Light source packaging structure, and positioning and coupling method thereof

A packaging structure and grating coupler technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of inability to produce high-power light sources, low yield, and chip heat dissipation, and achieve optical passive alignment, Improved service life and compact package structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings.

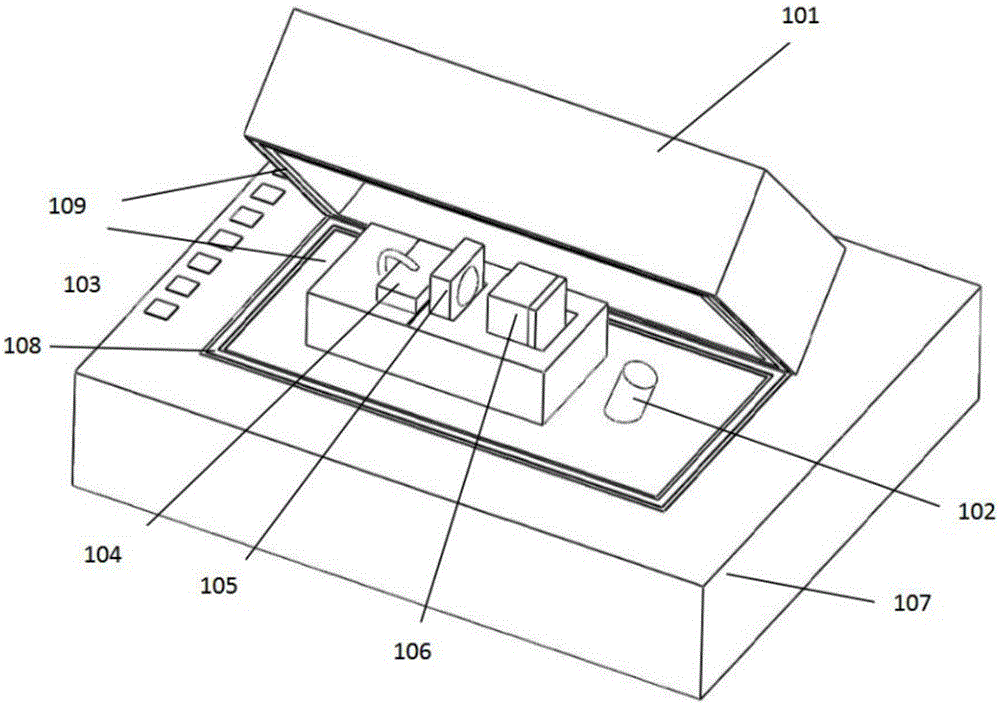

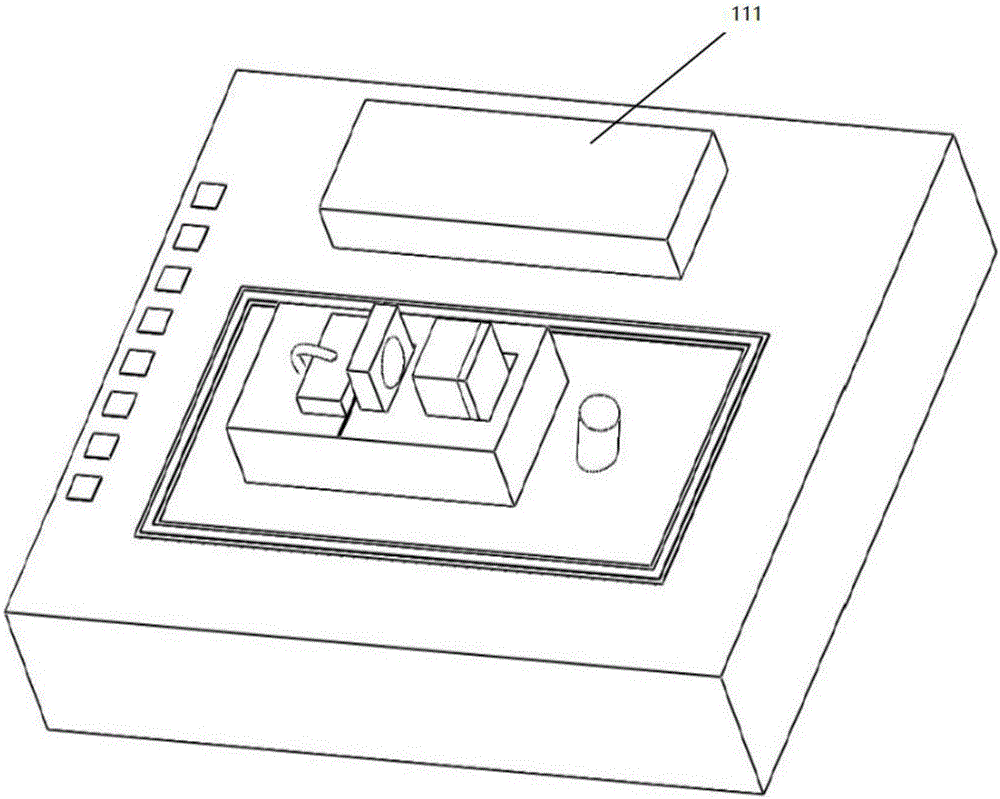

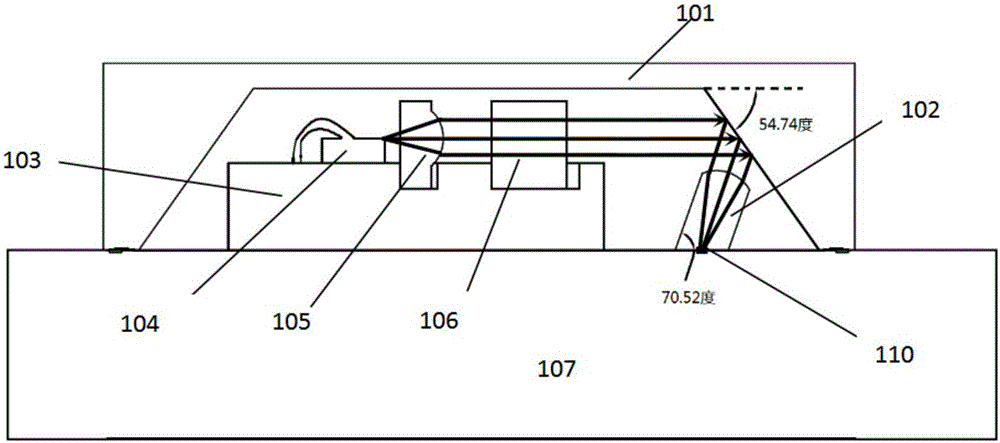

[0041]The device of the present invention includes a sealed box cover 101, a C lens 102, a silicon-based heat sink 103, a laser chip 104, a collimator lens 105, an isolator assembly 106, and a silicon photonic chip 107; wherein, the laser chip 104, the collimator lens 105, the isolation The device assembly 106 is disposed on the silicon-based heat sink 103 , and the silicon-based heat sink 103 is disposed on the silicon photonics chip 107 . The silicon photonic chip 107 includes a grating coupler 110, the C lens 102 is bonded on the silicon photonic chip 107 by ultraviolet glue and aligned with the grating coupler 110, the convex side of the C lens 102 is upward, and the lower surface bonded to the silicon photonic chip 107 is polished The angle is 70.52 degrees; the silicon light chip 107 is provided with a square gold-plated layer 108 on the periphery of the silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com