Patents

Literature

33results about How to "Alignment speed is fast" patented technology

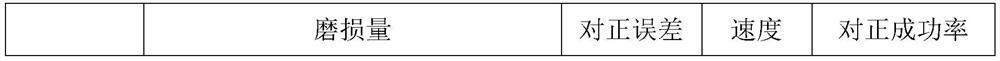

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

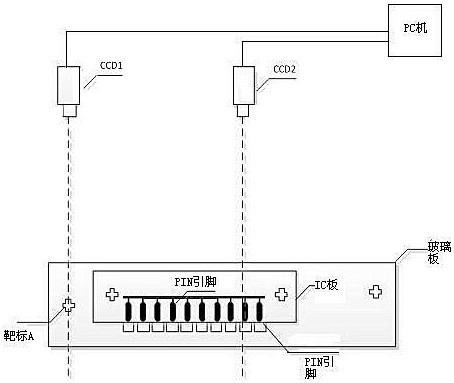

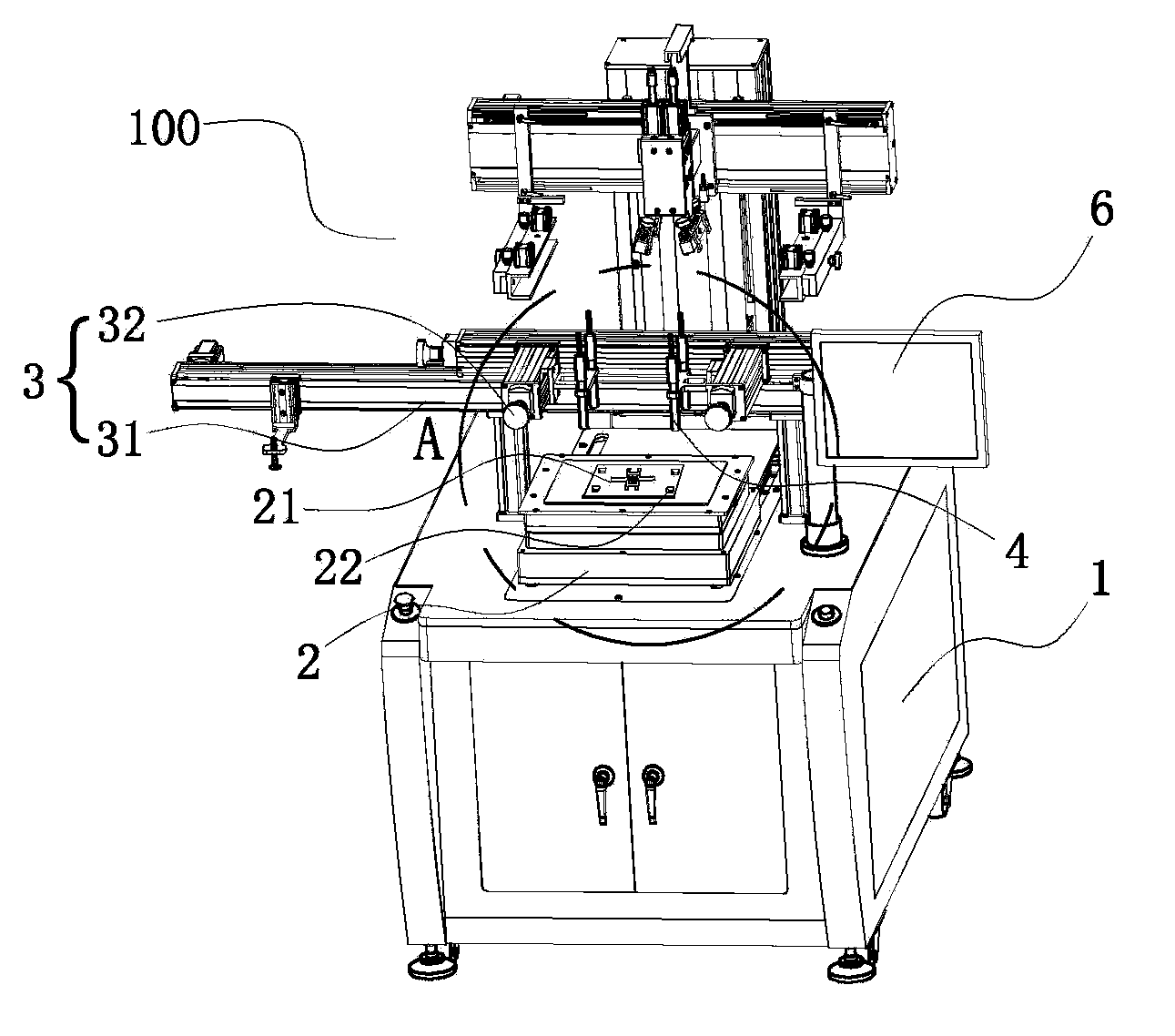

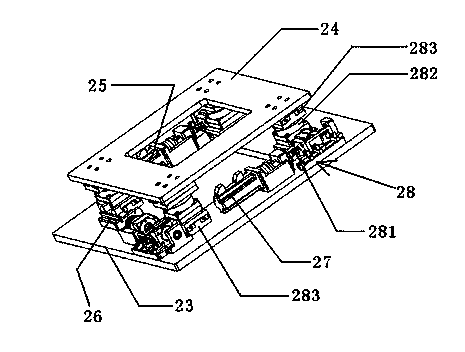

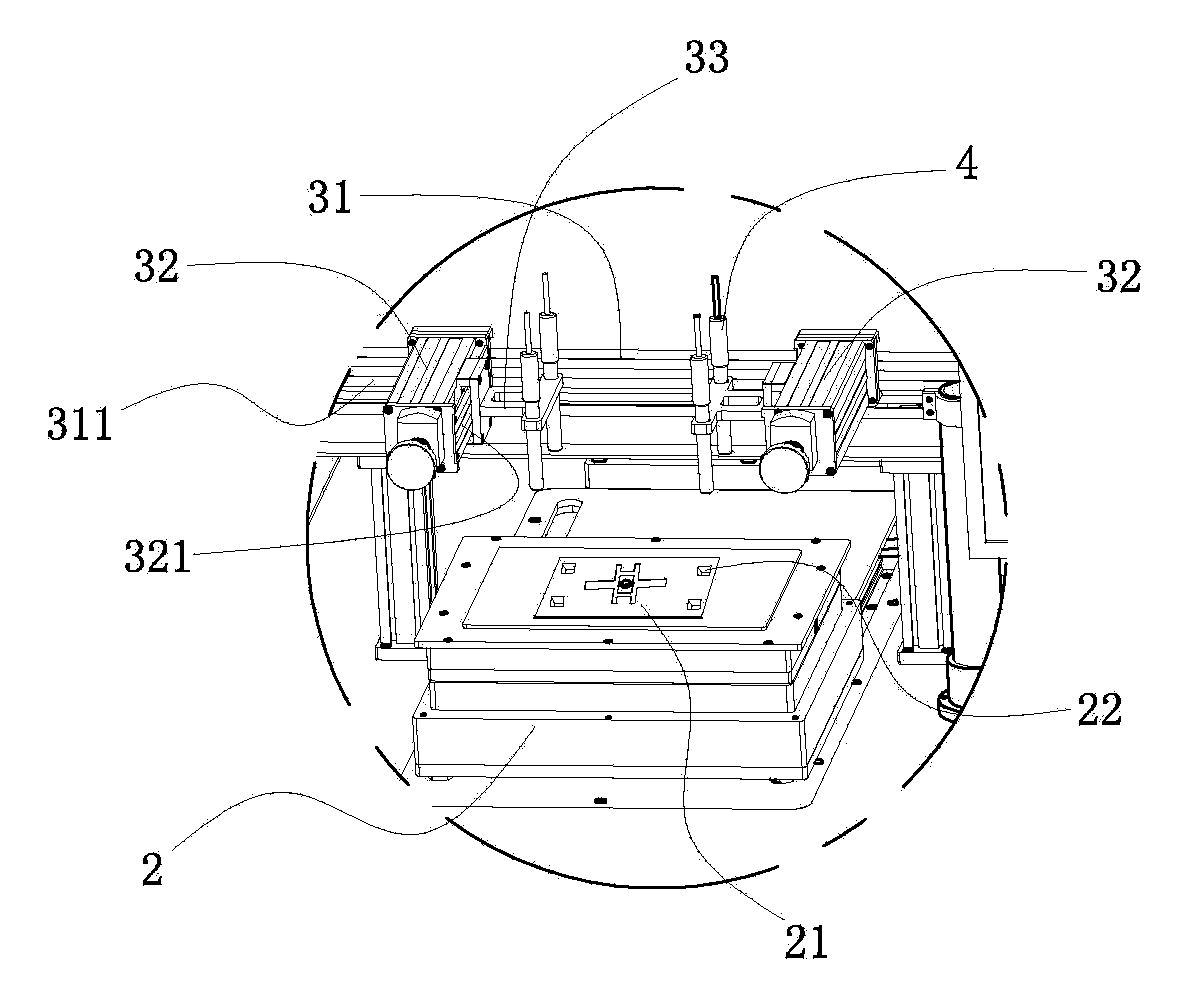

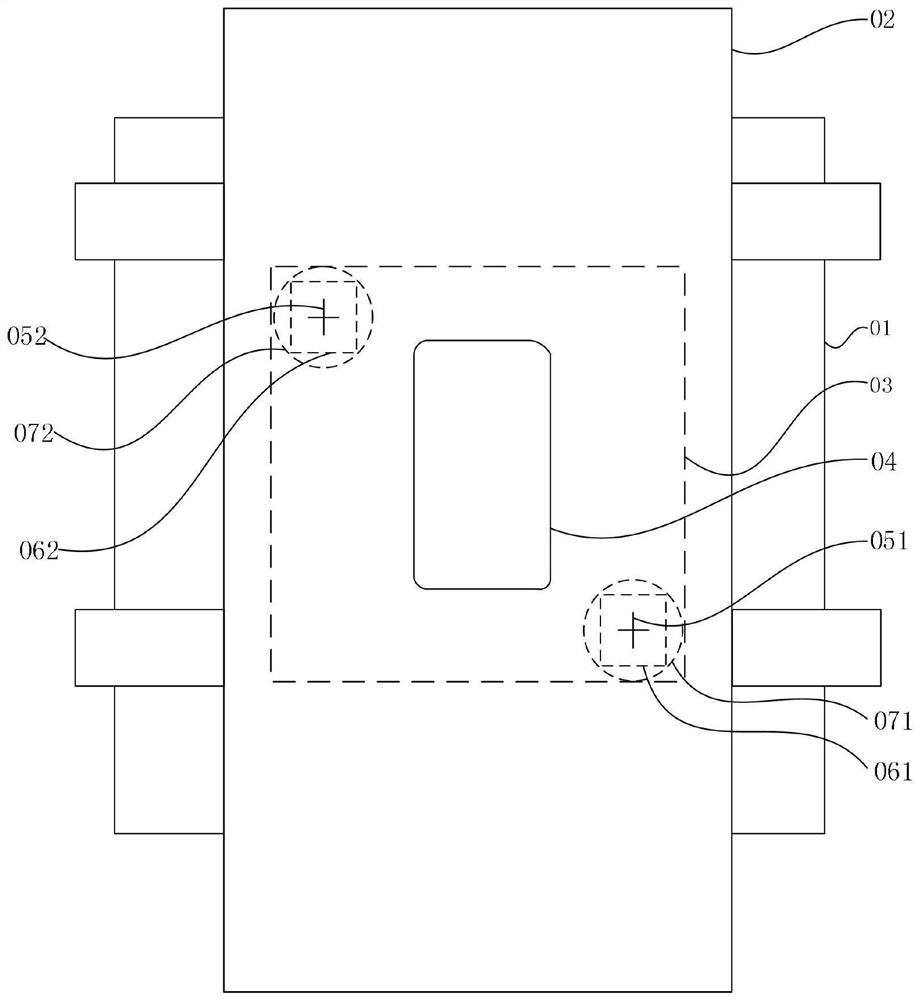

Screen printer and contraposition method for same

ActiveCN102615950AImprove resolutionImprove efficiencyScreen printersPrinting press partsCamera lensEngineering

