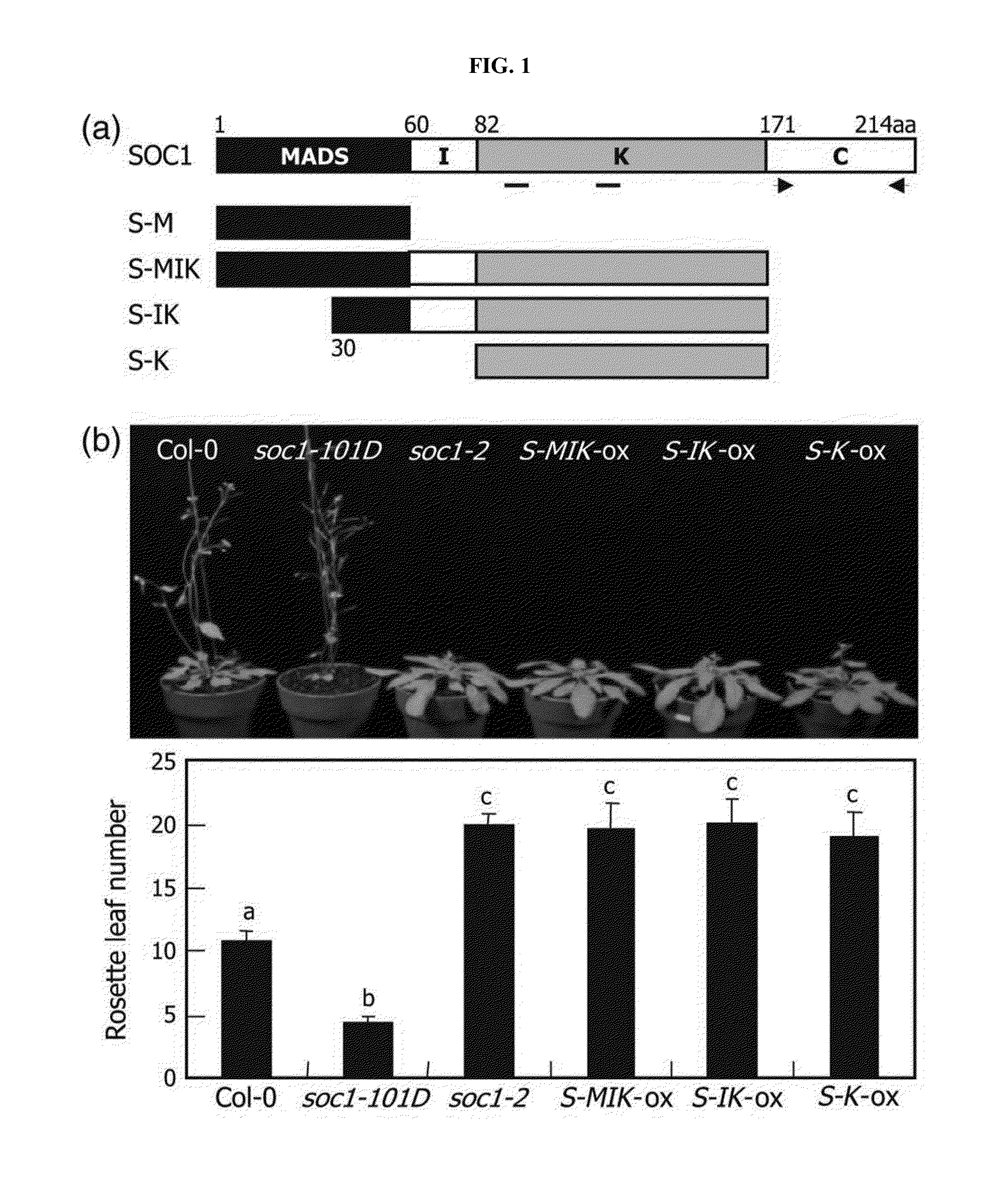

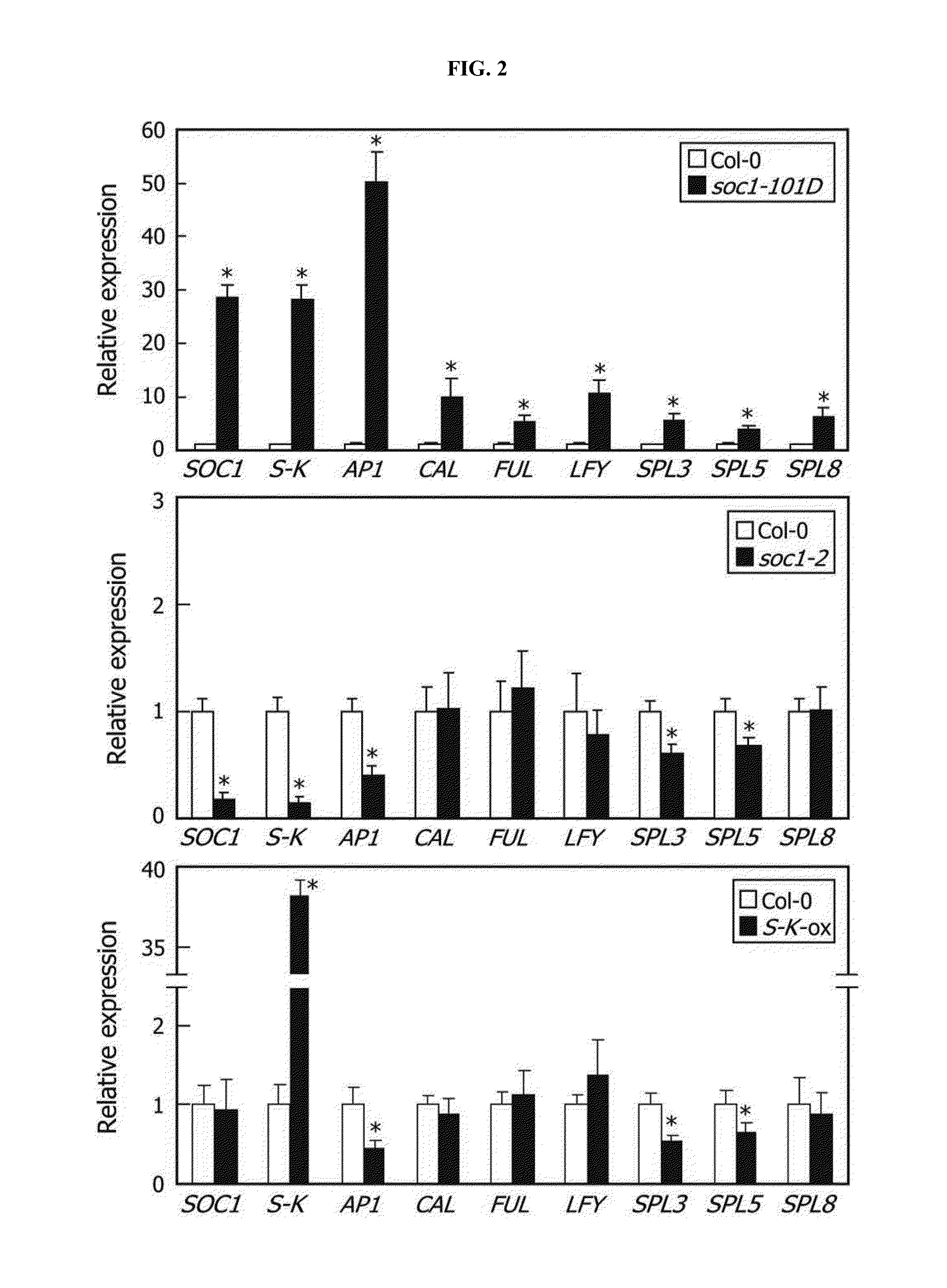

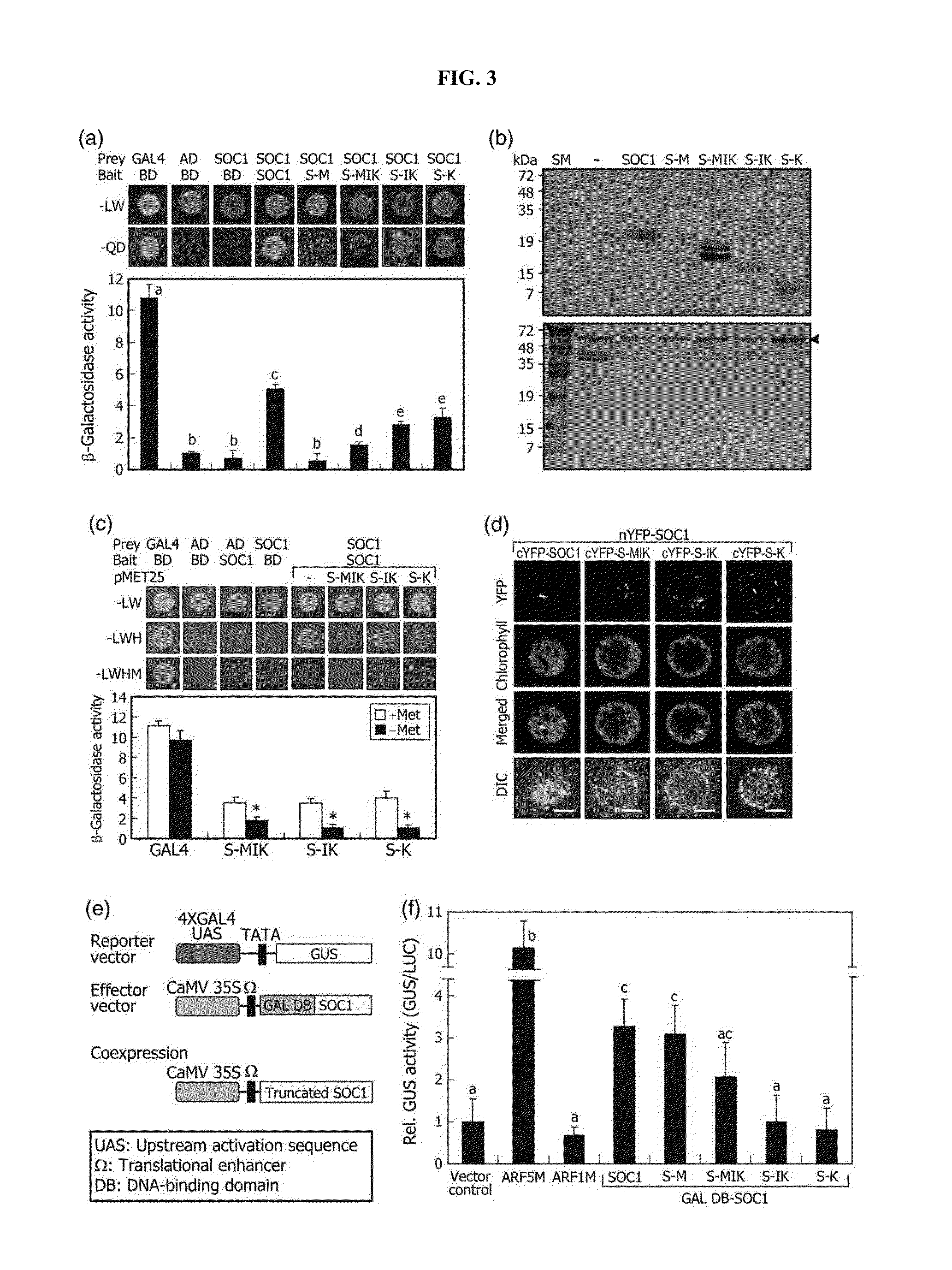

Method for inactivating target transcription factor using artificial small interfering peptide and use thereof

ActiveUS20160138036A1High precision and efficiencyInhibitory activitySugar derivativesPeptide/protein ingredientsTranscription factor activityProtein level

The present invention relates to a method for targeted inactivation of transcription factor using an artificial small interfering peptide and a use thereof. According to the present invention, an artificial small interfering peptide (a-siPEP) as a truncated from of the transcription factor for regulating transcription by dimerization was produced. It was also confirmed that, as a-siPEP forms a heterodimer with a transcription factor, DNA binding and transport into a nucleus of the transcription factor are inhibited, so that inactivation of the transcription factor is achieved at protein level. The method for inhibiting transcription factor activity using a-siPEP can replace a gene knock-out method and it allows protein-level inhibition of a transcription factor. Also, it is a transcription regulation method with high precision and high efficiency that can be applied for both monocot and dicot plants.

