Following management system for laser marking and product quality assurance based on network communication

A technology of laser marking and product quality, which is applied in the field of laser marking and its systems, can solve problems such as endangering human health, polluting the environment, and complex process processes, and achieves strong anti-pollution capabilities, simple and convenient operation, and reasonable system design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

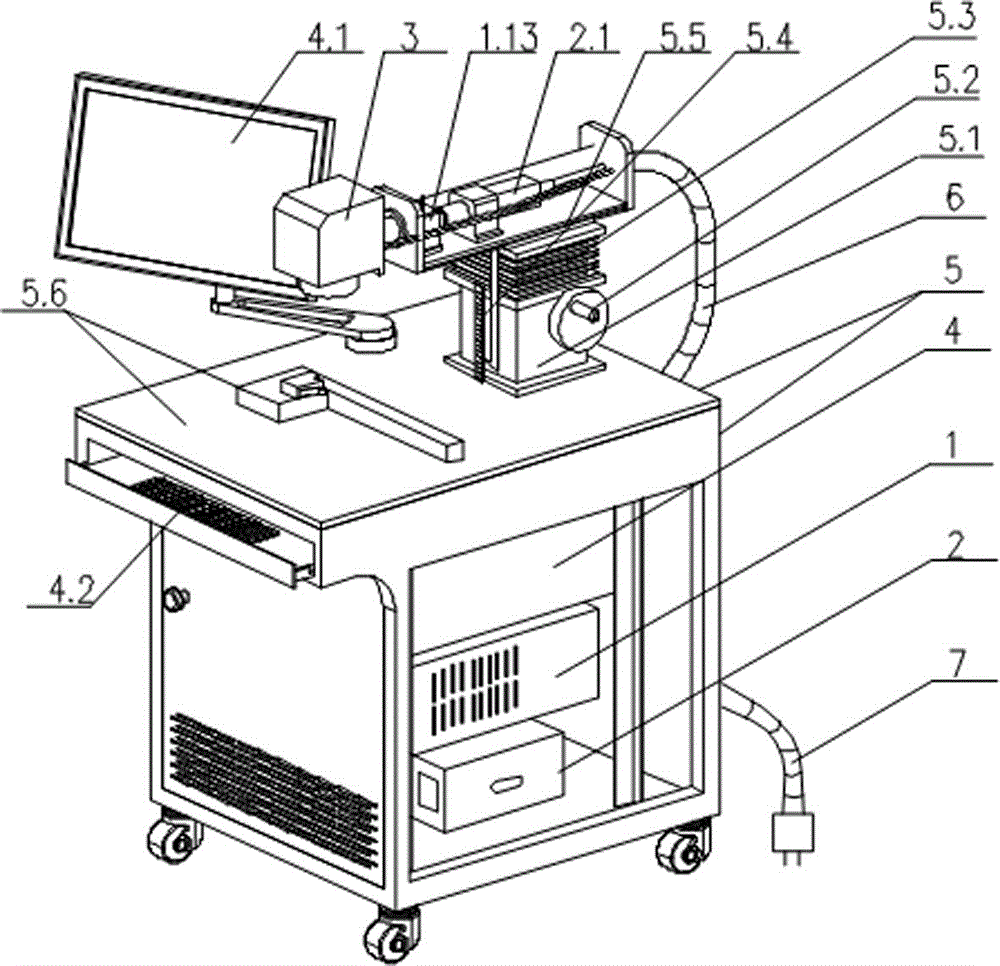

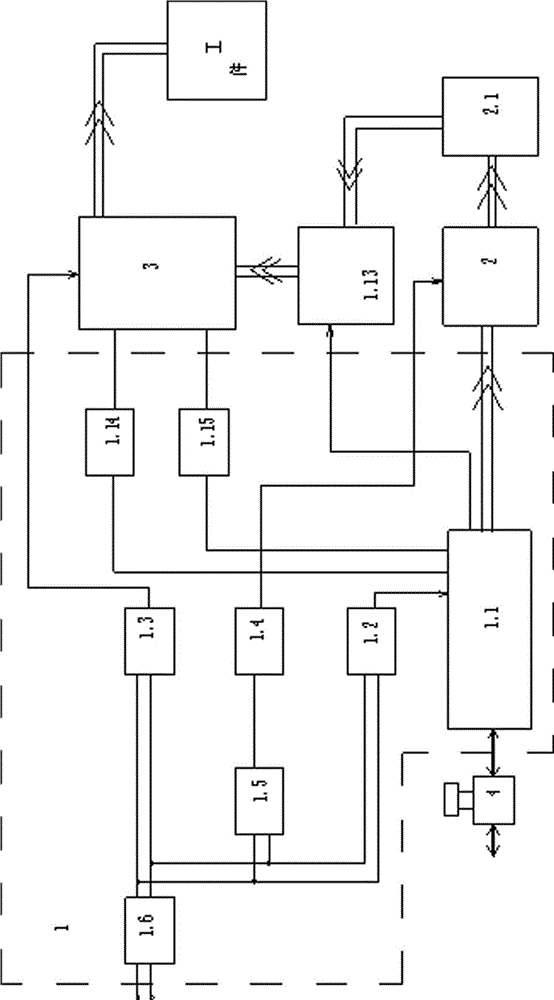

[0081] see Figure 1 to Figure 5 Shown is a specific embodiment of the present invention.

[0082] combine figure 1 and figure 2 It can be seen that the present invention includes a control box 1, a laser 2, a vibrating mirror 3, a PC 4, an installation