High-precision high-speed processing and gear-hobbing machine

A gear hobbing machine, high-precision technology, applied in the field of high-precision high-speed processing gear hobbing machines, can solve the problems of limited gear types, low versatility, low processing efficiency, etc., to achieve the effect of automatic adjustment, high versatility, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

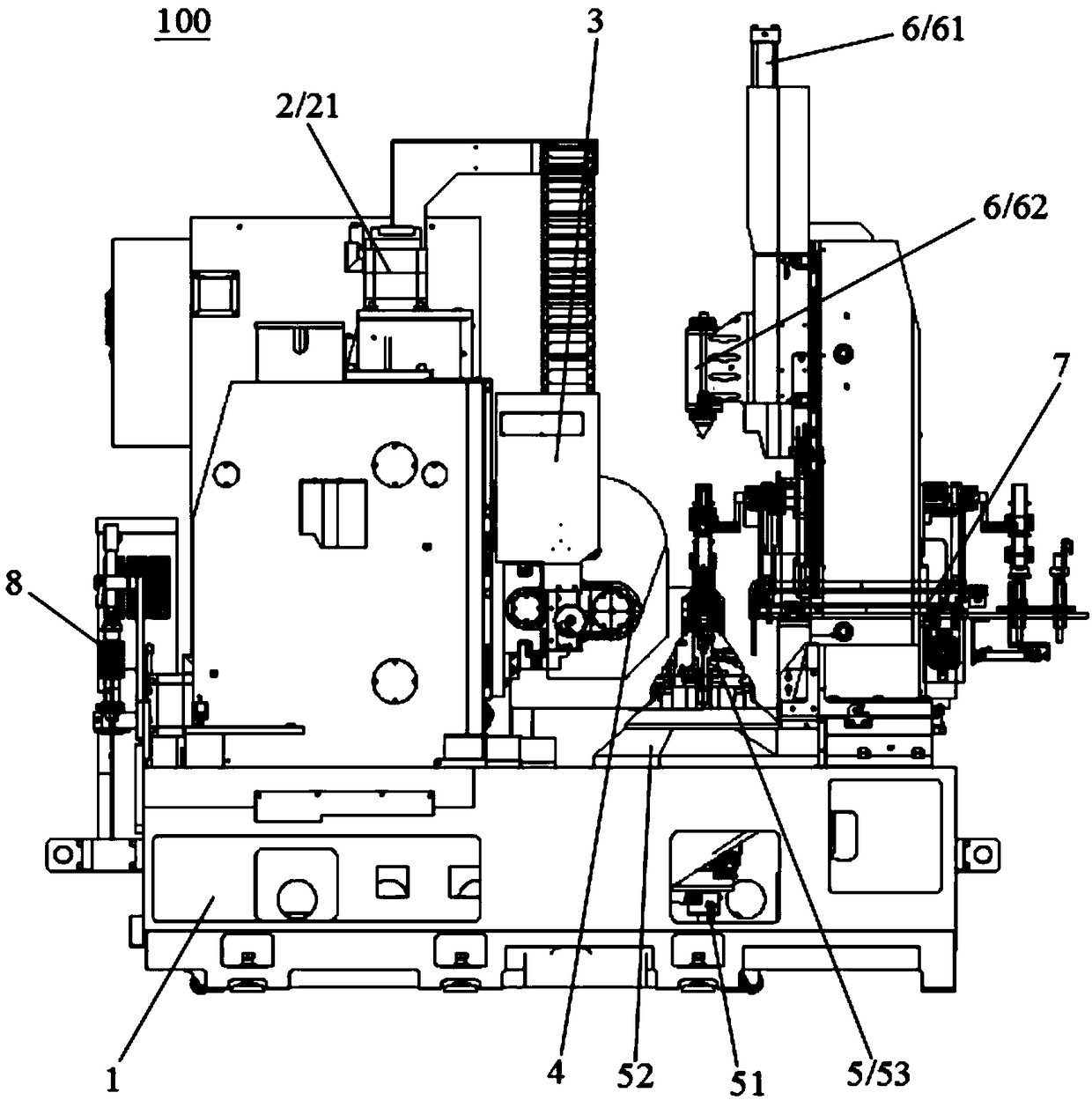

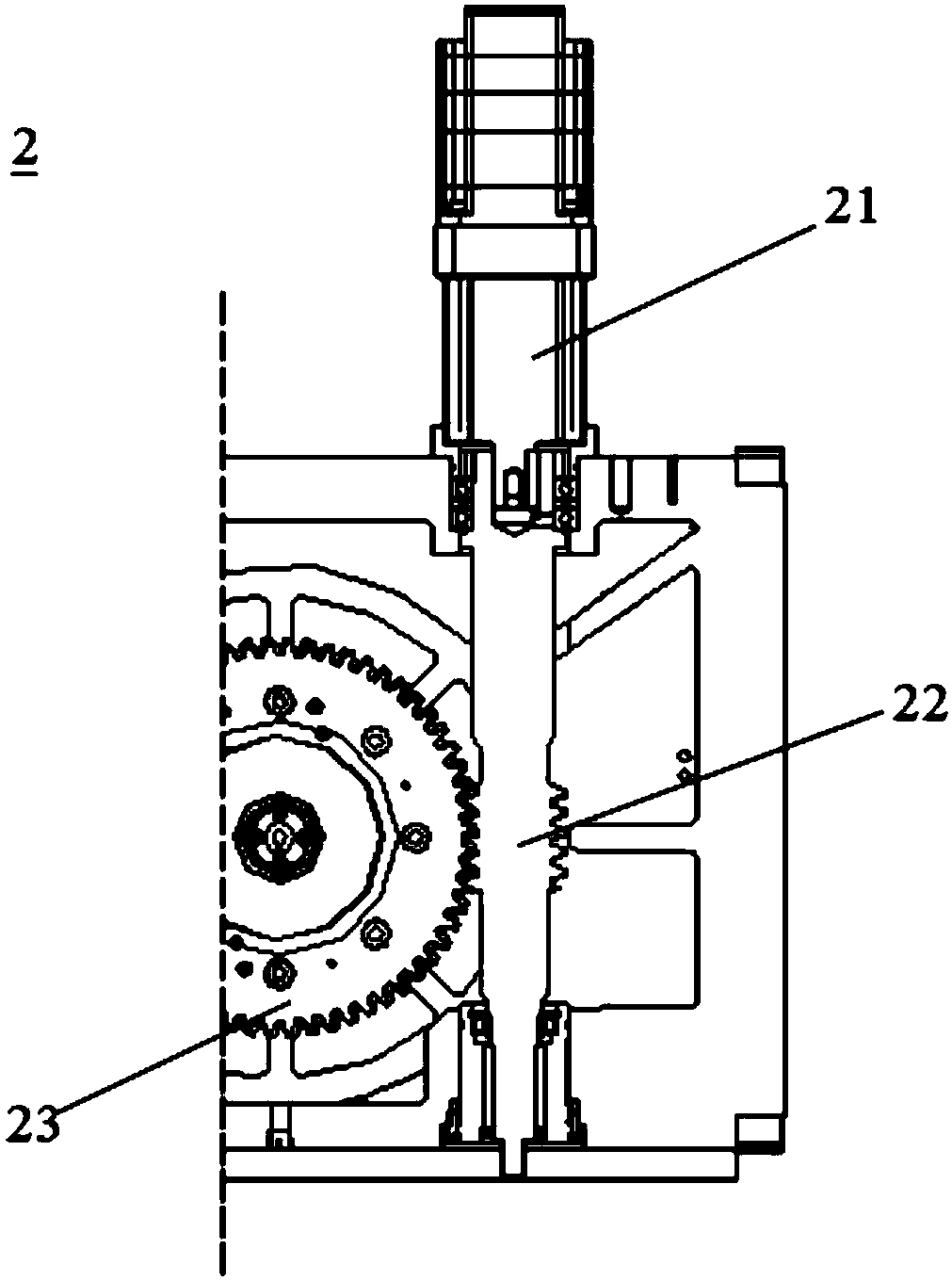

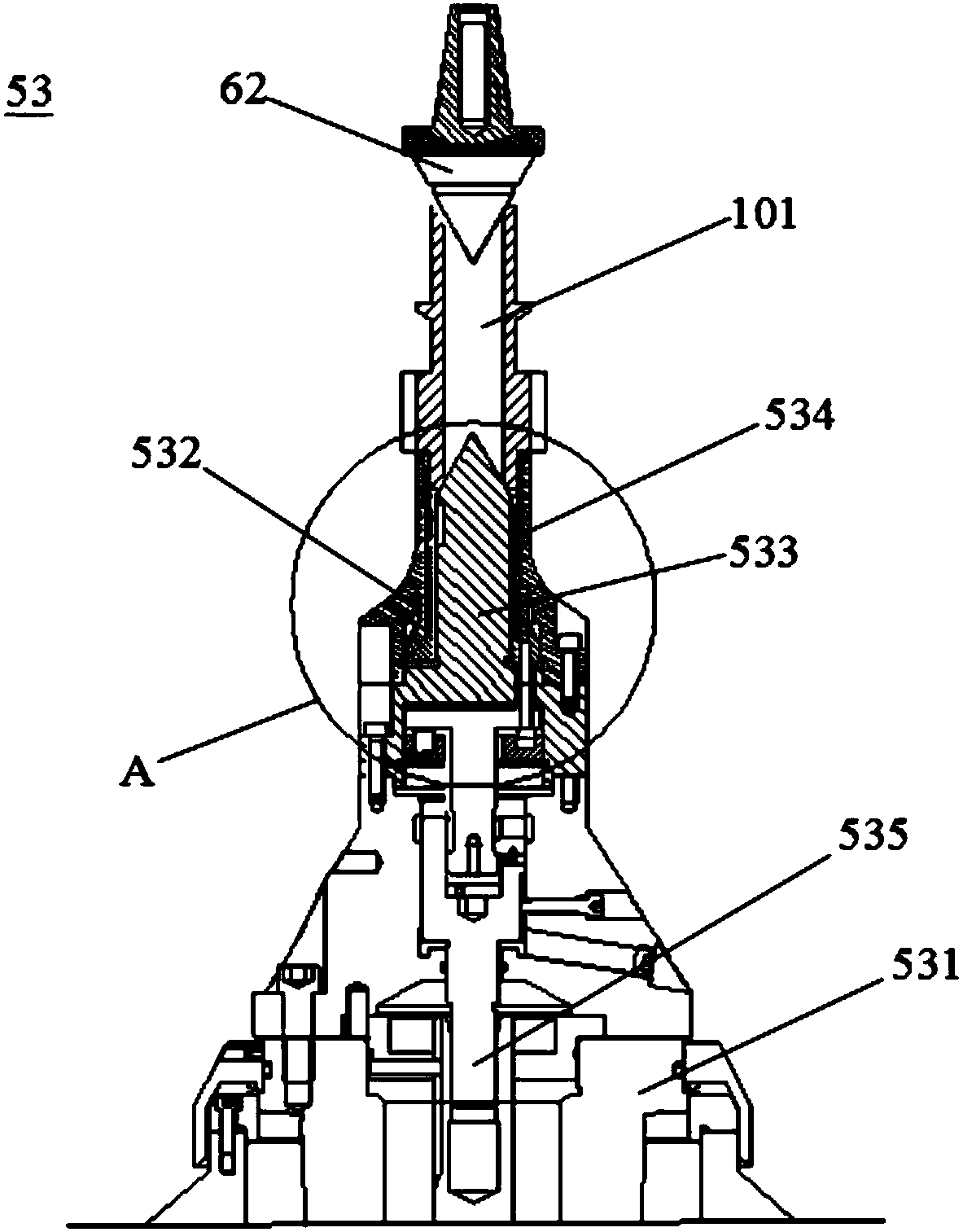

[0034] Please refer to Figure 1-Figure 11 , the present embodiment is a high-precision high-speed machining gear hobbing machine 100, which includes a machine base 1, a knife rest angle adjustment mechanism 2 fixed on the machine base 1, a knife seat 3 arranged on the knife rest angle adjustment mechanism 2, driven by the knife seat 3 The hobbing cutter 4 that moves, the gear base that is fixed on the machine base 1 and positions the gear to drive it to rotate 5, the tailstock limit mechanism that limits the concentricity of the rotation of the gear 6, is sleeved on the tailstock limit The gear automatic loading and unloading mechanism 7 on the outer peripheral surface of the positioning mechanism 6, and the hob correction mechanism 8 arranged on the machine base 1.

[0035] The hob correction mechanism 8 includes a hob connection assembly 81 and a detection assembly 82 for detecting jumping errors of the hob. The hob connection assembly 81 includes a support base 811, a hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com