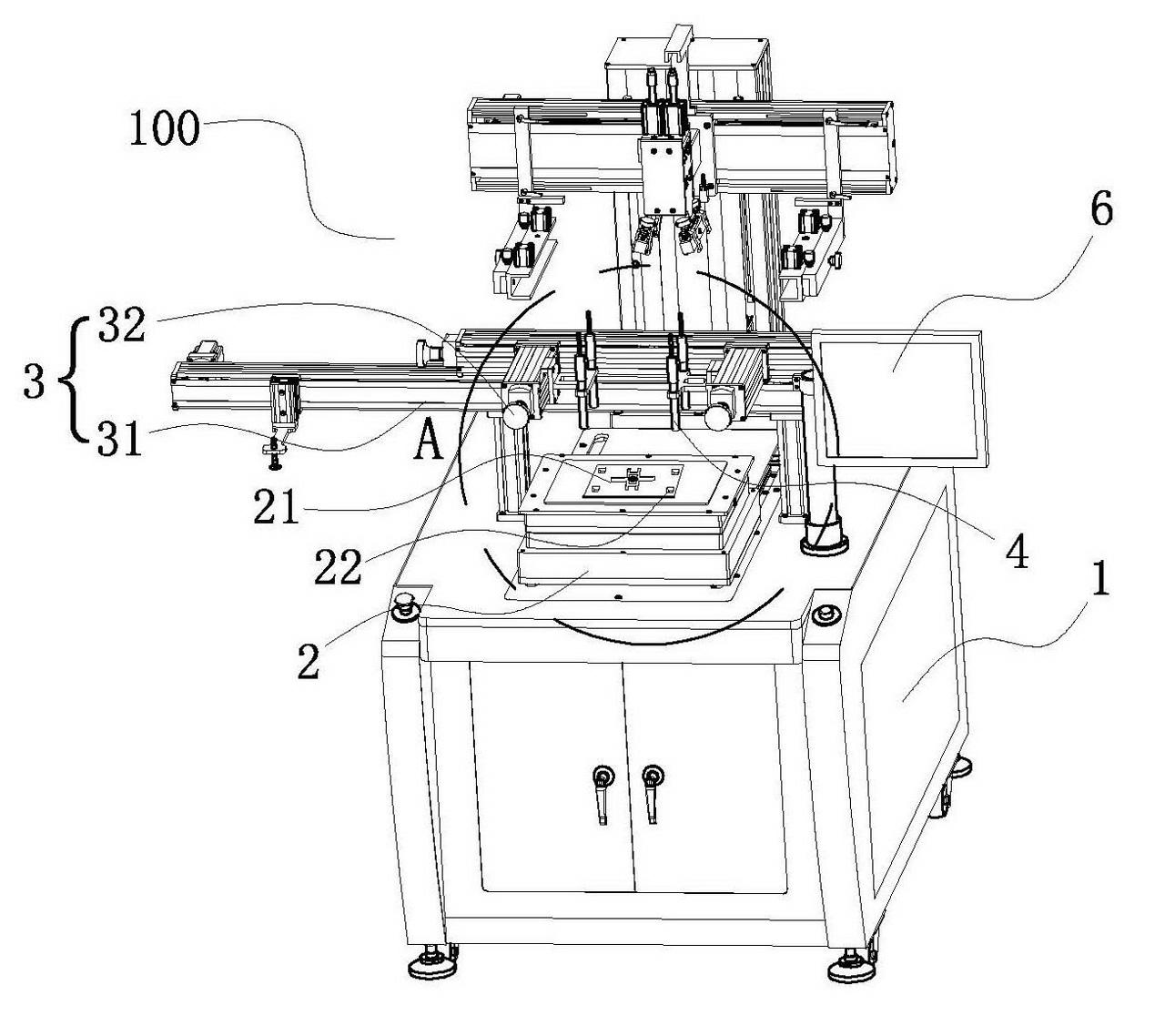

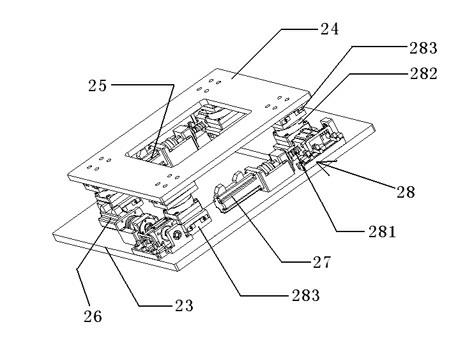

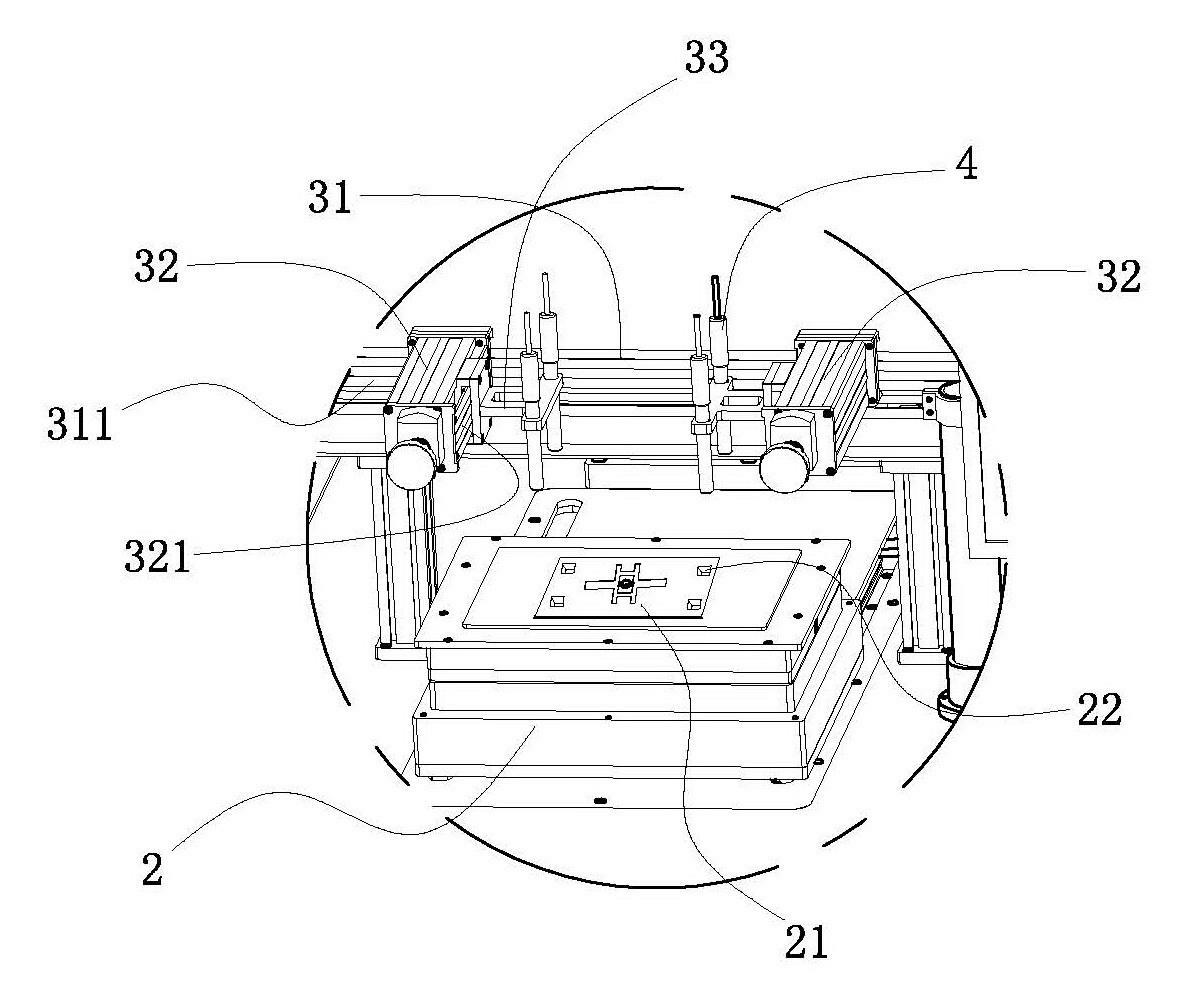

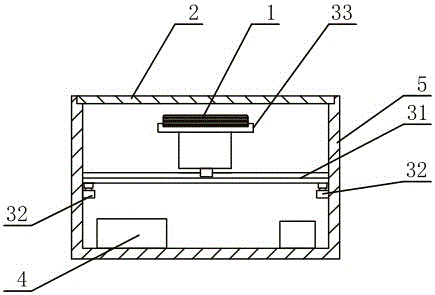

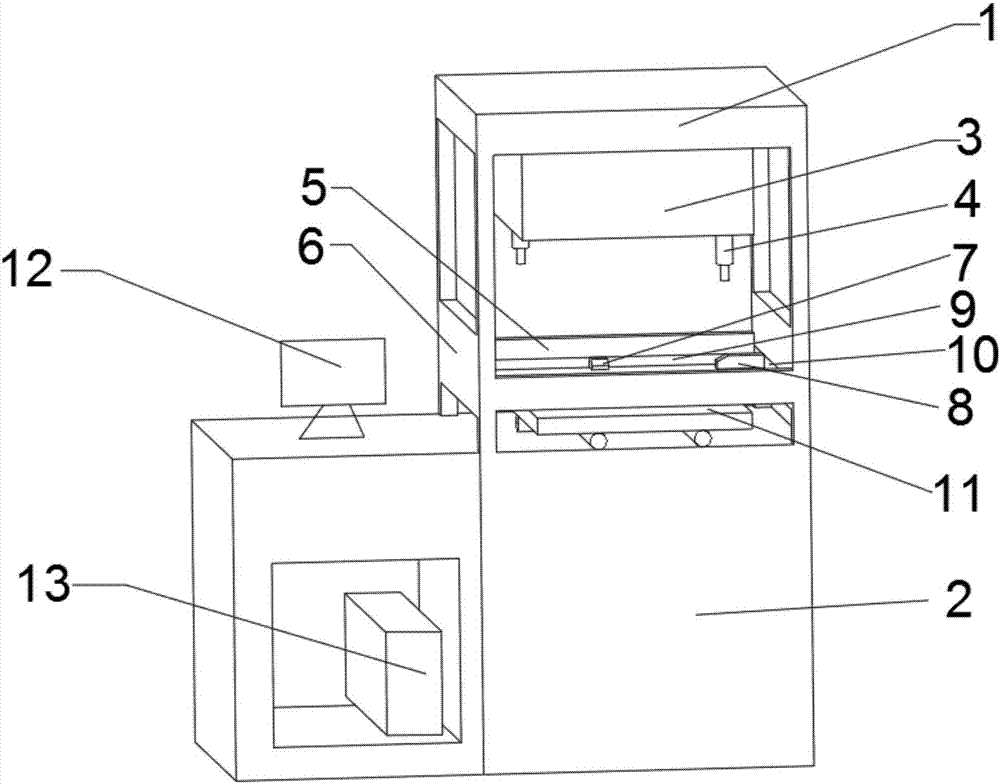

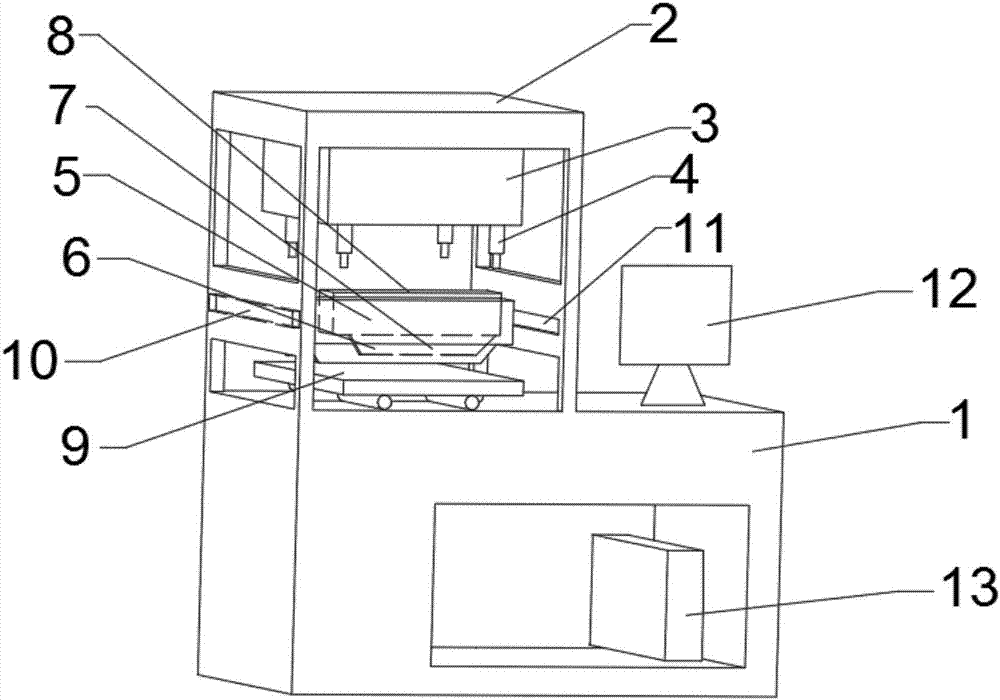

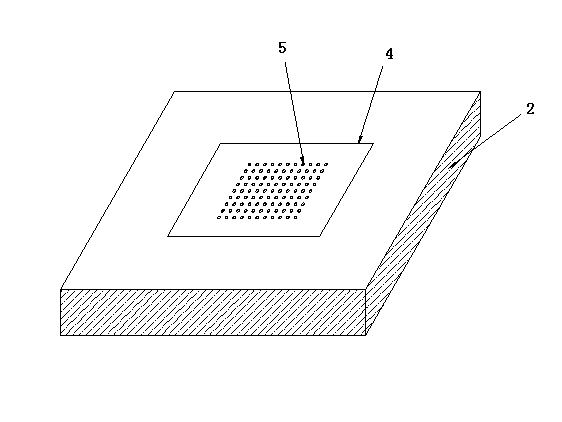

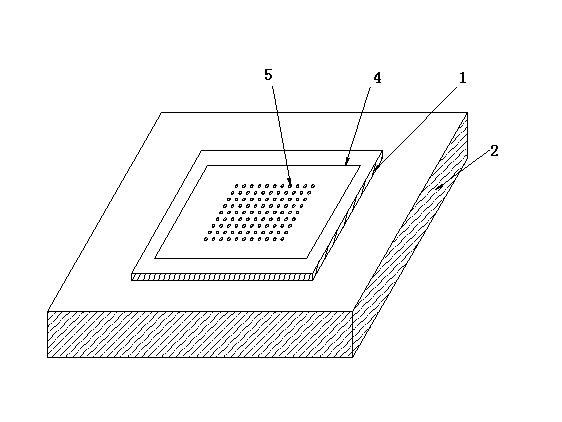

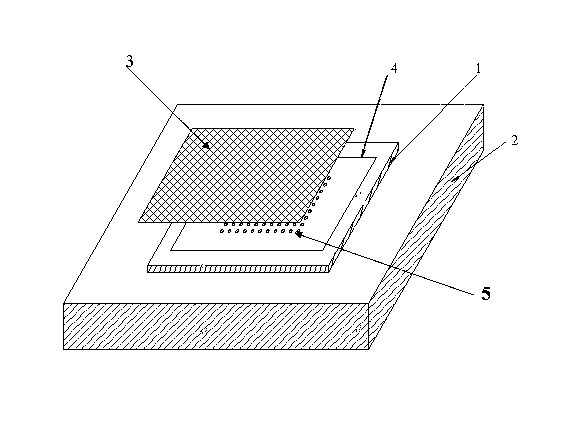

The invention discloses a screen printer and a contraposition method for the same. The screen printer comprises a screen printer body; the screen printer body is provided with a computer and an XYtheta platform, wherein the computer is electrically connected with the XYtheta platform and can drive the XYtheta platform to move in the X-axis direction, the Y-axis direction and the theta-axis direction; a to-be-printed product placing part is arranged on the upper side of the XYtheta platform; the screen printer body further comprises a light source, a bracket and at least two CCD cameras, wherein the light source is arranged in the XYtheta platform; a light transmitting hole is formed on the edge of the to-be-printed product placing part on the XYtheta platform; the CCD cameras are mounted on the bracket; the camera shots of the two CCD cameras just face the light transmitting hole to enable light emitted by the light source to transmit the light transmission hole to reach the camera shots of the two CCD cameras; and signal output ends of the two CCD cameras are electrically connected with the computer. The two CCD cameras are adopted to conduct the contraposition. The screen printer has the advantages of simple structure, easiness in manufacturing, high contraposition speed and accuracy in contraposition.

Owner:东莞市嘉腾仪器仪表有限公司

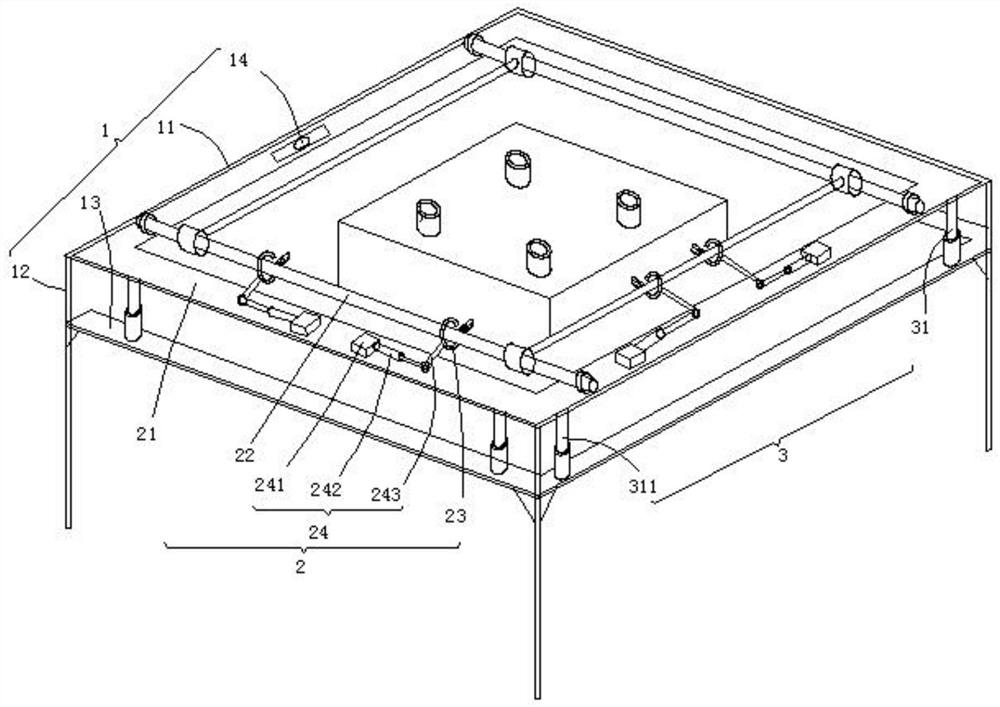

Wireless charging coil alignment method, wireless charging device and charging method of unmanned aerial vehicle

ActiveCN106655395AAlignment speed is fastAccurate alignment speedBatteries circuit arrangementsSecondary cells charging/dischargingInductive chargingFixed position

The invention provides a wireless charging coil alignment method, a wireless charging device and a charging method of an unmanned aerial vehicle, and relates to the technical field of wireless charging. The wireless charging coil alignment method comprises the following steps of arranging a touch control panel above a power delivery coil, and determining an initial orthographic projection position of the power delivery coil on the touch control panel; touching the touch control panel by using more than three touch pieces in a fixed position relation with a power receiving coil to acquire a position where a contact point of each touch piece and the touch control panel is located; calculating an orthographic projection position of the power receiving coil on the touch control panel according to the position where the contact point of each touch piece and the touch control panel is located and a position relation between the power receiving coil and each touch piece; and moving the power delivery coil and / or the power receiving coil so that the orthographic projection positions of the power delivery coil and the power receiving coil on the touch control panel are coincided and the alignment of the power delivery coil and the power receiving coil is completed. The wireless charging coil alignment method has the advantages of rapid coil alignment speed and accuracy and is particularly suitable for charging of the unmanned aerial vehicle.

