A Forming Method of Complex Curved Aluminum Foam Parts

A technology of complex curved surfaces and forming methods, applied in the field of forming aluminum foam parts with complex curved surfaces, can solve the problems that the aluminum foam sandwich panels cannot meet the requirements of daily automobile use, differences in internal cells, differences in mechanical parameters, etc., and achieve a foam-free structure. Defects, low cost, suitable cell distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

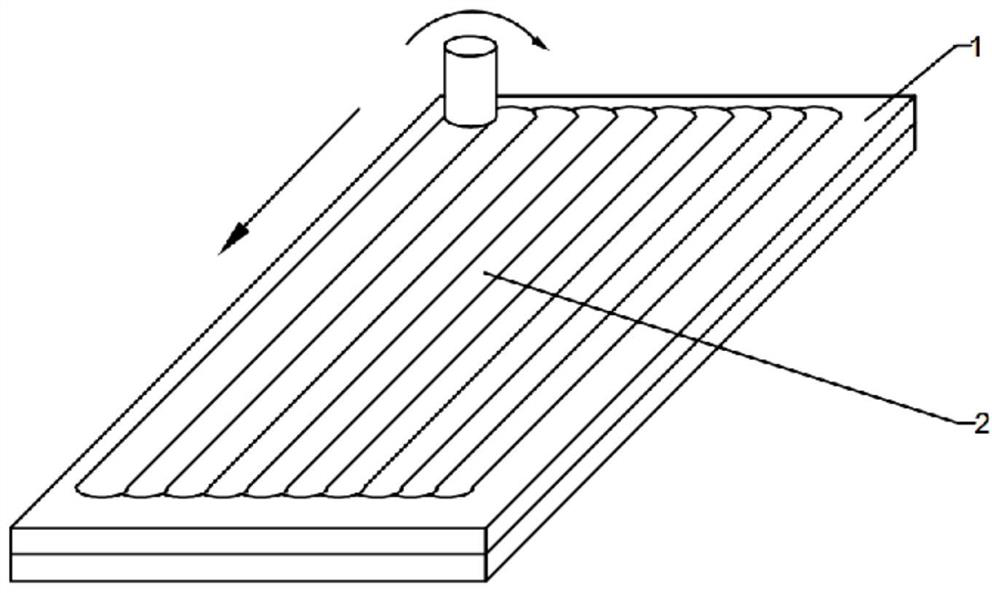

[0034] S1. Friction stir welding stage: use the metal plate 1 to perform friction stir processing on the friction stir welding workbench to obtain the foamed aluminum prefabricated body 2;

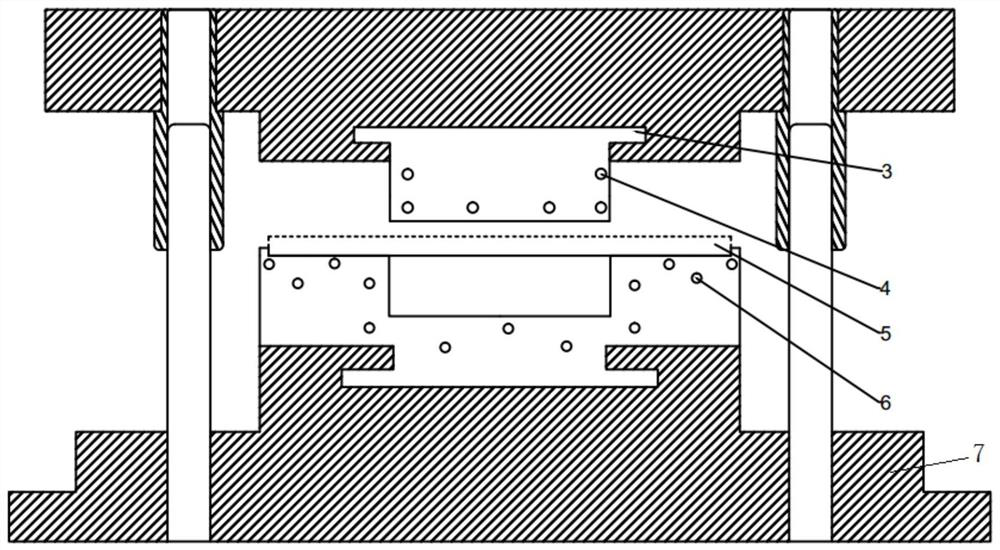

[0035] S2. Preparatory stage before stamping: Put the aluminum foam preform prepared in S1 into a heating furnace to heat to 500°C and keep it warm for 10 minutes. After the heating is completed, the heated preform is quickly transferred to the punch 3 and the die 7 for positioning Clamping, the transfer time is kept at about 10s;

[0036] S3. Stamping deformation stage: quickly close the punch 3 and the die 7 of the mold to stamp the preform to an ideal shape;

[0037] S4. Foaming stage: After the mold is quickly closed for stamping, the punch is moved up by 5mm to give the heated preform 5 foaming space, so that the deformed preform can complete the remaining foaming operation;

[0038] S5. Heat preservation stage: continue to heat the mold to complete the remaining foaming action of th...

Embodiment 2

[0042] The specific method is the same as in Example 1, and the different process conditions are as follows: when the foaming is heated at the beginning, the foamed aluminum preform is directly placed in the mold for heating, which saves the time wasted in transferring the preform from the heating furnace to the mold. , the follow-up temperature and pressure holding time are the same.

[0043] The final porosity of the foamed aluminum product obtained in Example 2 is about 70%.

[0044] The present invention can not only form molded parts with almost any desired curved surface, but also the whole process does not last long, consumes simple equipment, and is easy to operate as a whole, which can greatly improve the efficiency of producing complex curved surface parts and effectively reduce costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com