A mechanical shearing machine with three-point support and its processing method

A technology of three-point support and processing method, which is applied in the direction of metal processing equipment, cutting tools for shearing machine devices, manufacturing tools, etc., can solve the problems of inability to realize three-point support and lack of fixed support points, etc., to reduce thermal deformation, The structural design is reasonable and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

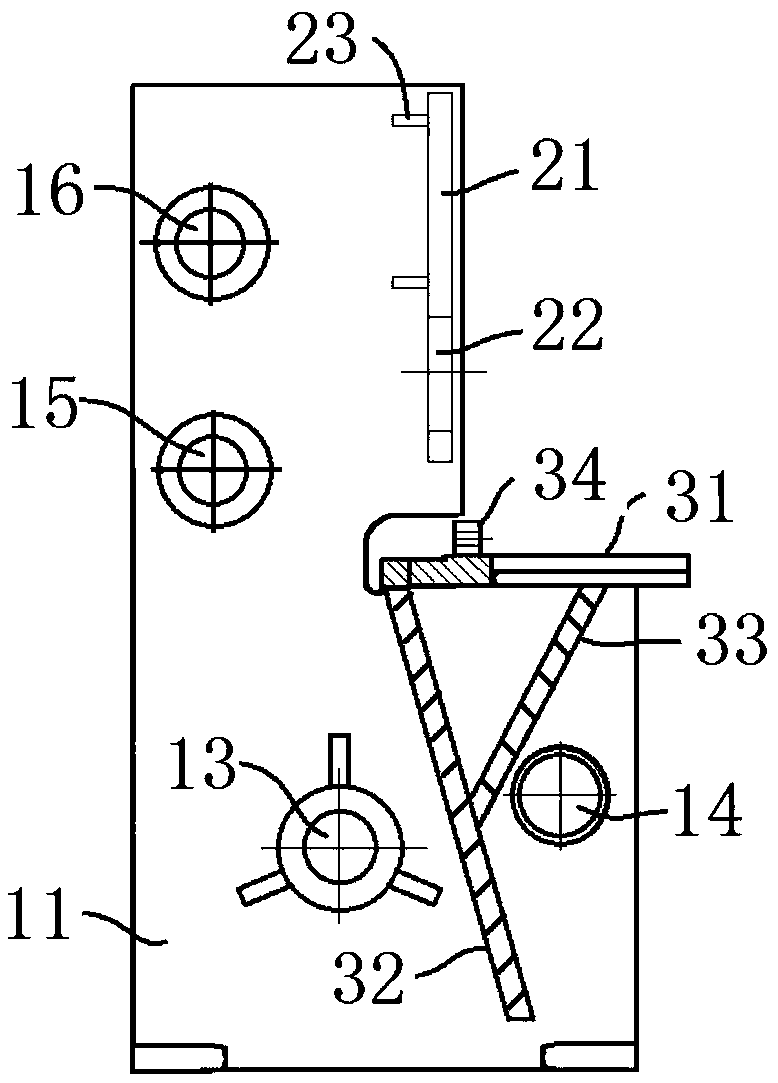

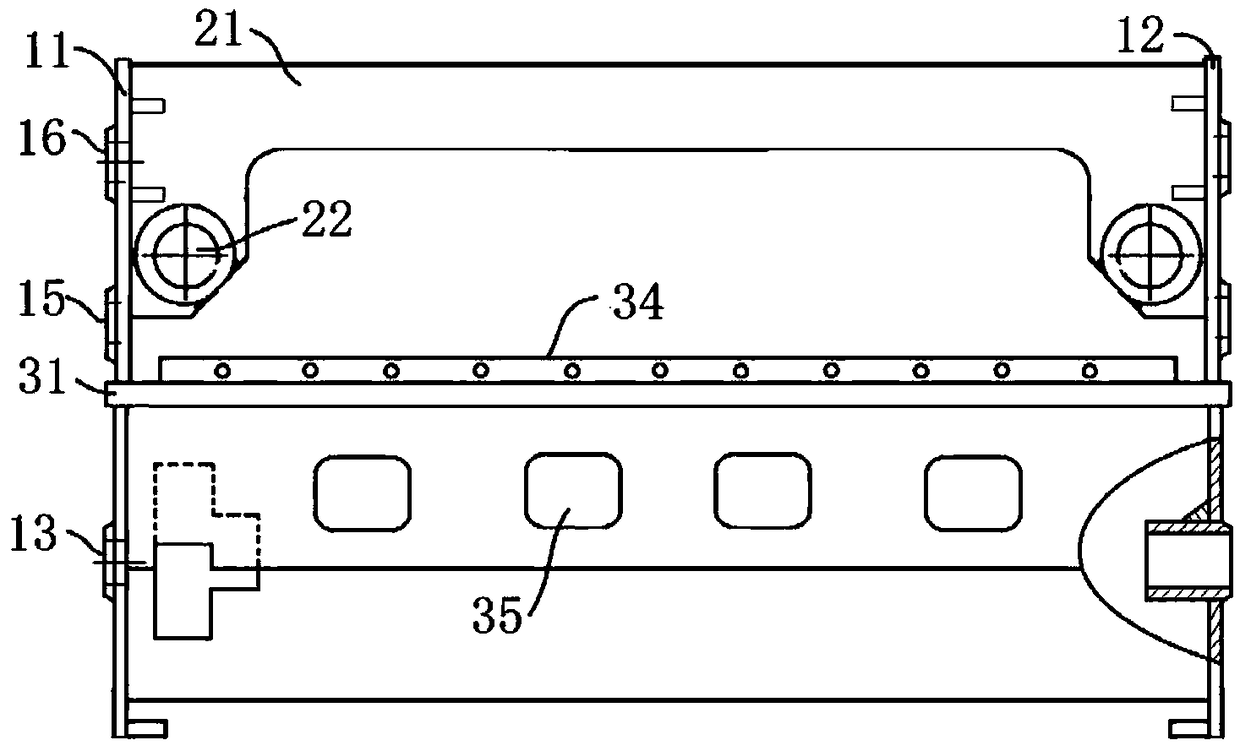

[0045] combine figure 1 , figure 2, a kind of mechanical shearing machine that adopts three-point support in this embodiment includes two wallboards arranged in parallel, and also includes a knife rest, a front panel 21 and a bracket, and the bracket is welded and connected to the bearing platform on the front side of the wallboard Above, the front panel 21 is welded and connected to the upper section of the front side of the wallboard, that is, the upper section on the side facing the workbench panel, and the main shaft hole 13 and the power shaft hole 14 are arranged on the wall board for installing the main shaft and connecting the drive of the motor axis. The wallboard is also provided with a lower roller shaft hole 15 and an upper roller shaft hole 16, and the lower roller shaft hole 15 and the upper roller shaft hole 16 are located on the same vertical line for installing rollers; the two ends of the front panel 21 are provided with protruding Section, the protruding ...

Embodiment 2