structure 5, an optical cable 6 and a cable 7, and the laser 2, the control box 1 and the PC 4 are arranged in sequence from bottom to top In the mounting frame 5, the vibrating mirror 3 is arranged on the front end of the sliding frame 5.5 at the top of the mounting frame 5, and its input is sequentially passed through the red light positioning indicator 1.13 and then in turn with the optical fiber isolator 2.1, the optical cable 6 and the laser beam at the output end of the laser 2. The docking form is combined with the cable 7 to form a whole. in:

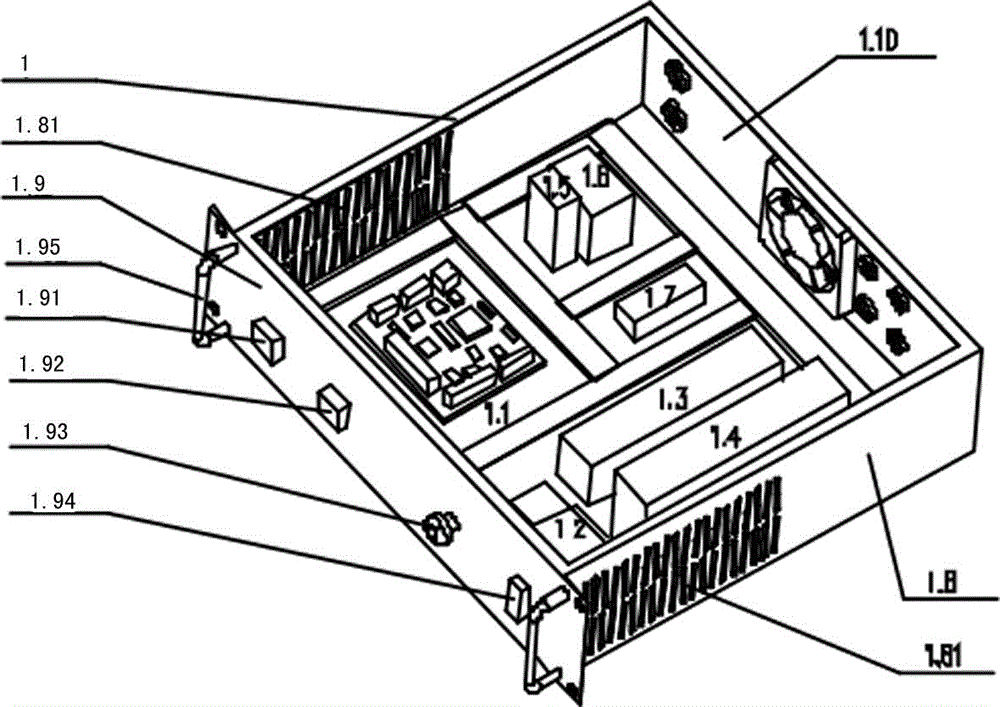

[0083] The control box 1 is an independent box structure, including a central control module 1.1, a +5 volt power module 1.2, a +15 volt power module 1.3, a +24 volt power m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com