Welding method and welding system

A welding system and welding method technology, applied in the field of solar cells, can solve the problems of fragmented cells and poor quality of cell components, and achieve the effects of reducing the impact, omitting the overturning operation, and avoiding the phenomenon of missing welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

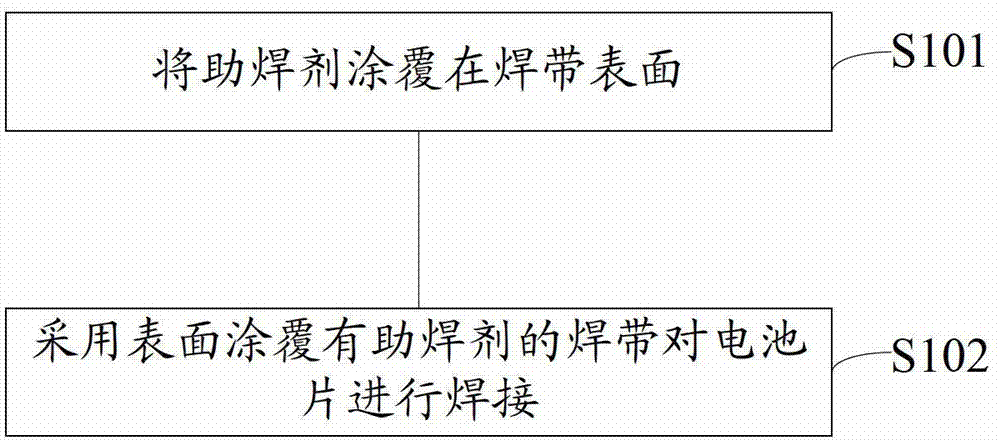

[0035] Embodiment 1 of the present invention provides a welding method, such as figure 1 Shown, described welding method comprises the following steps:

[0036] Step S101: Coating flux on the surface of the solder strip.

[0037] The process of coating the soldering flux on the surface of the soldering strip includes: firstly, uniformly coating the liquid soldering flux on the surface of the soldering strap; Wherein, the process of uniformly coating the liquid flux on the surface of the welding strip is to evenly brush the liquid flux on the surface of the welding strip, or uniformly spray the liquid flux on the surface of the welding strip, or soak the welding strip in the liquid In the flux, the liquid flux is evenly distributed on the surface of the solder strip, which is not limited in the present invention.

[0038] Step S102: Soldering the battery sheets with a soldering tape coated with flux.

[0039] The welding process of using the soldering tape coated with flux i...

Embodiment 2

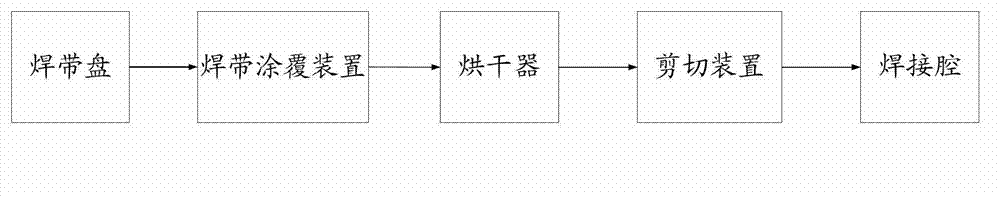

[0042] Embodiment 2 of the present invention provides a welding system, such as figure 2 As shown, the welding system includes, in addition to the ribbon reel containing the ribbon, the shearing device for cutting the ribbon, and the welding cavity, the first end is connected to the ribbon reel, and the second end is connected to the ribbon reel. A flux coating device whose end is connected with the shearing device, and flux is contained in the flux coating device.

[0043] The welding ribbon is generally a reel of welding ribbon, and the reel of welding ribbon is placed on a designated position of the welding ribbon reel.

[0044] The welding ribbon coating device is located between the welding ribbon reel and the shearing device, and is used to coat the flux on the surface of the welding ribbon coming out of the welding ribbon reel. The welding ribbon coating device can be a brushing device, which can be The spraying device may also be a container containing flux, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com