An overall processing method for a frame of a hydraulic shearing machine

A technology of overall processing and hydraulic shearing, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as difficult to control precision and easy deformation, improve processing quality and service life, reduce thermal deformation, and improve overall welding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

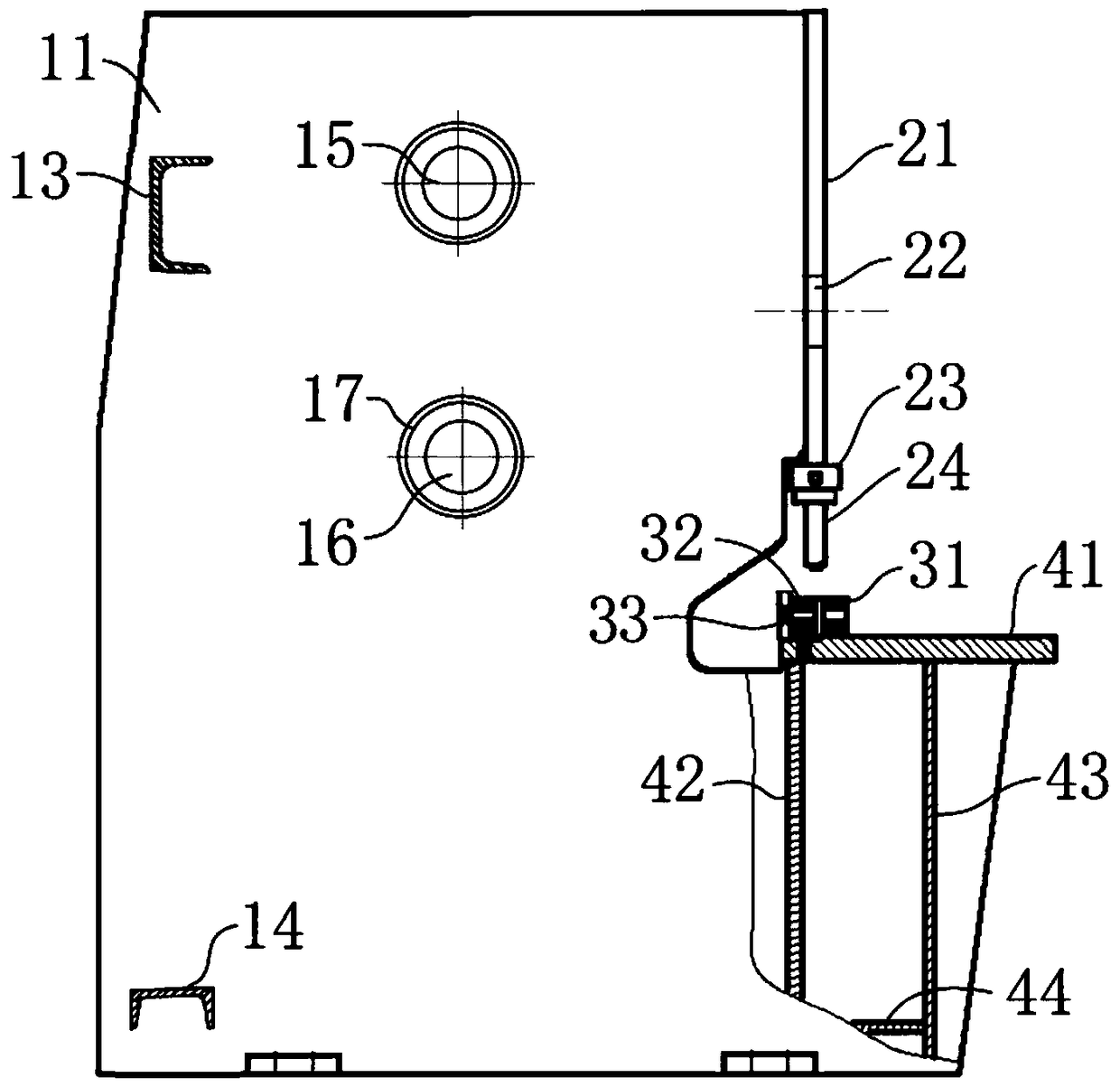

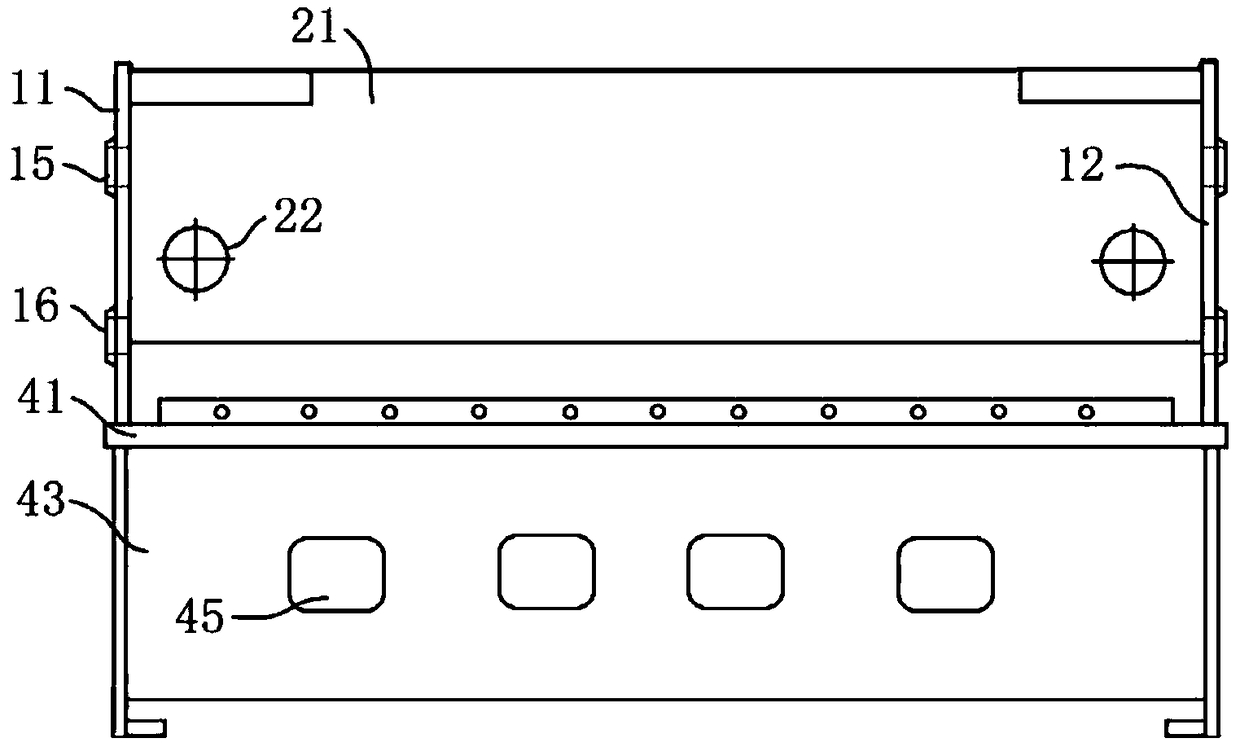

[0043] combine figure 1 , figure 2, the general hydraulic shearing machine includes the first wall panel 11 and the second wall panel 12, the front panel 21, the bracket with the workbench panel 41, the first wall panel 11 and the second wall panel 12 are distributed on the frame The two sides of the shearing machine play a main supporting role, and the first and second ones are only for the convenience of distinguishing and describing, and there is no specific restriction on the actual structure of the shearing machine. The front panel 21 is positioned at the front side of the frame, and the binder seat 23 below the front panel 21 is used to fix the binder mechanism 24, which is connected to the binder seat 23 by bolts to hold down the plate when shearing. The rear side of the frame is provided with a top support beam 13, which can further improve the structural strength of the frame.

[0044] combine Figure 5 , for the frame structure of the above shearing machine, the ...

Embodiment 2

