3D printer

A 3D printer and driving motor technology, applied in the field of 3D printing, can solve the problems of poor structure of the finished product, inability to print, slippage of the feeding device, etc., and achieve the effect of fast heating efficiency, improved printing effect, and molding standard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

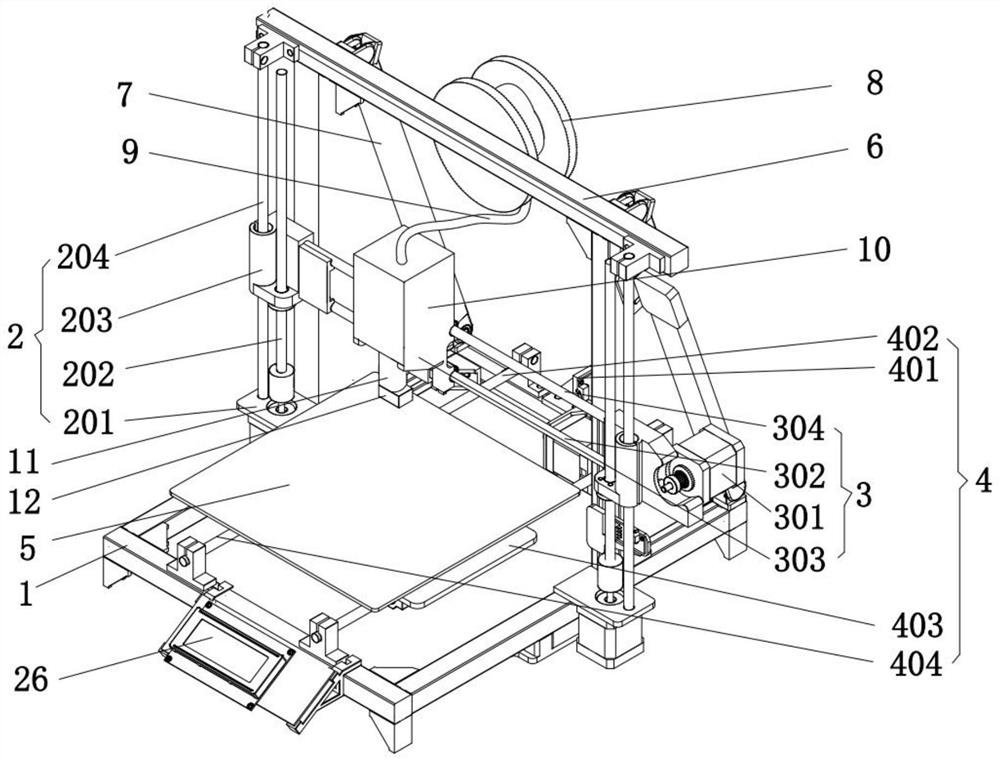

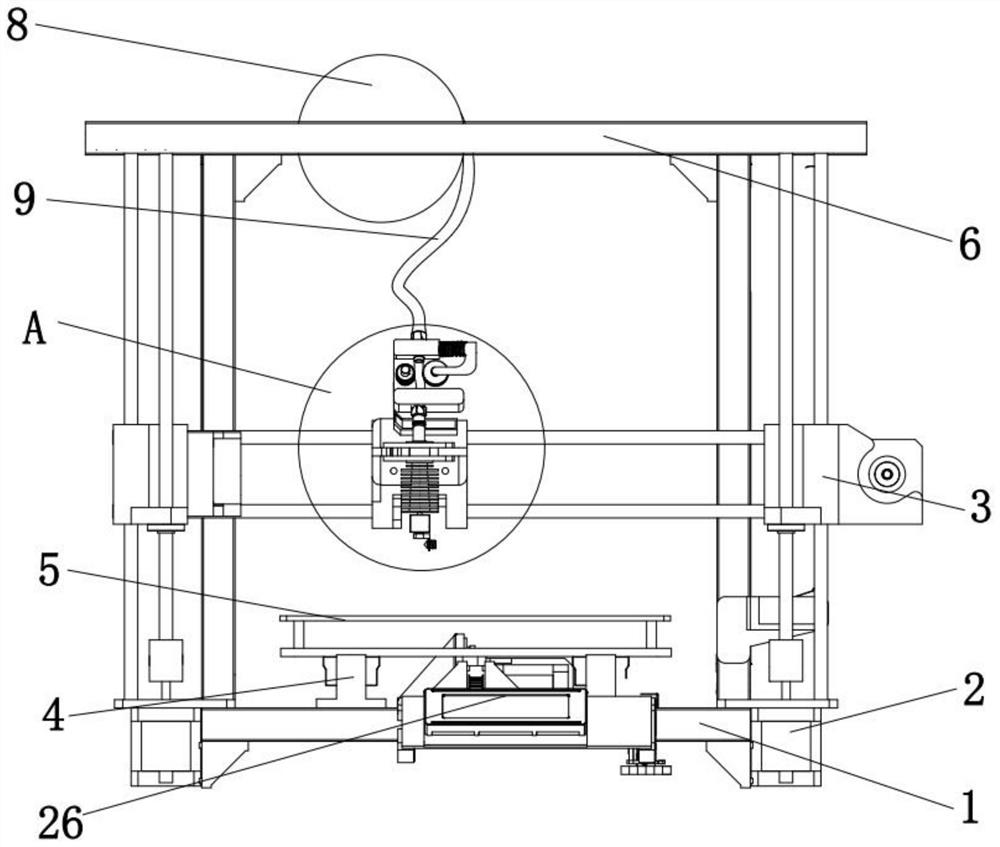

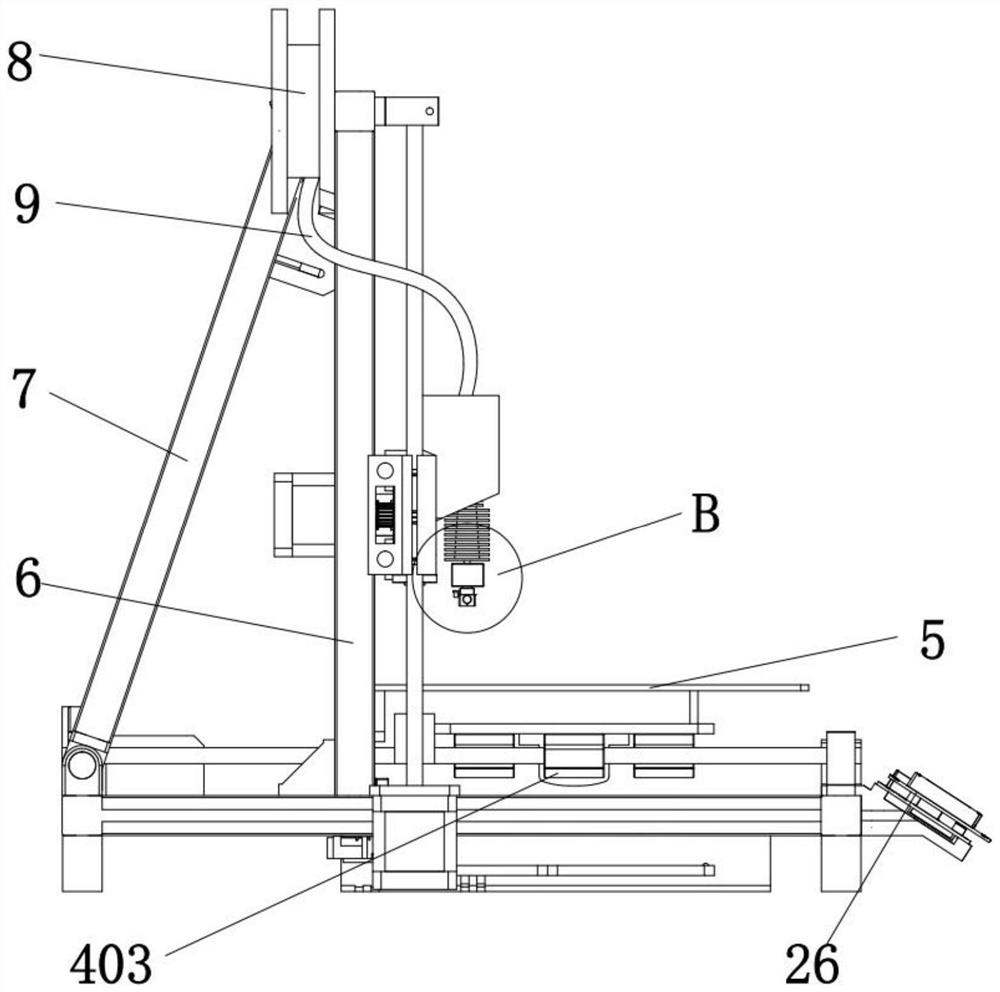

[0024] First Example: Combining Figure 1-3 , the present embodiment provides a 3D printer, comprising a base plate 1, a controller 26 is provided on one side of the base plate 1, and the controller 26 electrically controls each electrical component, a bracket 6 is provided on the top of the base plate 1, and the connection between the base plate 1 and the bracket 6 Reinforcing ribs 7 are provided between them, and the reinforcing ribs 7 are used to strengthen the strength of the whole device and prevent the bracket 6 from being bent and damaged. The opposite sides of the bottom plate 1 are provided with a Z-direction power device 2, and the outer surface of the Z-direction power device 2 is slidingly connected. There is an X-direction power device 3, the outer surface of the X-direction power device 3 is slidingly connected with a feeding device 10, the top of the bottom plate 1 is provided with a Y-direction power device 4, and the outer surface of the Y-direction power devic...

no. 2 example

[0032] Based on the first embodiment, there will be defects or knots in the material filament 9 during actual printing. When the material filament 9 is defective, the feeding device 10 will slip and cannot feed further. Similarly, when the material filament 9 is knotted, the feeding device 10 will 10, there will be a blockage, and it is also impossible to feed further; and there will be a printing gap during printing. This position requires that the nozzle 12 does not discharge. If only the feeding device 10 does not feed or return the material, there will still be part of the melted material. The filament 9 flows out from the nozzle 12 to cause wire drawing. Excessive wire drawing will affect the printing quality, reduce the printing effect, and increase the difficulty of repeated corrections. In addition, the nozzle 12 will inevitably be blocked during the printing process for a long time, resulting in insufficient output from the nozzle 12. Uniformity, reduce the printing ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com