Owner:SEOUL NAT UNIV R&DB FOUND

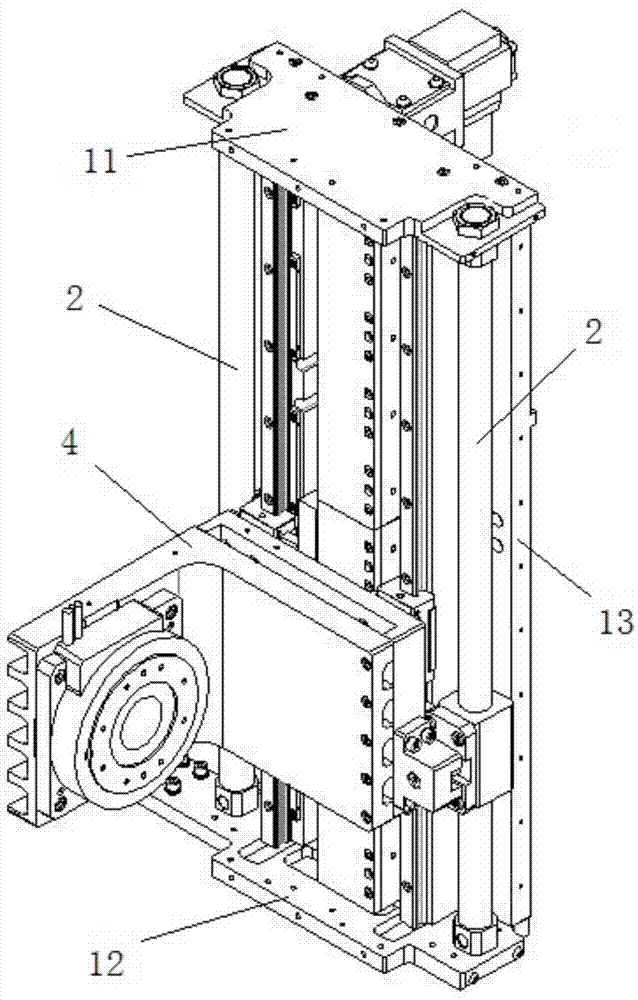

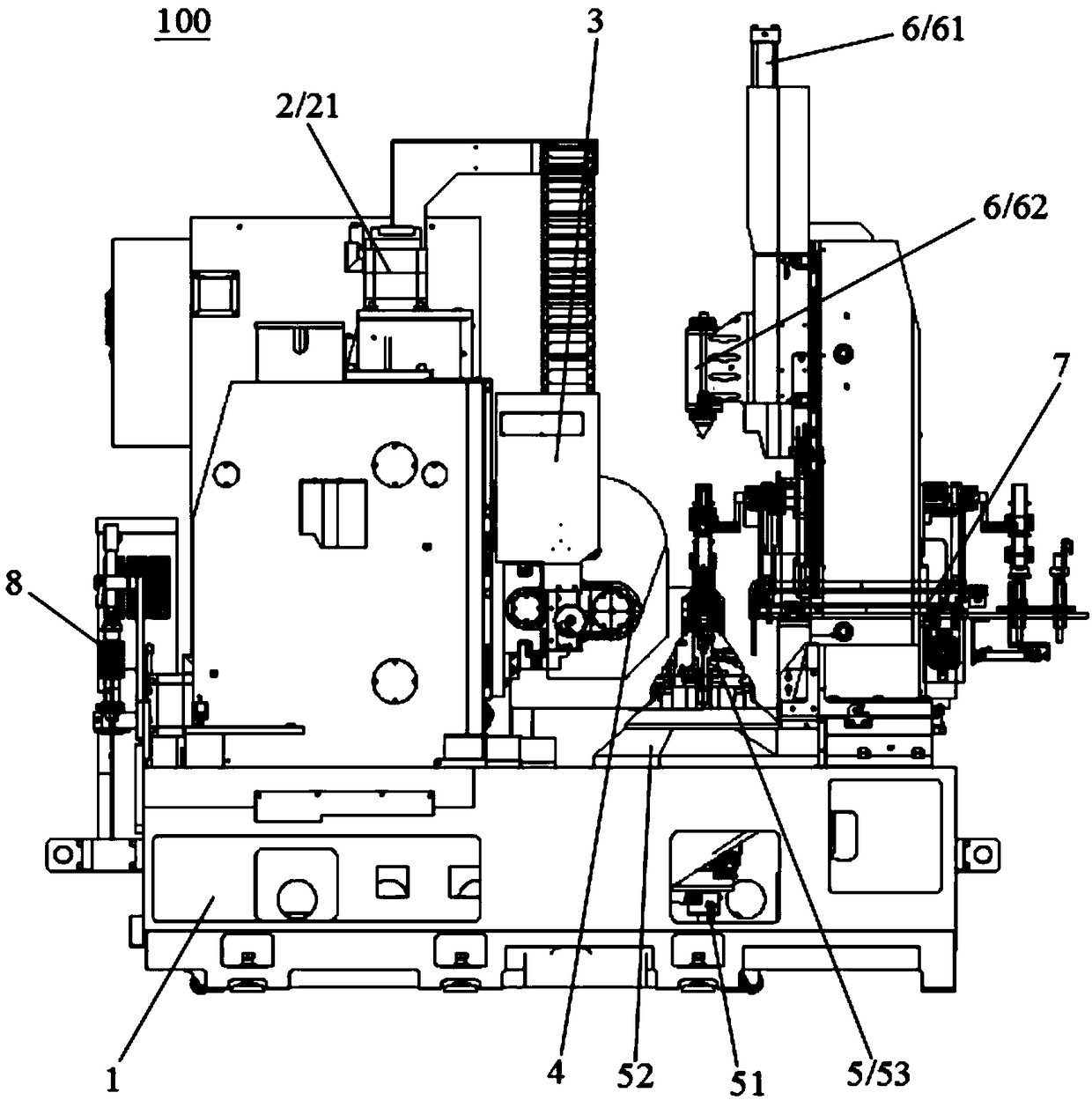

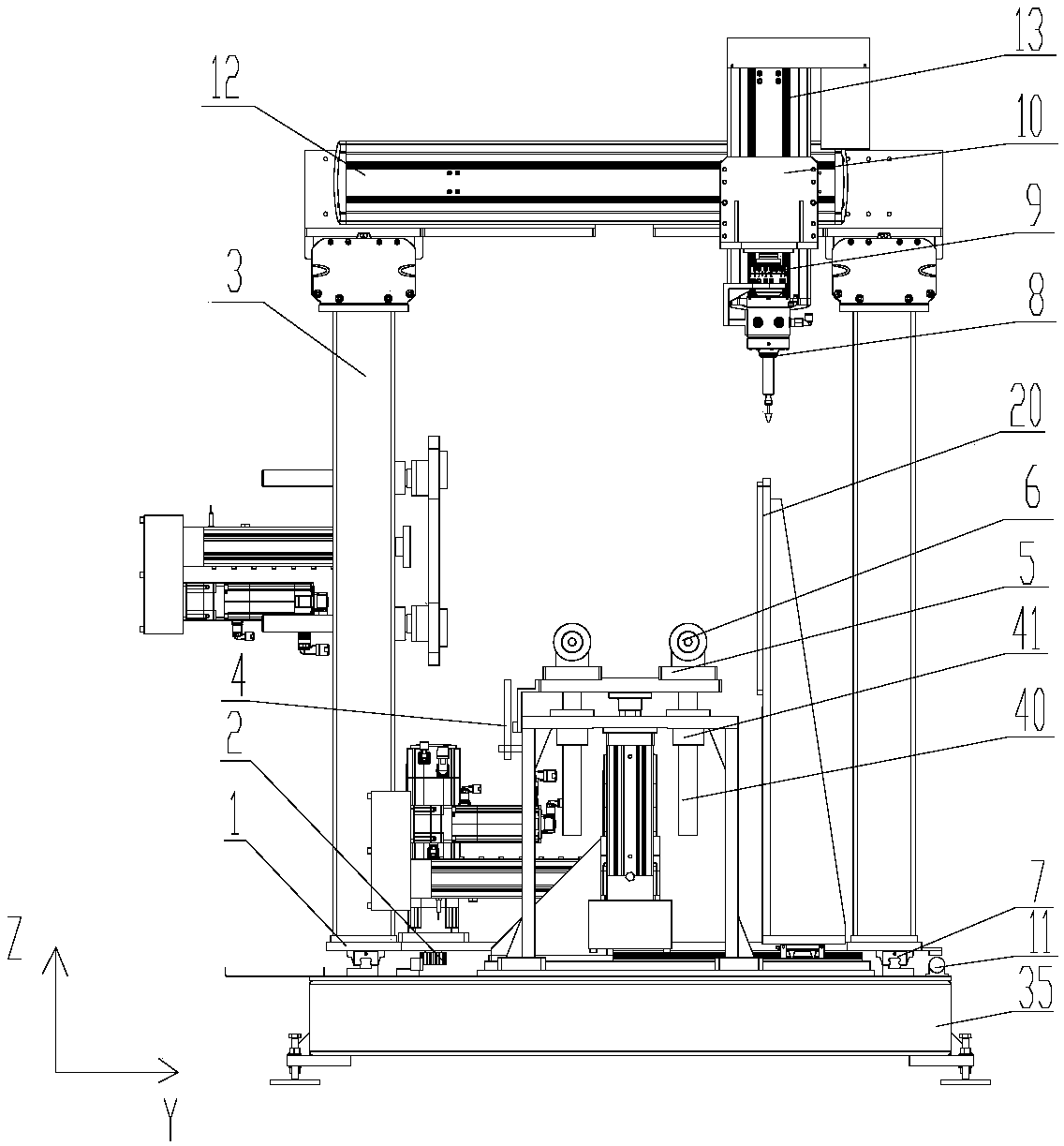

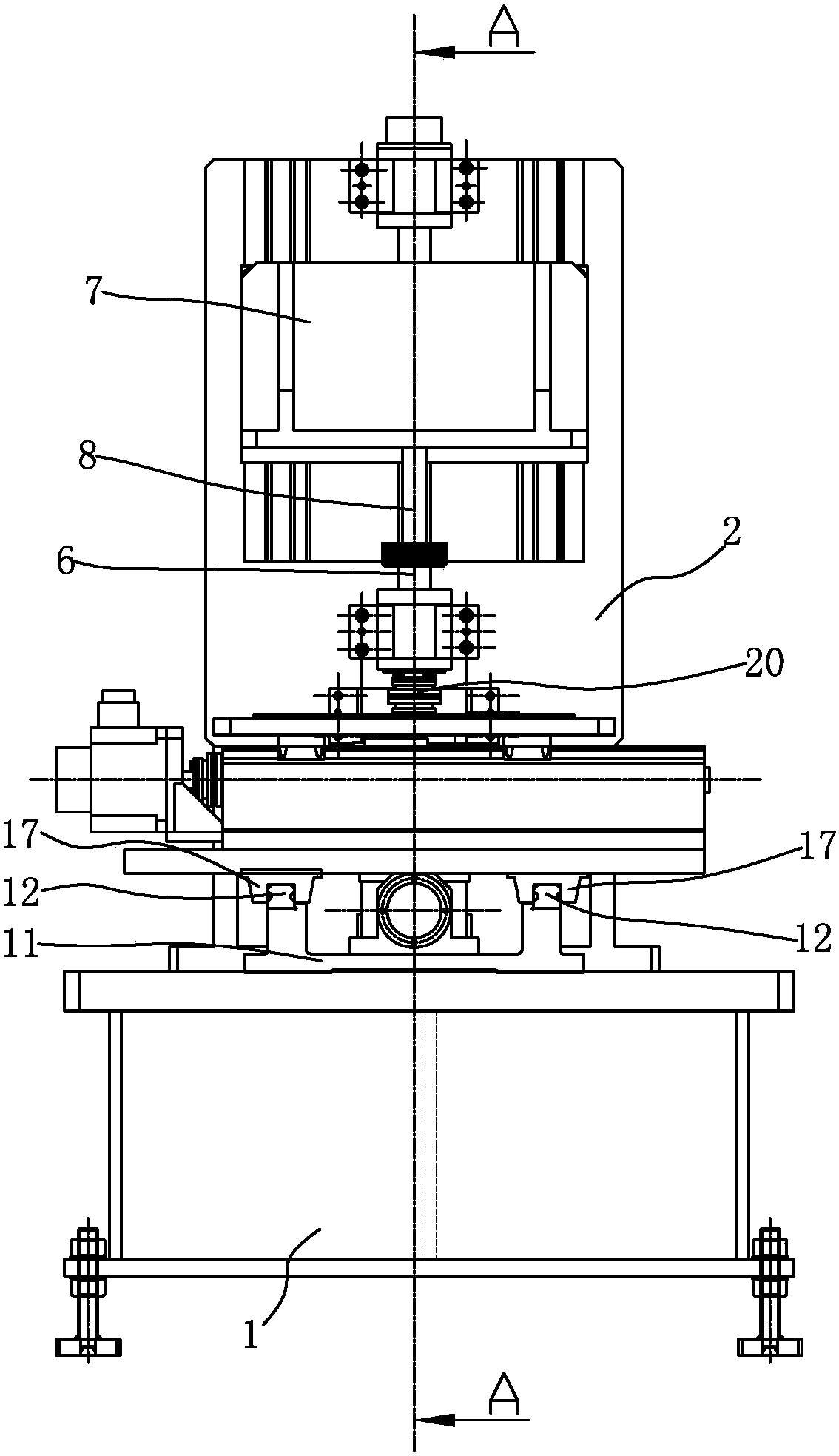

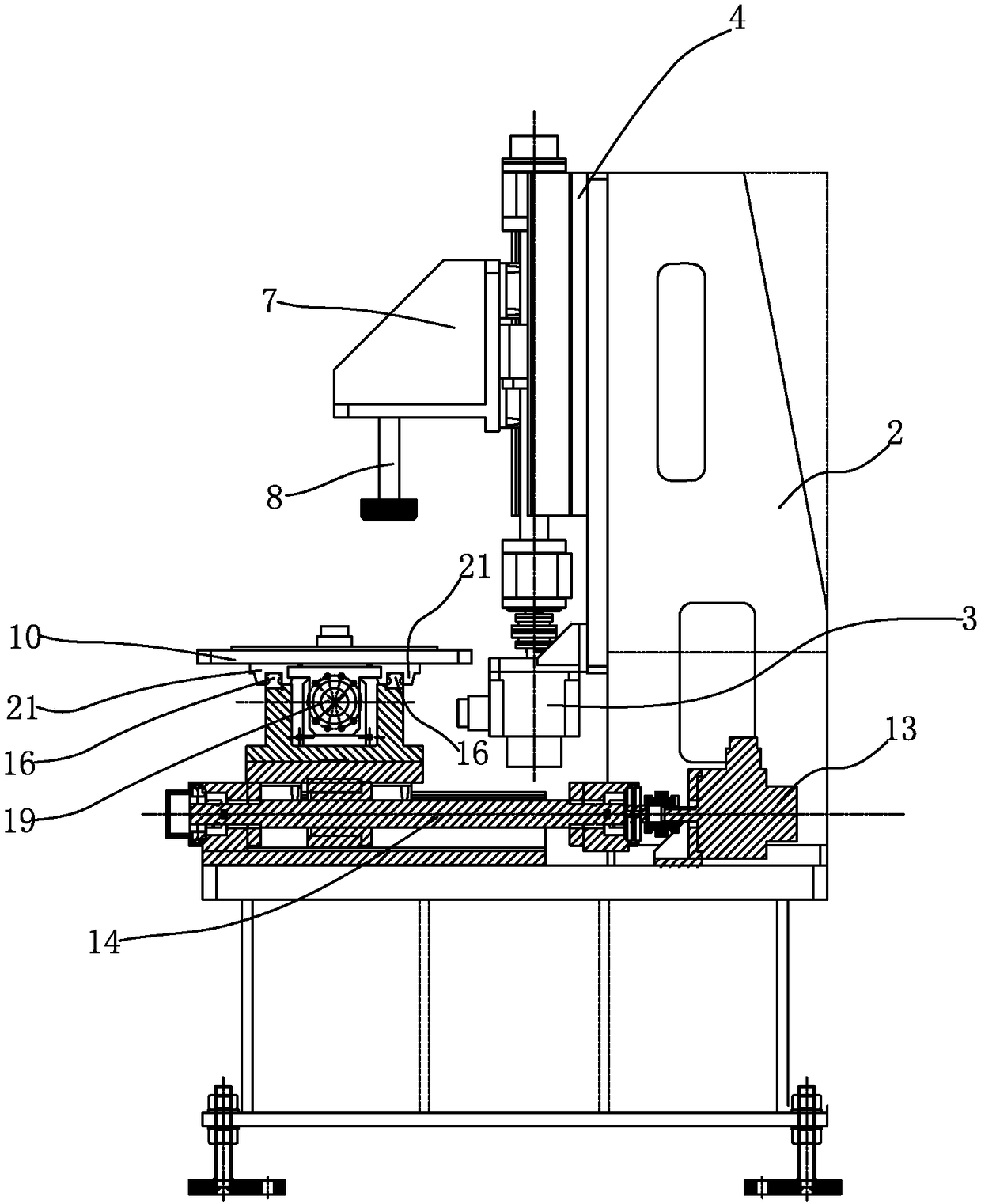

High-precision high-speed processing and gear-hobbing machine

PendingCN108145253AHigh precisionImprove efficiencyGear-cutting machinesGear teethHobbingEngineering

The invention discloses a high-precision high-speed processing and gear-hobbing machine. The high-precision high-speed processing and gear-hobbing machine comprises a machine base, a tool rest angle regulating mechanism fixedly arranged on the machine base, a tool apron which is arranged on the tool rest angle regulating mechanism, a gear-hobbing knife which is driven by the tool apron to move, agear base which is fixedly arranged on the machine base and is driven to rotate by positioning a gear, a tail base