Solder paste printing press and vision aligning method thereof

A solder paste printing machine and visual alignment technology, which is applied to printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of complex structure, high cost and long alignment time, and achieve low printing efficiency, The effect of low cost and long alignment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

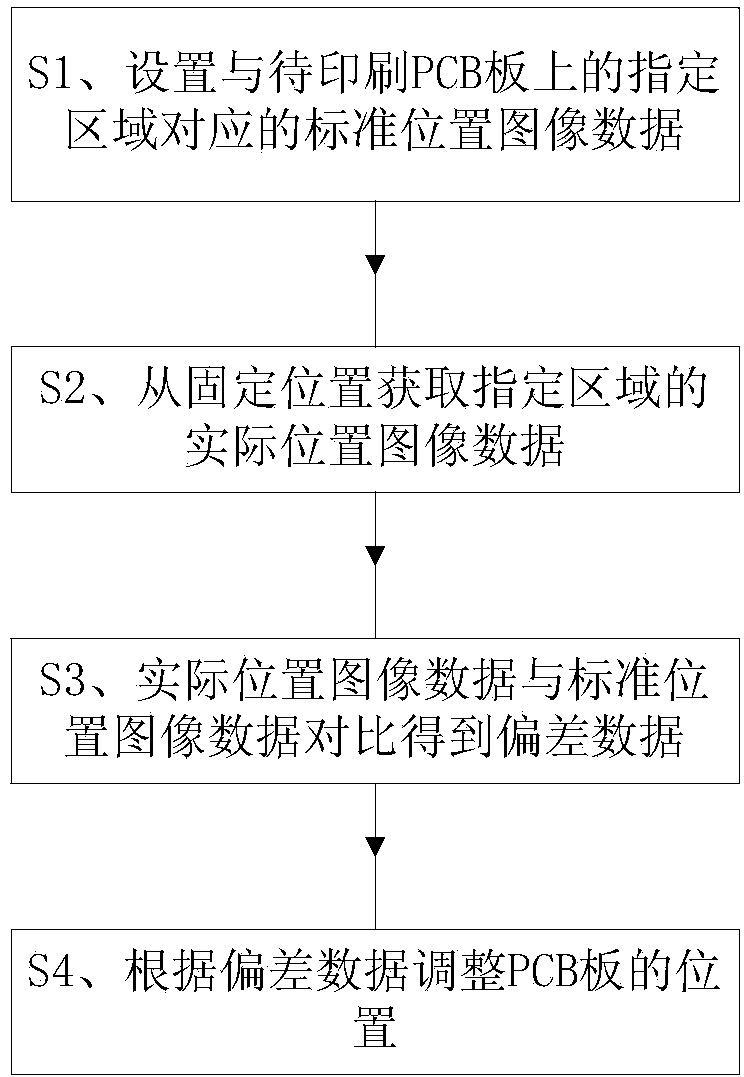

[0030] see figure 1 , a visual alignment method for a solder paste printing machine in this embodiment, comprising steps:

