Method of producing optical element by patterning liquid crystal films

a liquid crystal film and patterning technology, applied in the direction of polarising elements, instruments, chemistry apparatus and processes, etc., can solve the problems of low patterning precision, inability to form colored patterns by removing a part of cholesteric liquid crystal film, and inability to maintain film thickness precision high, high precision and efficiency, the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

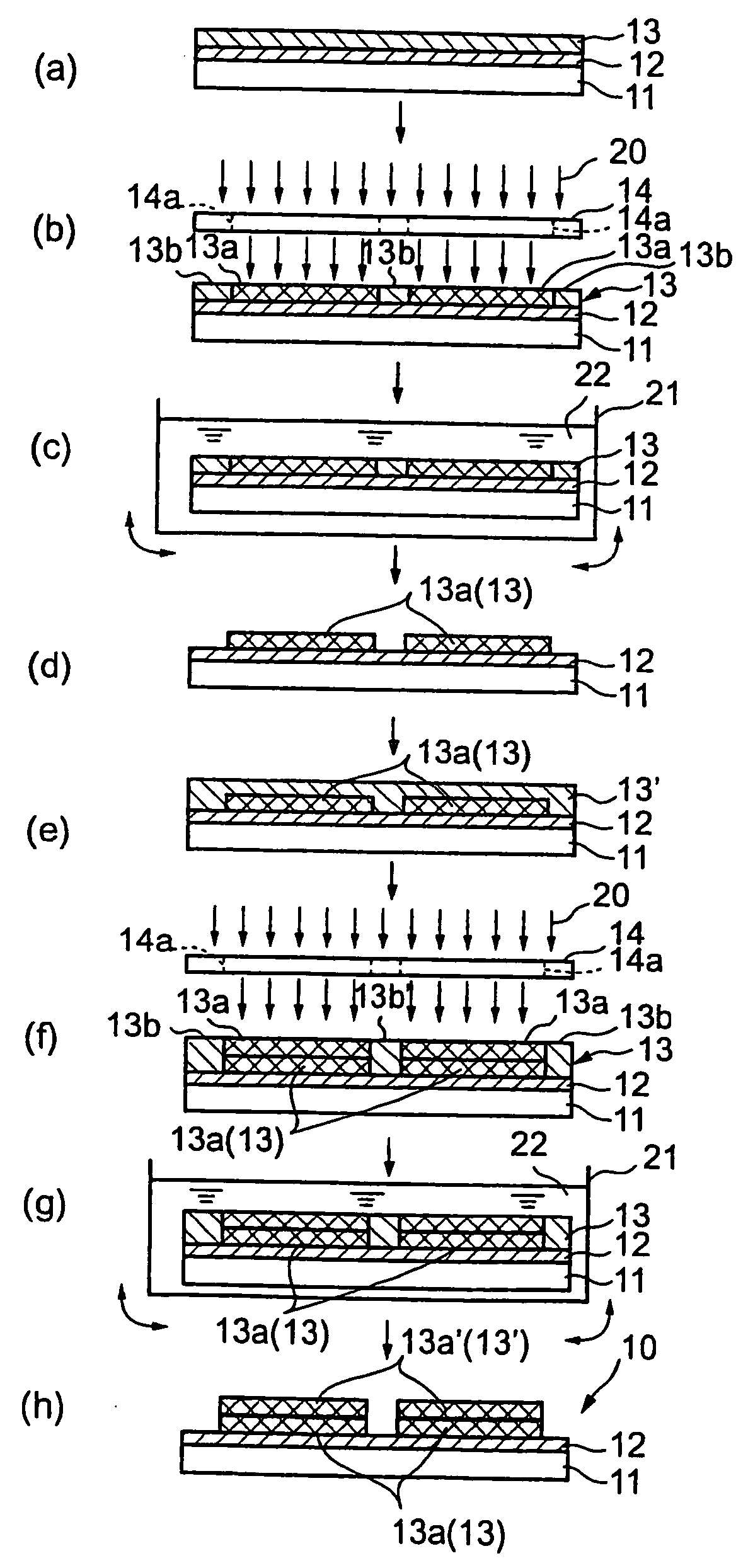

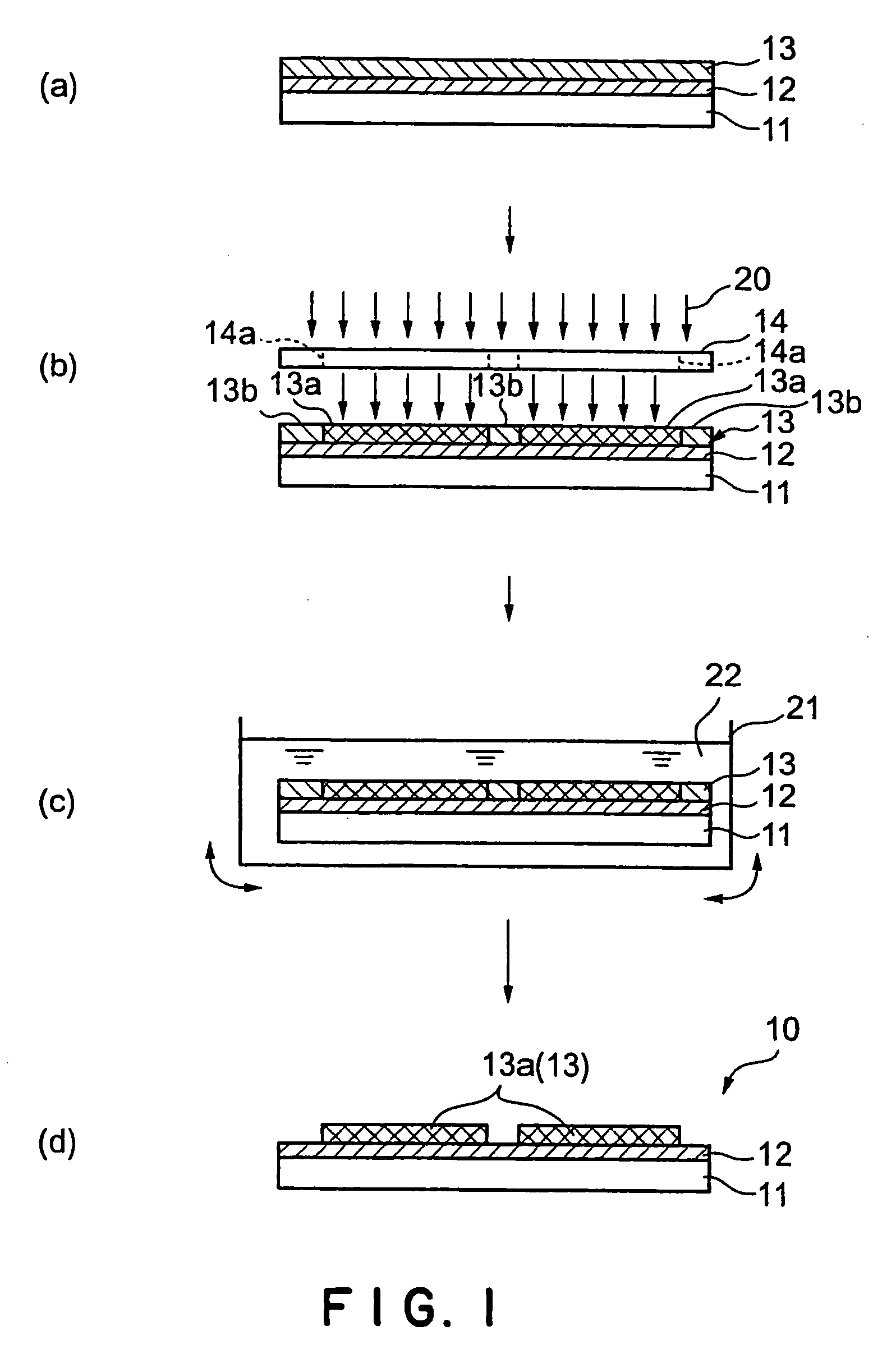

example 1

[0052] In toluene were dissolved: 89 parts of a monomer containing, in its molecules, polymerizable acrylates at both ends and spacers between mesogen existing at the center and the acrylates, having a liquid crystalline phase transition temperature of 100° C.; and 11 parts of a chiral agent having, in its molecule, polymerizable acrylates at both ends. To this toluene solution was added a photopolymerization initiator (“Irg 184” available from Ciba Specialty Chemicals K.K., Japan) in an amount of 5% by weight of the above-described monomer.

[0053] Separately, polyimide was applied to a glass substrate; and the polyimide film formed was rubbed in a definite direction to make it into an alignment layer.

[0054] The glass substrate provided with this alignment layer was set in a spin coater; and the alignment layer was spin-coated with the above-prepared toluene solution so that the thickness of the toluene solution applied would be approximately 10 μm.

[0055] The glass substrate coate...