limiting mechanism which performs concentricity limitation on rotation of the gear, and a gear automatic loading and unloading mechanism which sleeves the peripheral surface of the tail base limiting mechanism. The high-precision high-speed processing and gear-hobbing machine can realize a series of automatic operations such as automatic loading, automatic gear-hobbing knife angle regulating, automatic processing and forming and automatic unloading, is high in processing efficiency and is high in processing precision.

Owner:爱思恩梯(苏州)机床有限公司

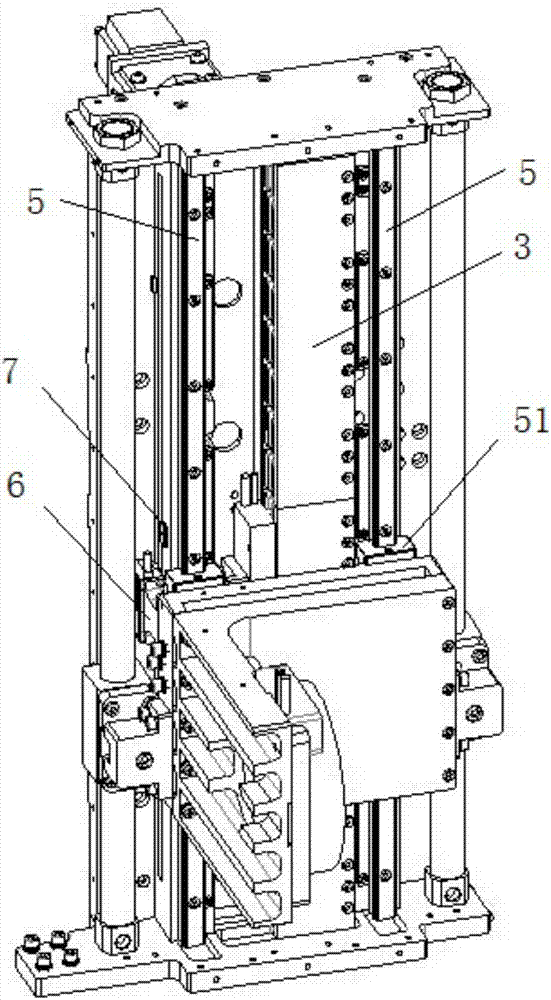

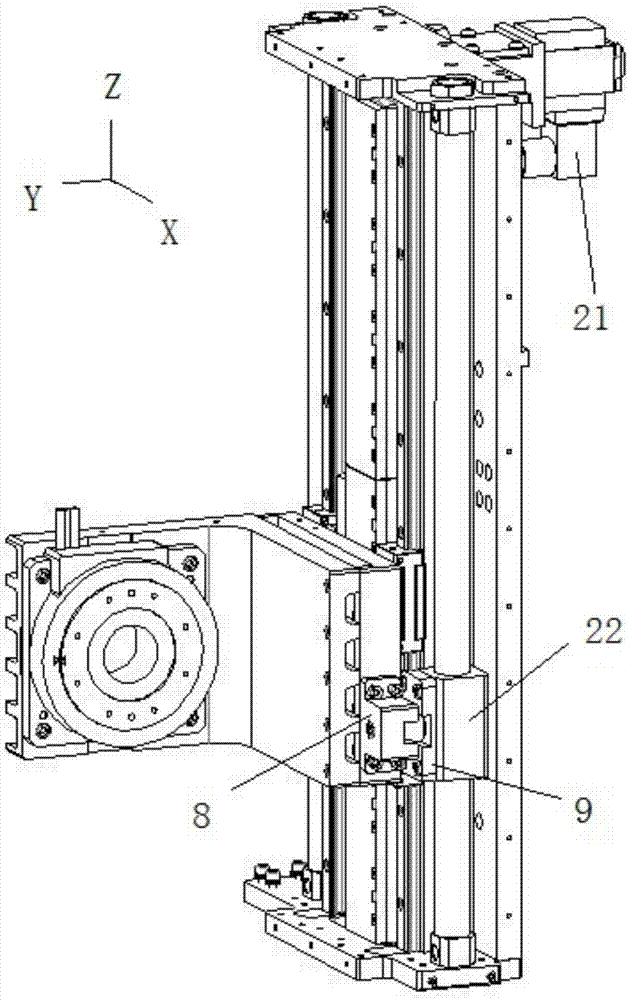

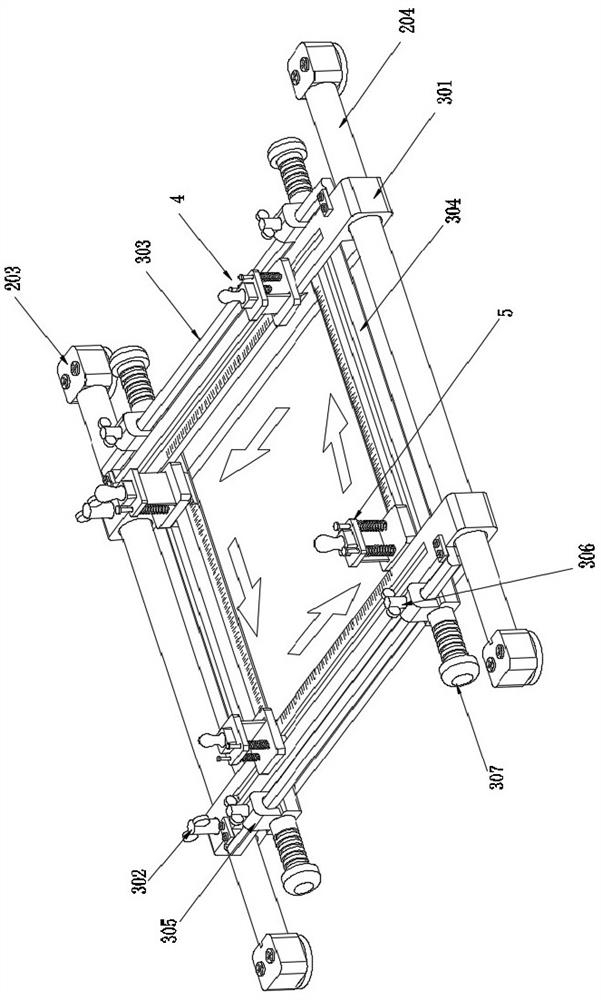

Full-automatic grinding mechanism achieving automatic posture adjustment based on force feedback

ActiveCN111113266AHigh precision and high efficiencyHigh-precision action is accurateGrinding carriagesGrinding drivesDrive by wireControl engineering