[0066] The overall processing method of a frame of a hydraulic shearing machine in this embodiment, its basic processing process is the same as that of Embodiment 1, the difference is that the outer surface of the wallboard corresponds to the upper roller shaft hole 15 and the lower roller shaft hole The position of 16 is welded with thickening plate 17, and this thickening plate 17 is circular, and is coaxially arranged with roller axle hole. Since the wallboards on both sides of the small shearing machine are relatively thin, the welded thickening plate 17 helps to improve the structural strength, and facilitates the overall machining operation in step 6. The outer surfaces of the upper roller shaft hole 15 and the lower roller shaft hole 16 processed in step 6 are located on the same plane, so the machining of the entire surface can be completed in one pass, and the efficiency is high.

Embodiment 3

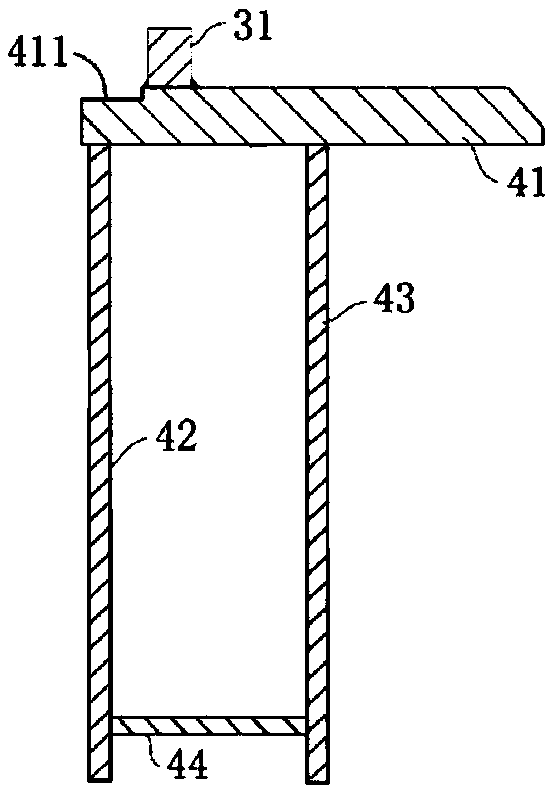

[0068] The overall processing method of a frame of a hydraulic shearing machine in this embodiment, its basic processing process is the same as that of Embodiment 2, the difference is that the order of diagonal welding in step 5 is: first weld the main support plate 42 and the second The junction of a wallboard 11, then weld the junction of the auxiliary support plate 43 and the second wallboard 12, then weld the junction of the main support plate 42 and the second wallboard 12, and finally weld the auxiliary support plate 43 and the first wallboard 12. The junction of wall panels 11.

[0069] The lower knife mounting surface 441 of the workbench panel must be used as the benchmark for subsequent processing, and the welding accuracy of the bracket must be guaranteed. Through diagonal welding, the thermal deformation generated during welding can be offset by each other; and the main support plate plays a main supporting role. Welding the main support plate first can ensure its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com