Owner:HUNAN INST OF TECH

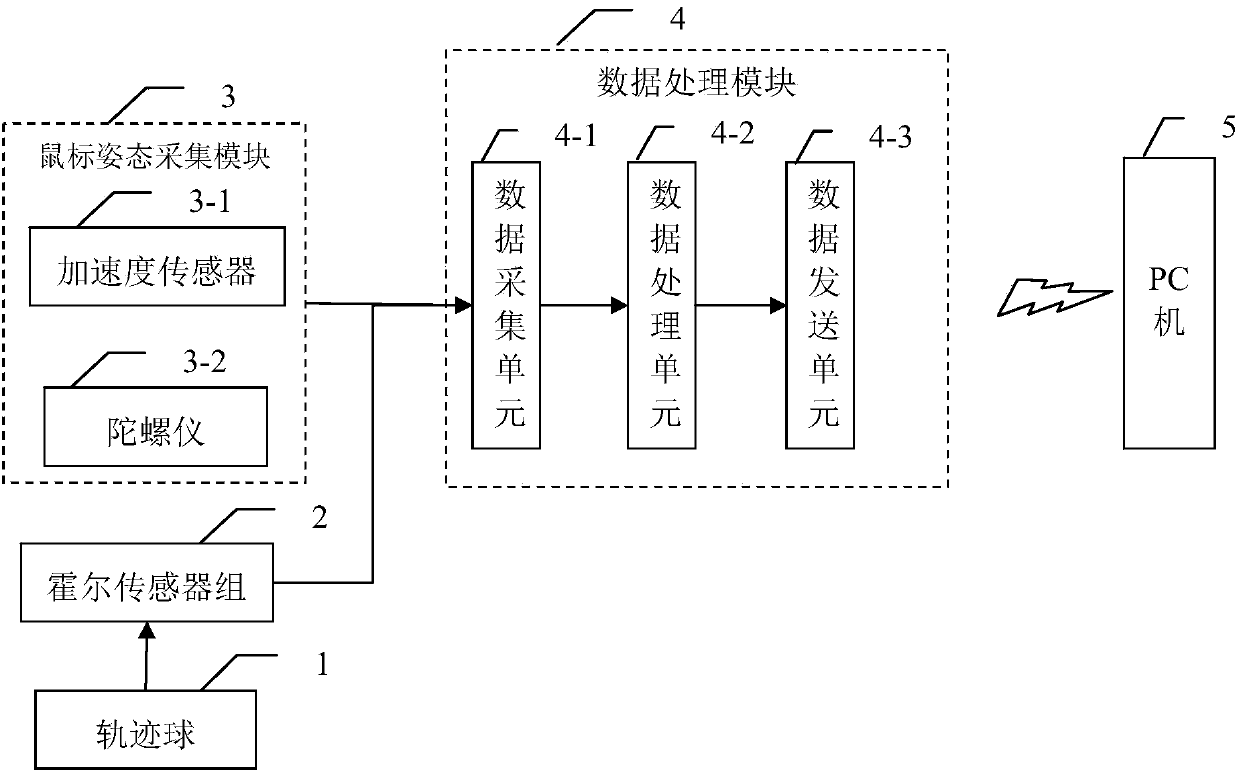

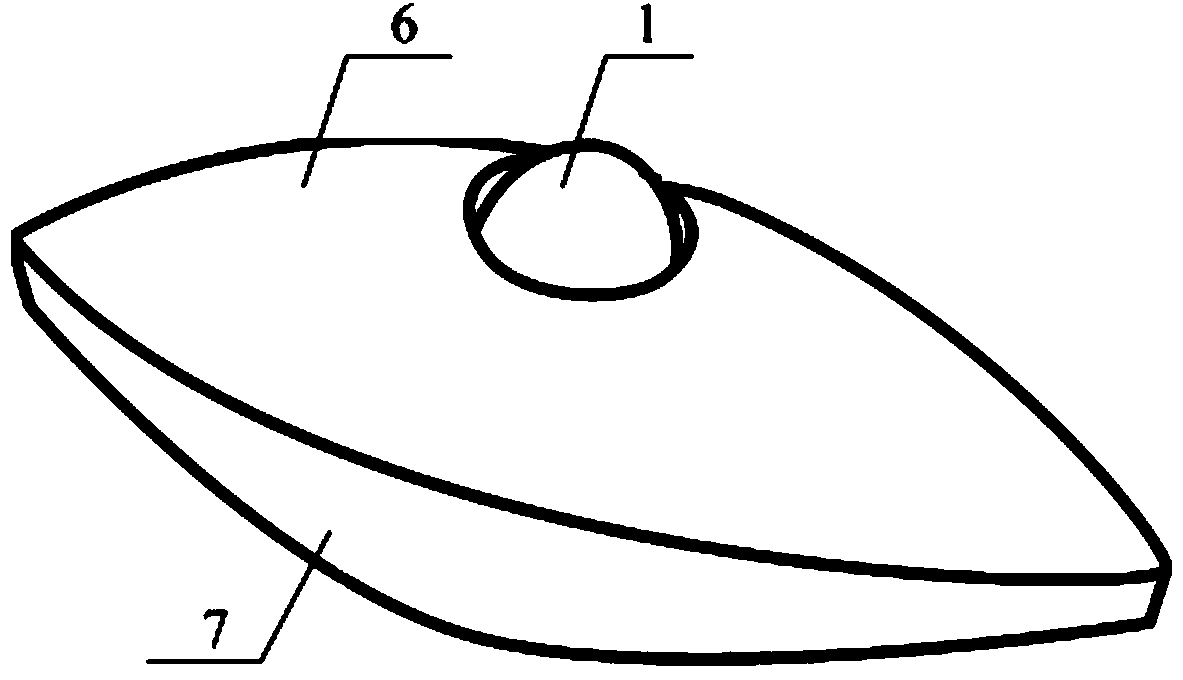

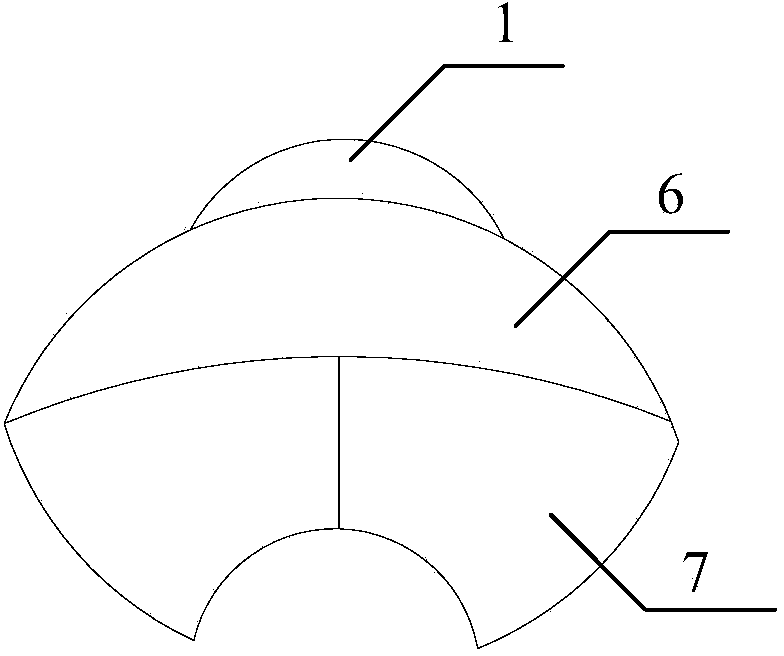

Space operation type mouse

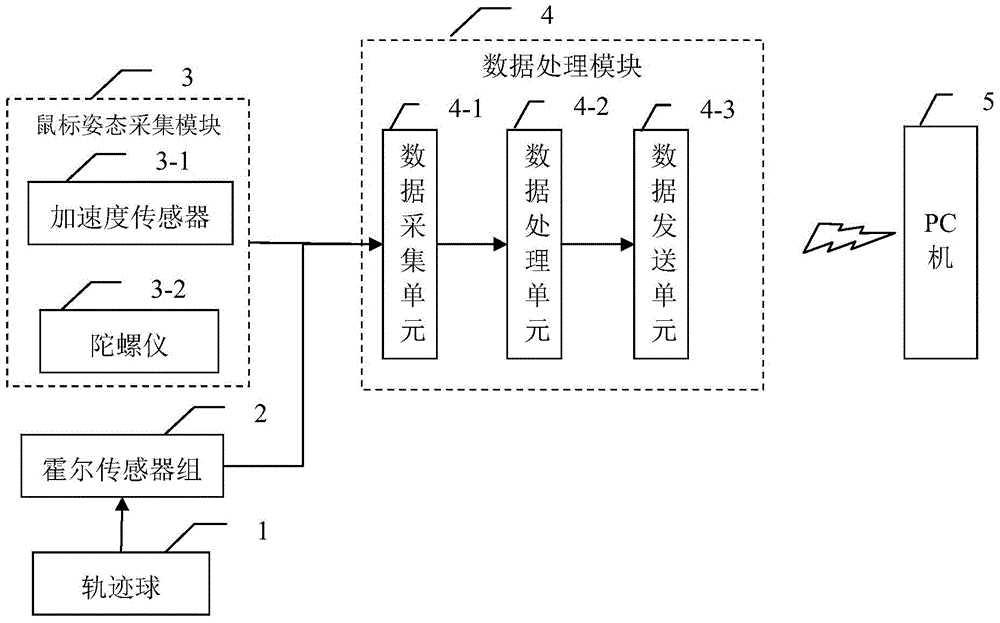

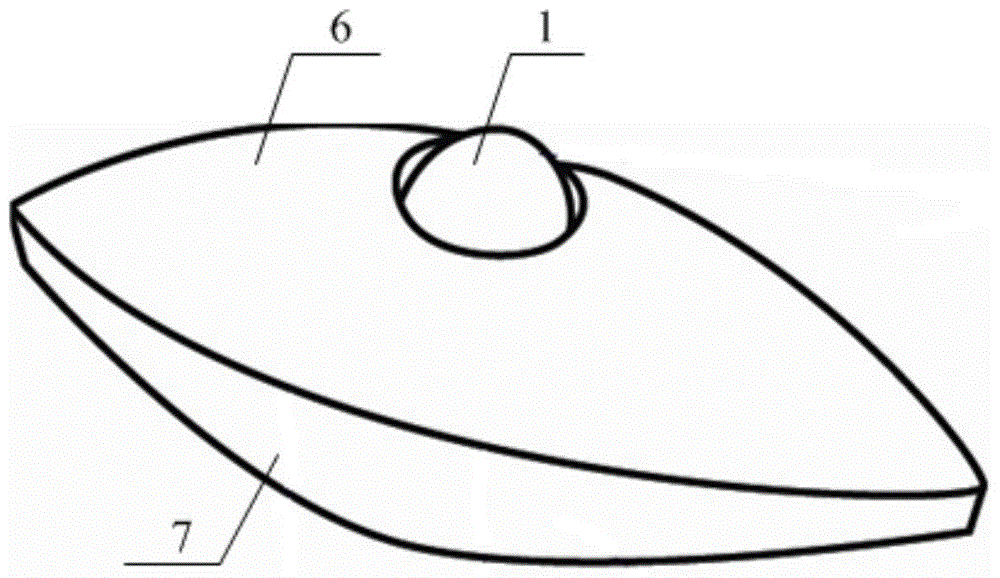

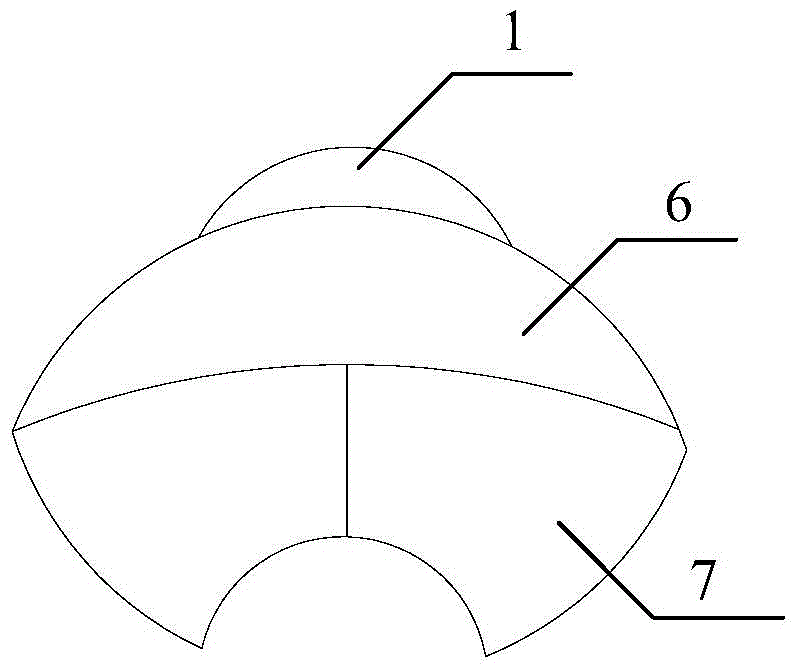

InactiveCN103955297APrecise positioningAlignment speed is fastInput/output processes for data processingDiseaseLow-pass filter

The invention provides a space operation type mouse, and relates to a mouse, which aims at solving the problem of the traditional mouse that the assisting of operation carriers is needed in use, the attitude of a user operating the mouse is limited in the use process, and the influence on the body health of the user is caused. When the space operation type mouse is used, a user can hold the mouse by hand through various methods, or wear on an index finger, an attitude collecting module in the mouse can collect the displacement of the mouse, the displacement is directly sent into a PC (personal computer) after data processing, the assisting of any operation carrier is not needed, the human-machine interaction is natural, a keyboard is controlled through gestures, and the limitation is avoided. The space operation type mouse adopts the software low pass filter principle, the positioning is accurate, the alignment speed is high, and the advantages of trackball mousse and optical mousse are integrated. When the space operation type mouse is used, the attitude of the user is not limited, so the problem of cervical vertebra diseases due to long-time use is effectively avoided.

Owner:HARBIN UNIV OF SCI & TECH

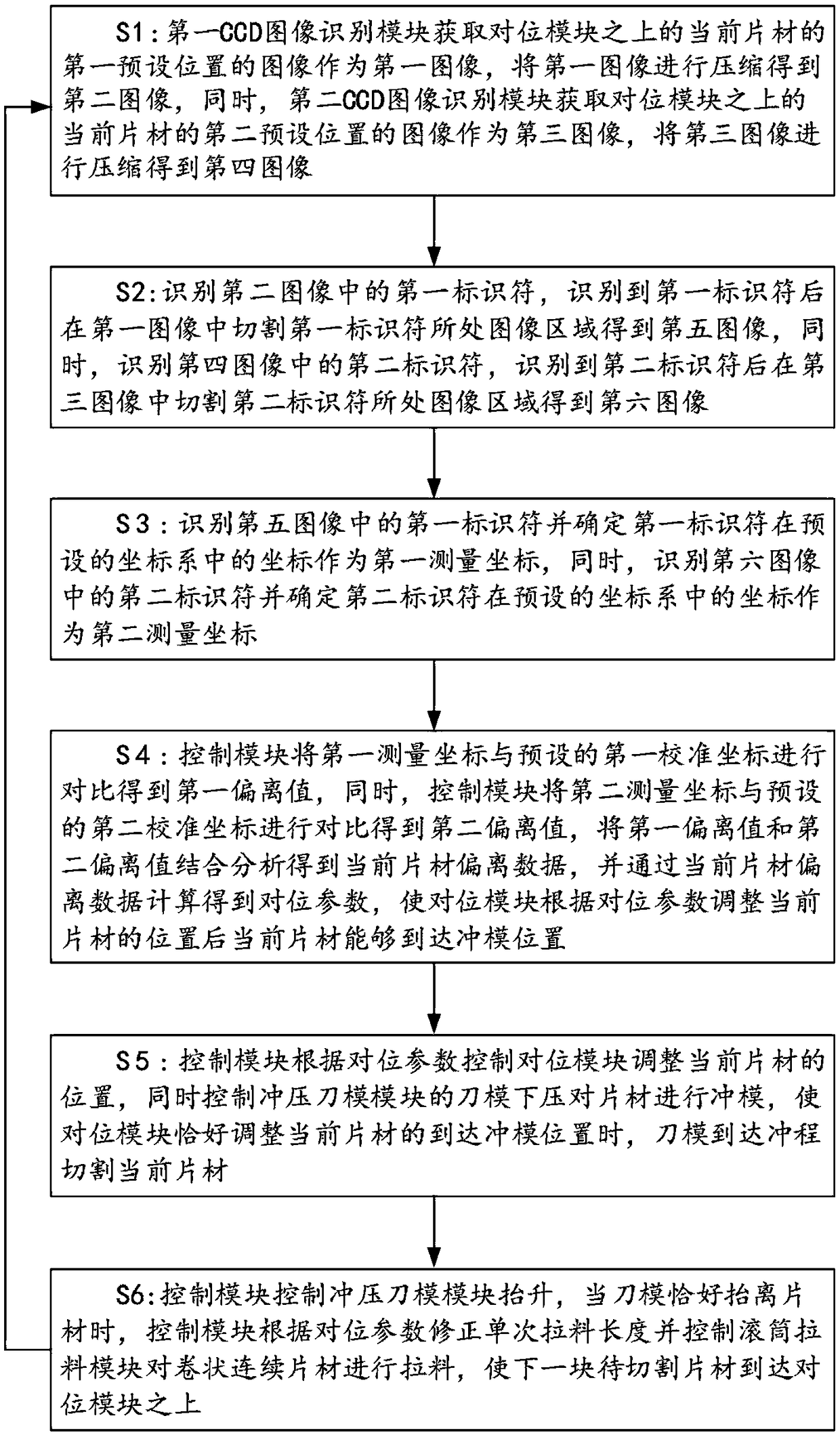

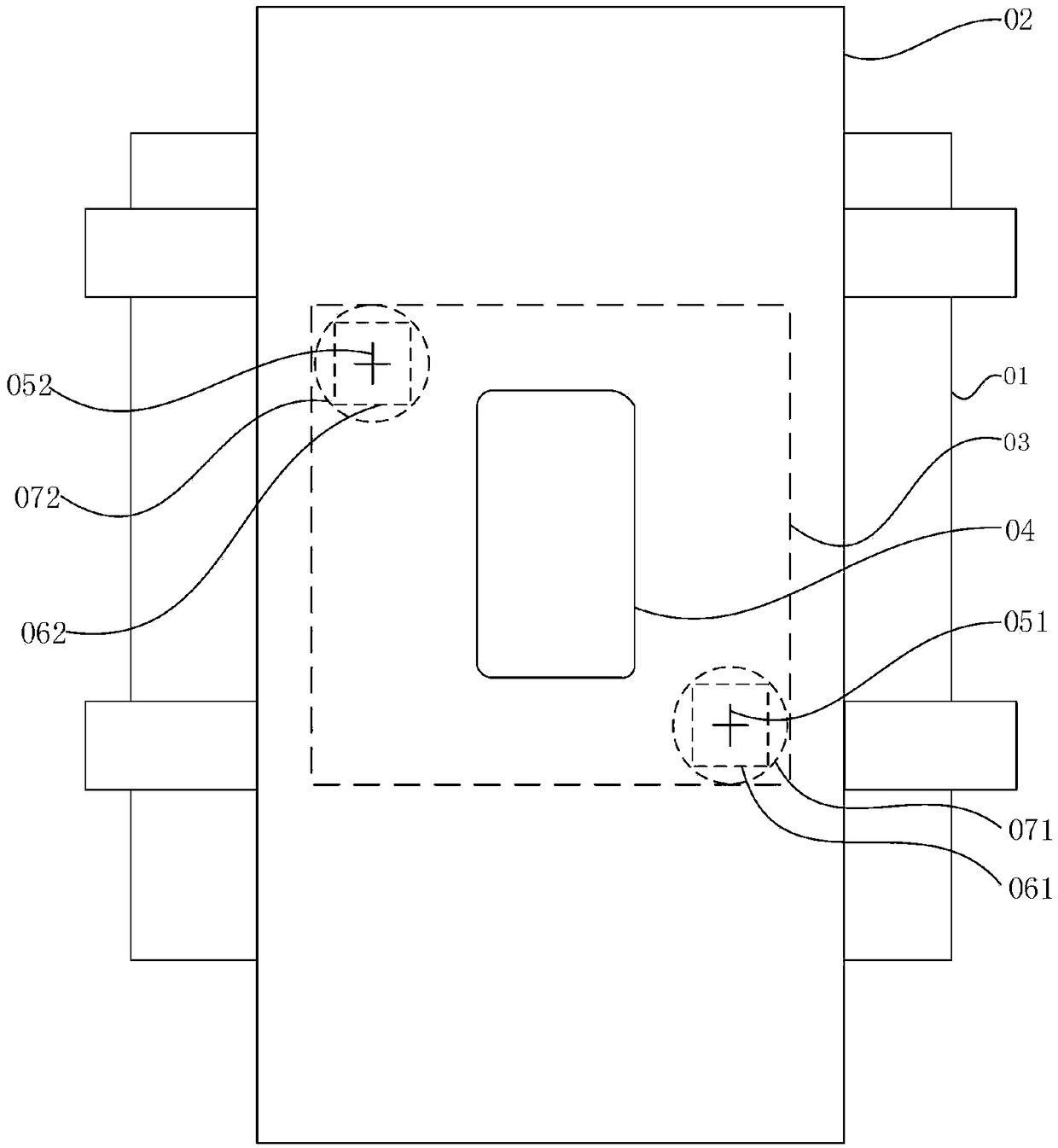

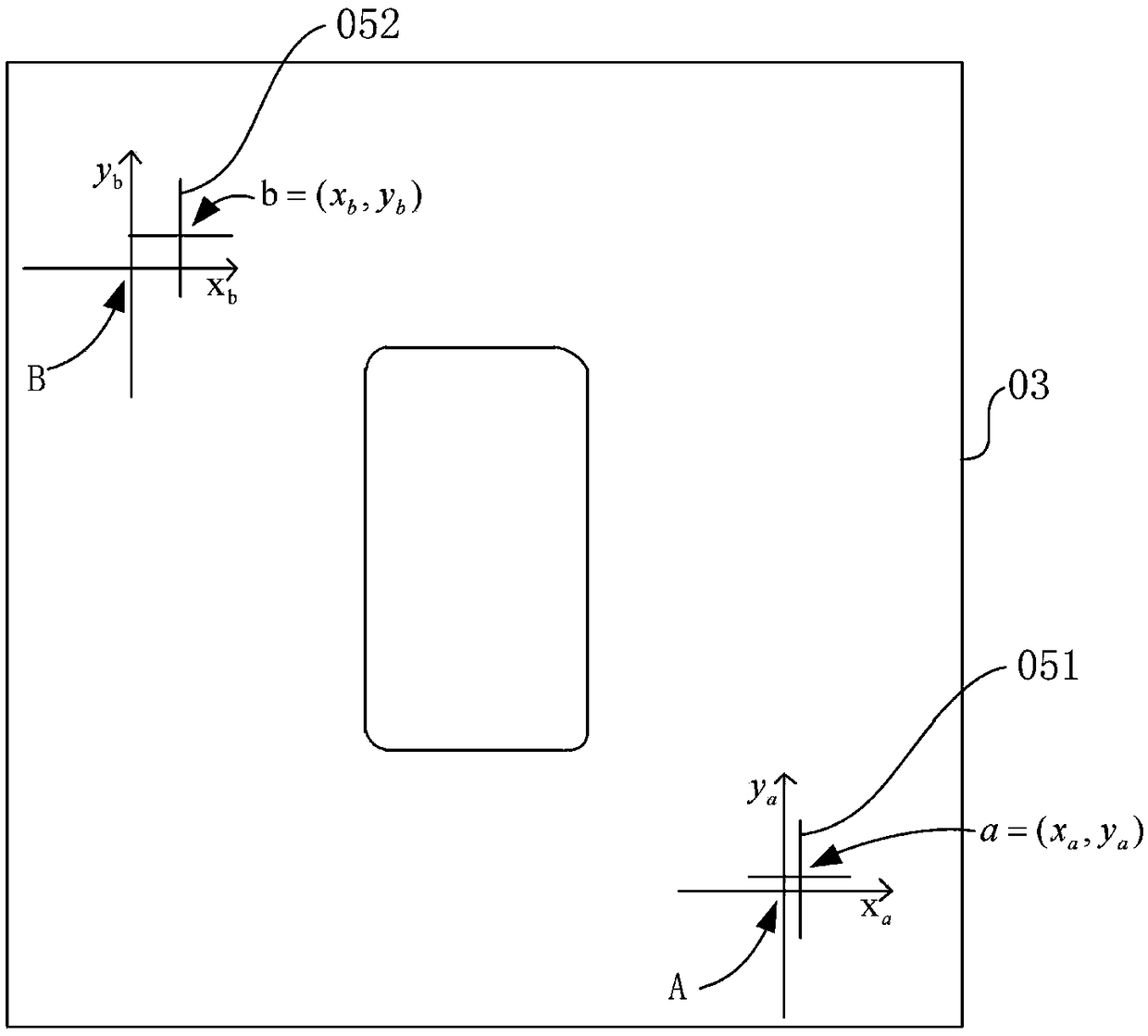

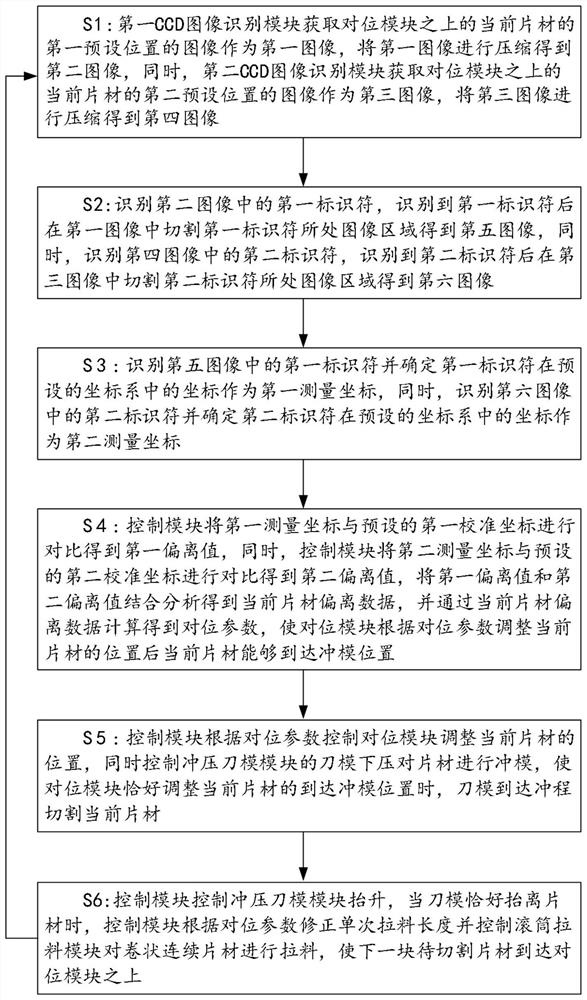

Coiled continuous sheet cutting method based on CCD (charge coupled device) image recognition die-cutting machine

The invention discloses a coiled continuous sheet cutting method based on a CCD (charge coupled device) image recognition die-cutting machine. Coordinates of a first identifier and second identifier are quickly recognized by making full use of cooperation of a first CCD image recognition module and a second CCD image recognition module; the coordinates are compared with preset coordinate, and analyzing is performed to obtain deviation data of current sheets; calculating is performed according to the deviation data of the current sheets to obtain alignment parameters; an alignment module can quickly acquire the alignment parameters and adjust positions of the current sheets according to the alignment parameters, and then, the current sheets may reach a die-cutting position to take cutting;a control module corrects single pull length according to the alignment parameters and controls a drum drawing module to draw each coiled continuous sheet. The die-cutting machine herein can perform aligning quickly to finish single cutting at the premise of precision guaranteed; cutting speed of continuous cutting can be further increased.

