CCD (Charge Coupled Device) galvanometer type laser welding device and method

A technology of laser welding and welding position, which is applied in the direction of laser welding equipment, auxiliary equipment, welding equipment, etc., to achieve the effect of simple equipment and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

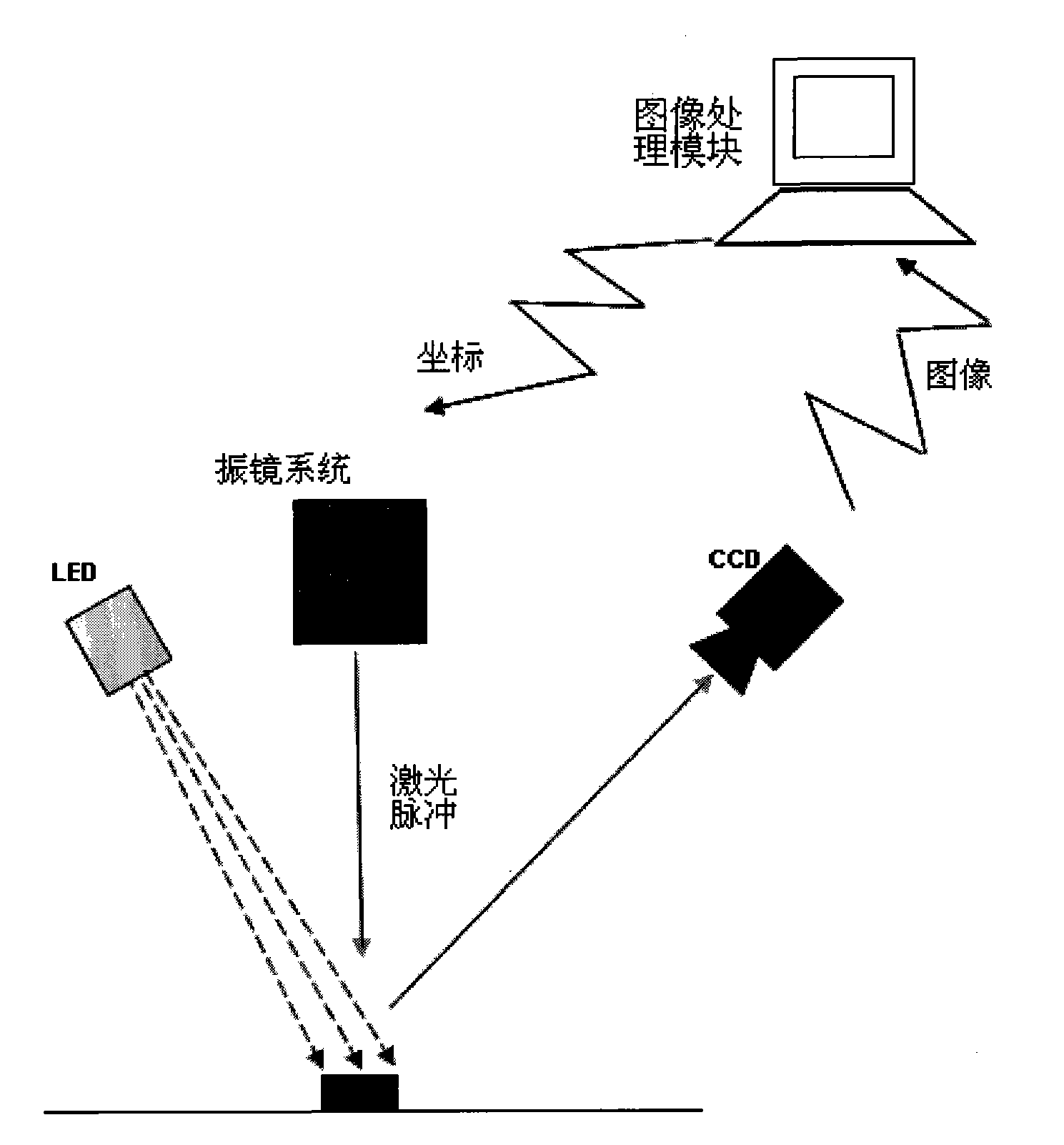

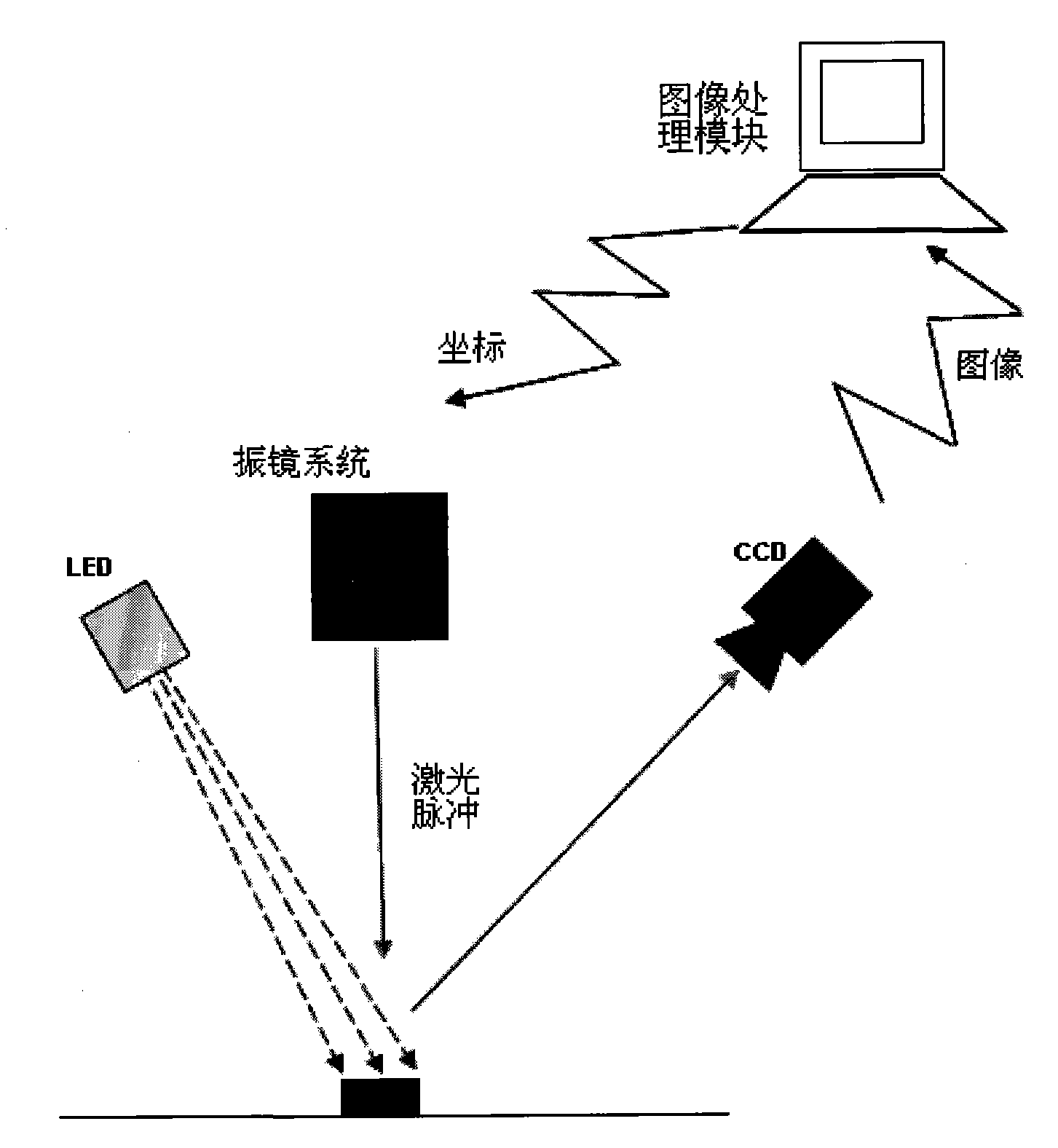

[0018] One embodiment of the CCD galvanometer type laser welding device and method of the present invention is as follows figure 1 As shown, it includes LED lights, CCD (Charge Coupled Device, Charge Coupled Device) image acquisition device, image processing module, galvanometer system (there are two mirrors driven by high-precision servo motors inside the galvanometer system, and the servo motor is controlled by a microcomputer. The angles of the two reflectors are respectively rotated under the control of the two reflectors, and the laser is focused on different positions of the workpiece through the reflection of the two reflectors), the electronic components to be welded are placed on the printed circuit board (PCB) and the pins of the electronic components The position that needs to be soldered is in close contact with the corresponding soldering point on the pad of the printed circuit board, and the LED light is used to obliquely illuminate the pin of the electronic compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com