Forming method of special-shaped curved surface structural member

A technology for special-shaped curved surfaces and structural parts, which is applied in the field of precision sheet metal processing. It can solve problems such as easy cracks in shape correction, heavy workload, and inability to form products with non-uniform wall thickness at one time, so as to ensure product quality, prevent stacking, Effect of reducing the risk of wrinkling and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A specific embodiment of the present invention discloses a forming method of a non-uniform wall-thickness special-shaped curved surface structural part, which is used for one-time forming of the non-uniform wall thickness special-shaped curved surface structural part.

[0073] Figure 8 (a) is a schematic diagram of the target product formed by a traditional mold, Figure 8 (b) is a schematic diagram of the target product formed by the forming die of the present invention. Figure 8 (a) and Figure 8 The products of (b) are identical, but superficially Figure 8 (a) The upper surface of the product is parallel to the horizontal plane, and the lower surface is inclined upward by an angle β; and Figure 8 (b) The lower surface of the product is parallel to the horizontal plane, and the upper surface is inclined downward at a certain angle.

[0074] The forming process of the product is described in detail below.

[0075] First, the part preform blank is made. Specif...

Embodiment 2

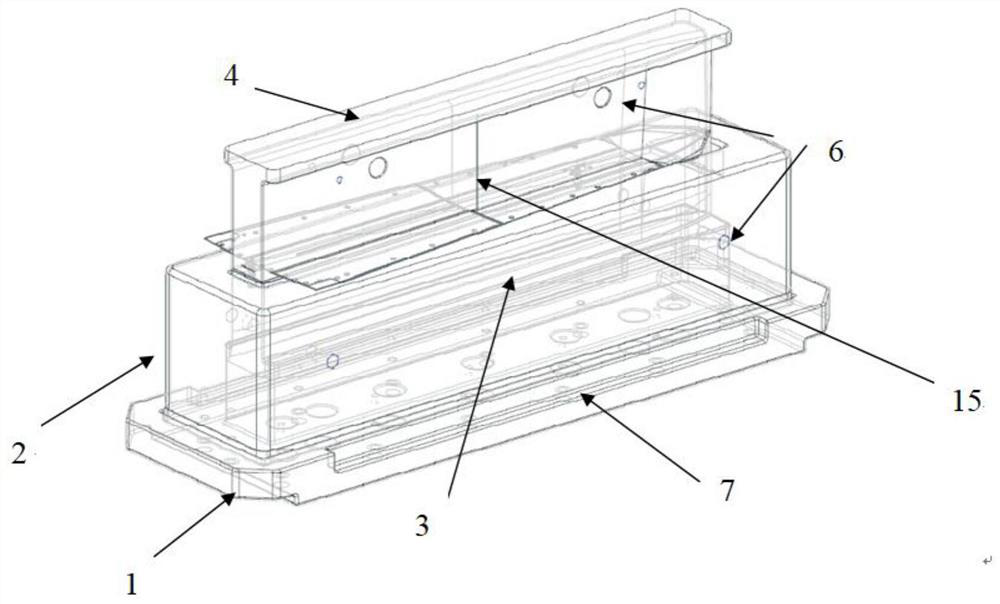

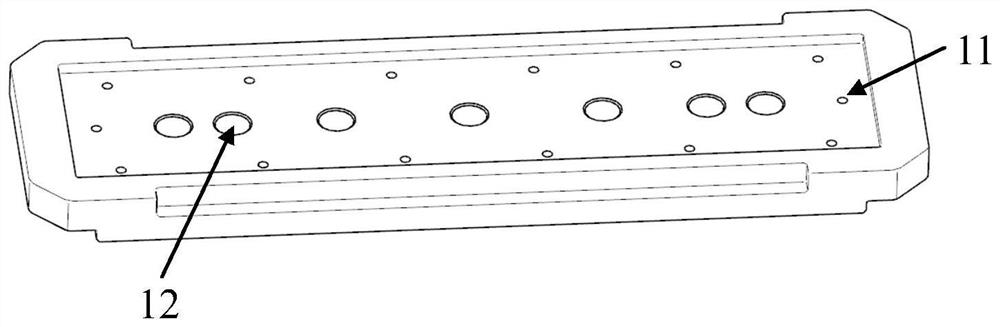

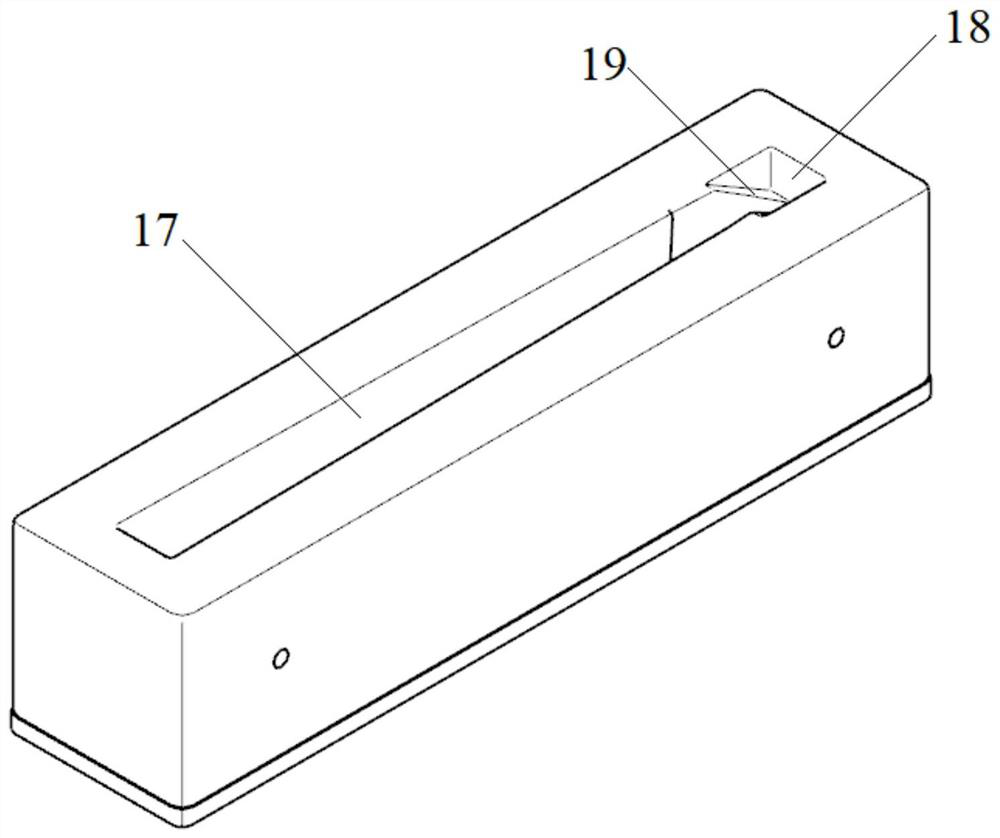

[0092] Another specific embodiment of the present invention discloses a forming device for forming the non-uniform wall-thickness special-shaped curved surface structural member of the first embodiment.

[0093] Non-equal wall thickness special-shaped curved surface structural parts include front section 8, shrinkage section 9 and tail section 10; the product material is: 1Cr18Ni9Ti stainless steel, the material thickness is 1mm and 2mm respectively, that is, the front section and shrinkage section are 1mm, the rear section is 2mm, and the product length × width × height is 1100mm × 130mm × 100mm, the product model after forming is as follows Figure 7 shown. The bottom surface of the formed special-shaped curved surface structure is inclined upward from the tail section to the front section, and the angle between the bottom surface and the horizontal plane is β, such as Figure 8 (a) and Figure 8 (b) shown.

[0094] According to the traditional design idea, in order to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com