Owner:深圳市四元数数控技术有限公司

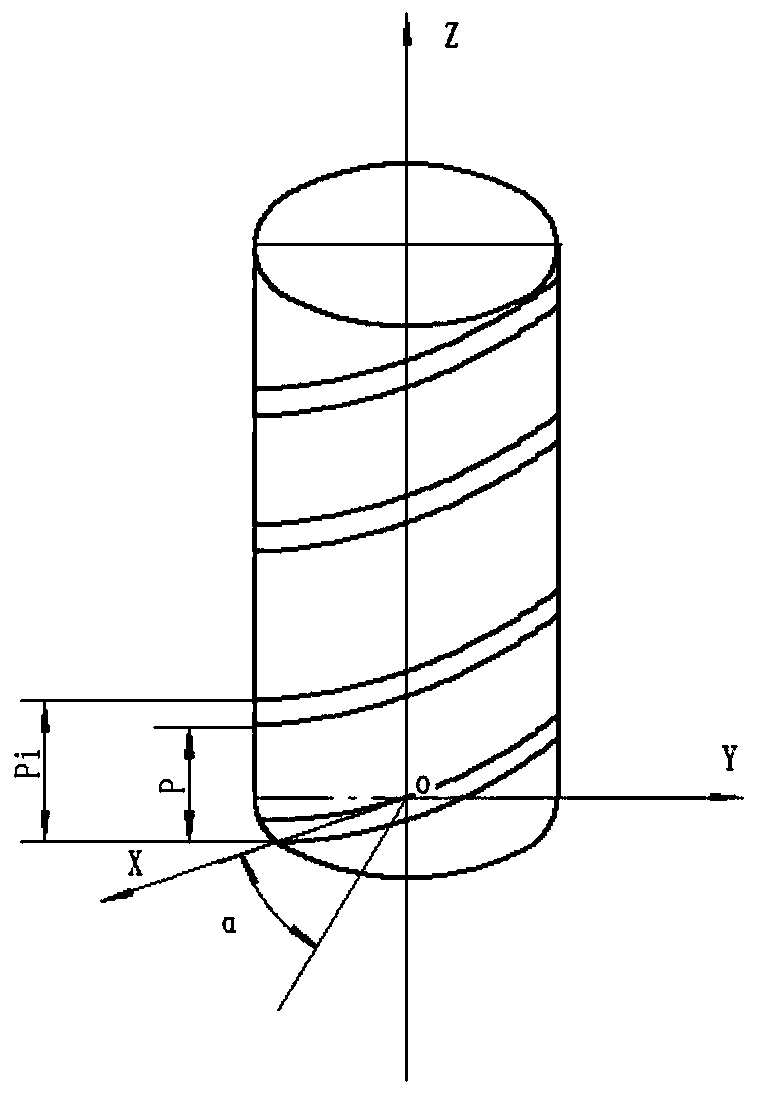

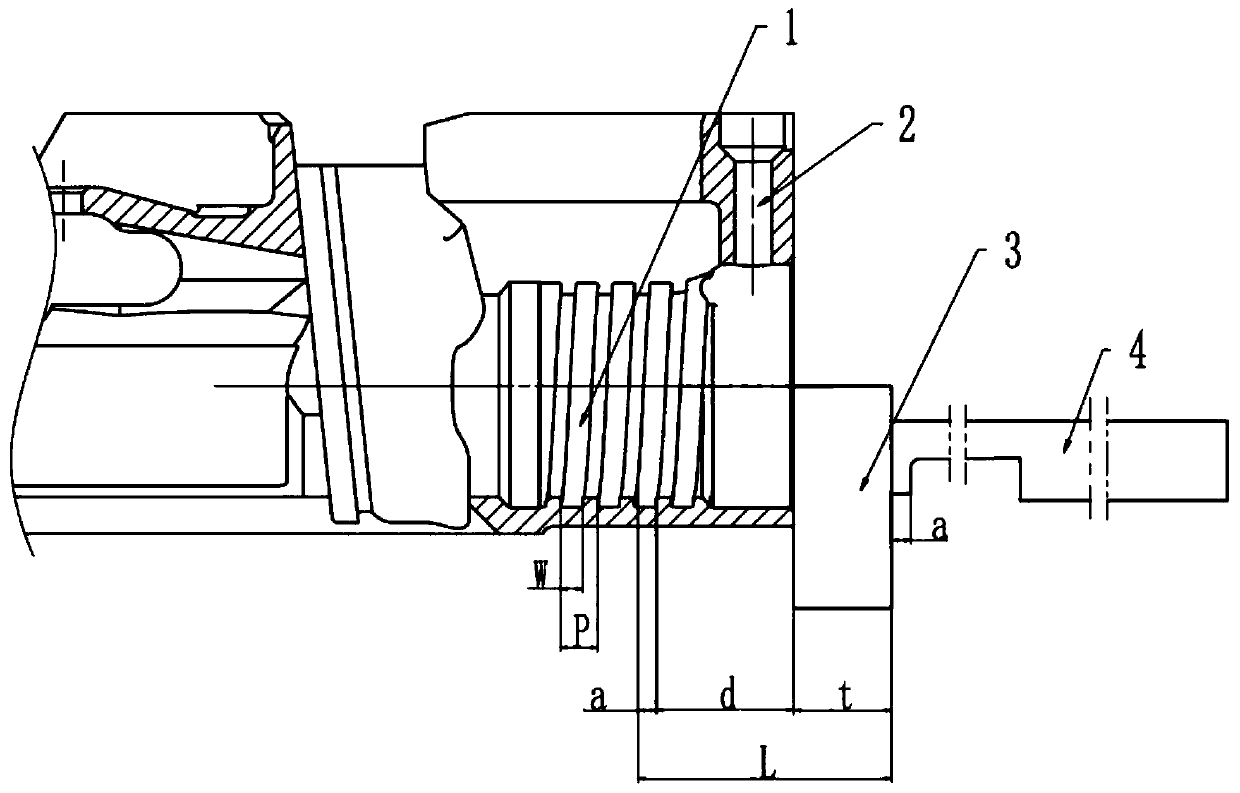

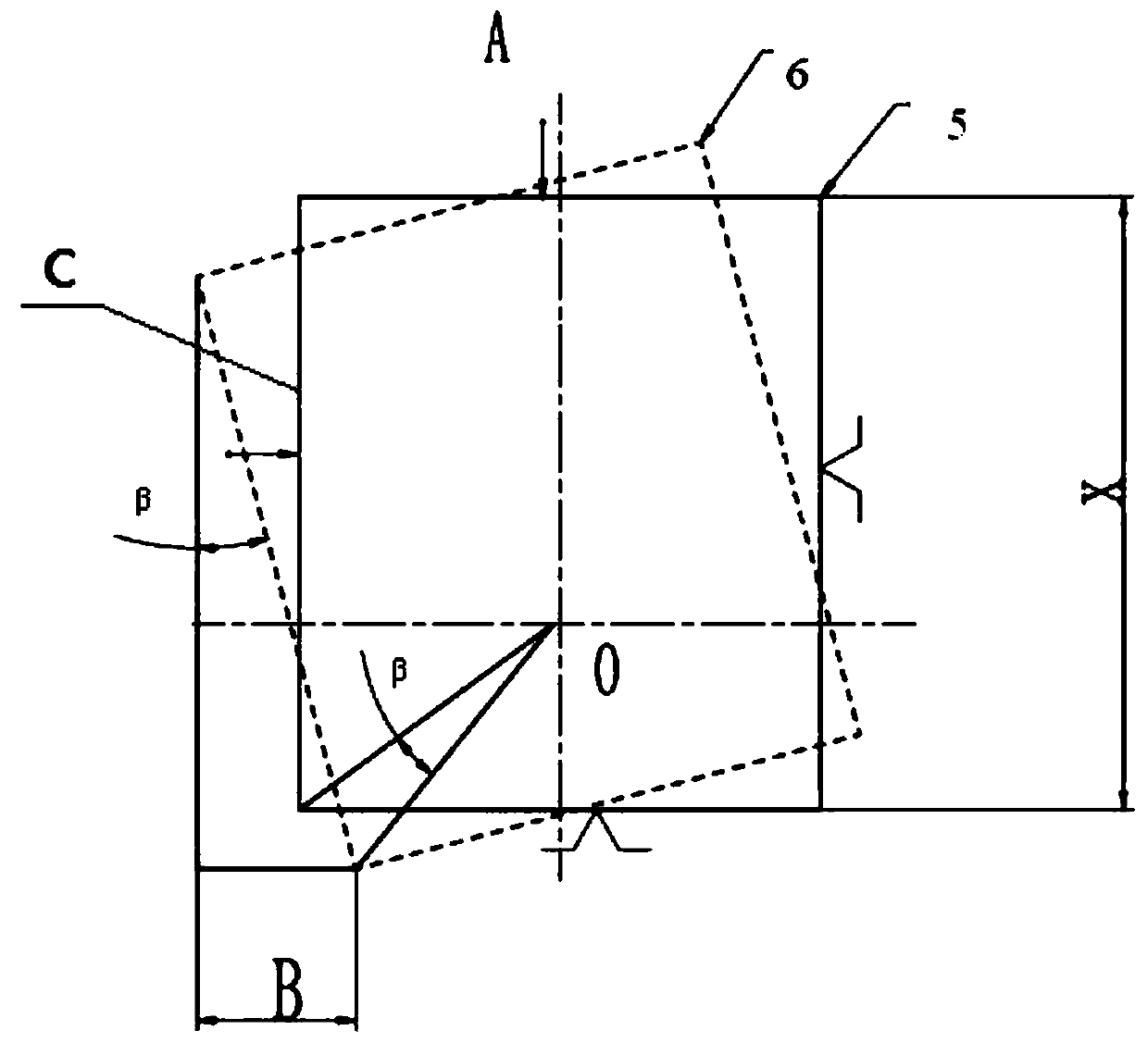

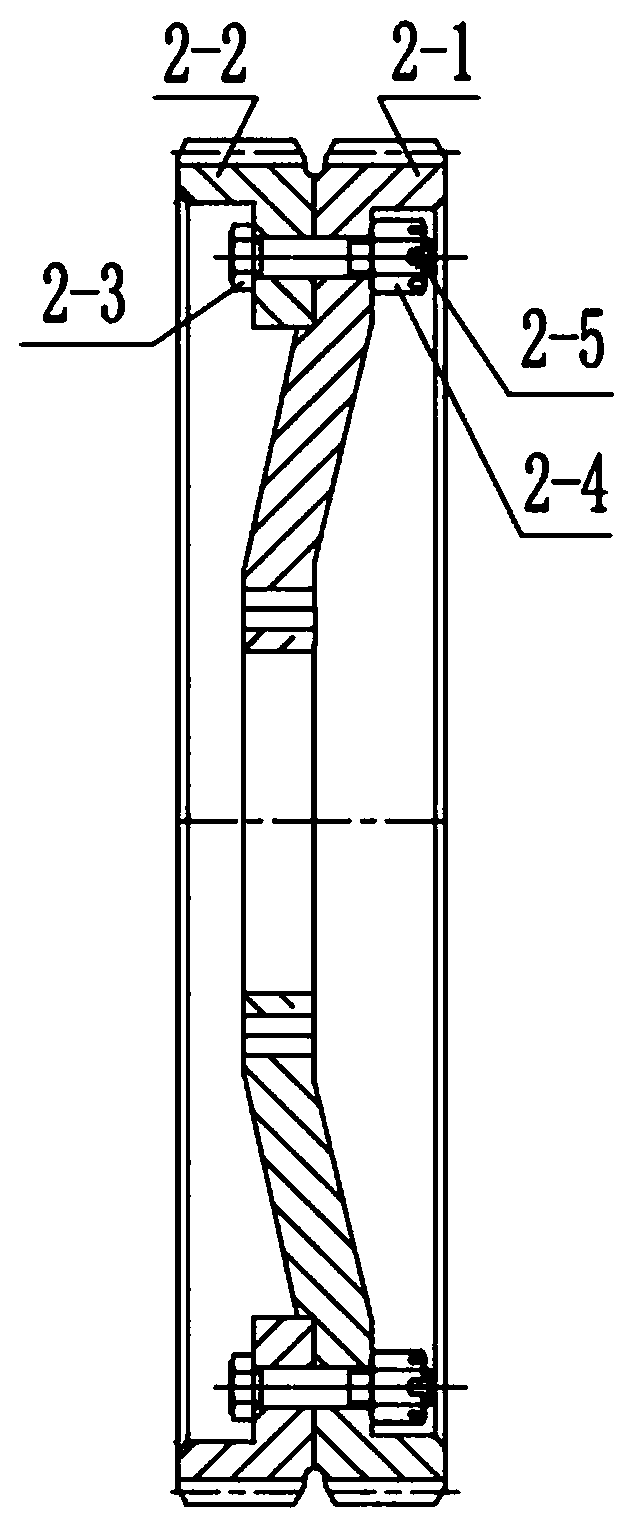

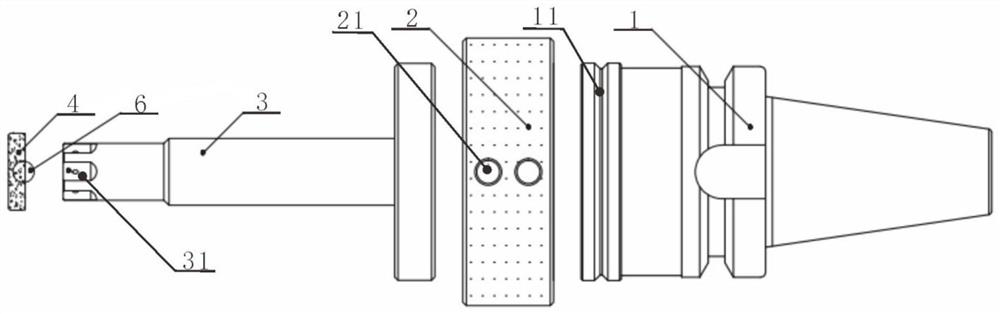

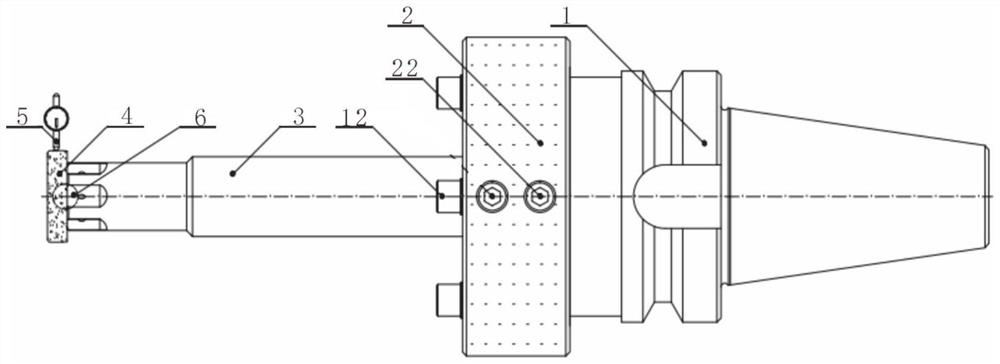

Fixed-starting-point rectangular internal thread manufacturing method

ActiveCN111037008AGuaranteed tool setting valueAlignment speed is fastThread cutting machinesNumerical controlScrew thread

The invention provides a fixed-starting-point rectangular internal thread manufacturing method, and belongs to the field of machining. The method comprises the following steps of clamping; determininga starting point of a thread line, calculating a tool setting value, and aligning a part plane; setting a tool, processing a thread, and measuring by using a special measuring tool after processingis finished; and calculating a tool setting value for guaranteeing a starting point size through a fixed-starting-point rectangular internal thread tool setting formula, determining a starting point position, and then carrying out thread machining. By using the machining method, the starting point position is firstly determined on a common lathe or a numerical control lathe, and then the thread ismachined so that the thread starting point meets a preset requirement; and rectangular threads in complex non-revolving body parts can be machined, and the method is suitable for single-piece or batch production.

