Tool setting method for micro CNC milling machine

A CNC milling machine, micro-miniature technology, applied in the direction of automatic control device, measuring/indicating equipment, feeding device, etc., can solve the problems of tool setting accuracy and low tool setting efficiency, achieve easy workpiece processing, simple principle, and improve tool setting The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

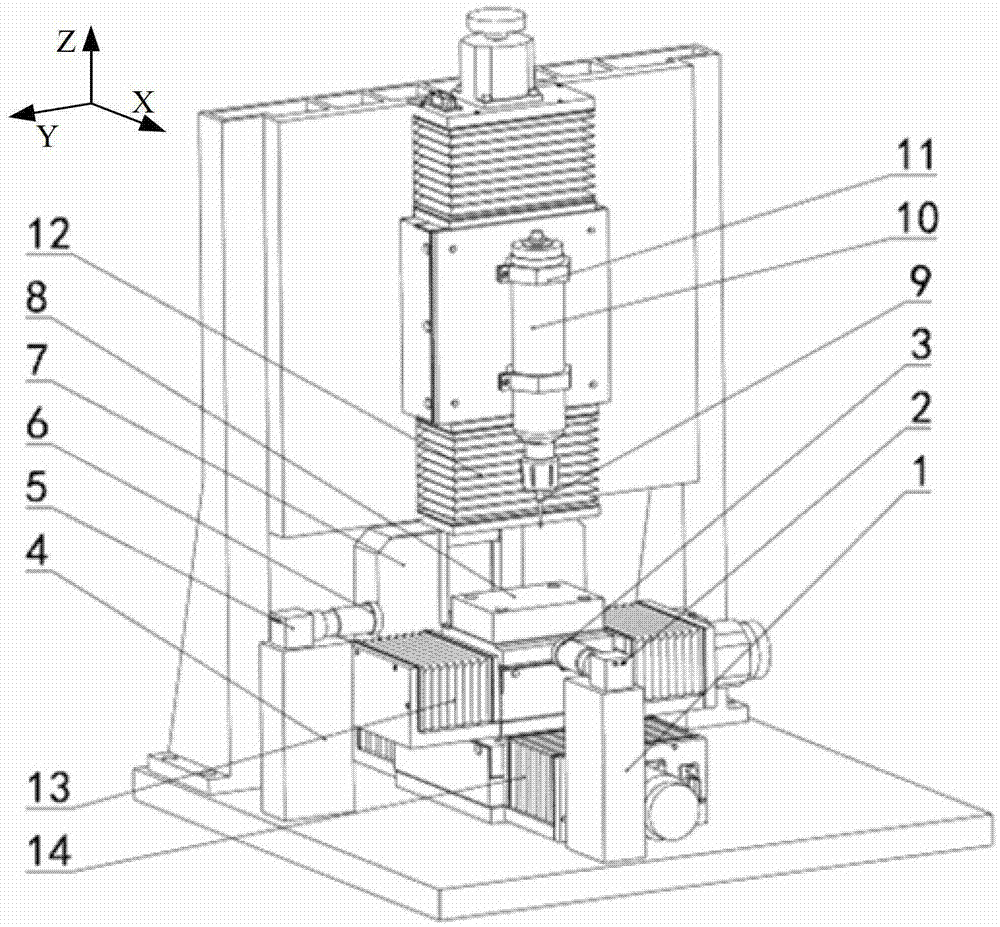

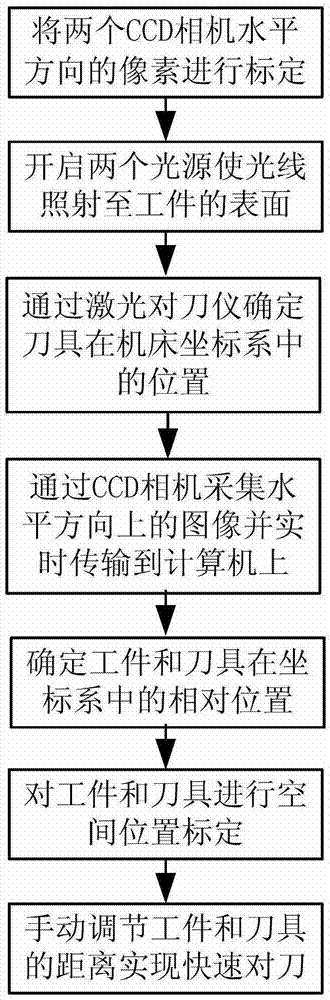

[0020] See attached figure 1 , the tool setting device for micro-sized CNC milling machine of the present invention comprises a CCD camera A2, a CCD camera B5 and a laser tool setting instrument 7 and a computer; the CCD camera A2 is placed orthogonally to the CCD camera B5, and the CCD camera A2 The image of the relative position of the workpiece 8 to be processed and the tool is collected in the X direction, and the CCD camera B5 collects the image of the relative position of the workpiece 8 to be processed and the tool along the Y direction. 14, the CCD camera A2, the CCD camera B5 and the laser tool setting instrument 7 are connected to the computer respectively, and the position of the cutter 11 is adjusted so that the tip of the tool 11 contacts the laser light emitted by the laser tool setting instrument 7. The computer realizes rapid tool settin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com