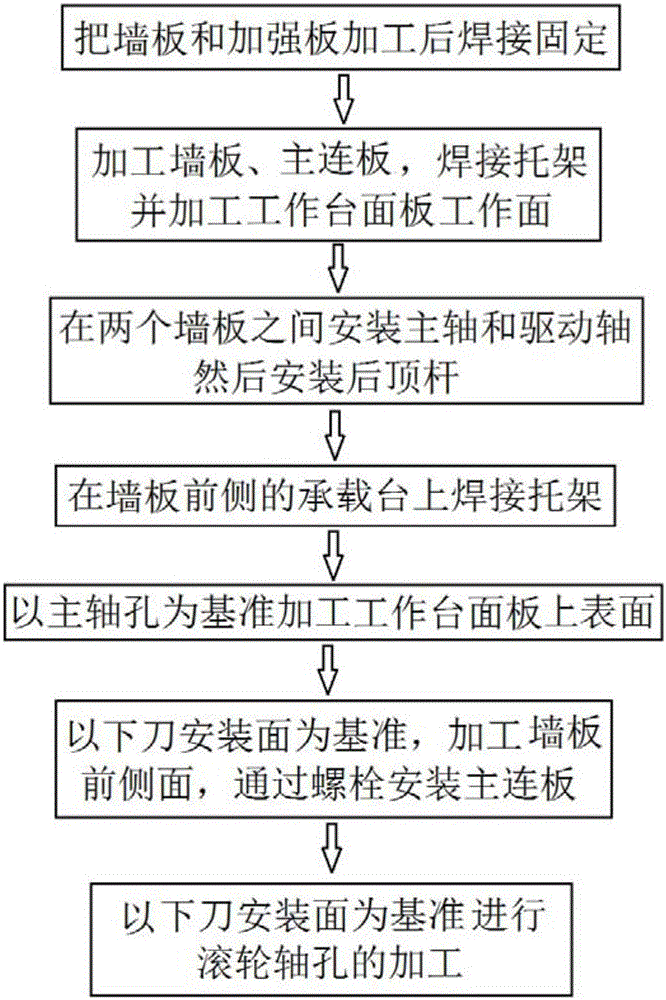

Machining method of rolling wheel type mechanical plate shearing machine supporting mechanism

A technology of mechanical shearing machine and support mechanism, which is applied in the field of shearing machine processing, can solve the problems of lack of fixed support points and insufficient strength of wallboards on both sides, and achieve the effects of easy promotion and use, guaranteed strength, and reduced thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