Owner:XIAN KUNLUN IND GRP

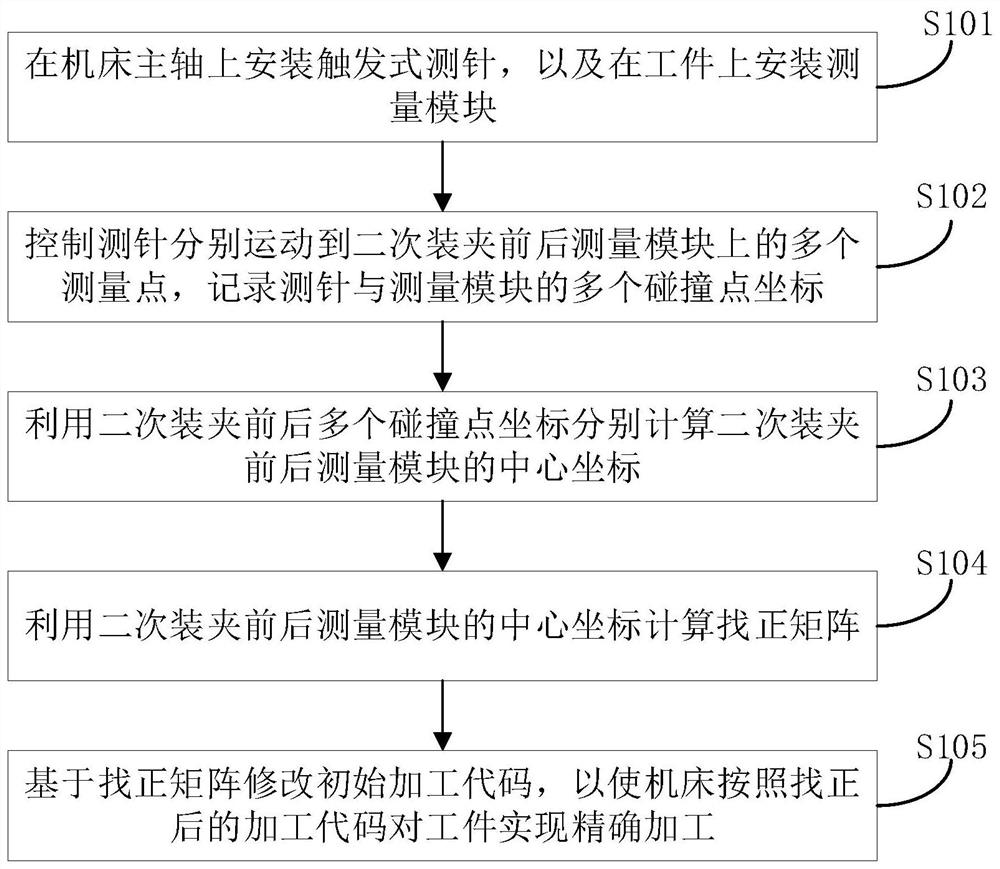

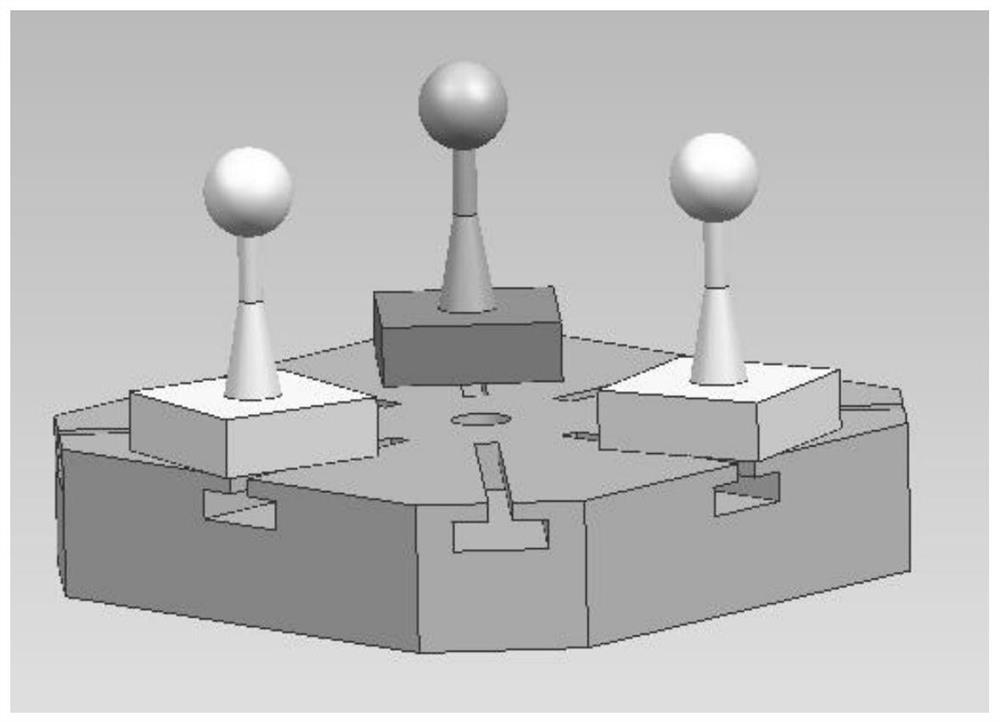

Workpiece alignment method and device for secondary clamping of machine tool and computer storage medium

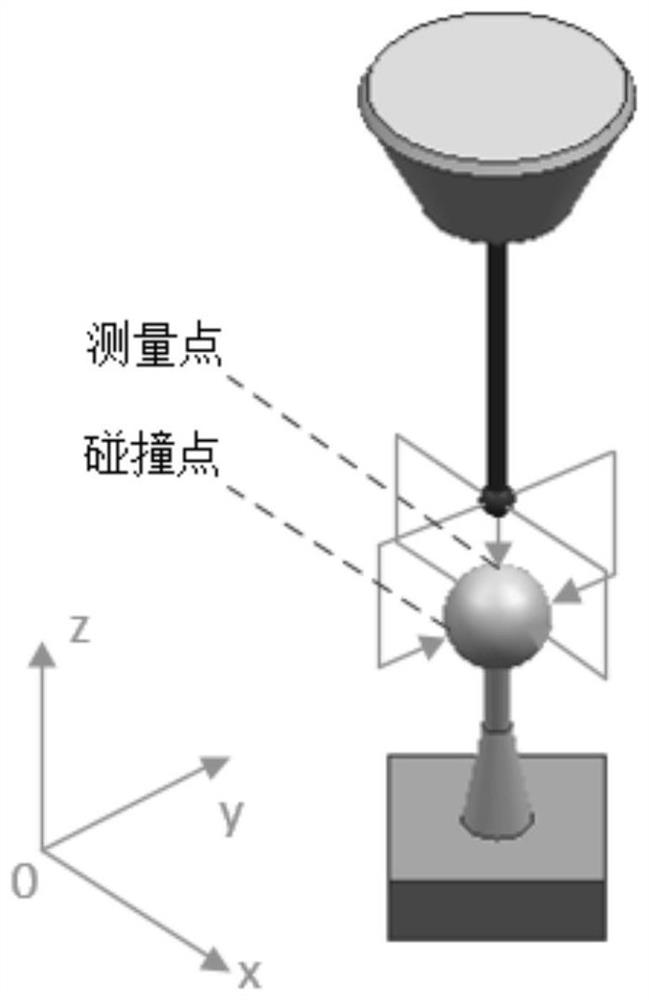

PendingCN113334112ASolve alignment problemsReduce labor intensityAutomatic control devicesMeasurement/indication equipmentsEngineeringMachine tool

The invention provides a workpiece alignment method and device for secondary clamping of a machine tool and a computer storage medium. The project development method comprises the following steps that a trigger type probe is arranged on a machine tool spindle, and a measurement module is arranged on a workpiece; the probe is controlled to move to a plurality of measurement points on the measurement module before and after secondary clamping, and coordinates of a plurality of collision points of the probe and the measurement module are recorded; center coordinates of the measurement module before and after secondary clamping are calculated by utilizing the coordinates of the multiple collision points before and after secondary clamping; an alignment matrix is calculated by utilizing the center coordinates of the measurement module before and after secondary clamping; and the initial machining code is modified based on the alignment matrix, so that the machine tool can accurately machine the workpiece according to the aligned machining code. According to the workpiece alignment method and device and the computer storage medium, by means of the mode, the project development method can effectively solve the problem of alignment of the position and the posture of the workpiece, the alignment speed of secondary clamping of the workpiece is increased, the measurement time is shortened, and therefore the labor intensity of an operator is greatly reduced.

Owner:ADTECH SHENZHEN TECH

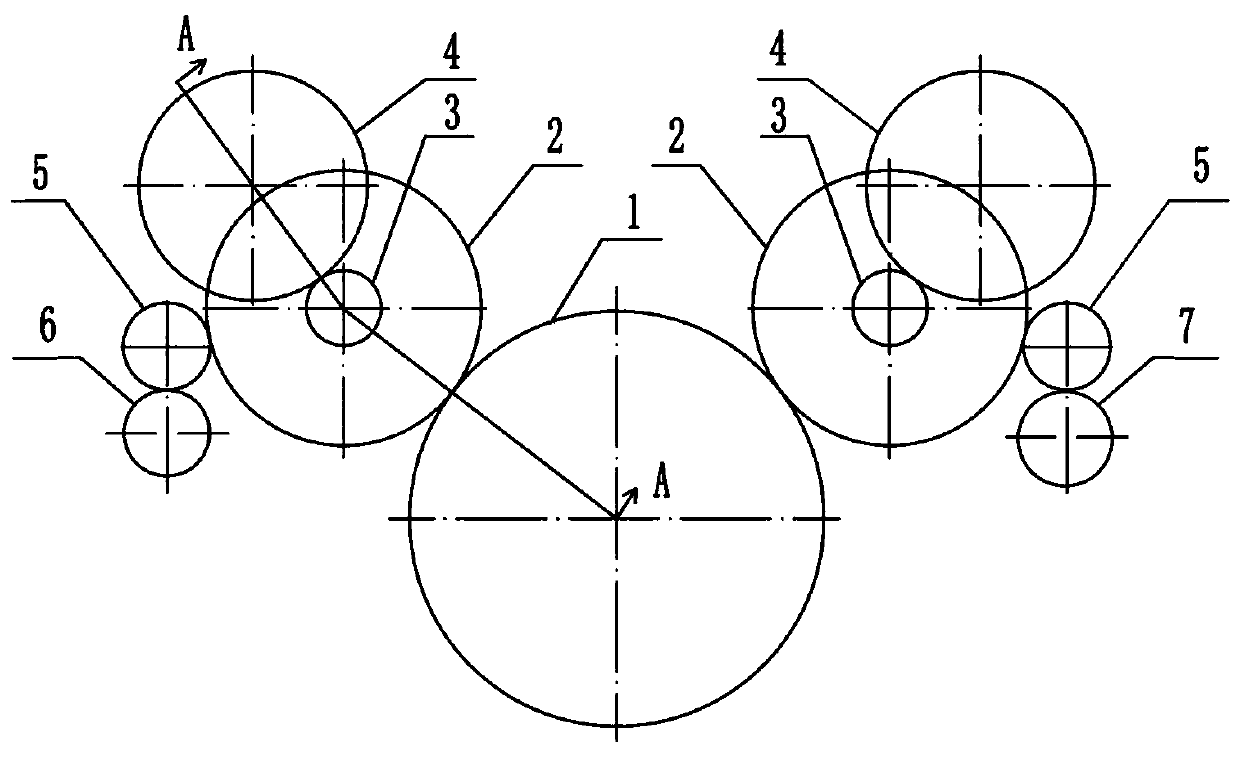

Herringbone gear assembly positioning method and device, assembling method and high-power diesel engine

The invention belongs to the technical field of diesel engine manufacturing, and discloses a herringbone gear assembly positioning method and device, an assembling method and a high-power diesel engine. The herringbone gear assembly positioning method includes the steps that datum tooth scale lines of a right-rotation gear tooth ring and datum tooth scale lines of a left-rotation gear tooth ring are aligned for visual inspection coarse tuning; and datum teeth of the left-rotation gear tooth ring are used as a datum for fixation with fixed positioning teeth of a positioning device, automatic alignment is conducted through movement of movable positioning teeth to obtain the correct positions of datum teeth of the right-rotation gear tooth ring based on the positional accuracy between the movable positioning teeth and the fixed positioning teeth of the positioning device as well as the body dimensional accuracy of the two positioning teeth, and positional assembling between the datum teeth of the right-rotation gear tooth ring and the datum teeth of the left-rotation gear tooth ring is carried out. According to the herringbone gear assembly positioning method and device, the assembling method and the high-power diesel engine, by using the intermediate-speed high-power diesel engine combined-type herringbone gear assembly, assembly accuracy is improved, assembly technology stability is ensured, the economic cost of herringbone tooth gears is reduced, and operational reliability of diesel engine gears is guaranteed; and the application field is broad and the popularization valueis good.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