The invention belongs to the technical field of machining and assembling of large pipe seat structural members, and particularly relates to a full-automatic grinding mechanism achieving automatic posture adjustment based on force feedback. The full-automatic grinding mechanism achieving automatic posture adjustment based on force feedback comprises a bottom plate, an automatic grinding mechanism,a grinding linear driving mechanism, a vertical posture adjusting mechanism, a pitching posture adjusting mechanism and an adjusting supporting mechanism, wherein the automatic grinding mechanism, thegrinding linear driving mechanism, the vertical posture adjusting mechanism, the pitching posture adjusting mechanism and the adjusting supporting mechanism are arranged on the bottom plate, the grinding linear driving mechanism and an X-axis linear guide rail are arranged on the bottom plate, the automatic grinding mechanism is connected with the X-axis linear guide rail in a sliding mode and connected with the grinding linear driving mechanism, the vertical posture adjusting mechanism and the pitching posture adjusting mechanism are positioned on two sides of the adjusting supporting mechanism respectively, the pitching posture adjusting mechanism is used for adjusting the pitching angle of a workpiece, and the vertical posture adjusting mechanism is used for adjusting the horizontal position of the workpiece. The full-automatic grinding mechanism achieving automatic posture adjustment based on force feedback realizes automatic positioning, automatic high-precision posture adjustment and full-automatic high-precision grinding for grinding in the production and assembling processes of large pipe seat structural members.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

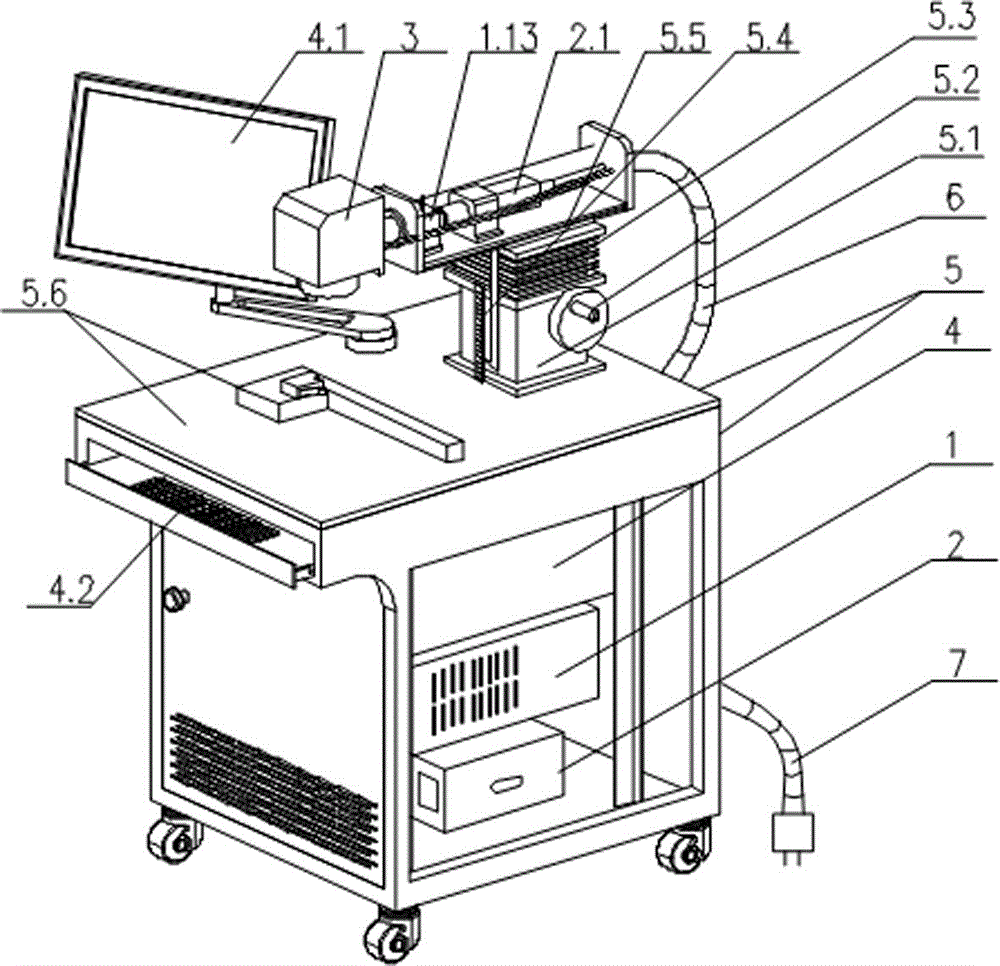

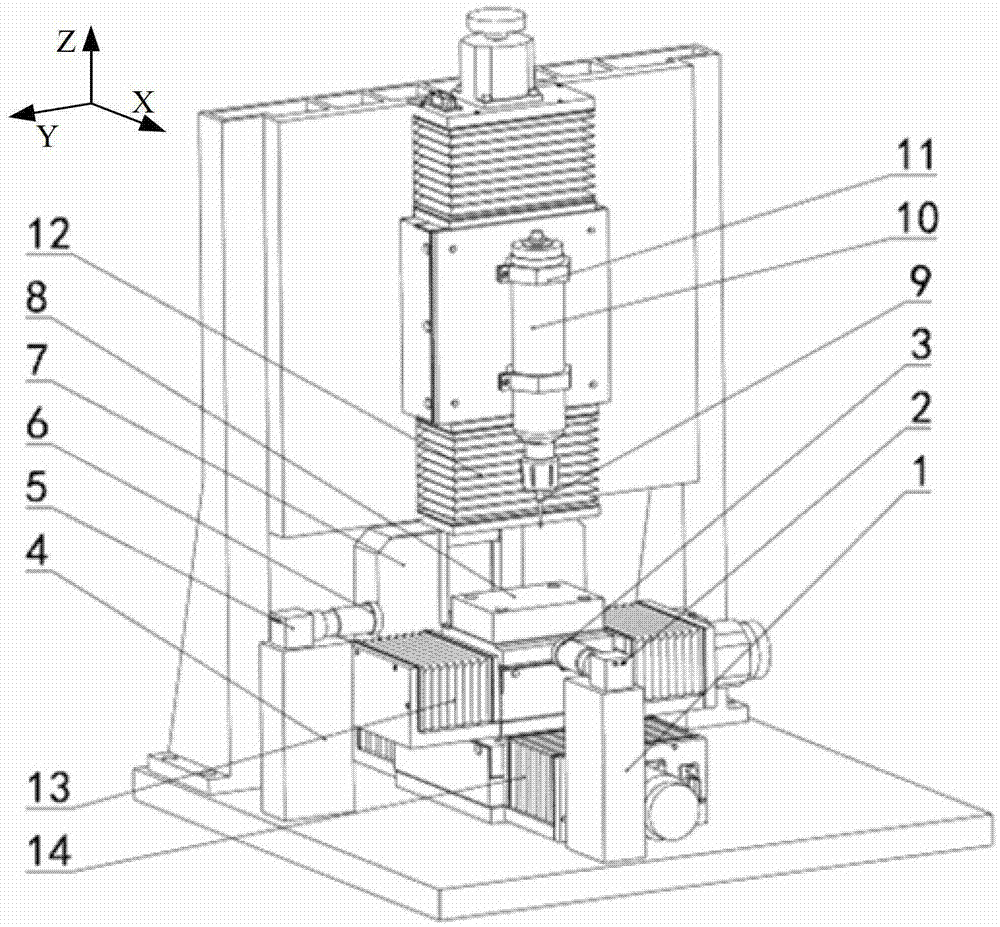

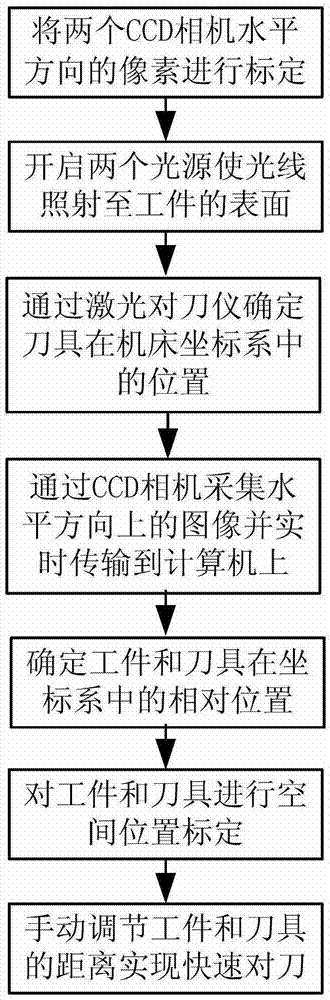

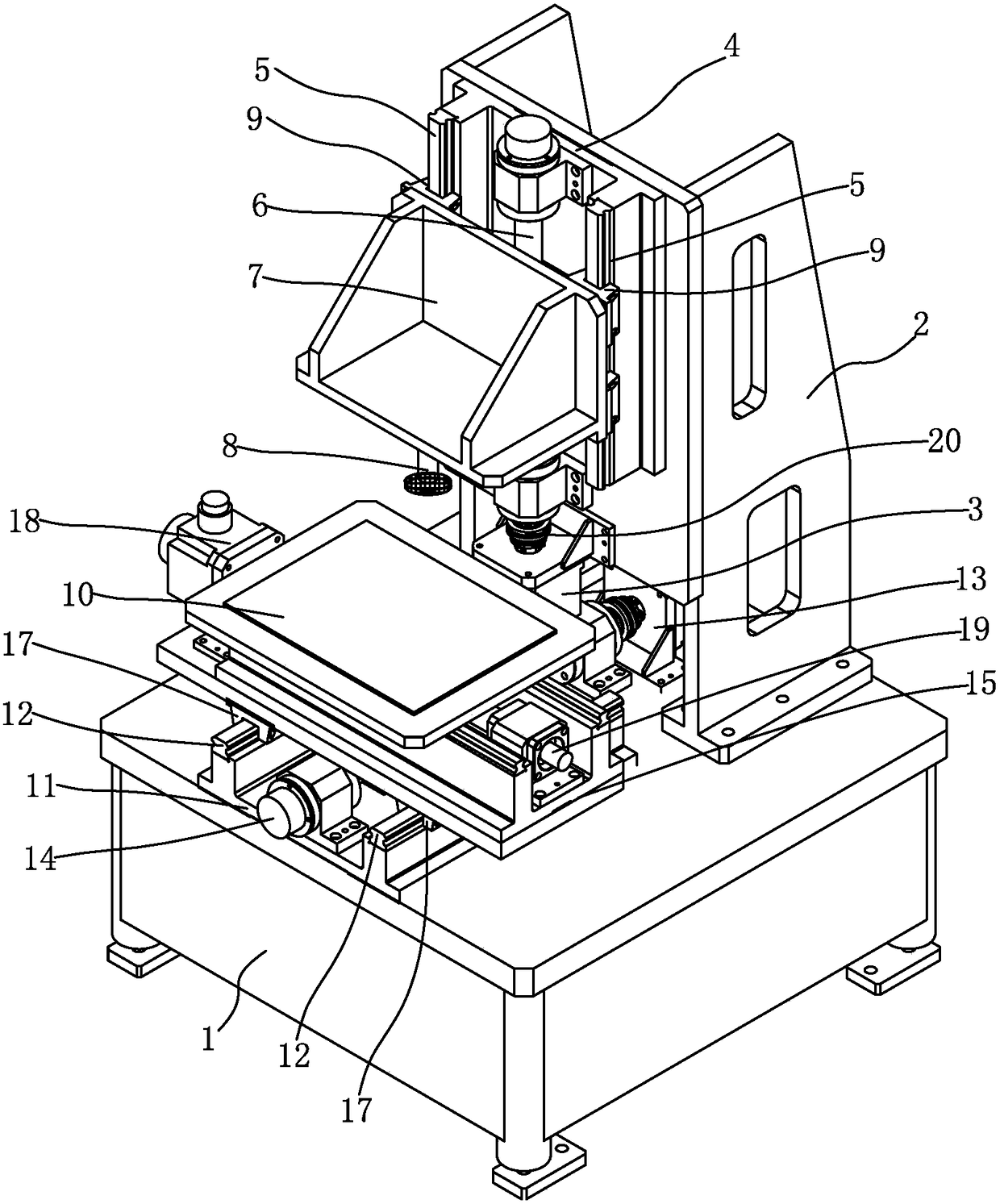

Tool setting method for micro CNC milling machine

ActiveCN103029004BHigh precisionHigh precision and efficiencyAutomatic control devicesMeasurement/indication equipmentsNumerical controlAutomatic control