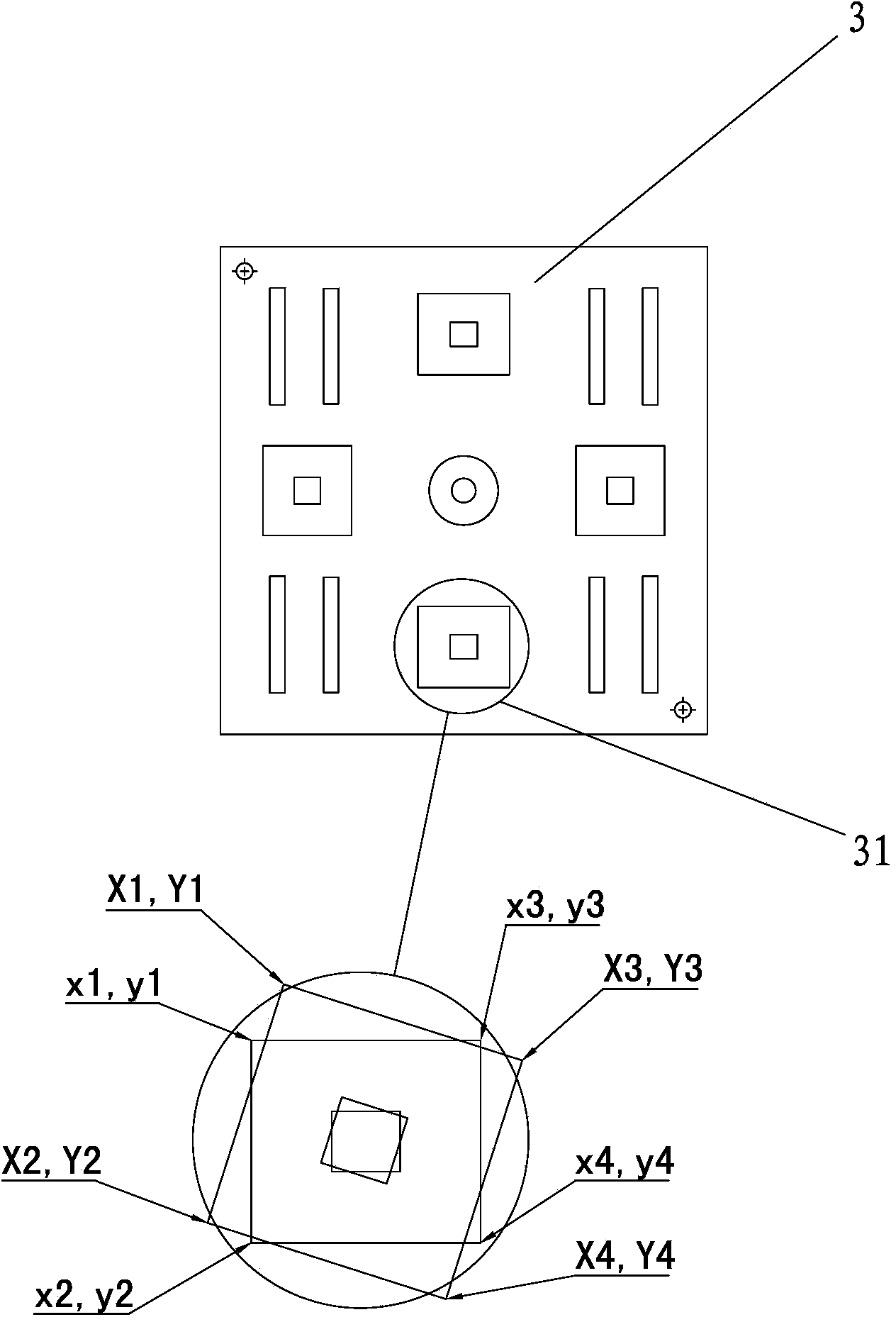

[0031] S1. Set the standard position image data corresponding to the designated area on the PCB board to be printed. Any area can be designated as the designated area. Generally, a certain pad will be designated as the designated area;

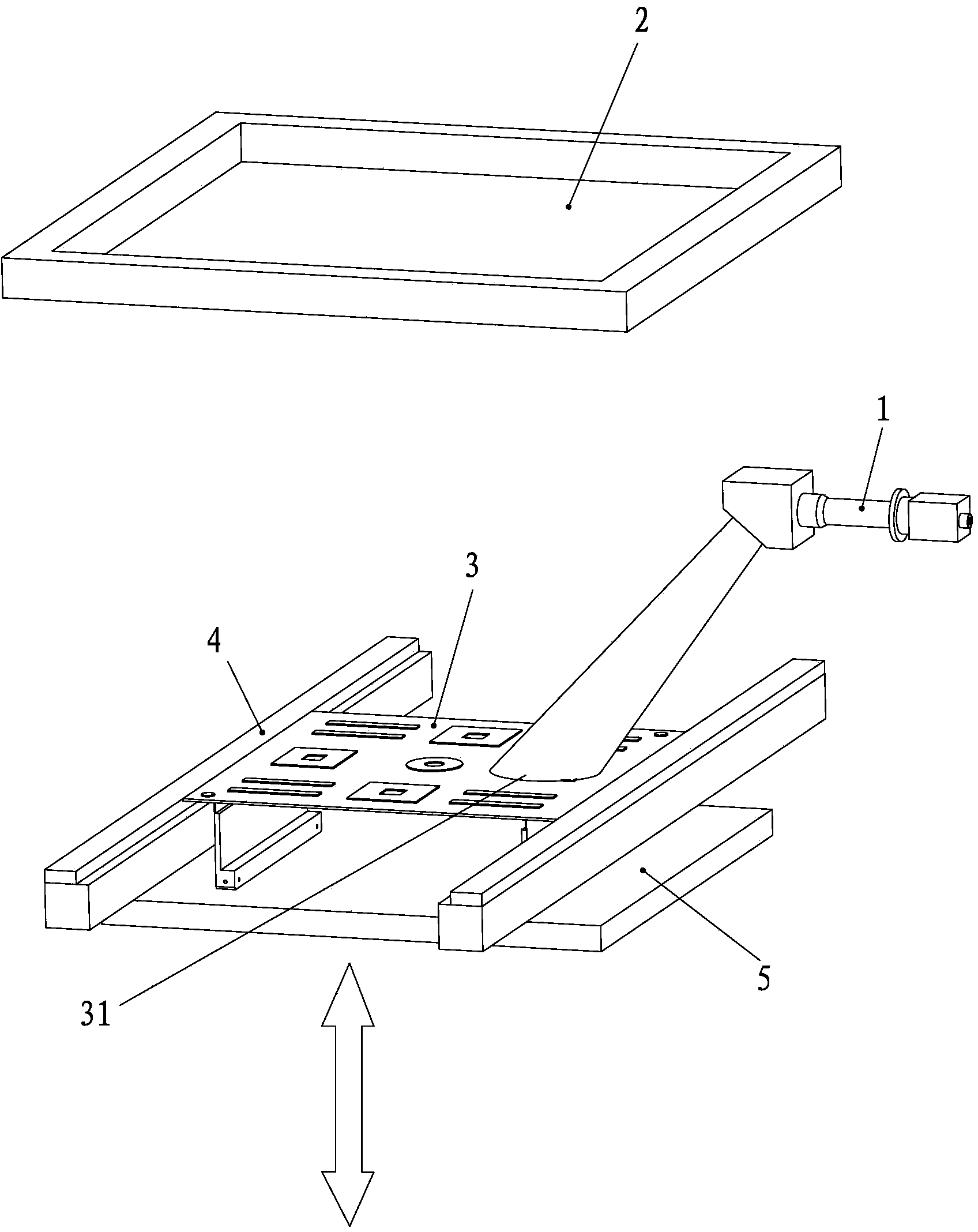

[0032] S2, obtain the actual position image data of the specified area on the PCB board to be printed from the fixed position, because the image data of the specified area is obtained from the fixed position, so the acquisition equipment such as the CCD camera that collects the image data can be fixed, so can Quickly and accurately collect the image data of the actual position, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com