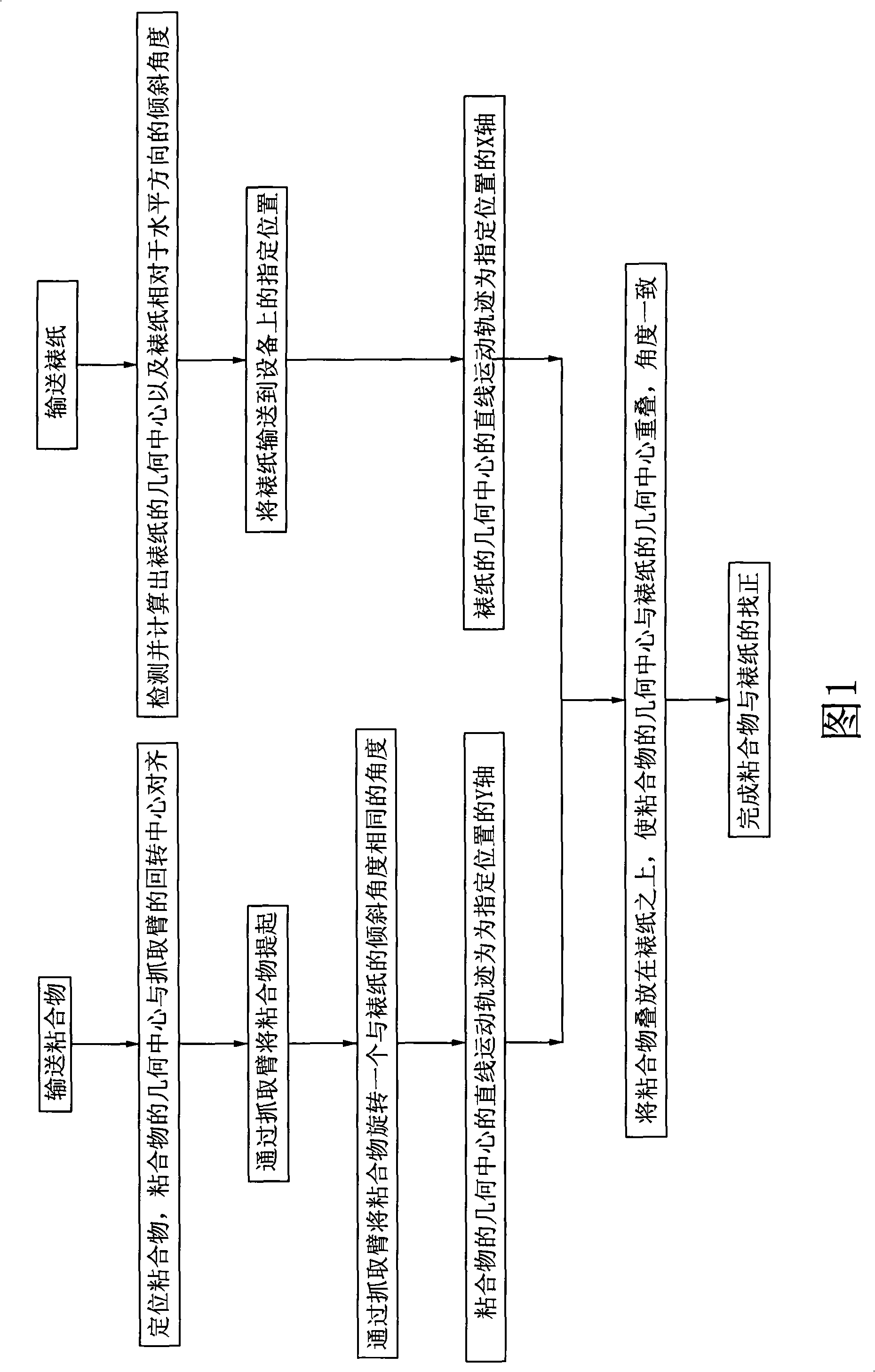

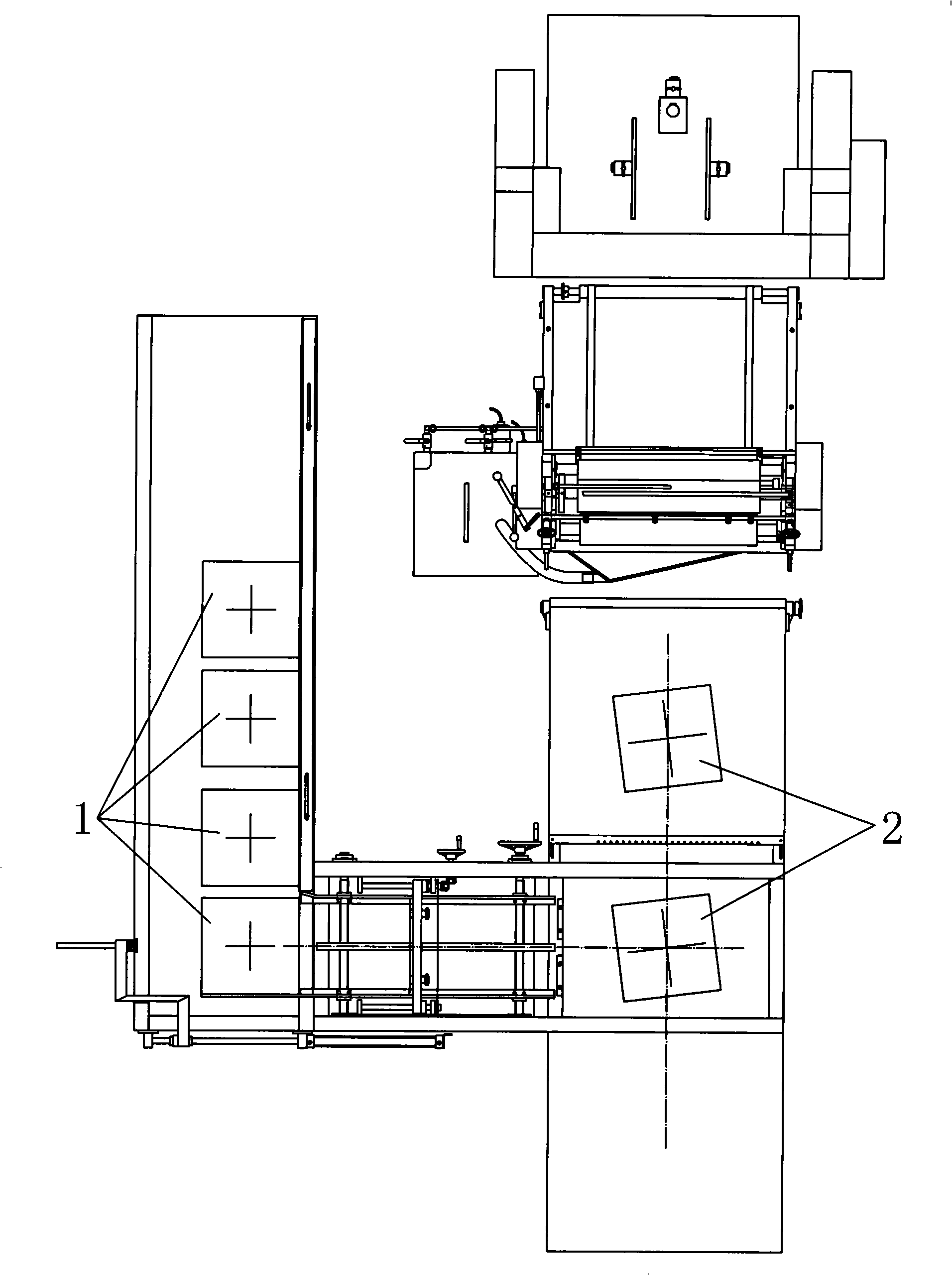

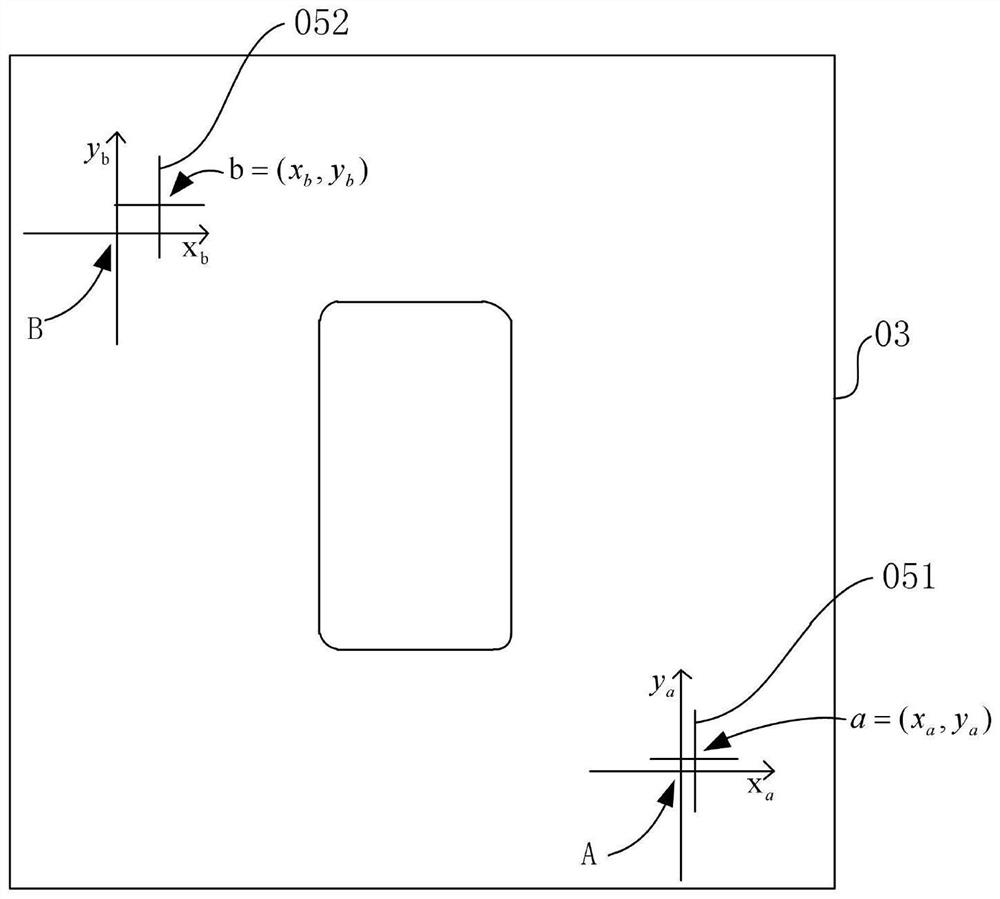

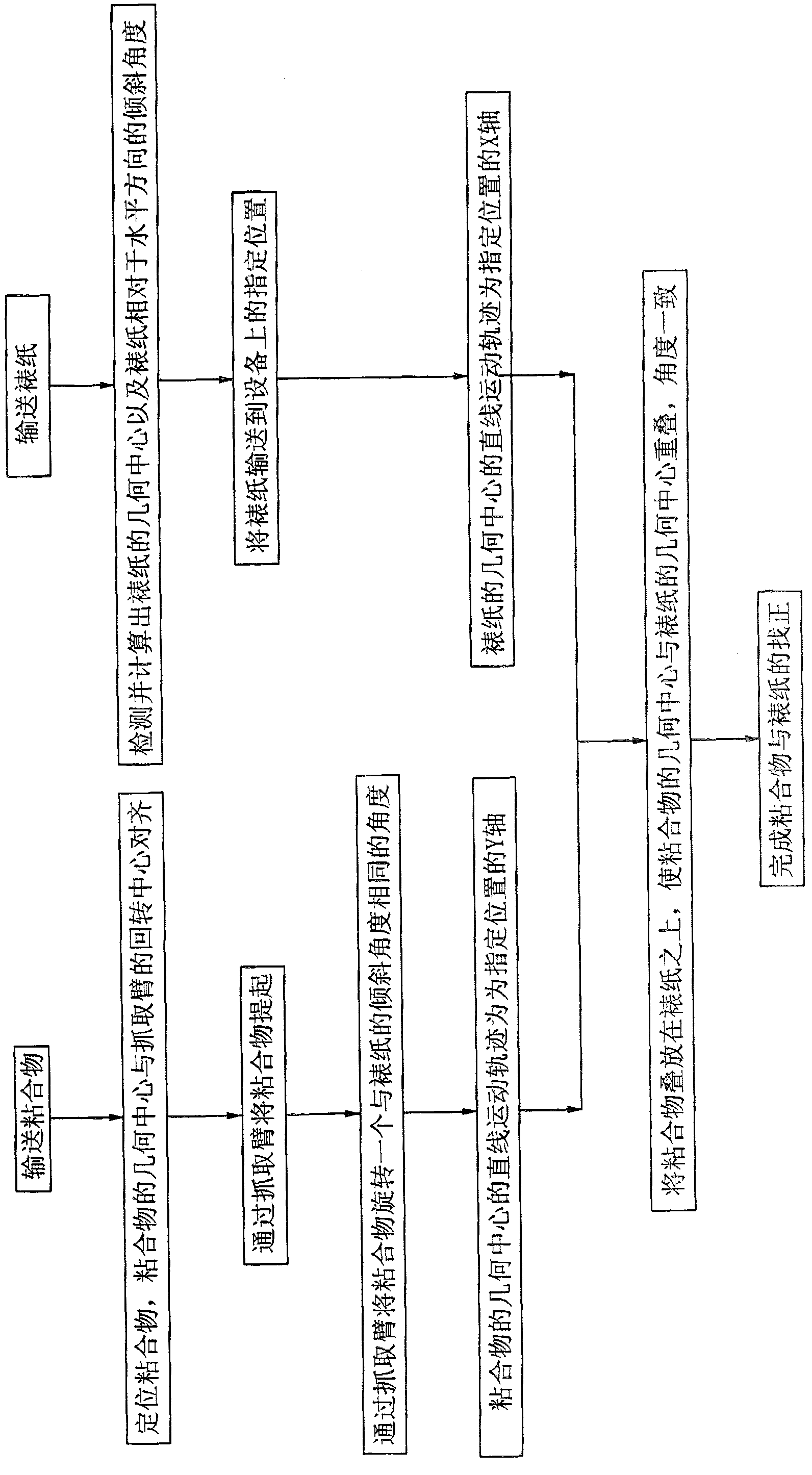

Alignment method for paperhanging paper and binding article

The invention relates to the field of transverse alignment method technique between backing paper and binder, in particular to a transverse alignment method between the backing paper and the binder. The method is characterized in that the inclined angle of the backing paper corresponding to the horizontal direction is firstly detected and calculated; furthermore, the binder is positioned, the geometric centre of the binder is determined, namely, the rotating center of the binder is determined; subsequently, the binder is lifted up by a grasping arm; the binder is then rotated by an angle which is identical to the inclined angle of the backing paper; finally, the binder is laminated on the backing paper so as to lead the geometric center of the binder to be coincident to that of the backing paper and complete the alignment of the backing paper and the binder; the transverse alignment speed of the backing paper and the binder is quick, the aligning precision of the backing paper and the binder is high; furthermore, the technical proposal is easy to be realized, and the structure of the binder laminating machine of the technical proposal is simplified.

Owner:陈桢粦

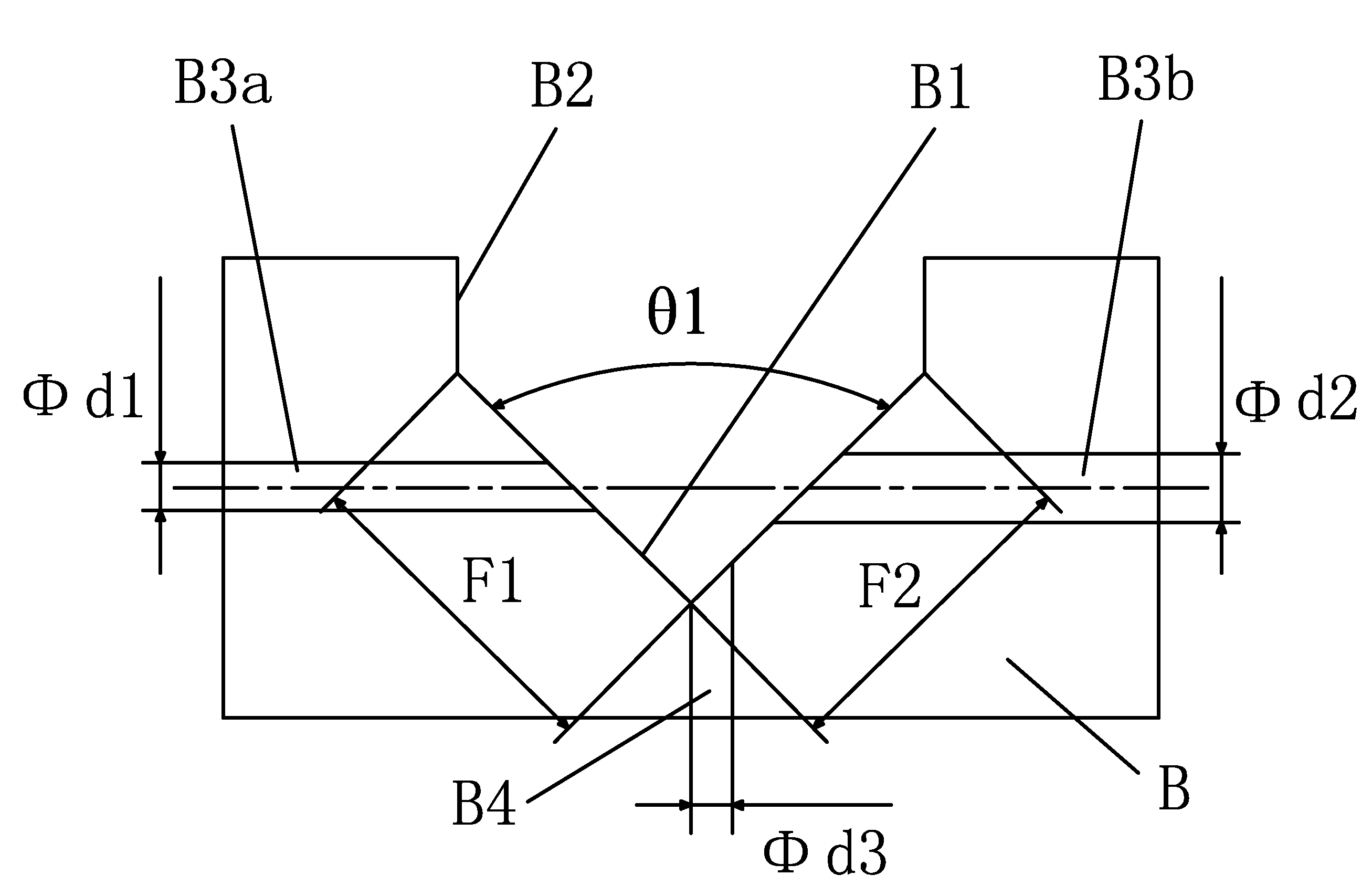

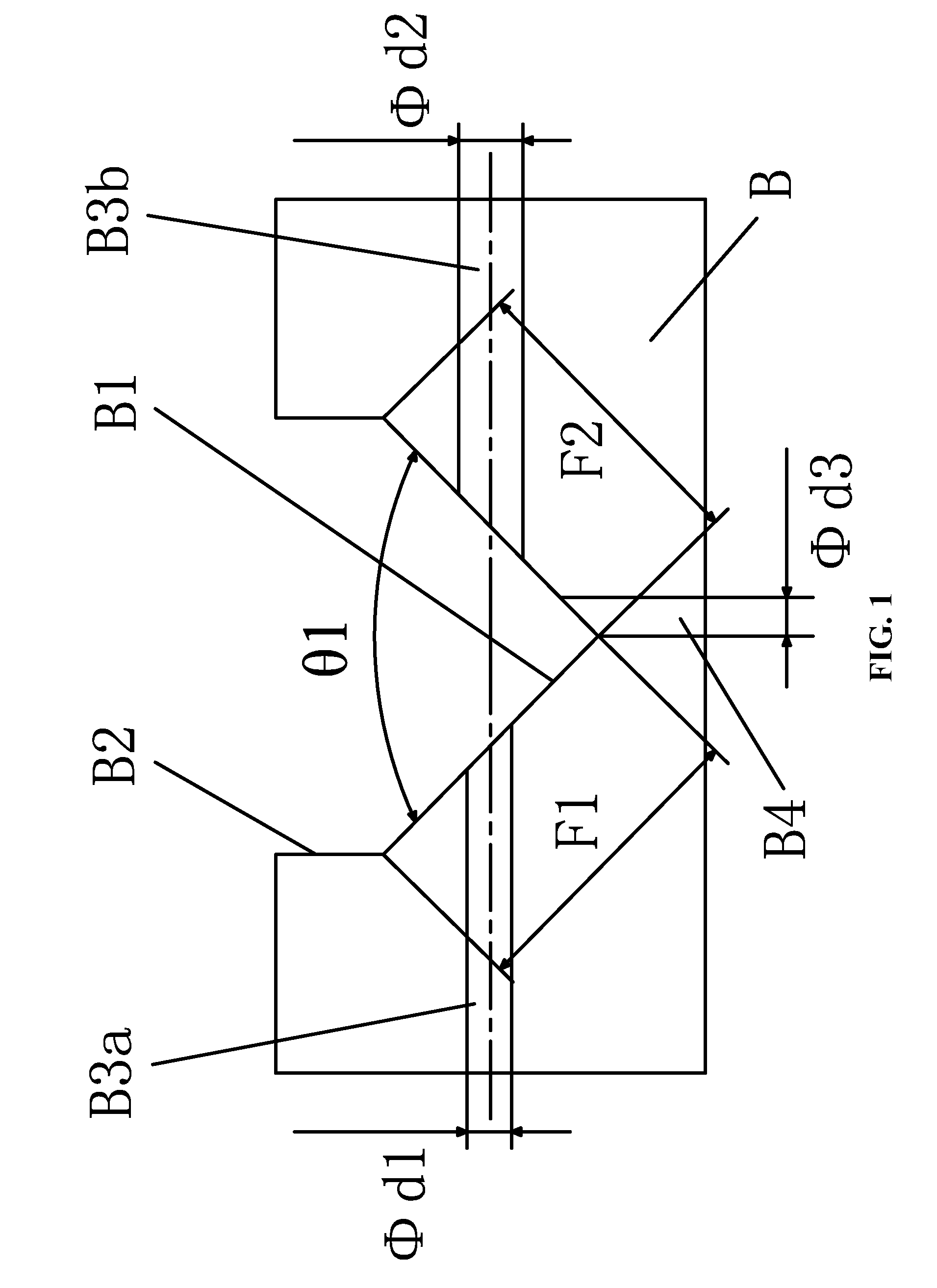

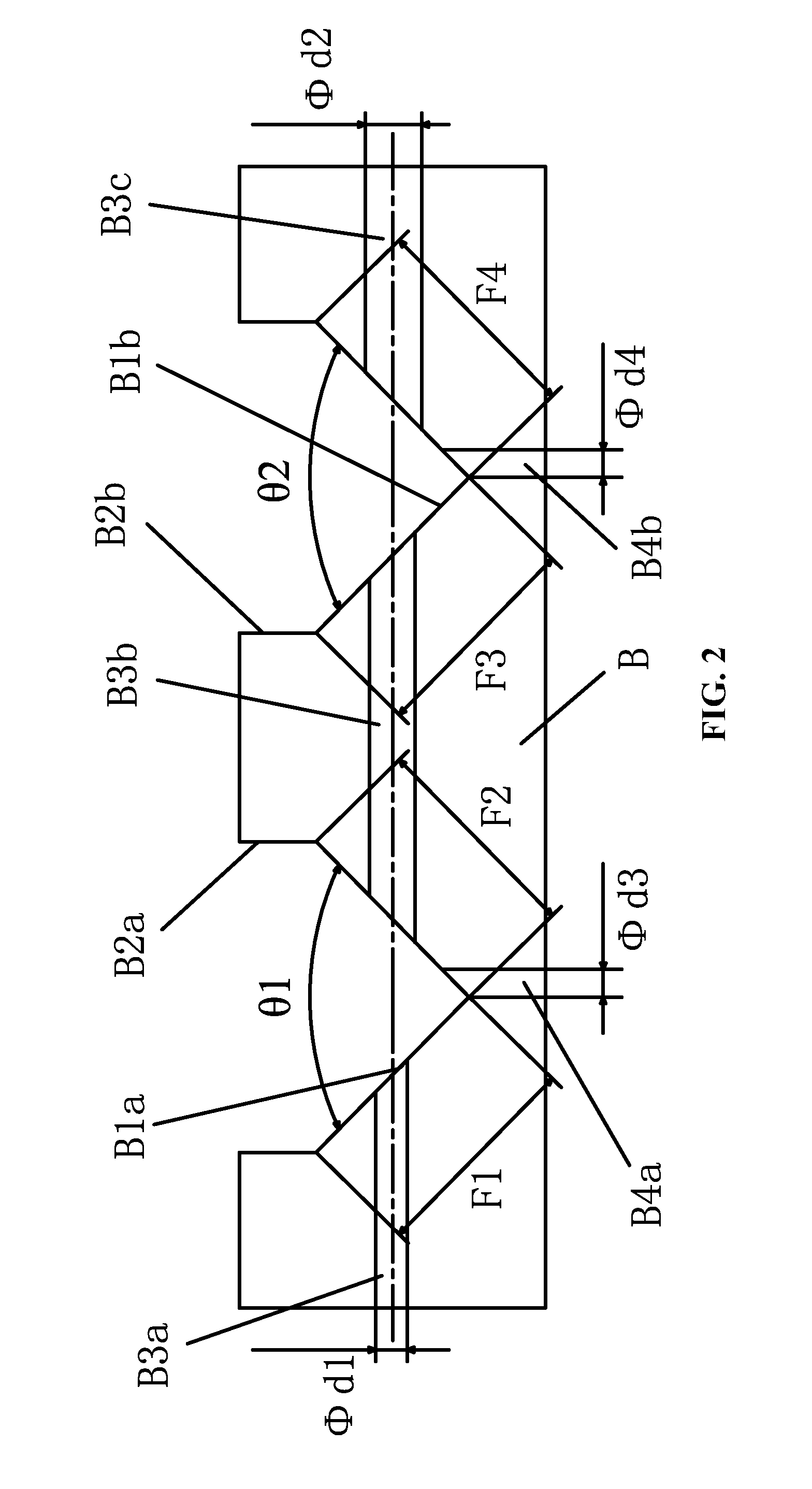

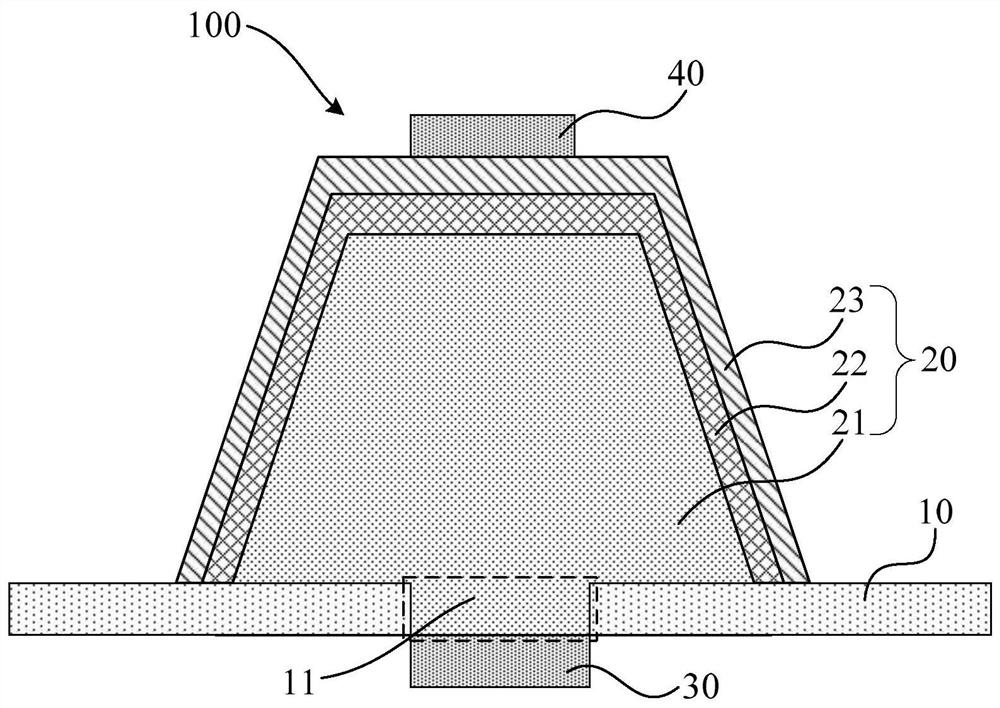

Optical device packaging structure and optical device module

ActiveUS20120288243A1Increase productivityLow production costCoupling light guidesOptical ModuleComputer module

An optical device packaging structure, including a main body (B). One or more V-shaped grooves (B1) are formed in the main body (B), and an optical signal transmission hole system communicated with two side walls of the V-shaped groove (B1) is disposed in the main body (B). The optical signal transmission hole system includes an optical signal transmission hole perpendicular and / or parallel to the central line of the included angle of the V-shaped groove, and the included angle of the V-shaped groove is 90°±10°. An optical device module packaged by the optical device packaging structure is also provided.