The invention provides a tool setting device and method of a mini-type numerical control milling machine, belongs to the field of a machine tool automatic control technology and aims to solve the problems in the prior art that the tool setting precision and the tool setting efficiency are low. The tool setting device comprises CCD (Charged Coupled Device) cameras, light sources and a laser tool setting instrument, wherein the two CCD cameras are orthogonally placed; the two light sources are respectively sleeved at the front ends of the two CCD cameras to illuminate a workpiece; after light is reflected, the light is received by the CCD cameras and is transmitted to an outer computer, so as to determine the positions of the workpiece and a tool in a machine tool coordinate system; the laser tool setting instrument and the workpiece are placed in parallel; a tool nose contacts laser emitted by the laser tool setting instrument and a signal generated by the laser tool setting instrument is transmitted to the outer computer, so as to further determine the position of the tool in the machine tool coordinate system; and data processing is carried out through computer program software so as to realize rapid tool setting. According to the tool setting device and method of the mini-type numerical control milling machine, the tool nose and the workpiece to be machined do not need to be actually contacted to carry out trial cutting, so that an error caused by contacting the tool nose with the workpiece to be machined is avoided, and the tool setting precision and the tool setting efficiency of the workpiece are improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

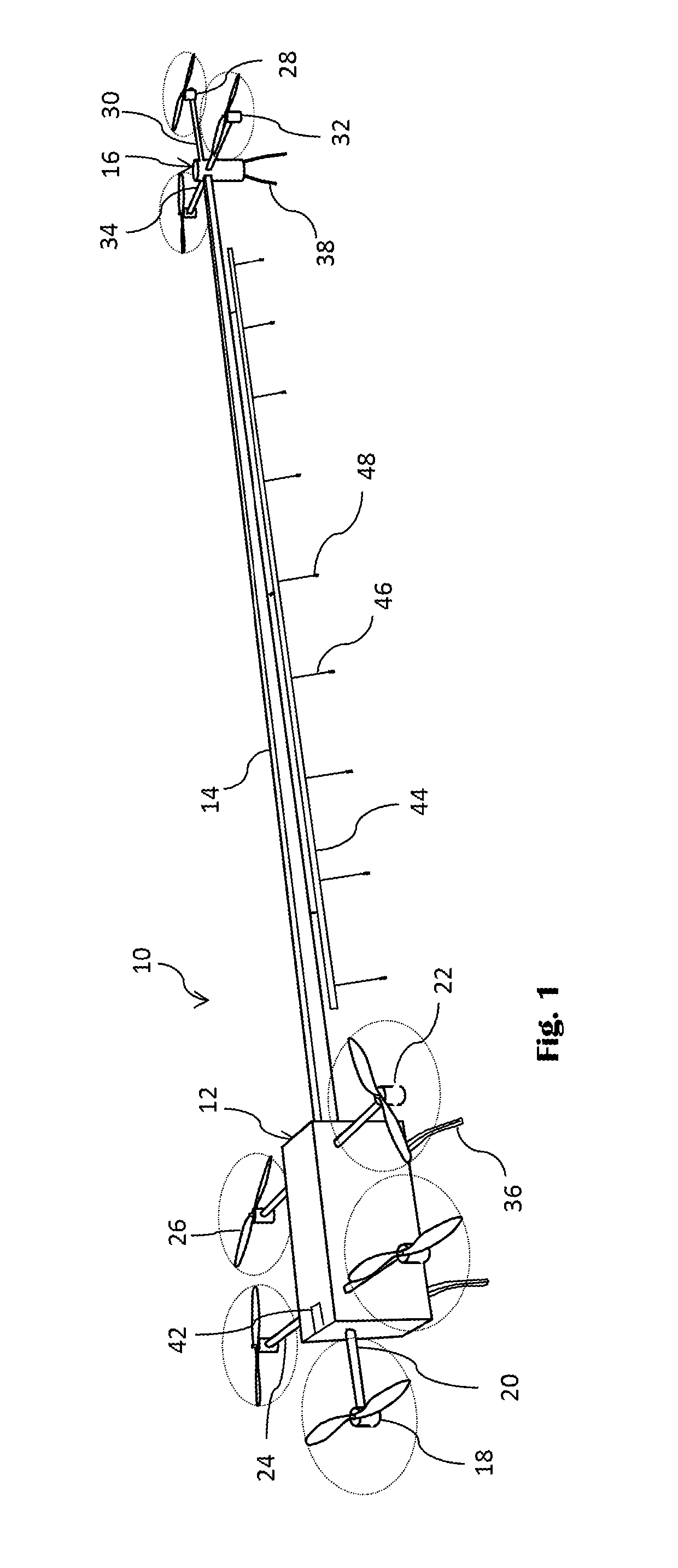

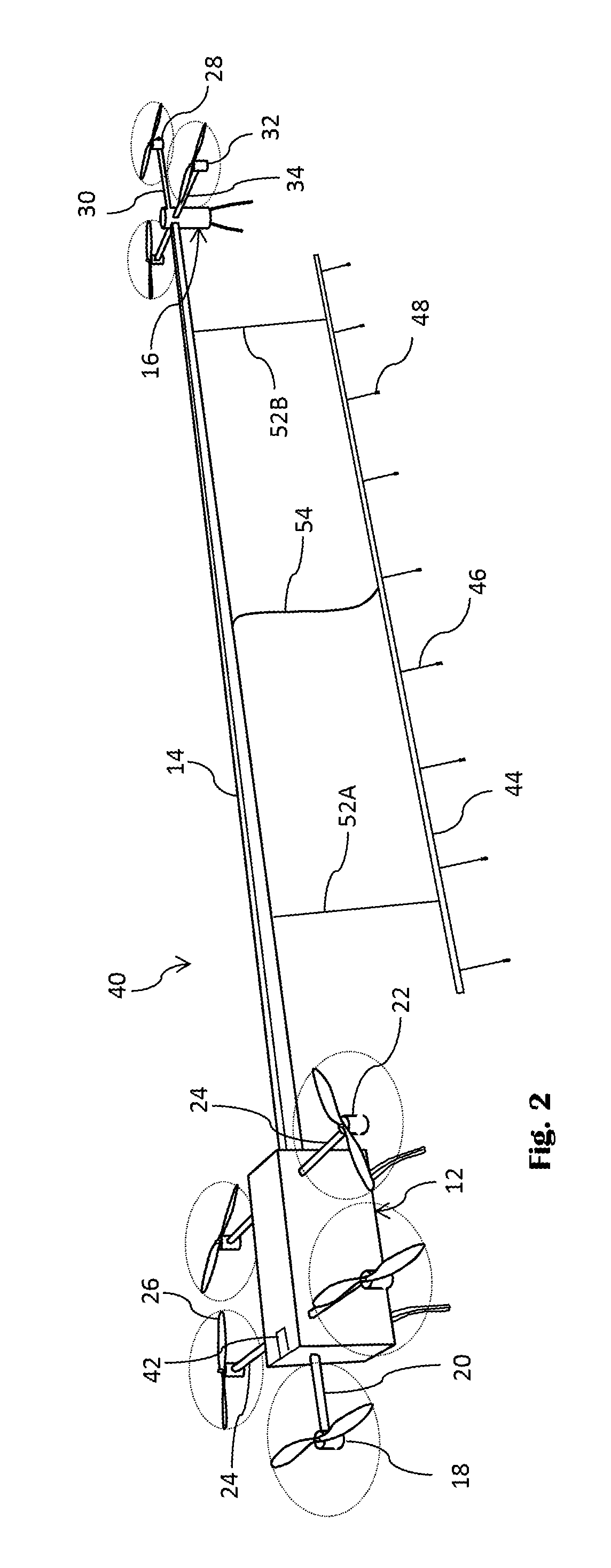

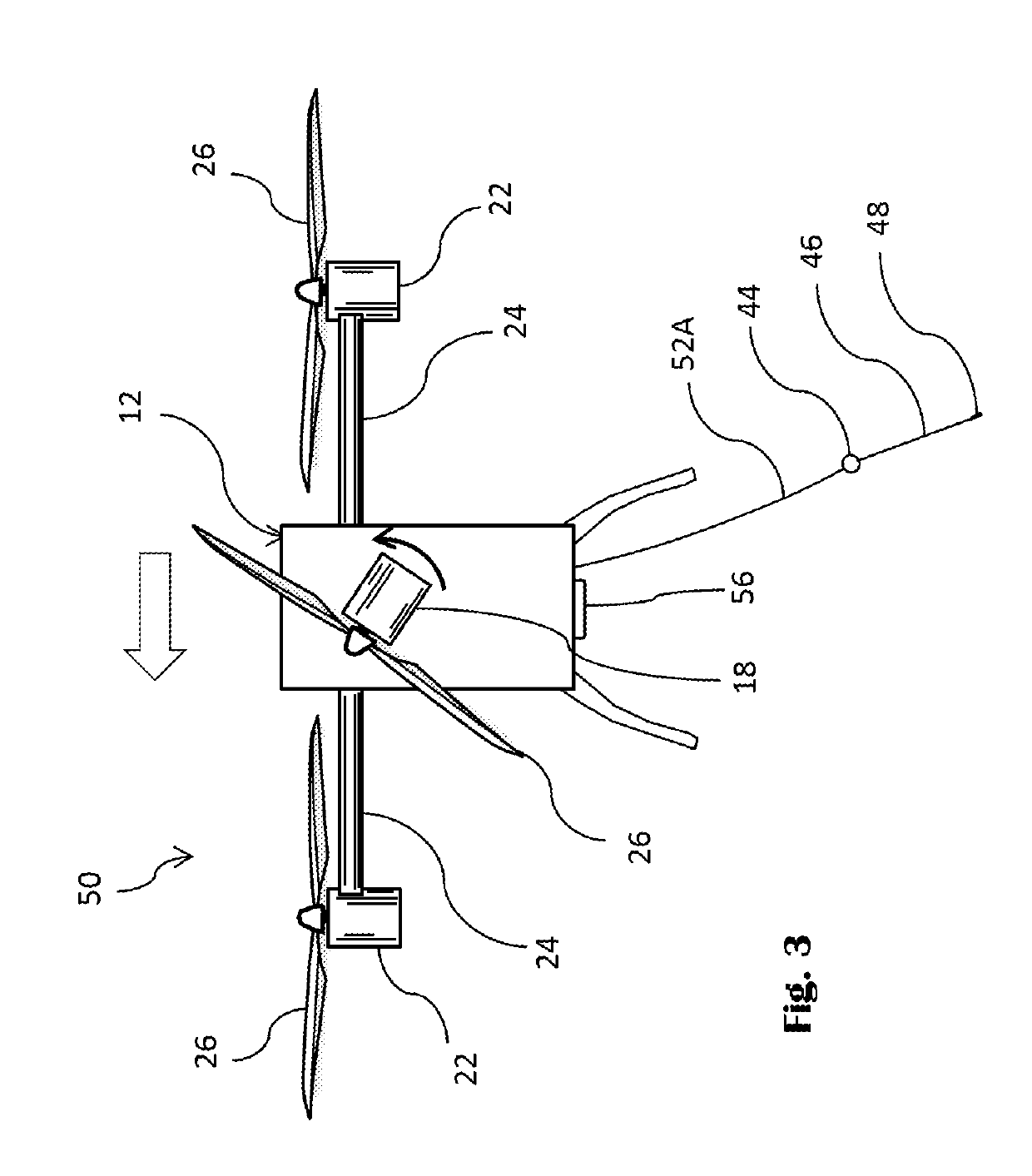

Drone for agriculture

InactiveUS10364029B2High precision and efficiencyEfficient and cost-effective in applyingAircraft componentsUnmanned aerial vehiclesControl systemElectronic control system

A drone for spraying liquid over field crop includes: a frame with a slender rigid beam in the middle and two base structures at the two ends, a rigid tube with an array of nozzles on elongated stems and the rigid tube is suspended below the beam structure with retractable wires, at least three propellers on motors with arms that are rotatably mounted to each of the two base structures of the frame, a power source, at least one distance detector for measuring height, an antenna for communication, an electronic control system to operate motors and sensors, a container for a liquid material and electronic valve to allow liquid in the container to be transferred and sprayed from the nozzles, and a remote controller. The drone is intended to spray liquid over a wide strip of the field with high efficiency, precision, and safety and reduced drift of sprays.

