Hydraulic pipeline inner butt-jointing device

It is a hydraulic-type technology with internal counterparts, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve problems such as inability to achieve nozzle shaping, failure to meet welding construction requirements, and poor nozzle quality. To achieve the effect of light weight, simple structure, and large jacking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

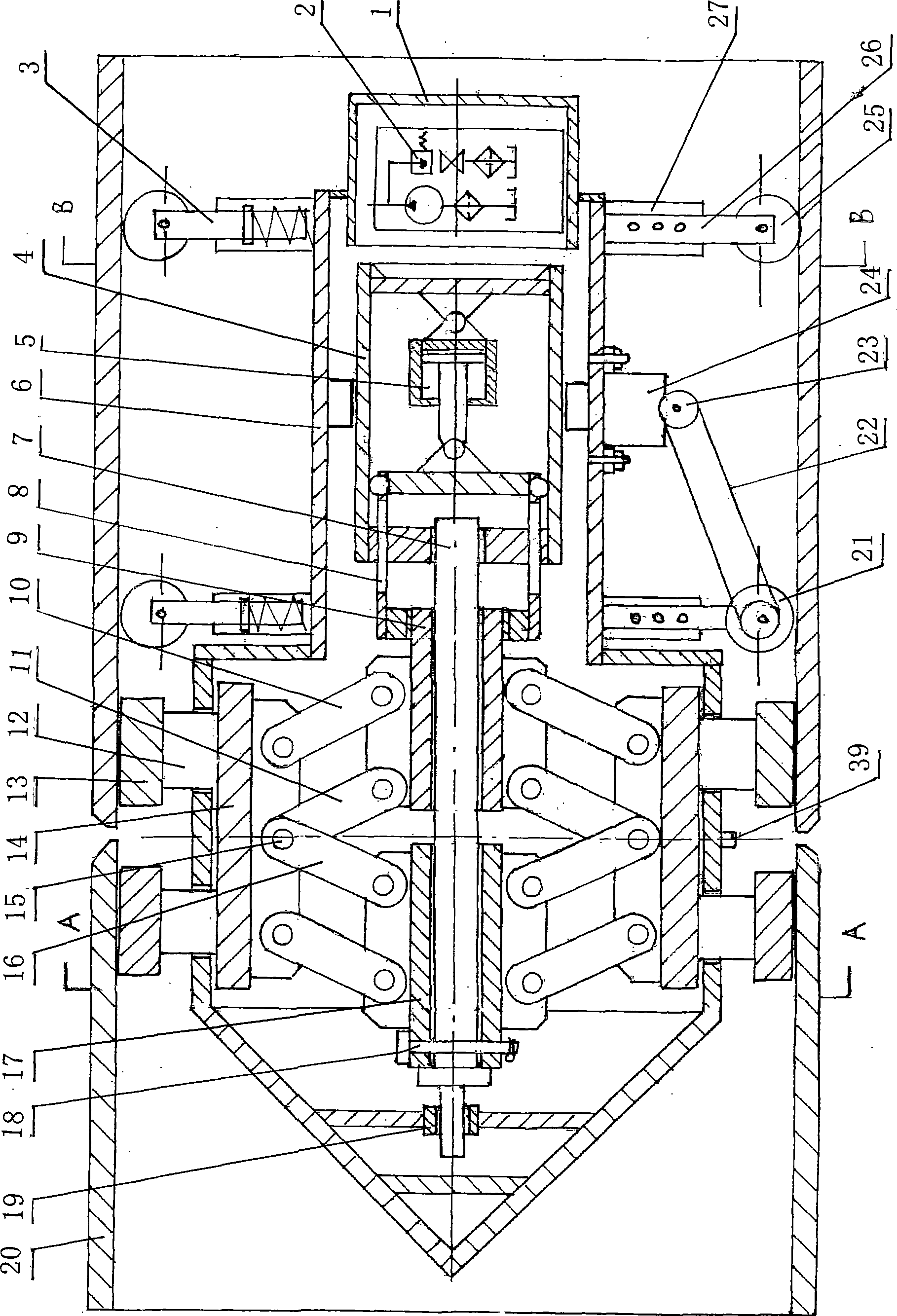

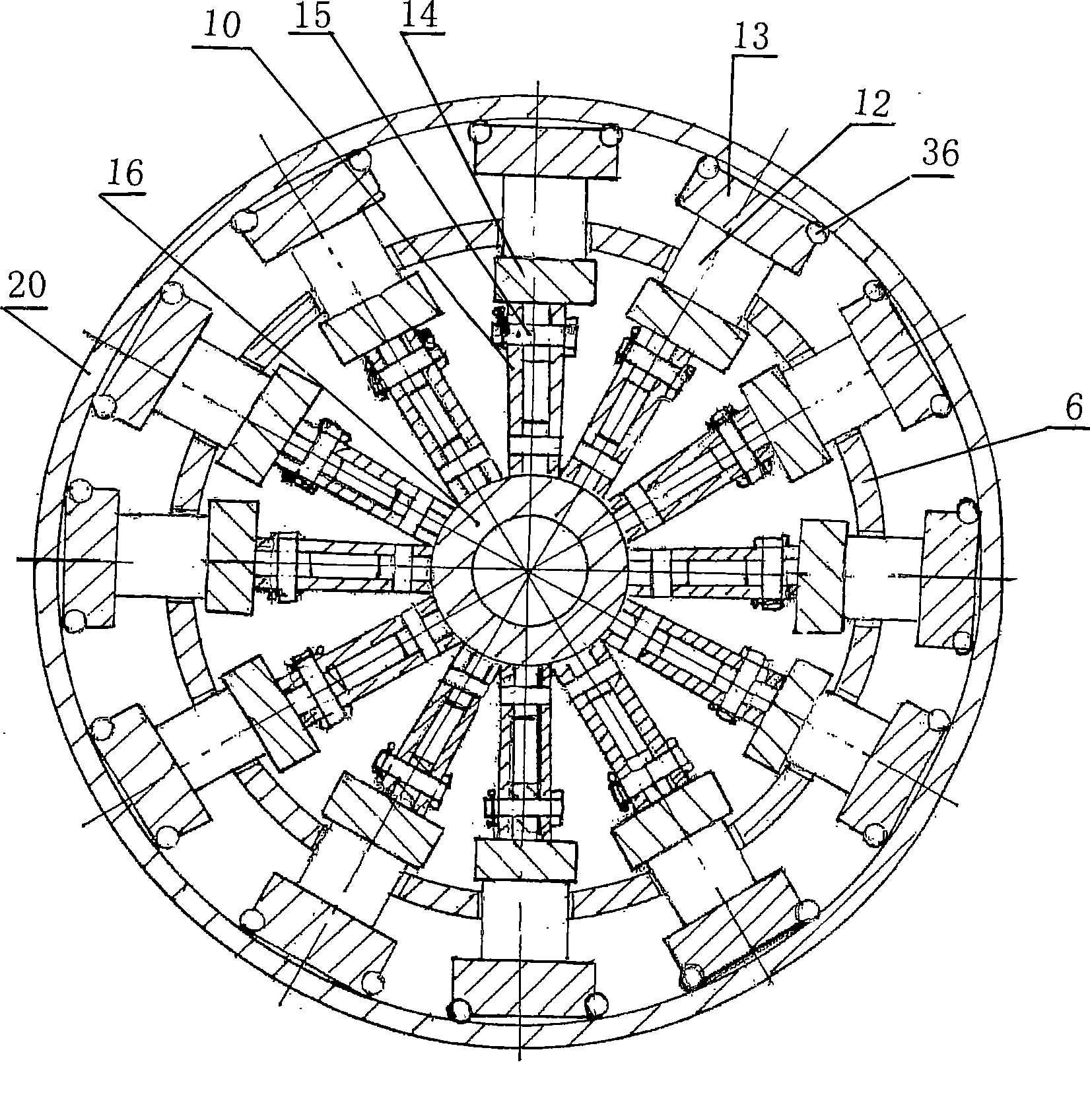

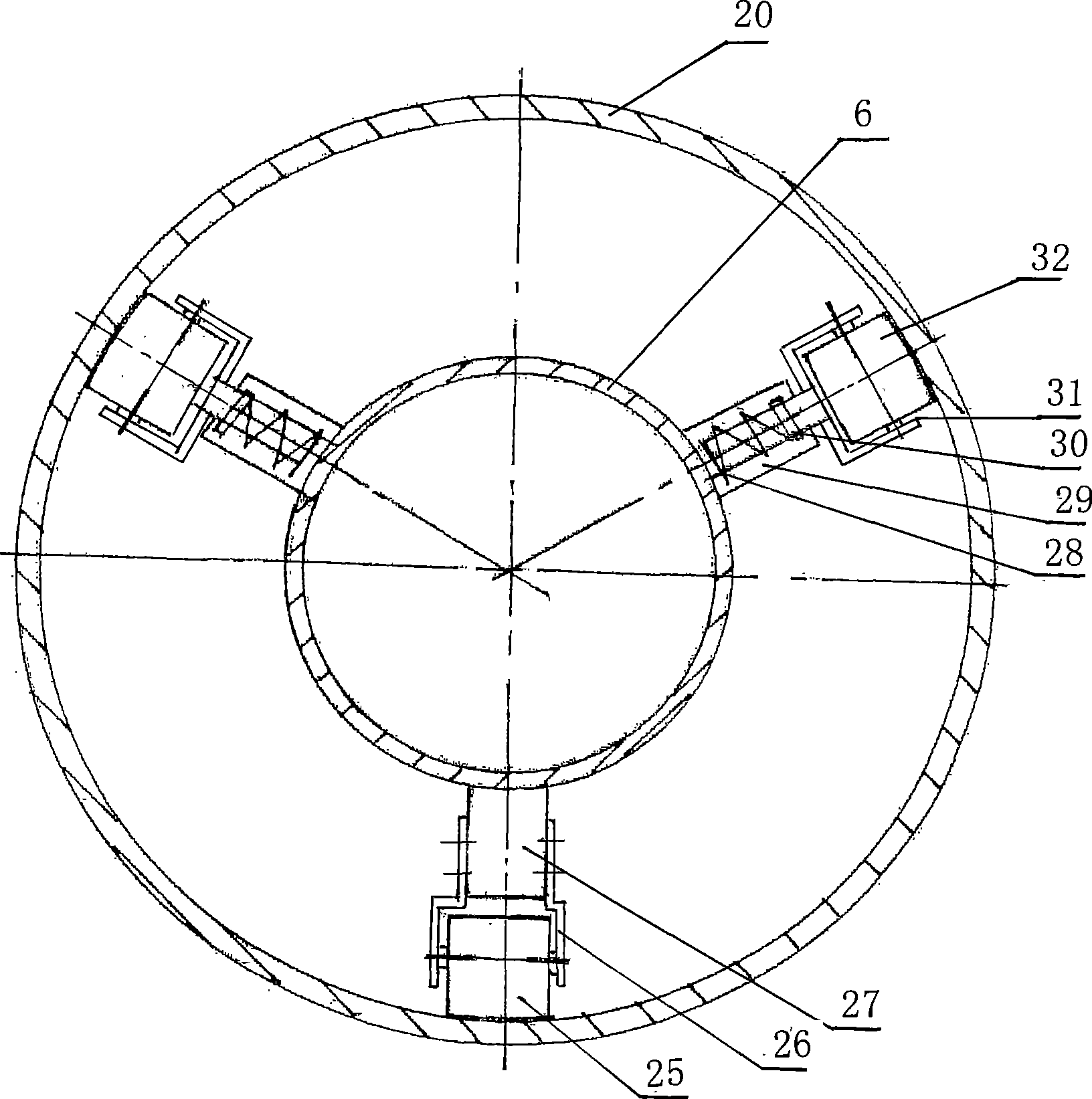

[0036] Embodiment 1: Taking a hydraulic pipe internal counterpart that can be applied to a welded pipe with an inner diameter of 711 mm as an example, further description will be given in conjunction with the accompanying drawings.

[0037] refer to figure 1 . The structure of the housing 6 is a cylinder welded by stepped steel plates, and the rear portion of the housing 6 is a cylinder with an internal diameter of 300 mm and a length of 700 mm. The front portion of the housing 6 is a cylinder with an internal diameter of 680 mm and a length of 400 mm. The front end of the large diameter cylinder is welded into a cone shape. It is composed of welded steel plates with a thickness of 8 mm, a hydraulic power station part, a sliding mechanism, an expanding mechanism, and a walking and righting mechanism.

[0038] In the rear end of the housing 6 there is a cylinder cover 4 , and the cylinder cover 4 can slide in the housing 6 . A hydraulic cylinder 5 is arranged in the hydraul...

Embodiment 2

[0050] Embodiment 2: The difference from Embodiment 1 is that 24 pin plates 37 are fixed on the outer walls of the rear sliding sleeve 9 and the front sliding sleeve 17, and the number of expansion mechanisms is 24.

Embodiment 3

[0051] Embodiment 3: The difference from Embodiment 1 is that 36 pin plates 37 are fixed on the outer walls of the rear sliding sleeve 9 and the front sliding sleeve 17, and the number of expansion mechanisms is 36.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com