Owner:WUHAN UNICELL TECH CO LTD

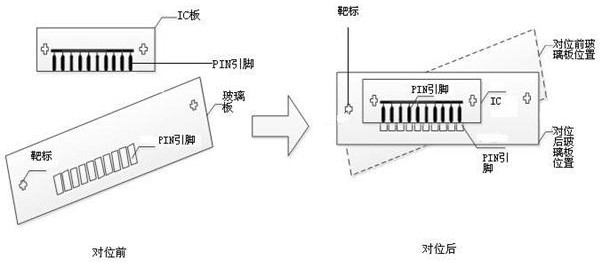

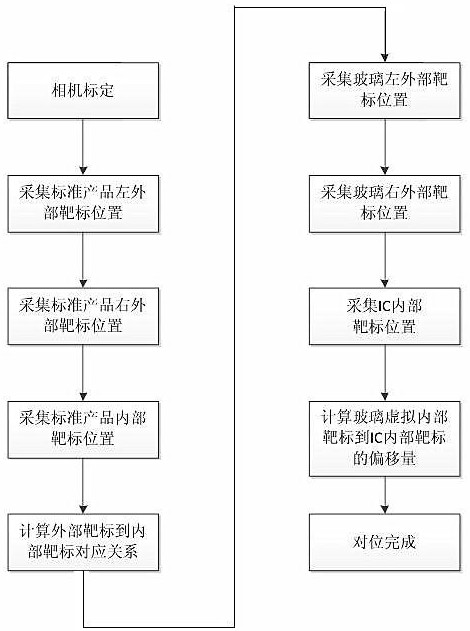

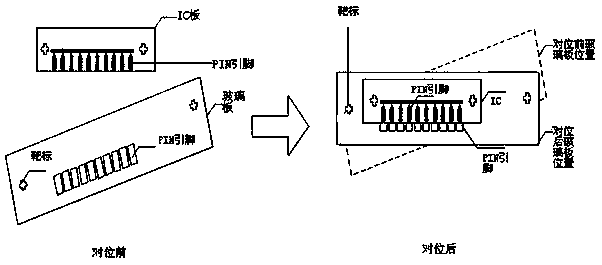

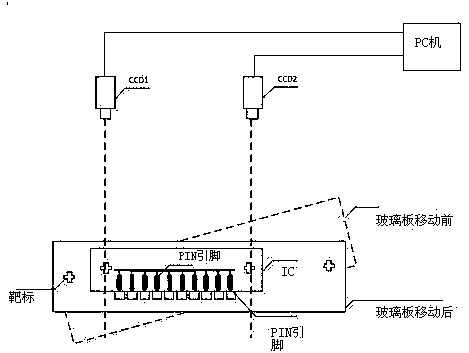

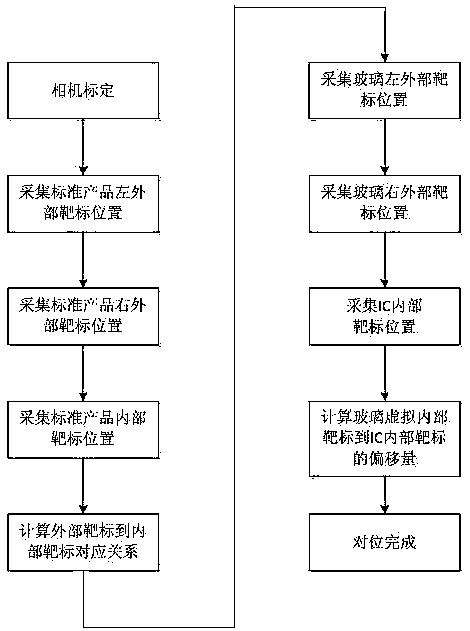

A pin automatic alignment method between a small liquid crystal display glass plate and an ic plate

ActiveCN109001920BAlignment speed is fastAccurate operationNon-linear opticsLiquid-crystal displayEngineering

A method for automatically aligning the pins of a small liquid crystal display glass plate and an IC plate, which is divided into the following steps to achieve alignment: 1. Determine the corresponding relationship between camera coordinates converted into world coordinates through PC control software; 2. Collect standard products The position of the left outer target, the right outer target of the glass plate and the left and right targets of the IC board inside the glass plate; Position correspondence; 4. Actual production, collect the positions of the left and right external targets of the glass plate and the left and right targets of the IC; 5. Calculate the positions of the virtual left and right external targets of the glass plate, and the positions of the left and right external targets of the IC plate According to the calculation results, the electric alignment platform drives the glass plate to automatically move a certain amount to complete the alignment program between the glass plate signal input terminal pins and the IC board pins. The alignment speed of the invention is fast and the alignment is accurate.

Owner:上海视眸自动化科技有限公司

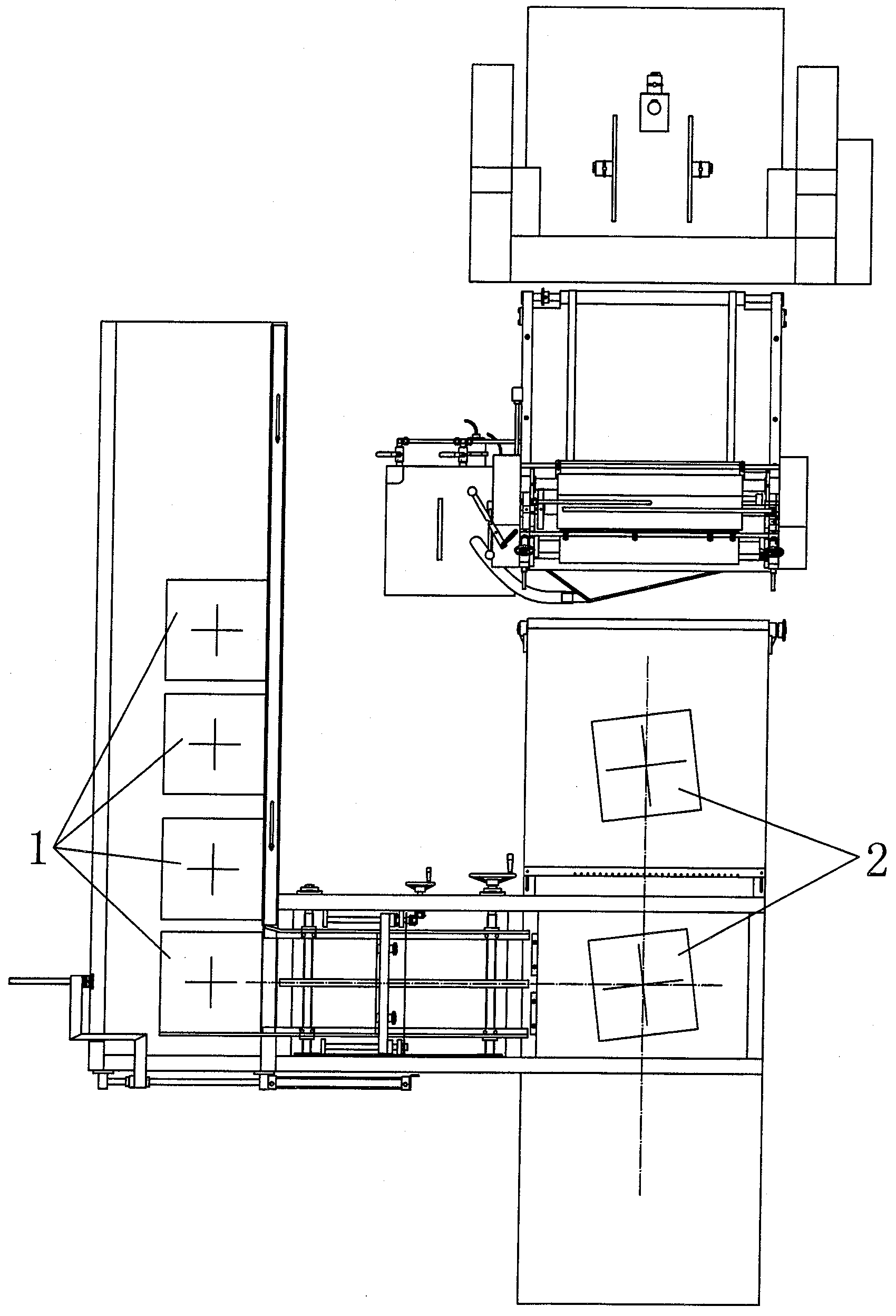

Binocular positioning solar cell module trimming device

InactiveCN107134508AAlignment speed is fastPrecise automatic positioningFinal product manufactureSemiconductor/solid-state device manufacturingEmbedded systemMovement control

The invention discloses a binocular positioning solar cell module trimming device, which belongs to the field of manufacturing of solar cell modules. The binocular positioning solar cell module trimming device comprises a supporting frame, a bearing table, a servo controller, cameras, long knife control units, short knife control units, long knife heads, short knife heads, long knife sliding rails, short knife sliding rails, an operation platform, a computer and a host. A to-be-trimmed solar cell module enters the operation platform, the binocular camera is controlled by the servo controller to capture a marking point of the to-be-trimmed module, the operation platform adjusts the angle to enable the to-be-trimmed module to be accurately positioned, the knife head is controlled by the knife head control unit, and through the sliding rail, the automatic trimming function is realized. The device combines machine vision and motion control, the counterpoint speed is quick, accurate and automatic positioning can be realized, the knife head control unit completes trimming of the solar cell module, manual errors are avoided, the device is simple and easy to operate, high-efficiency production is realized, and the production cost is effectively reduced.

Owner:ZHENJIANG SYD TECH CO LTD

A space-operated mouse

InactiveCN103955297BPrecise positioningAlignment speed is fastInput/output processes for data processingDiseaseLow-pass filter

The invention provides a space operation type mouse, and relates to a mouse, which aims at solving the problem of the traditional mouse that the assisting of operation carriers is needed in use, the attitude of a user operating the mouse is limited in the use process, and the influence on the body health of the user is caused. When the space operation type mouse is used, a user can hold the mouse by hand through various methods, or wear on an index finger, an attitude collecting module in the mouse can collect the displacement of the mouse, the displacement is directly sent into a PC (personal computer) after data processing, the assisting of any operation carrier is not needed, the human-machine interaction is natural, a keyboard is controlled through gestures, and the limitation is avoided. The space operation type mouse adopts the software low pass filter principle, the positioning is accurate, the alignment speed is high, and the advantages of trackball mousse and optical mousse are integrated. When the space operation type mouse is used, the attitude of the user is not limited, so the problem of cervical vertebra diseases due to long-time use is effectively avoided.

Owner:HARBIN UNIV OF SCI & TECH

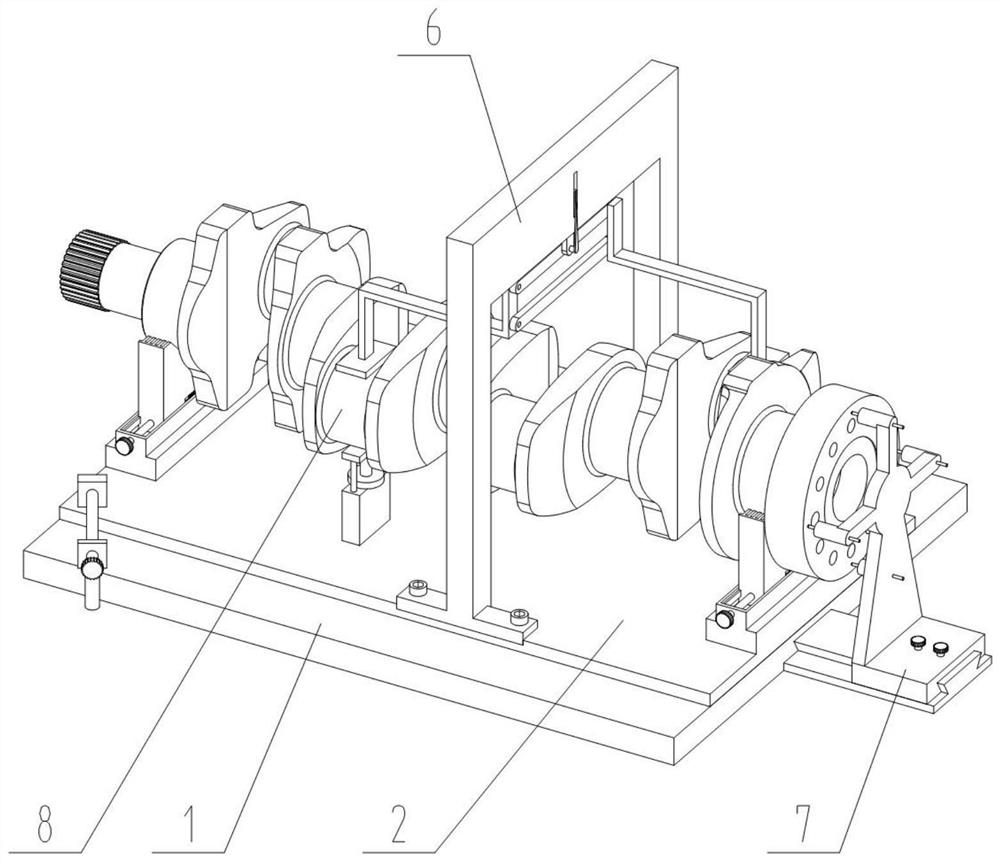

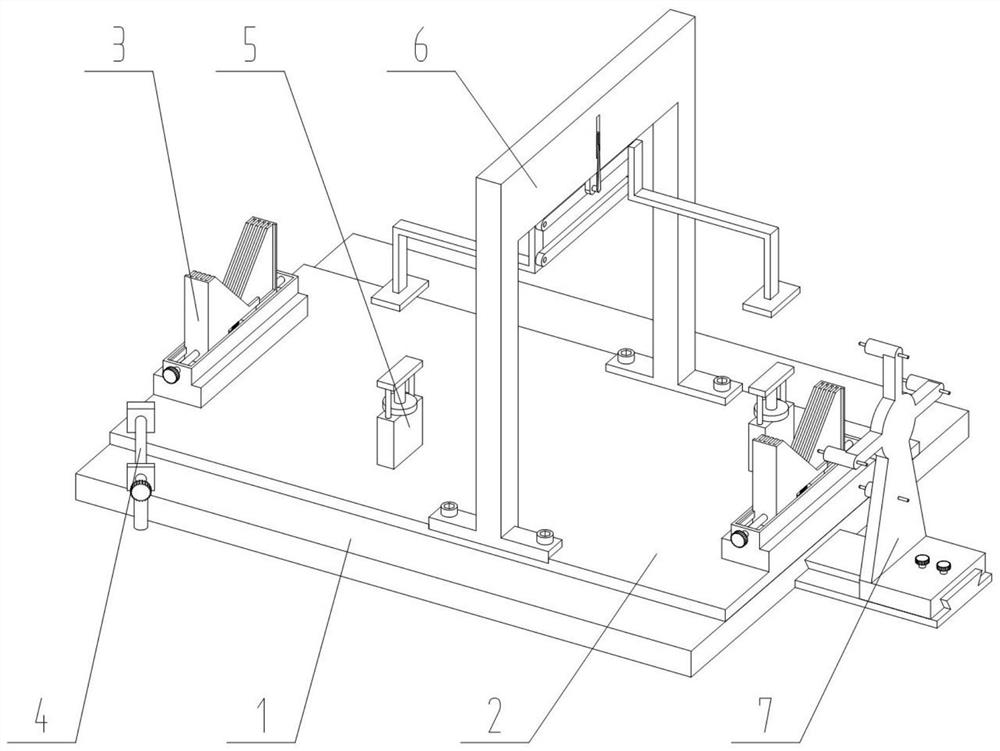

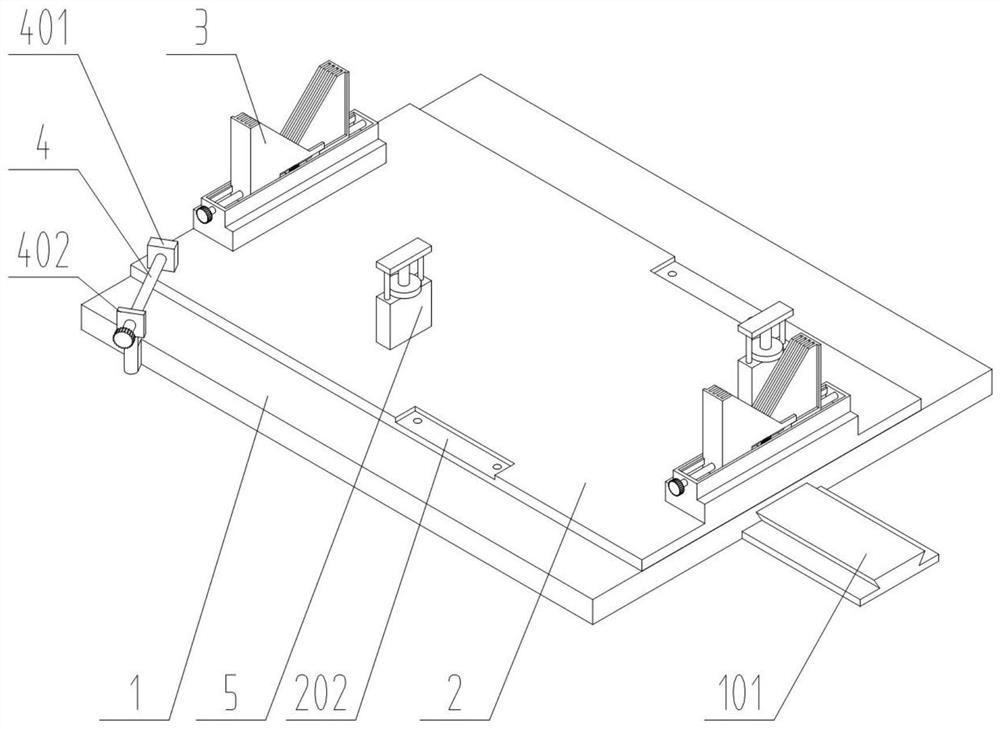

Detection and measurement quick alignment device for the production of heavy truck spare parts

The invention provides a detection and measurement quick alignment device for the production of heavy truck spare parts, comprising: a bottom plate and a crankshaft part; a group of bottom swing adjustment plates are axially connected to the top of the bottom plate; The side is connected to the bottom plate through a set of offset adjustment screws; the upper end surface of the bottom swing adjustment plate is fixedly connected with a set of leveling and alignment devices by bolts; the upper end surface of the bottom plate is slidingly connected to a right side The end face aligning device is assembled; the crankshaft part is placed on the end face of the adjustable support block. The device can quickly and real-time measure the up and down directions, front and rear directions, and the height of the eccentric shaft of the crankshaft parts. The measurement is convenient, the display is intuitive, and it is convenient for alignment. Fast, realize fast alignment, greatly save working hours, and improve work efficiency.