[0048] A mechanical shearing machine that adopts three-point support in this embodiment has the same basic structure as that of Embodiment 1, furthermore: the axis of the horizontal roller shaft hole 22 is located between the lower roller shaft hole 15 and the upper roller shaft hole 16 On the central symmetrical plane, that is, the distances between the lower roller shaft hole 15 and the upper roller shaft hole 16 are equal to the horizontal roller shaft hole 22 , it has better structural stability.

Embodiment 3

[0050] combine Figure 4 , for the mechanical shearing machine of embodiments 1-2, the present embodiment provides a processing method of a mechanical shearing machine using three-point support, and the processing steps are:

[0051] Step 1. Fix the first wallboard 11 and the second wallboard 12 together with bolts, machine the main shaft hole 13 and the power shaft hole 14 to the required size with a machine tool; then process the lower roller shaft hole 15 and the upper roller shaft hole 16, Reserve a margin of 2mm for the aperture; process the horizontal roller shaft hole 22 on the front panel 21, and reserve a margin of 2mm.

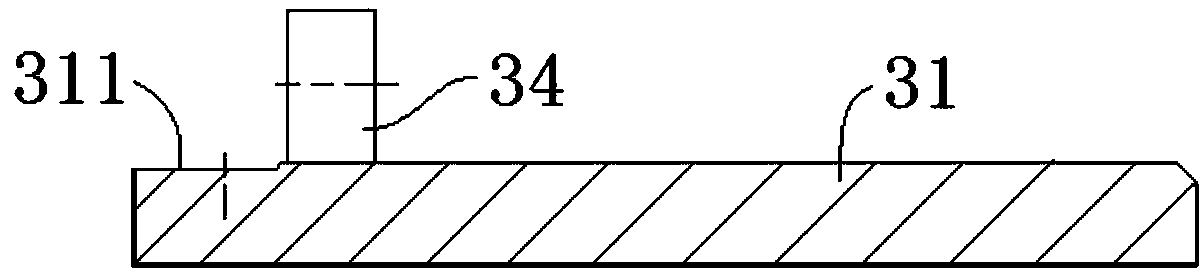

[0052] Step 2. Weld the workbench panel 31, the main support plate 32, and the auxiliary support plate 33 together to form a bracket, and then process the work surface of the workbench panel 31, reserving a margin of 0.5-2 mm, and this embodiment uses a margin of 1 mm .

[0053] combine image 3 , the main support plate used is welded with a knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com