A Drilling and Grinding Method Suitable for Lightweight Cross Core Lattice Foam Sandwich Panels Integrating Impact Resistance and Noise Reduction

A foam sandwich panel, cross core technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problem of not being able to fundamentally guarantee the drilling quality and precision requirements, and achieve a high degree of automation, high precision and efficiency , the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

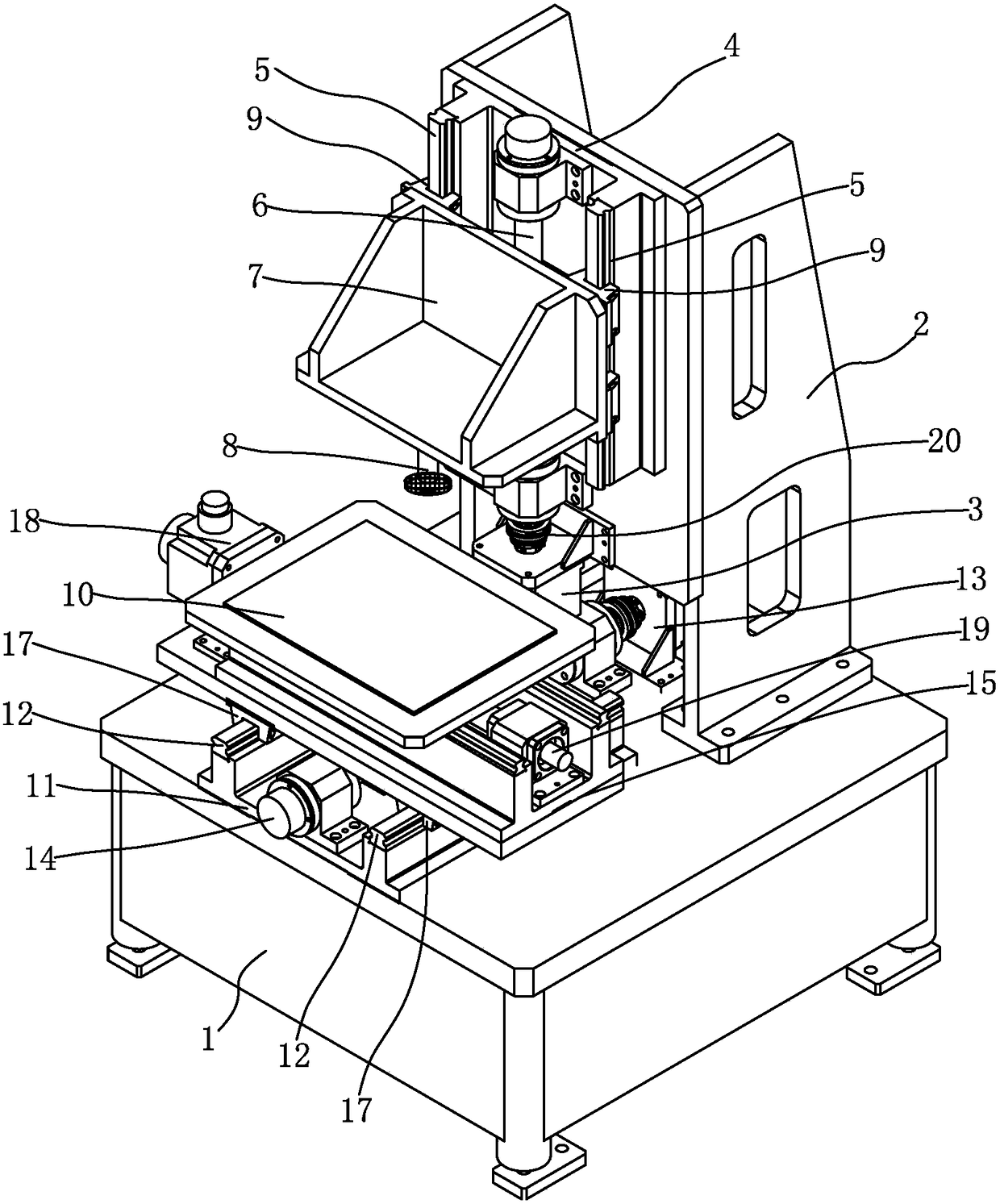

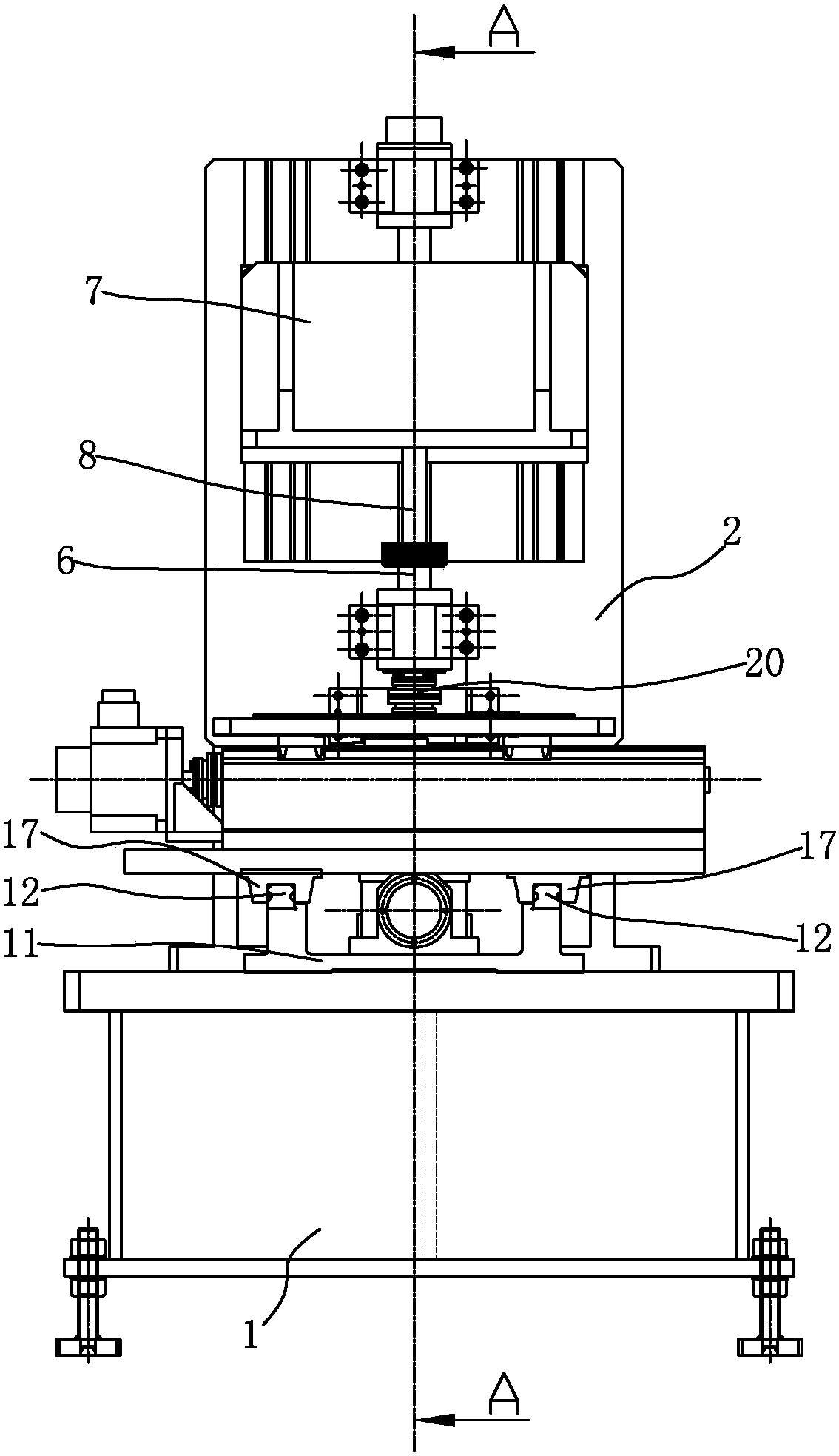

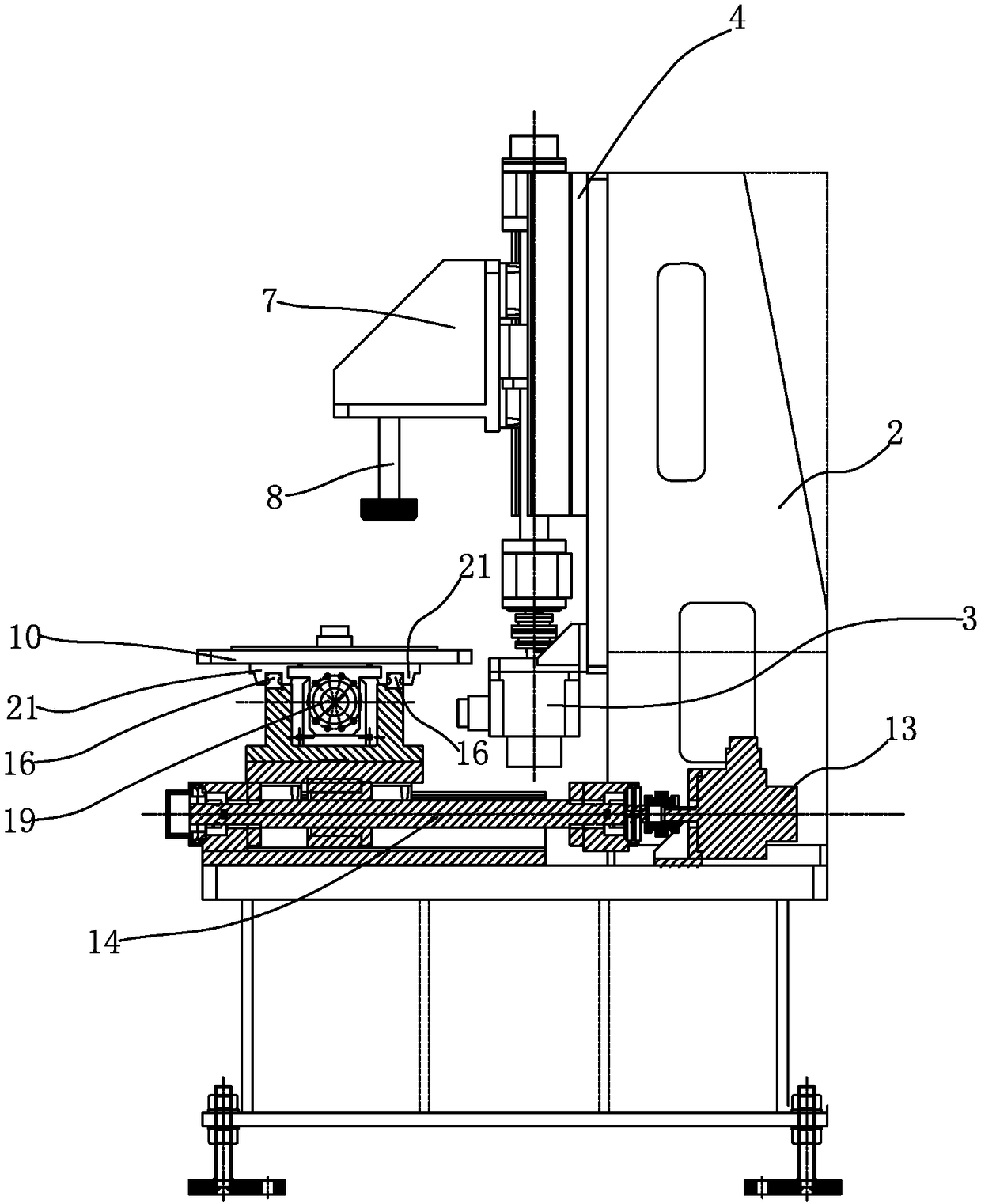

[0044] like Figure 1-Figure 5 The shown is a lightweight cross-core lattice foam sandwich panel drilling and grinding equipment that is suitable for impact resistance and noise reduction, including the equipment body and the drilling and grinding control system, in which:

[0045]The equipment body includes: a bed 1, a drilling and grinding mechanism placed on the bed 1 and a workpiece positioning mechanism; the drilling and grinding mechanism includes: a Y-axis support 2; a Y-axis on the Y-axis support 2 Servo motor 3 and Y-axis slide rail support; the Y-axis slide rail support includes a Y-axis slide rail support body 4 and a Y-axis slide rail 5 located on the Y-axis slide rail support body 4; a Y-axis lead screw 6; One end of the Y-axis lead screw 6 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com