Scrapping plate conveyor dynamic straightening method based on absolute motion trajectory of coal cutter

A scraper conveyor, absolute motion technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

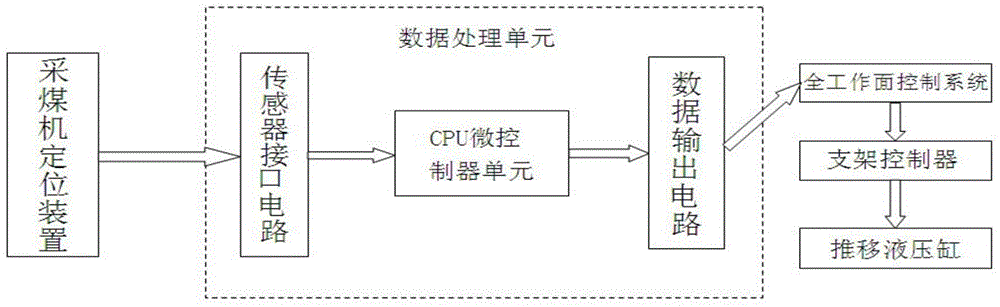

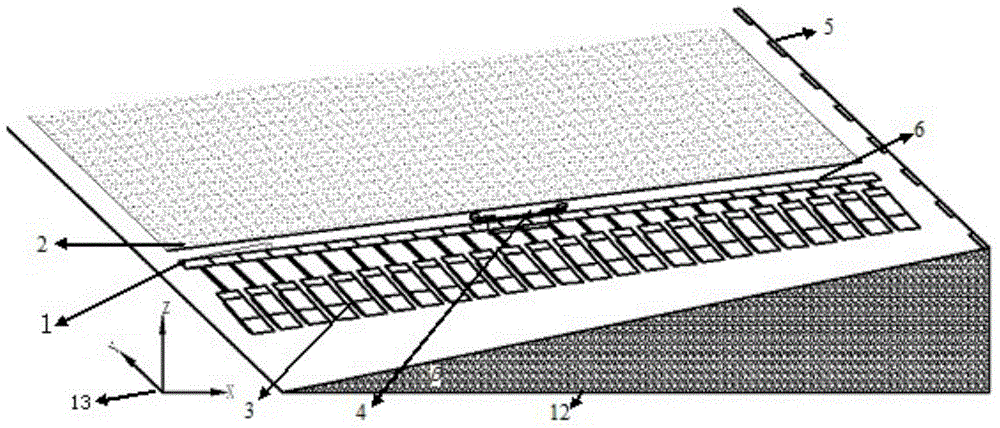

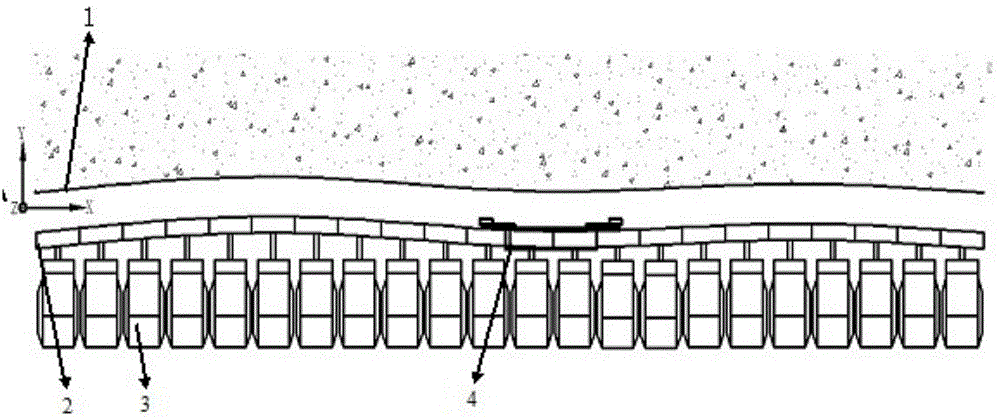

[0033]Embodiment 1: The straightening method includes: a dynamic straightening method of the scraper conveyor in the fully mechanized mining face and a dynamic straightening method of the scraper conveyor when the fully mechanized mining face is adjusted and tilted; using the positioning device installed on the shearer , monitor the running track of the shearer along the scraper conveyor in real time, analyze the dynamic position data of the shearer running along the scraper conveyor in the set space coordinate system by the signal processing circuit, and fit its The absolute motion trajectory curve under the geographic space coordinate system and the target reference trajectory 8 of this knife, and then the CPU microcontroller unit obtains the target trajectory 8′ of the next knife according to the target reference trajectory and the topographic conditions of the coal seam of the working face, and then calculates The moving distance of each hydraulic support. The CPU micro-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com