Owner:LIU YONGBIAO

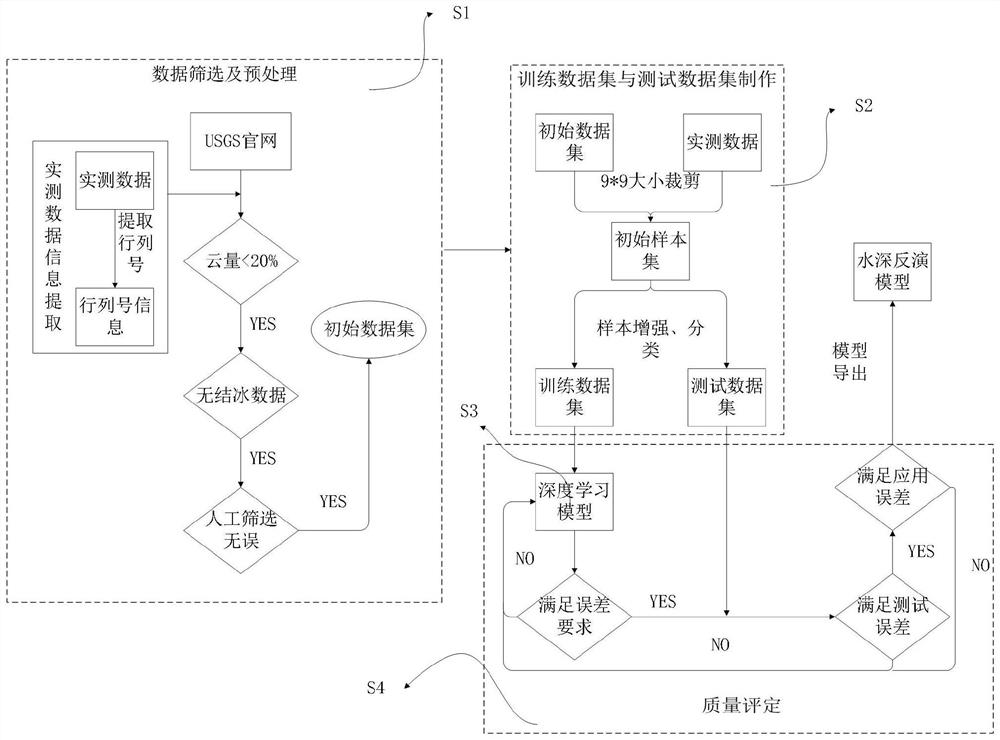

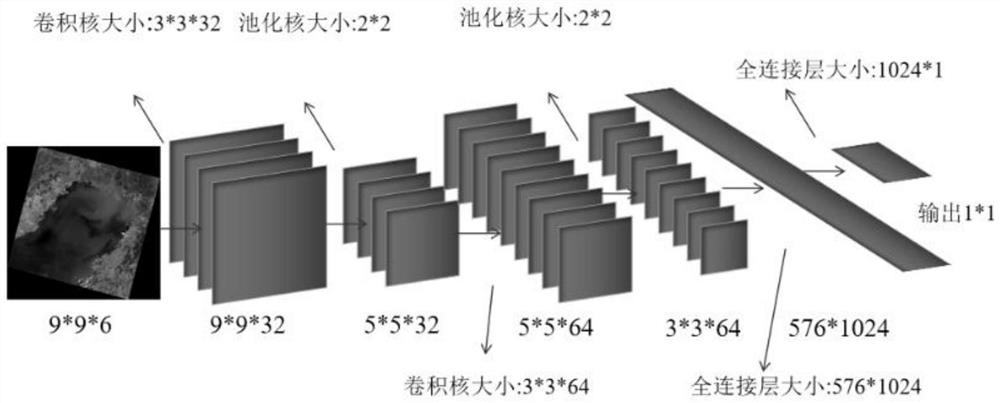

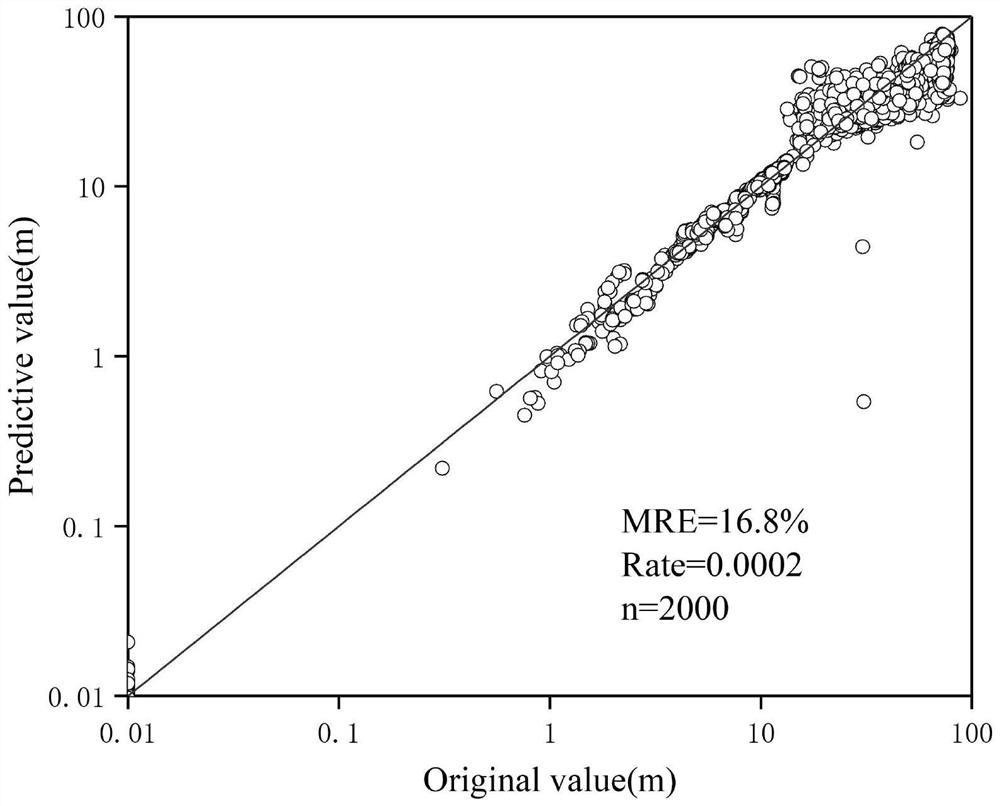

Inversion method for near-land shallow sea underwater topography

PendingCN114724045AHigh precisionHigh precision and high efficiencyClimate change adaptationScene recognitionMulti source dataLandform

The invention discloses a near-land shallow sea underwater topography inversion method, which realizes high-precision inversion of near-land shallow sea underwater topography under the support of a remote sensing theory and a deep learning technology based on a remote sensing and deep learning mode. The inversion method comprises the steps of constructing a model on the basis of a convolutional neural network, constructing a deep learning model by screening common parts of multi-source data and making samples through a series of processing, and training the model on the basis of coastal measured data and by taking a multiband remote sensing image as an input to achieve an expected effect. Physical information contained in the remote sensing image is fully considered, the mapping relation of the N * N sample window images is established on the basis of the measured data, and the limitation that a traditional water depth measurement method is time-consuming and labor-consuming and is easily influenced by actual factors is overcome. The limitation that a traditional water depth inversion algorithm needs various data such as sea surface roughness and meteorological data as supports is overcome, and the quality and the automation degree of a water depth inversion product are improved; the method is easy to implement and can be used for dynamically monitoring and improving the quality of water depth products.

Owner:陕西九州遥感信息技术有限公司 +2

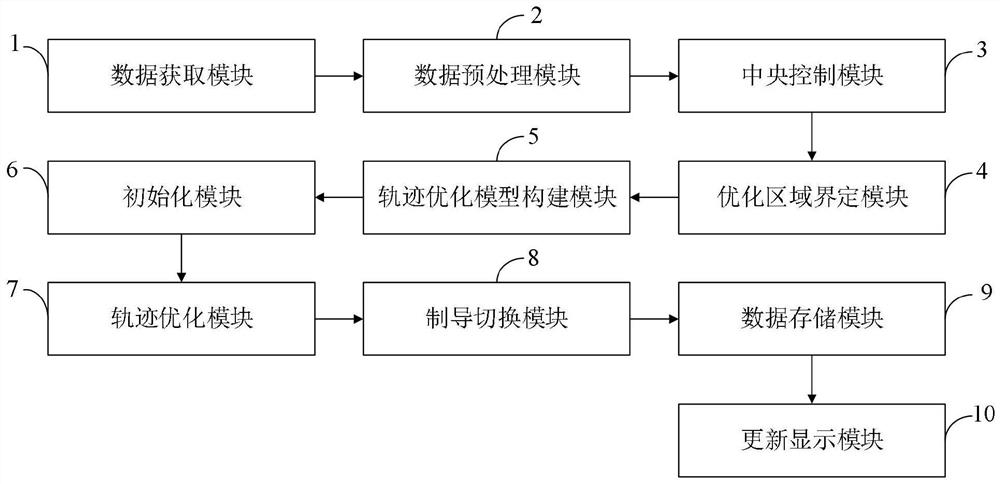

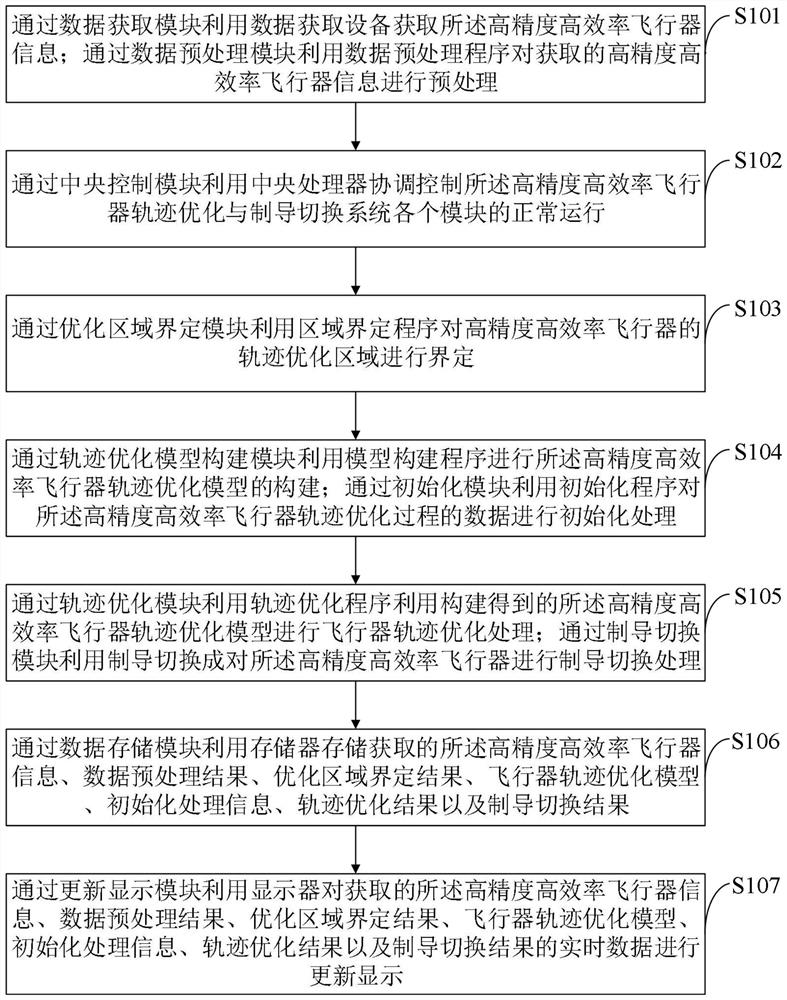

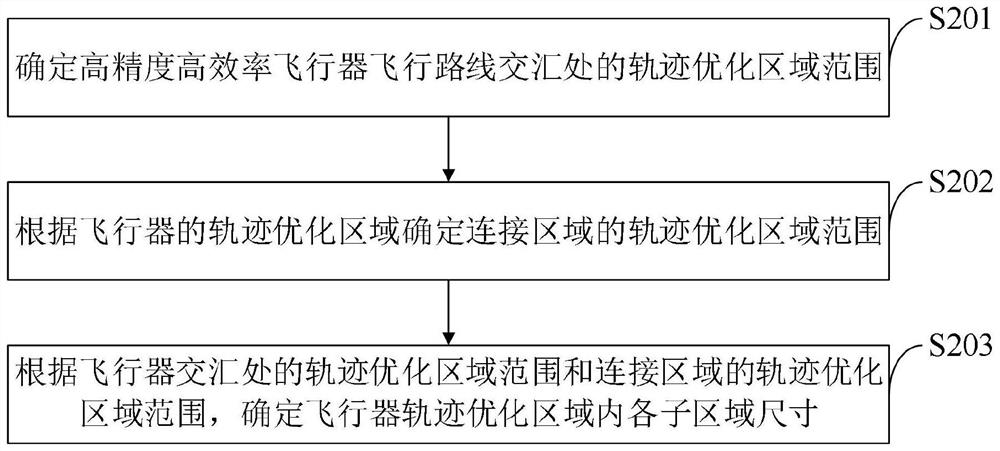

High-precision and high-efficiency aircraft trajectory optimization and guidance switching method and system

PendingCN113467509AHigh precisionHigh precision and high efficiencyPosition/course control in three dimensionsInternal combustion piston enginesFlight vehicleData acquisition

The invention belongs to the technical field of aircrafts, and discloses a high-precision and high-efficiency aircraft trajectory optimization and guidance switching method and system. The high-precision and high-efficiency aircraft trajectory optimization and guidance switching system comprises a data acquisition module, a data preprocessing module, a central control module, an optimization area defining module, a trajectory optimization model building module, an initialization module, a trajectory optimization module, a guidance switching module, a data storage module and an update display module. According to the invention, the trajectory optimization module utilizes the high-precision and high-efficiency aircraft trajectory optimization model to realize optimization processing of the aircraft trajectory, so that the precision of high-precision and high-efficiency aircraft trajectory optimization is improved, and high accuracy and high agility of a high-precision and high-efficiency aircraft precise strike task are ensured. Meanwhile, a multi-mode switching guidance law conforming to the current flight environment situation is formed through a guidance switching module by adopting a nonlinear model prediction control method, and the obstacle avoidance efficiency of the high-precision and high-efficiency aircraft is improved.

