Micro lens and optical waveguide power divider integrated component and manufacturing method thereof

A technology of integrated components and manufacturing methods, applied in the field of micro-optical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings .

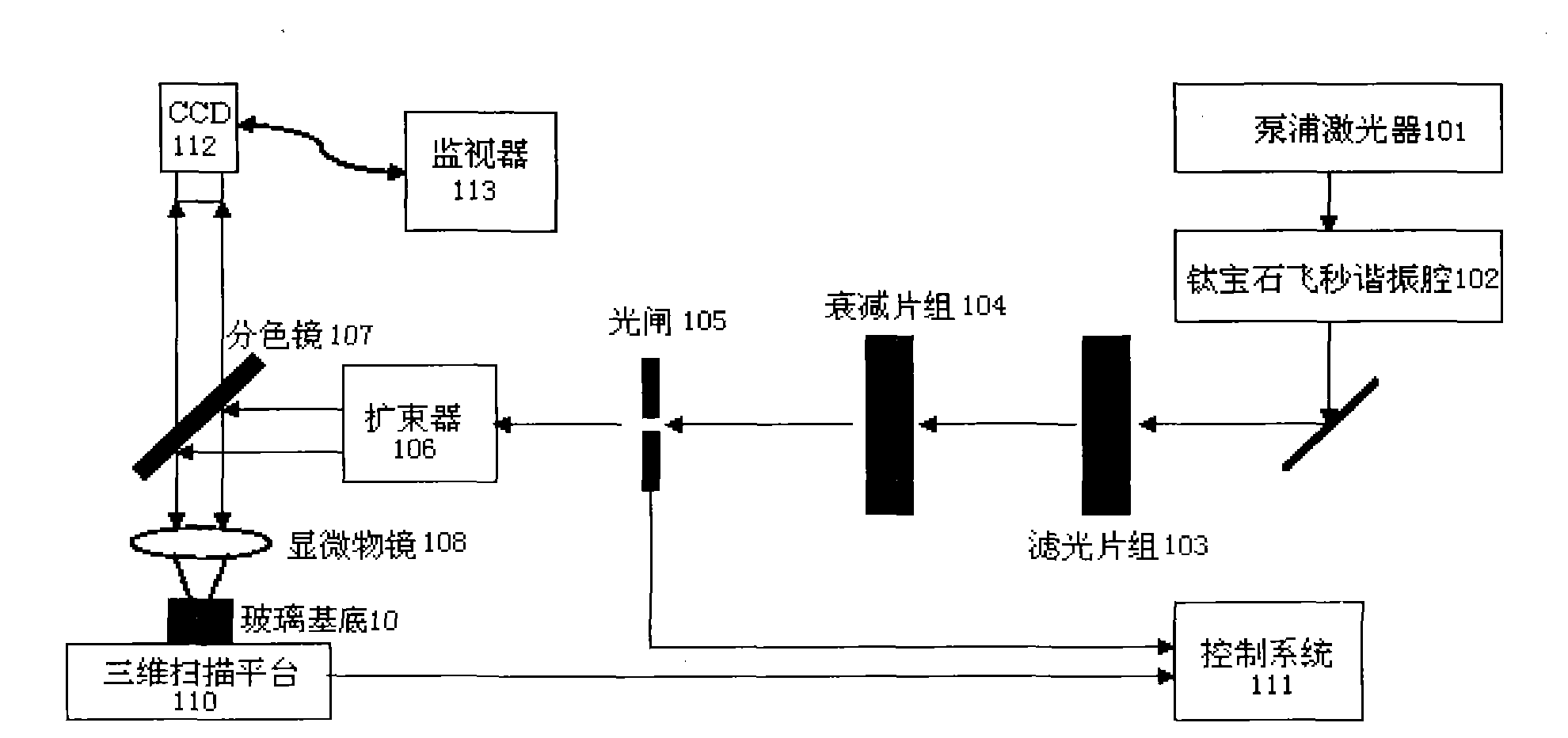

[0028] figure 1 In the embodiment of the present invention, it is used to manufacture the femtosecond laser control system of the microlens and optical waveguide power divider integrated component of the present invention. Among them, the pump laser 101 and the Ti:Sapphire femtosecond resonator 102 are used to generate femtosecond laser pulses; the generated femtosecond laser has an output wavelength of 800nm, a pulse width of 50fs, a repetition rate of 10Hz, and a single pulse energy of 30mJ. The femtosecond laser passes through the filter set 103 and enters the attenuation plate set 104 for energy attenuati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com