Welding fixture

A welding jig and fixture technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of manual and machine not being able to cooperate well, single direction of welding positioning and tightening, and welding seam damage, etc. Improve welding efficiency and the effect of low automation, proficiency and operational technical requirements, reducing the impact of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] The present application relates to a welding jig, which is used for double-sided welding of plates.

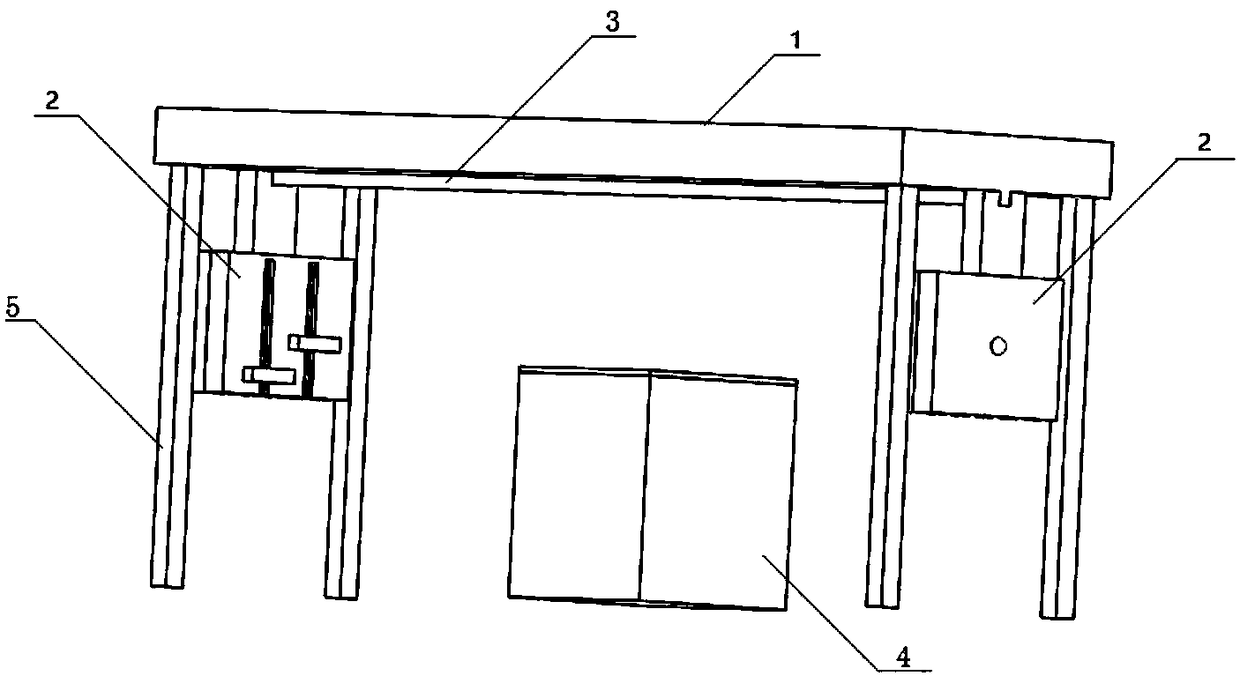

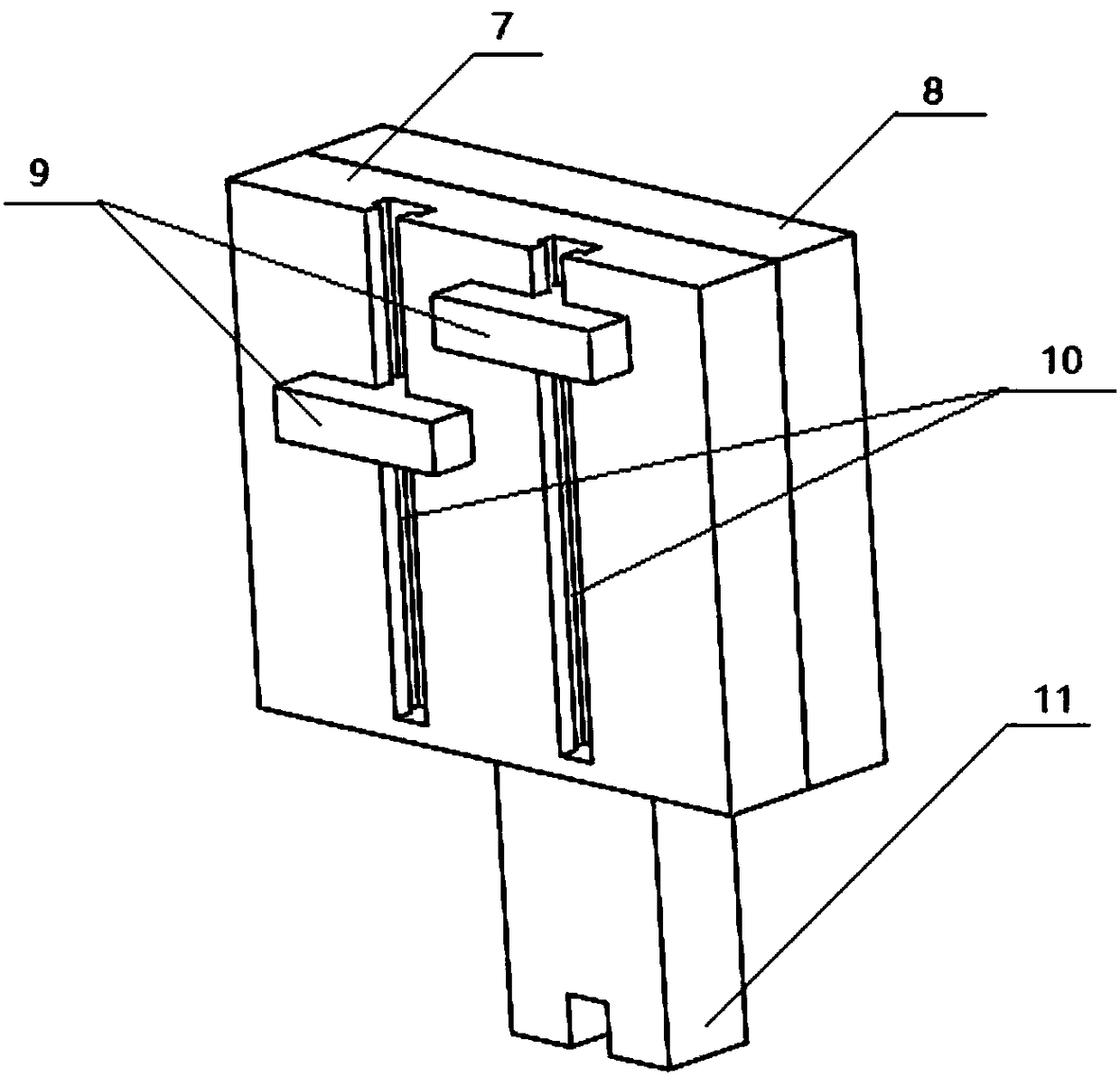

[0015] Such as figure 1 and figure 2 As shown, the welding fixture includes a workbench base 1, a double-sided welding combination splint 2 connected to the workbench base 1, a slide rail 3, a welding operation table 4 for placing weldments, and a welding table 4 connected to the workbench base 1. Bracket 5, the front clamp rotating plate 7 and the rear clamp rotating plate 8 that are connected by the rotating shaft and can rotate clockwise or counterclockwise around the rotating shaft, the slidable clamps 9, sliding grooves 10 and movable clamps positioned on both sides of the front clamp rotating plate 7 Lifting support rod 11.

[0016] The double-sided welding combination splint 2 is also connected with a motor, the double-sided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com