Owner:中国人民解放军火箭军工程大学

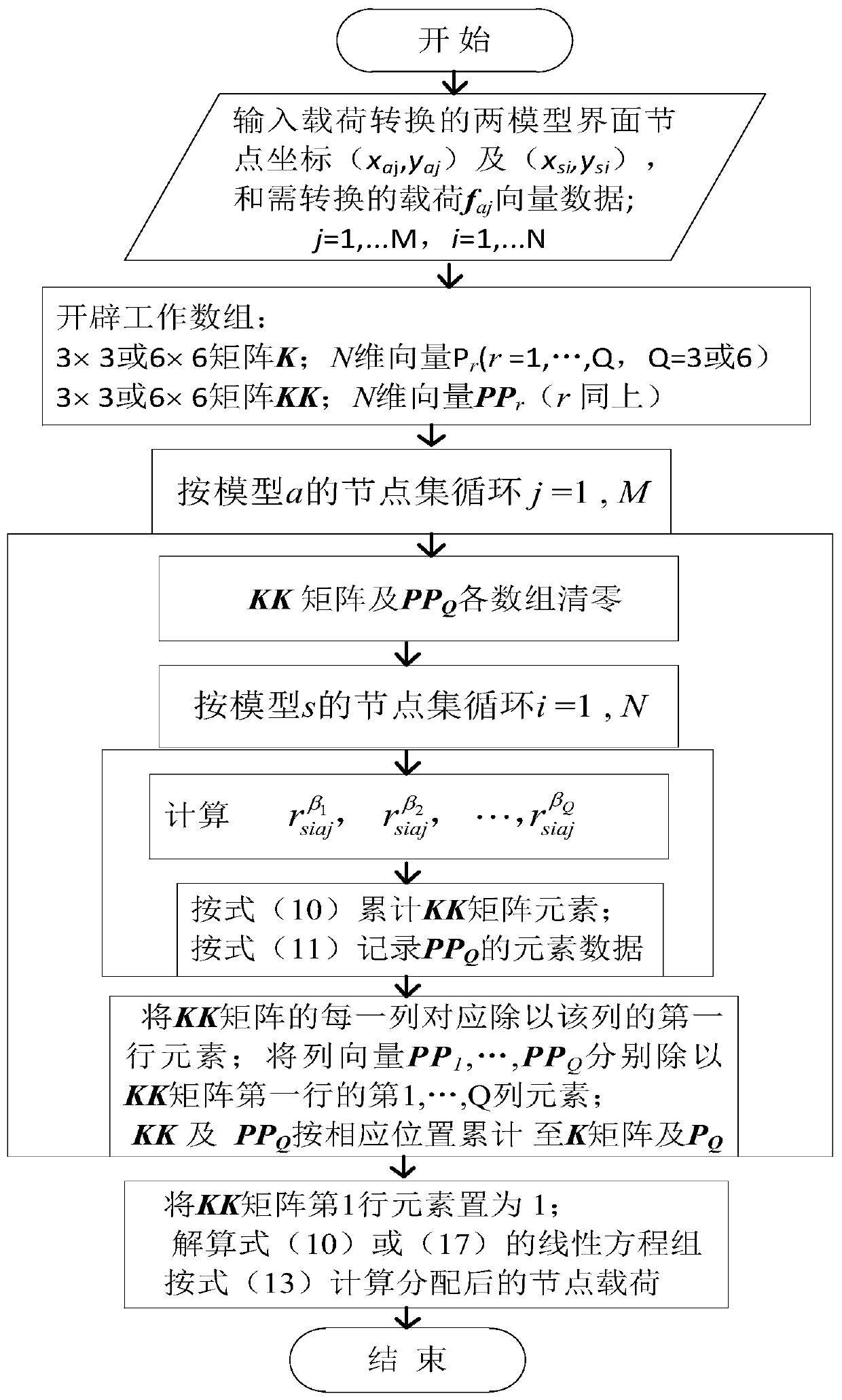

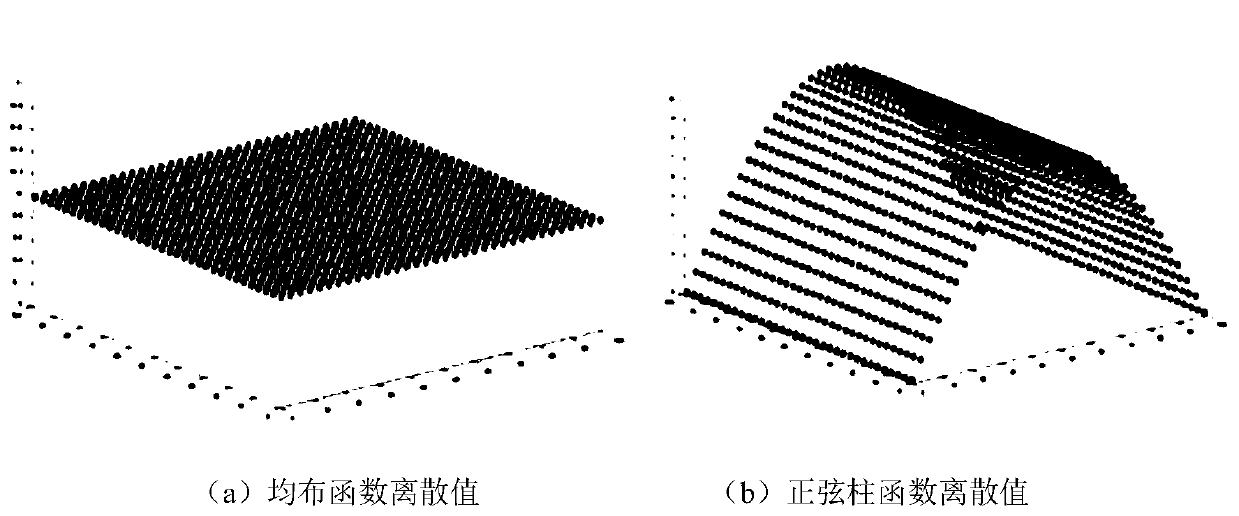

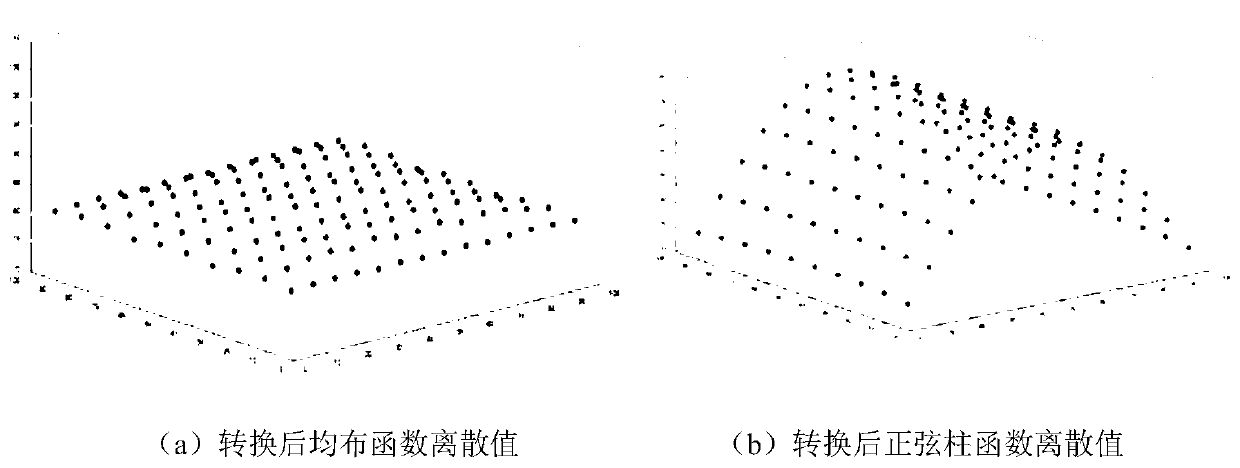

Efficient algorithm for node load conversion among different engineering physical model grids

ActiveCN110704945AEnhanced Intrinsic Constraint FeaturesEasy to adjustGeometric CADConcurrent computationTheoretical computer science

