Method for manufacturing power decentralization and power centralization type transformer oil tank

A technology of transformer oil tank and power concentration, which is used in inductor/transformer/magnet manufacturing, transformer/inductor cooling, electrical components, etc., can solve the problems of inability to complete welding at one time, non-conformance, low production efficiency, etc., and achieve large-scale production. The effect of the production line operation, the control of welding stress and deformation, and the improvement of the production qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

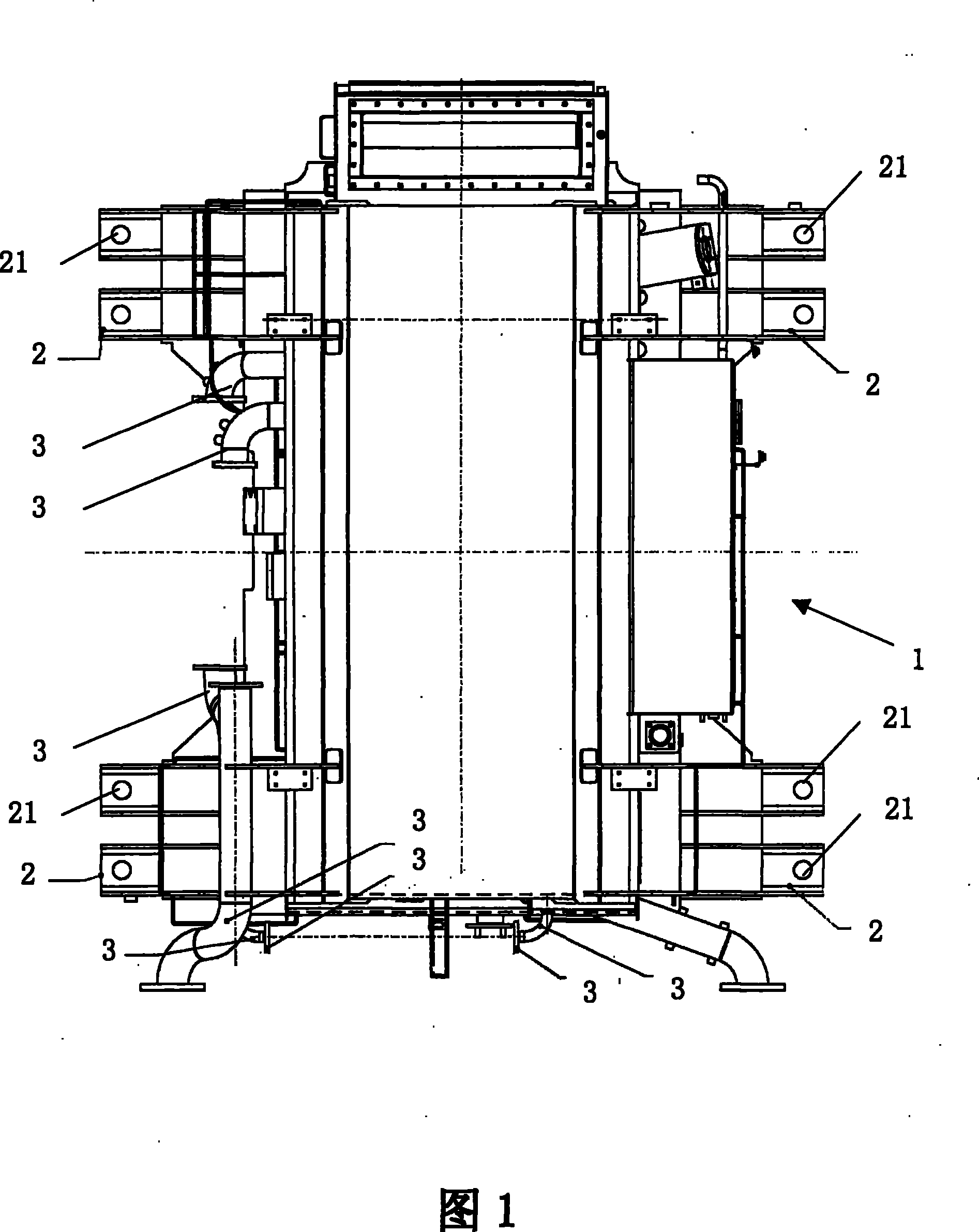

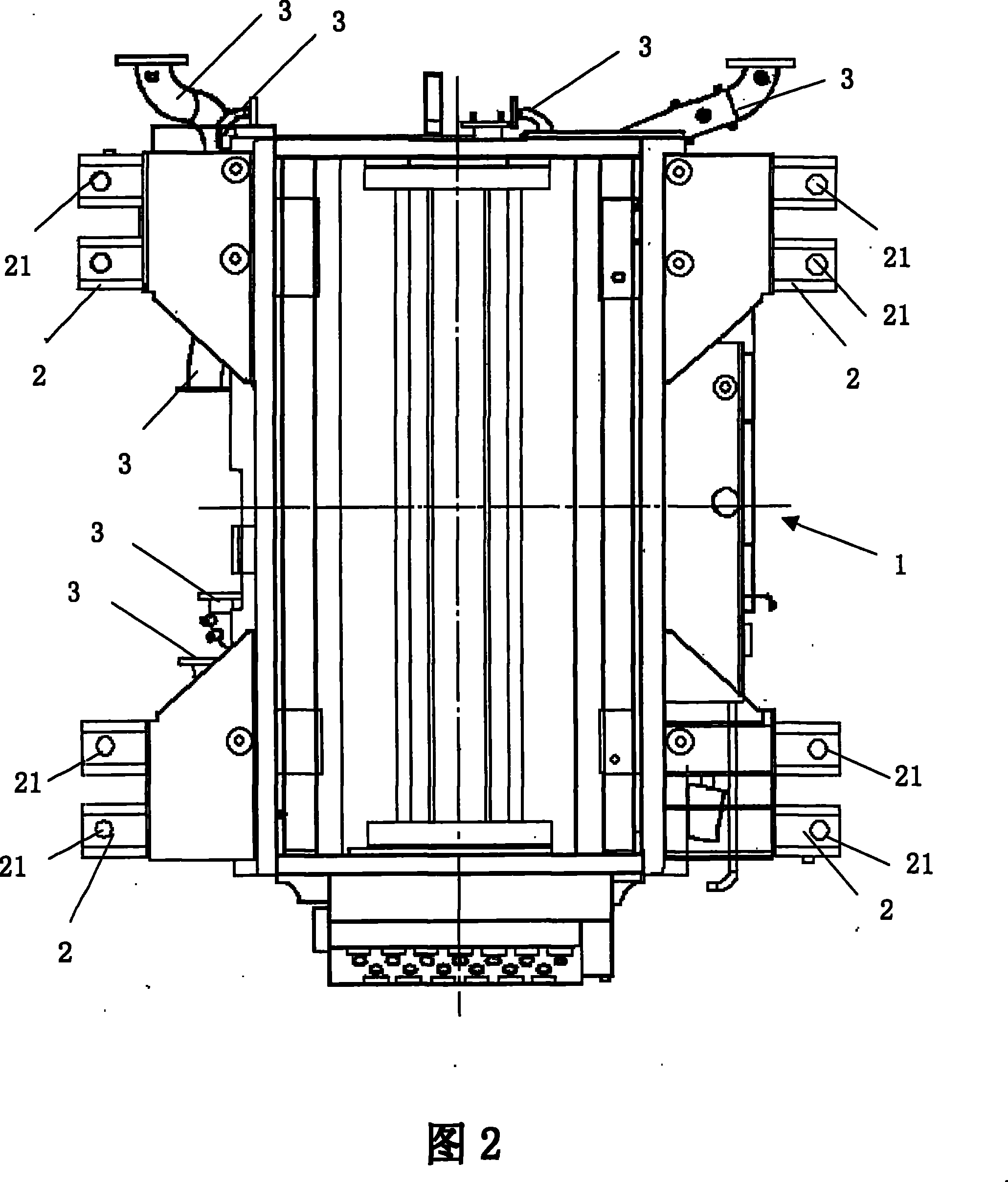

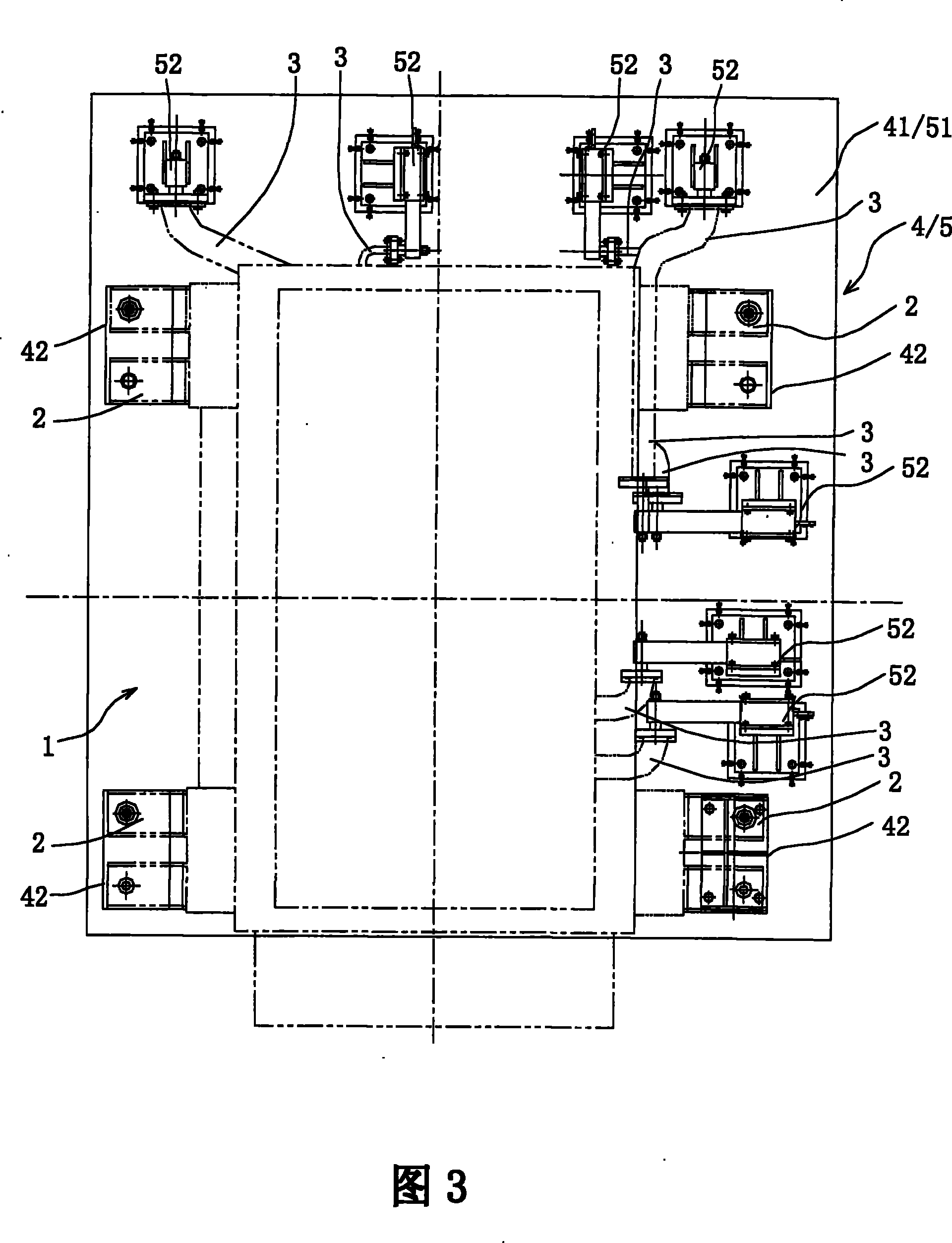

[0024] The invention provides a method for manufacturing a power-dispersed and power-concentrated transformer oil tank, referring to figure 1 , 2 As shown, the power dispersion and power concentration type transformer oil tank is an all-steel box structure, which includes a box body 1 and assembly accessories and non-assembly accessories arranged on the box body. Now the main transformer is pulled by an AWJ type locomotive The production process of the oil tank is taken as an example to specifically illustrate the manufacturing method of the present invention, and the manufacturing method may further comprise the steps:

[0025] A. Assembly welding box 1 and non-assembly accessories such as reinforcement plates, cable racks, and grounding seats;

[0026] B. Weld the assembly accessories such as the mounting base 2 and the 3 sets of oil pipes on the box body 1.

[0027] In the method of the present invention, the assembly accessories are welded at the end of the welding proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com