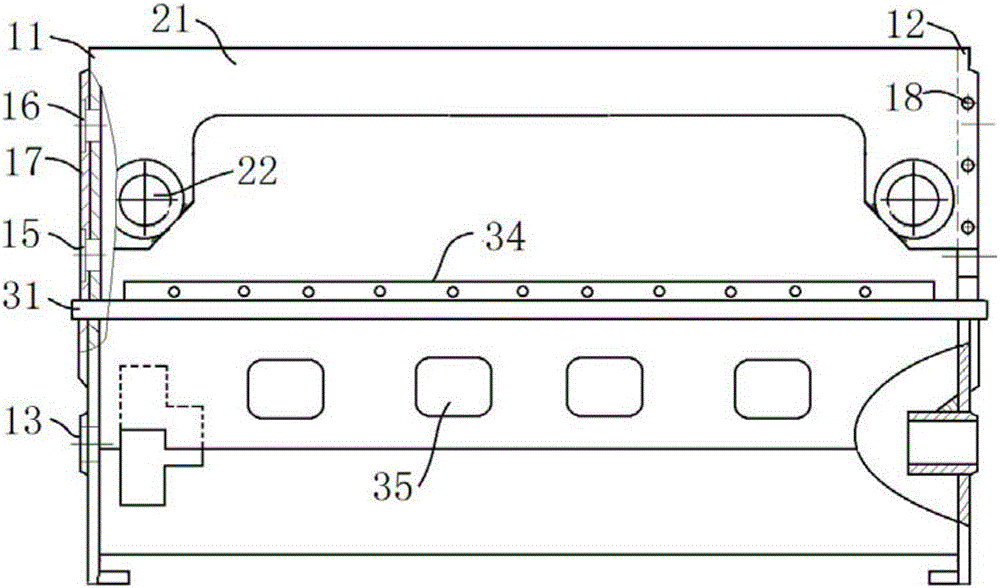

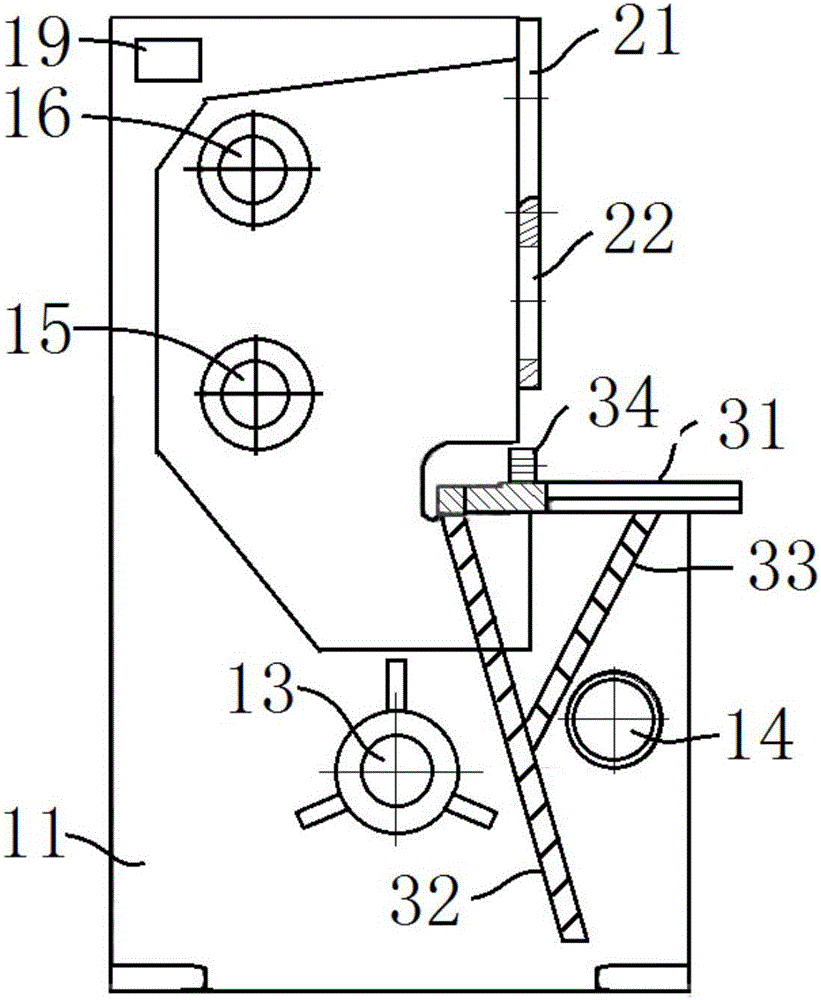

[0041] combine figure 2 with image 3 , the supporting mechanism of the roller-type mechanical shearing machine to be processed in this embodiment includes two wall panels arranged in parallel, and also includes a main connecting plate 21 and a bracket. The bracket is welded and connected to the bearing platform on the front side of the wall panel. The plate 21 is bolted to the upper section of the front side of the wallboard, that is, the upper section facing the side of the workbench panel. The main shaft hole 13 and the power shaft hole 14 are arranged on the wall board. The two shaft holes are used for installing the main shaft and connecting the drive of the motor. axis. The wallboard is also provided with a lower roller shaft hole 15 and an upper roller shaft hole 16, and the lower roller shaft hole 15 and the upper roller shaft hole 16 are located on the same vertical line for installing rollers; the two ends of the main connecting plate 21 are provided with The prot...

Embodiment 2

[0068] The processing method of a support mechanism of a roller type mechanical shearing machine in this embodiment is basically the same as that of Embodiment 1, the difference is that when welding the knife seat adjustment seat 34 on the workbench panel 31, first use The intermittent welding method is used for welding, and then the overall welding is carried out.

[0069] Such as Figure 4 As shown, that is, welding is performed in multiple welding sections, rather than welding the entire weld seam at one time. Specifically, the length of the welding section during intermittent welding is 150-220 mm, and the interval is 280-400 mm. Depending on the length of the shearing machine, it can be selected according to the actual situation. In this embodiment, the length of the welding section is 200 mm, and the interval is 320 mm.

[0070] Intermittent welding will cause some local deformation, but due to the short welding time, the accumulated heat is less and will not affect the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com