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA +1

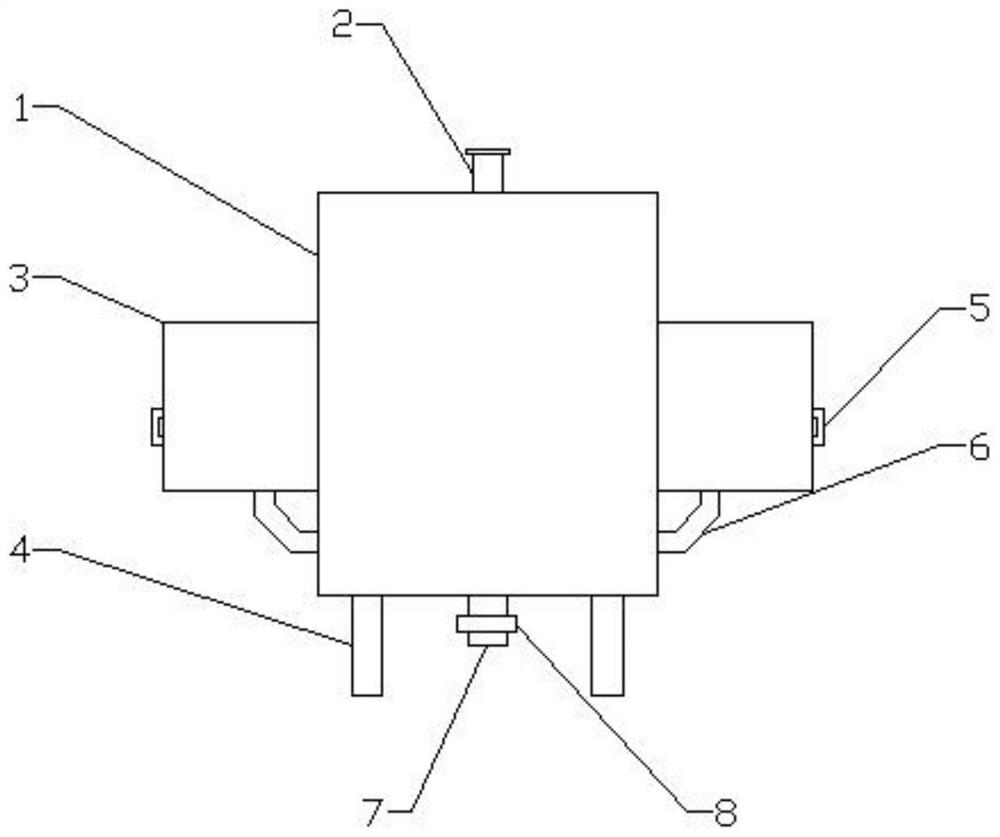

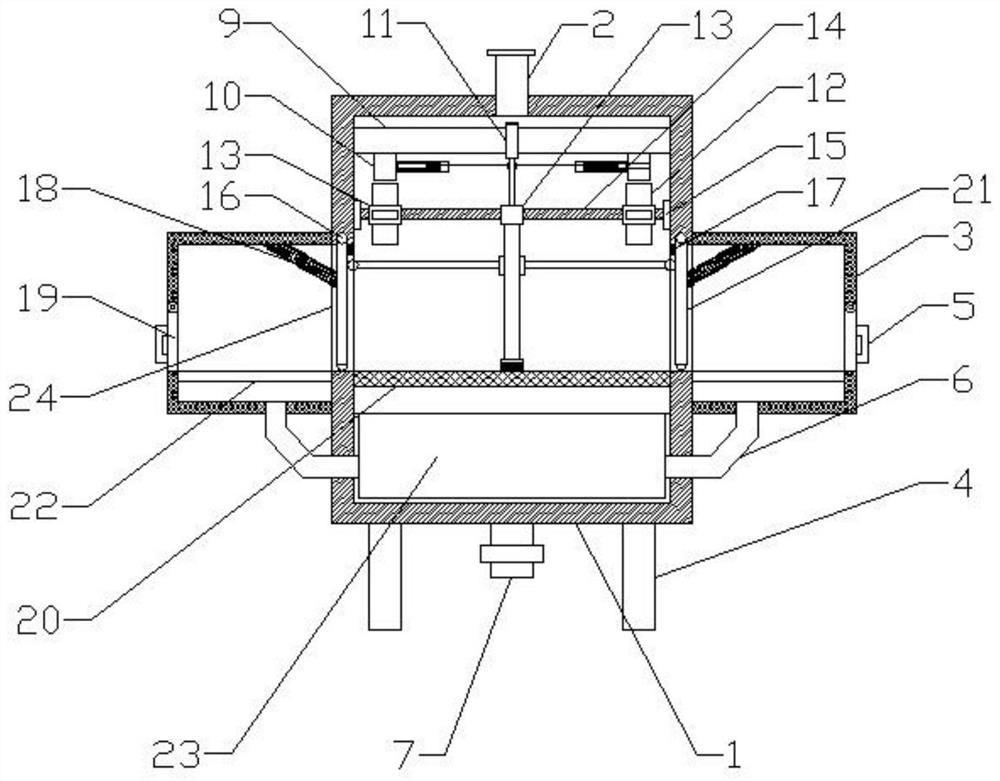

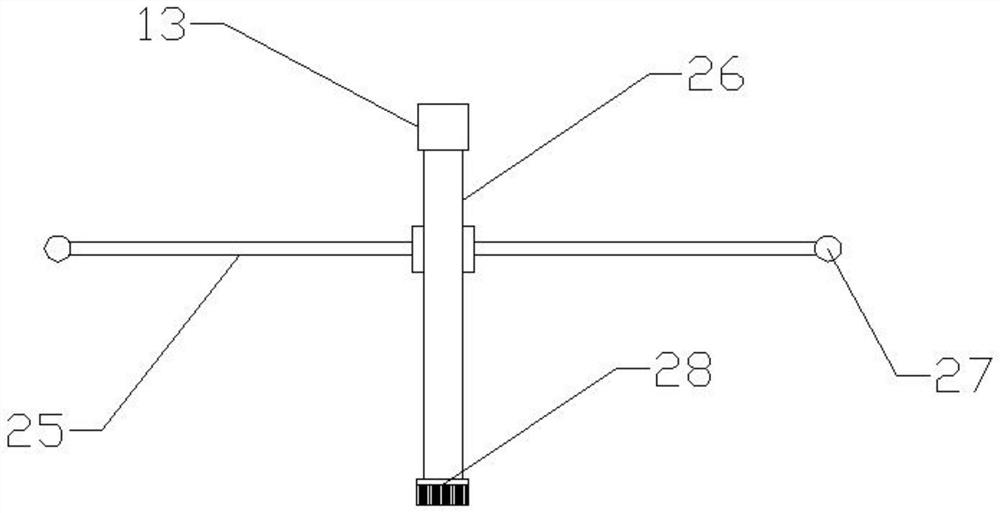

Environmental engineering water quality detection solid-liquid separation device

ActiveCN112999755AAvoid cloggingImprove water conduction efficiencyFiltration circuitsStationary filtering element filtersWater qualitySewage

The invention relates to the technical field of solid-liquid separation devices, in particular to an environmental engineering water quality detection solid-liquid separation device which comprises a box body, supporting legs are fixedly mounted at the bottom ends of the two sides of the box body, a water inlet pipe is fixedly mounted at the upper end of the box body, a water outlet pipe is fixedly mounted at the bottom end of the box body, and solid collection boxes are fixedly mounted on the two sides of the box body; and a connecting pipe is fixedly installed at the bottom end of the solid collection box, and the other end of the connecting pipe is fixedly installed on the two sides of the bottom of the box body. The environmental engineering water quality detection solid-liquid separation device provided by the invention realizes separation of sewage and solid pollutants thereof, avoids the phenomenon of blockage of a first filter plate caused by retention of the solid pollutants on the first filter plate, can collect and detect the separated sewage, is convenient for research and detection of researchers, is convenient to use, and is suitable for popularization and application. The detection data result is improved, and the detection accuracy and efficiency are improved.

Owner:邸晓莎

Pathological accurate sampling device

InactiveCN114088444AEasy to get materialsEasy to adjustWithdrawing sample devicesPreparing sample for investigationBiomedical engineeringMedical treatment

The invention relates to the technical field of medical instruments, in particular to a pathological accurate sampling device which comprises a base, a supporting assembly, an adjusting assembly, a first cutting assembly, a second cutting assembly and a clamping assembly, wherein the supporting assembly and the adjusting assembly are arranged at the top of the base; the first cutting assembly and the second cutting assembly are slidably arranged on the adjusting assembly; and the clamping assembly is arranged under the adjusting assembly and connected with the base. Firstly, tissue blocks needing to be subjected to material taking work are clamped through the clamping assembly, then adjustment is conducted through the supporting assembly and the adjusting assembly according to the material taking specifications of the tissue blocks, and scale marks are engraved on the adjusting assembly, so that workers can conduct millimeter-level accurate adjustment by sliding the movable vertical rod and the sliding rod; then the adjusting assembly is locked through the bolt; finally, the first cutting assembly and the second cutting assembly conduct cutting in an anticlockwise or clockwise mode; and therefore, the whole process is easy to operate, the material taking precision is high, the efficiency is high, and follow-up pathological research is facilitated.

Owner:淄博市中心医院

A Forming Method of Complex Curved Aluminum Foam Parts

The invention discloses a method for forming a foamed aluminum part with a complex curved surface. The foaming agent and stabilizer are evenly distributed between the metal plates, and the two stacked metal plates are welded for multiple times by friction stir welding to obtain a foamed aluminum prefabricated body; S3. Provide a heating mechanism or use a stamping die for heating The component heats and insulates the foamed aluminum prefabricated body in S2; S4, transfers the heated foamed aluminum prefabricated body to the stamping mold, closes the mold, stamps the foamed aluminum prefabricated body, opens the mold, and moves the punch to make a distance The concave mold is at a certain distance, and the heating component is started to heat the aluminum foam prefabricated body, so that it can complete the remaining foaming action, and the aluminum foam parts with complex curved surfaces can be obtained. The invention not only can mold any desired curved surface molded parts, but also has short duration and low cost of the whole process.

Owner:WUHAN UNIV OF TECH

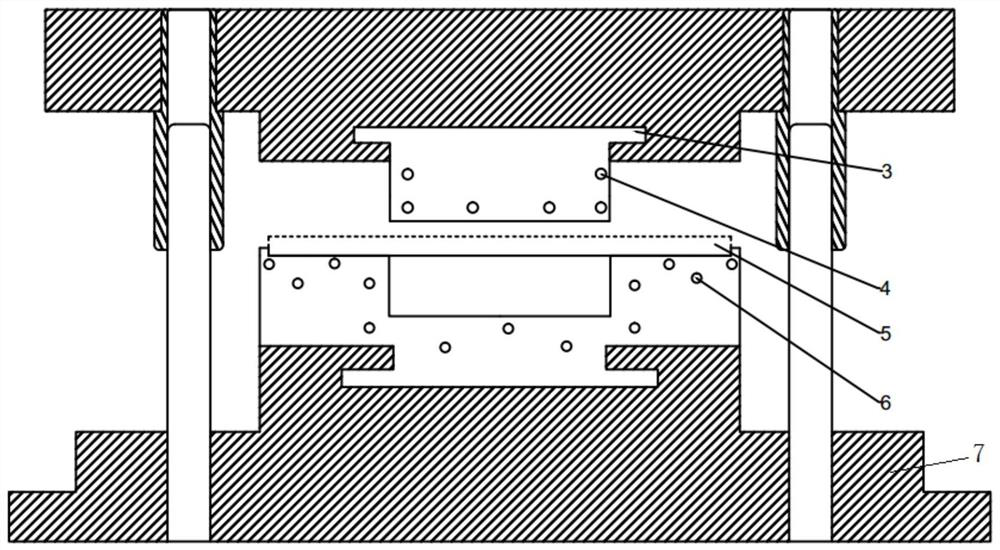

A Drilling and Grinding Method Suitable for Lightweight Cross Core Lattice Foam Sandwich Panels Integrating Impact Resistance and Noise Reduction

ActiveCN105773165BEasy to operateHigh degree of automationOther manufacturing equipments/toolsControl systemElectric machinery

The invention discloses light cross core lattice foam sandwich panel drilling and grinding equipment suitable for integrating impact resistance and noise reduction. The light cross core lattice foam sandwich panel drilling and grinding equipment comprises an equipment body and a drilling and grinding control system. The equipment body comprises a lathe bed, a drilling and grinding mechanism and a workpiece positioning mechanism; the drilling and grinding control system comprises an operation panel, a detection device and a PLC control system; the detection device detects whether a workpiece moves to the set position or not; and the PLC control system is used for controlling a drilling and grinding machine to perform drilling or grinding and used for controlling an X-axis servo motor, a Y-axis servo motor and Z-axis servo motor to adjust corresponding working states according to motion parameters and position parameters, set by the operation panel, of the workpiece in the X-axis direction, meanwhile, motion parameters and position parameters of the workpiece in the Y-axis direction, motion parameters and position parameters of the workpiece in the Z-axis direction and feedback parameters of the detection device. The equipment has the beneficial effects of being easy to operate, safe, reliable, high in automation degree, high in precision efficiency and the like.

Owner:DALIAN UNIV OF TECH

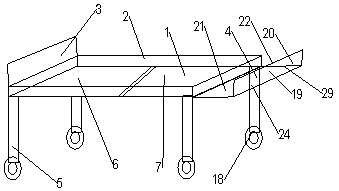

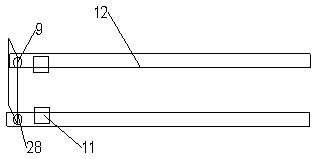

Silk wadding quilt cutting platform device with adjustable light intensity and scale marks

InactiveCN110424142AConvenient cutting workImprove accuracy and efficiencyLighting elementsSevering textilesWaddingEngineering

The invention discloses a silk wadding quilt cutting platform device with adjustable light intensity and scale marks. The device comprises a cutting platform, a guardrail frame, a measuring slider device, a placement space platform and a moving component, the measuring slider device comprises a measuring plate, slider wheels, a handle and clamping fixed blocks, the placement space platform is movably connected to the bottom surface of one end of the cutting platform through guide rails, the measuring slider device is arranged at the other end of the cutting platform, the peripheral surface ofthe upper portion of the cutting platform is connected with the guardrail frame through screws, the bottom ends of the surfaces on two sides in the width direction of the guardrail frame are fixedly connected with sliding guide rails, the slider wheels of the measuring slider device are connected into the middles of the sliding guide rails in a clamped manner, the measuring plate is arranged on the upper portions of the slider wheels, the handle is mounted on the surface of one side, opposite to a moving direction, of the measuring plate, and the clamping fixed blocks are connected to two sides of the slider wheels in a clamped manner when the slider wheels mounted at the bottom of the measuring plate move to needed marks on the sliding guide rails.

Owner:徐州光彩丝绵制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com