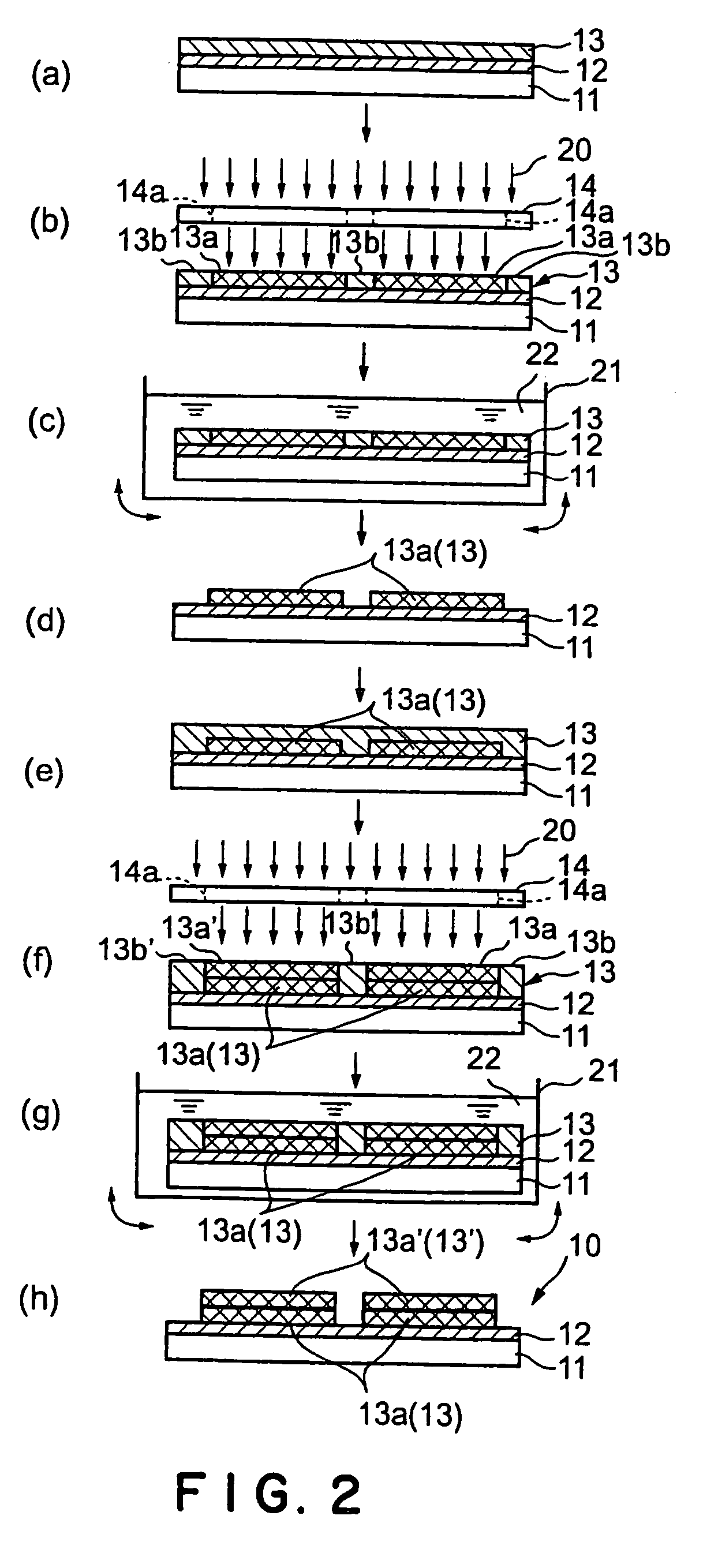

example 2

[0060] On the glass substrate provided with the alignment layer having thereon the cholesteric liquid crystal film patterned as desired, produced in Example 1, an additional cholesteric liquid crystal film was formed and patterned in the same manner as in Example 1.

[0061] The pattern of this newly formed additional cholesteric liquid crystal film was different from that of the cholesteric liquid crystal film formed in Example 1. Namely, a part of the patterned additional cholesteric liquid crystal film was present on the surface of the patterned cholesteric liquid crystal film formed in Example 1, and the rest of the patterned additional cholesteric liquid crystal film was present on the exposed surface of the alignment layer.

[0062] It was confirmed that the additional cholesteric liquid crystal film formed in this example was nearly uniform in thickness (3 μm) and that the pattern formed was extremely precise. In addition, although the patterned additional cholesteric liquid crys...

example 3

[0063] In the composition of the toluene solution used in Example 1, the amount of the chiral agent was changed to prepare three liquid crystals having selective reflection wavelengths of red, green and blue.

[0064] The same steps of forming and patterning a cholesteric liquid crystal film as those in Example 2 were repeated for each of these three cholesteric liquid crystals, provided that the patterning was conducted so that the resulting three cholesteric liquid crystal films would not be superposed on each other. Thus, a color filter having red-, green- and blue-colored patterns was obtained.

[0065] It was confirmed that the patterned cholesteric liquid crystal films of red, green and blue formed in this example, constituting the color filter, were nearly uniform in thickness (3 μm) and that the patterns formed were extremely precise. In addition, all of these additional cholesteric liquid crystal films of red, green and blue were found to be excellent in the state of alignment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquid crystalline phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com