Optimization method of stamping based on space mapping of response function

A technology of spatial mapping and response function, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as no rough solution, too large interval, and determination of corresponding values, so as to avoid uncertainty. factors, the effect of improving accuracy and improving efficiency

Inactive Publication Date: 2010-12-08

HUNAN UNIV

View PDF2 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Its main disadvantages are: it is difficult to determine the corresponding value in the rough space according to the design parameter value based on the fine finite element model; the interval and number of disturbance points are difficult to control, and if the interval is too large, it will affect the optimization solution efficiency; otherwise, it will lead to accurate The corresponding rough solution cannot be found; for high-dimensional problems, as the design space expands, the disturbance area will also expand, and the difficulty of solving increases exponentially, and it is even difficult to converge

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Login to View More

Abstract

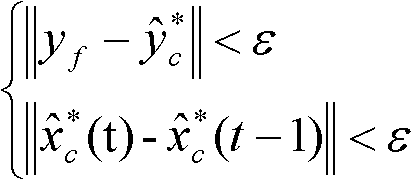

The invention relates to an optimization method of stamping based on space mapping of a response function. The method comprises the following steps: (1) establishing fine and rough finite element models of a forming system to be optimized; (2) preliminarily establishing an initial space mapping relation Pr between the fine and rough finite element models; (3) determining an initial solution in a response space of the fine finite element model at random, and determining a corresponding response in the rough finite element model through the space mapping relation Pr; (4) entering into an iteration step: when an approximate model based on the rough finite element model meets precision requirements, obtaining an optimal solution of the rough finite element model through reverse; (5) using the optimal solution of the rough finite element model as the initial solution of the fine finite element model to obtain corresponding yf; and (6) when the approximate model based on the rough finite element model meets conditions of convergence, finishing the iteration step to obtain an optimized result, and using the fine finite element model to check the calculation result. The invention has a simple principle, can ensure solution precision and can improve the efficiency of an approximate model optimization algorithm in a large scale.

Description

technical field The invention mainly relates to the field of sheet metal stamping process design, in particular to a space mapping theory based on response space, an approximate model structure and an optimization method for constructing sheet metal forming process design. Background technique The sheet metal forming process is a highly nonlinear problem including geometric nonlinearity, material nonlinearity, and boundary nonlinearity, and the deformation mechanism is very complicated. At present, sheet metal stamping forming technology is widely used in various fields of industry, such as aerospace, motorcycles, household appliances, automobiles and many other industries, especially the automobile industry. In the optimization process of sheet metal forming, the traditional optimization method must first determine the derivability of the objective function, which strictly limits the scope of the problem, so the traditional optimization method based on the gradient is no lo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F17/50B21D22/00

Inventor 王琥李光耀蔡勇龚志辉郑刚

Owner HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com