Owner:青岛迈朗格智能制造有限公司

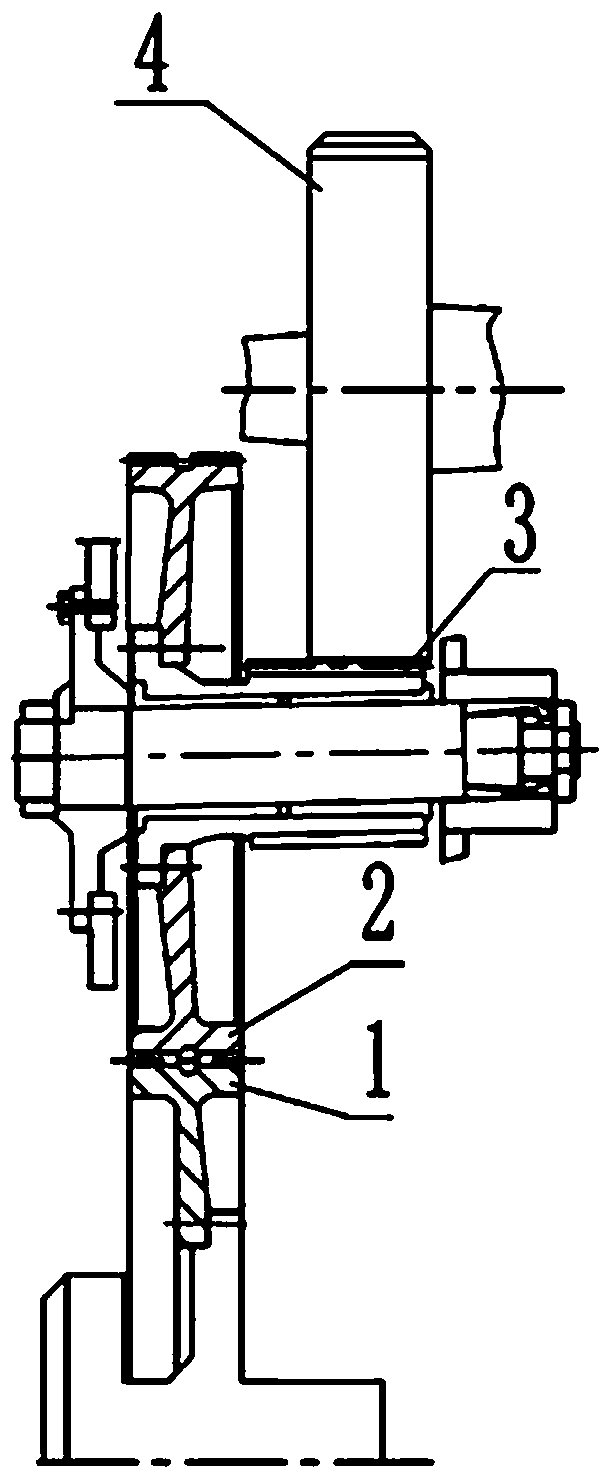

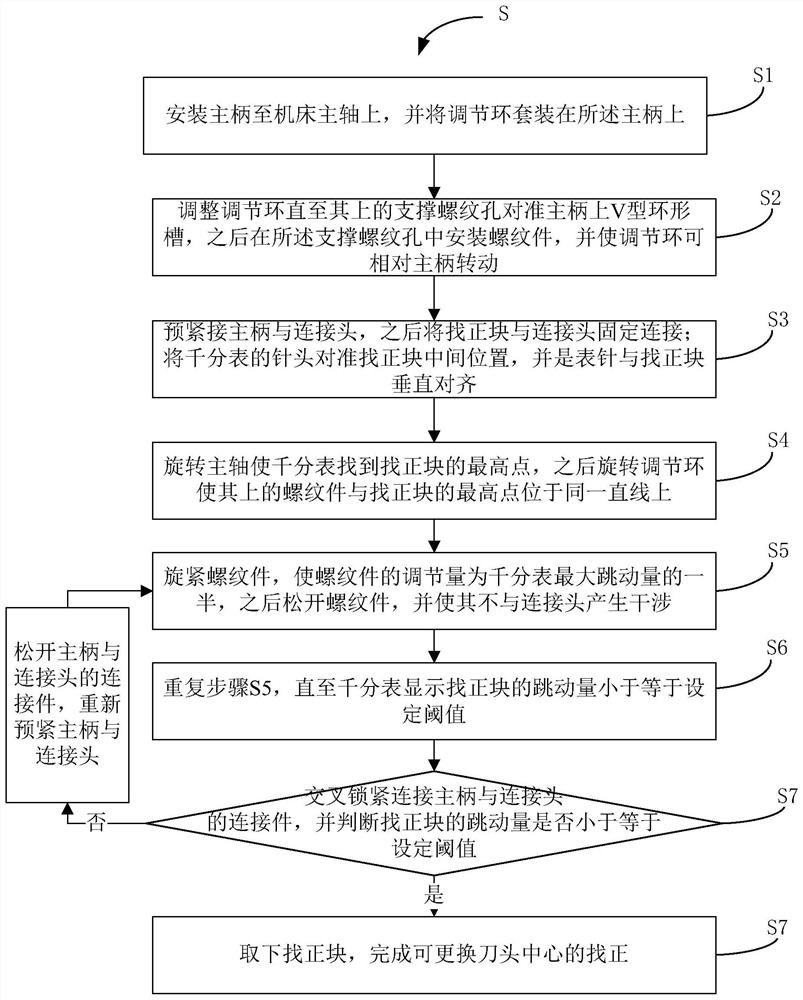

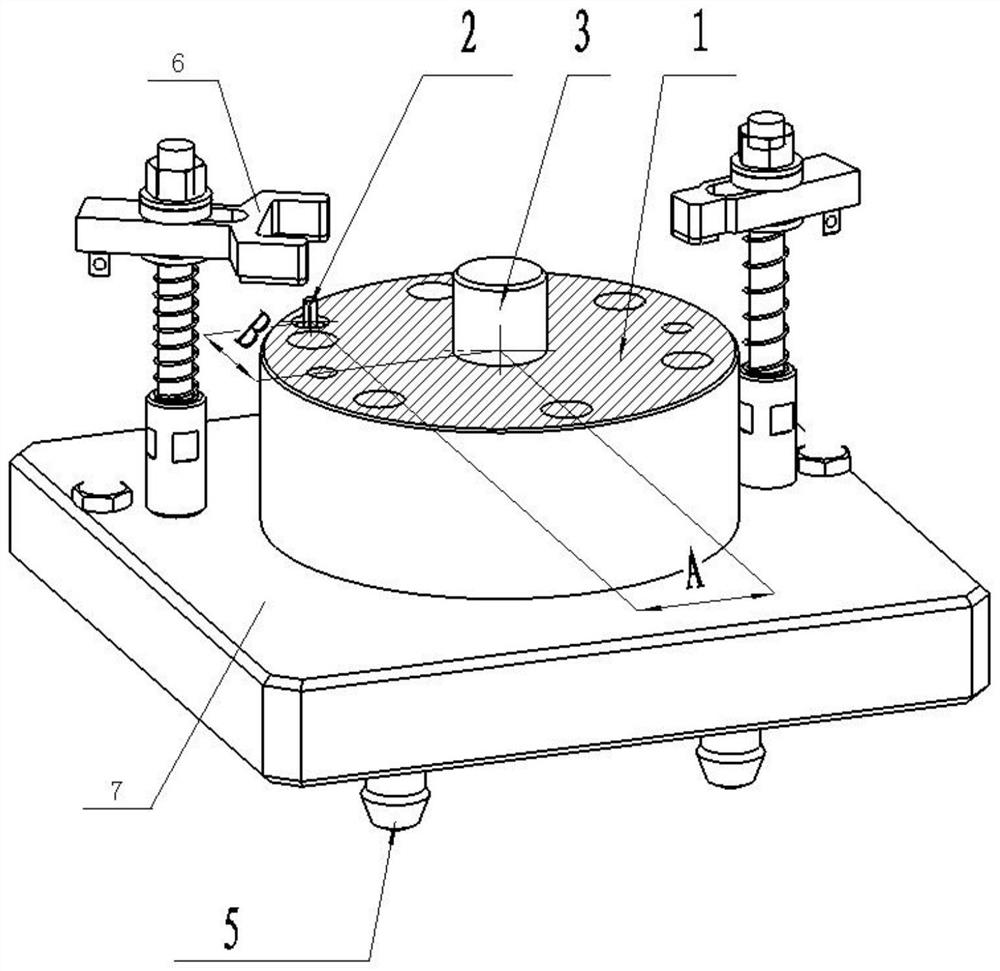

The method of finding the center of the replaceable head cutter head

ActiveCN112139852BAlignment speed is fastQuick alignmentAutomatic control devicesFeeding apparatusTool bitScrew thread

The invention discloses a method for centering a replaceable head cutter head, which comprises the steps of installing a main handle on a machine tool spindle, an adjusting ring being rotatably mounted on the main shaft; fixedly connecting the main handle and the connecting head, and connecting the alignment block to the connecting head Fixed connection; align the needle of the dial indicator with the middle of the alignment block; rotate the main shaft to make the dial indicator find the highest point of the alignment block, and rotate the adjusting ring to align the threaded parts with the highest point of the alignment block; tighten the thread The adjustment amount of the threaded part is half of the maximum runout of the dial indicator, and the threaded part is loosened so that it does not interfere with the connector; repeat the previous step until the dial indicator shows that the runout of the alignment block is less than or equal to Set the threshold; cross-lock the connector connecting the main handle and the connector, and judge whether the runout of the alignment block is less than or equal to the set threshold, if so, go to the next step, otherwise loosen the connector between the main handle and the connector, and restart Pre-tighten the main shank and the connecting head, and return to the step of rotating the spindle; remove the alignment block to complete the alignment of the center of the replaceable cutter head.

Owner:CHENGDU QIPING TECH CO LTD

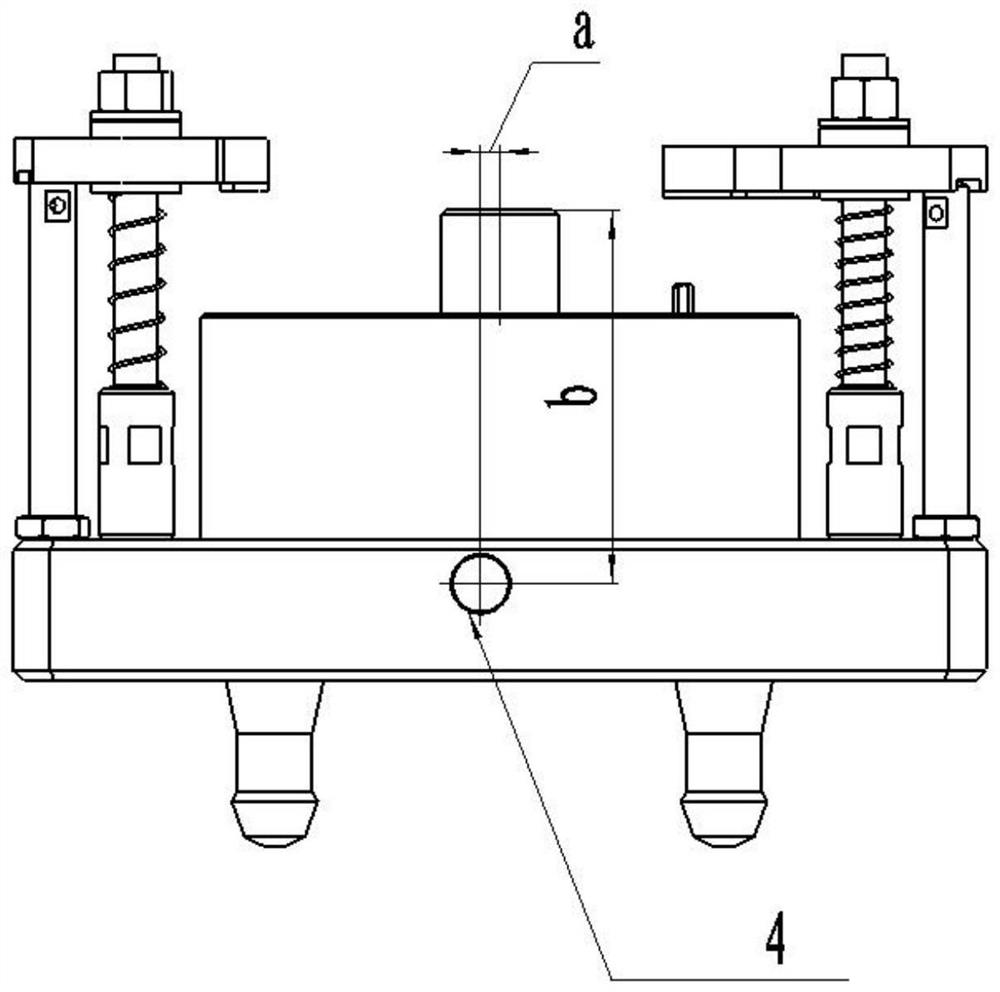

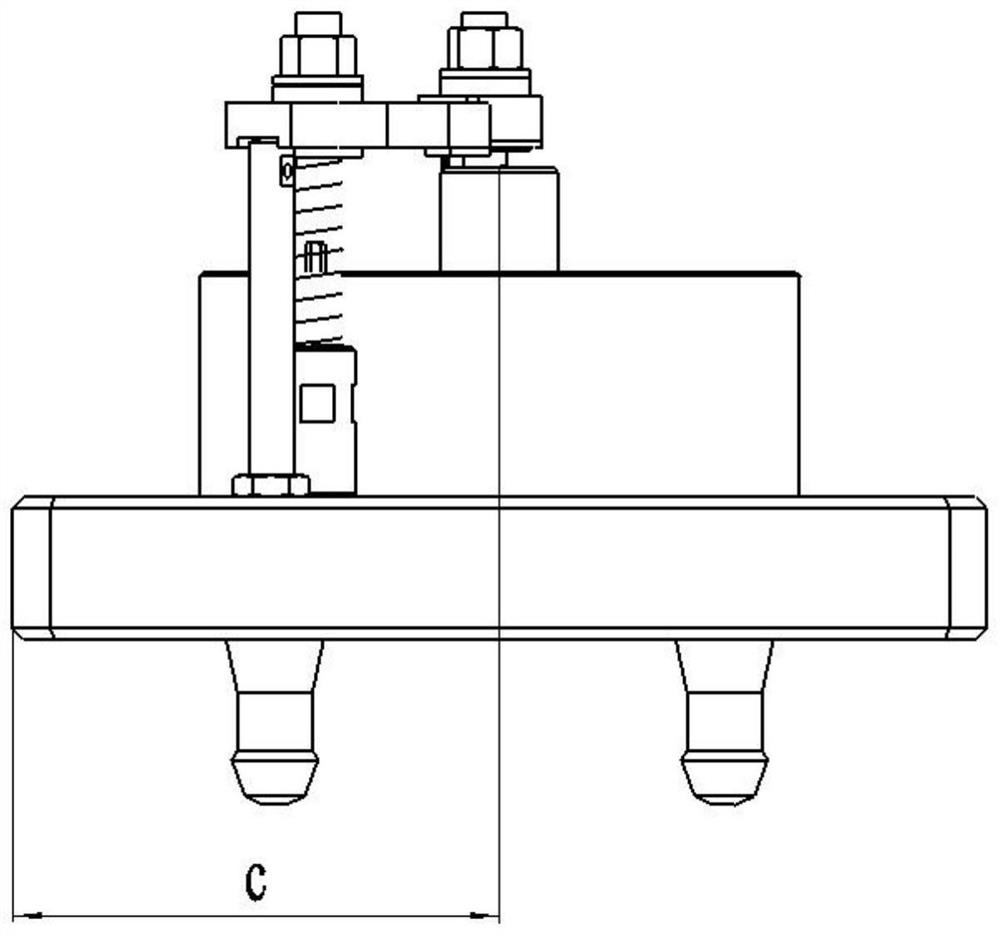

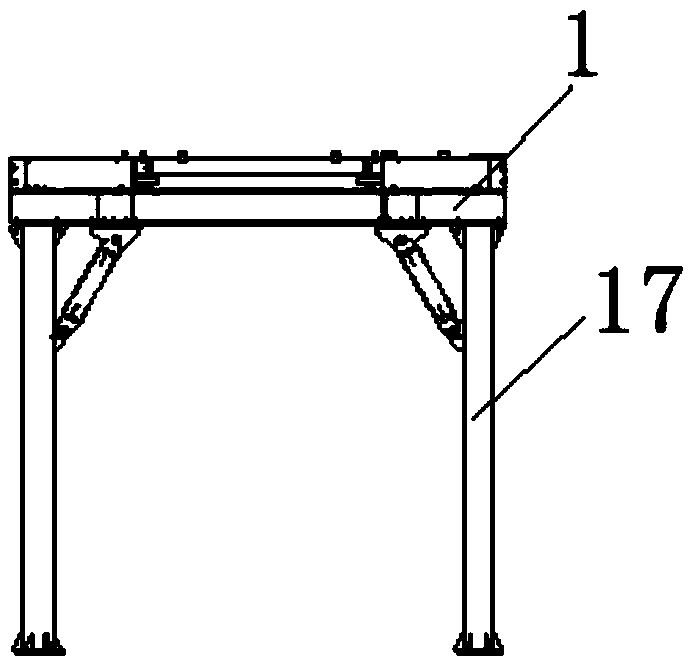

Anchor bolt alignment device

ActiveCN109629594BHigh precisionEven by forceFoundation engineeringConstruction engineeringAnchor bolt

Owner:STATE GRID CORP OF CHINA +2

Screen printer and contraposition method for same

ActiveCN102615950BImprove resolutionImprove efficiencyScreen printersPrinting press partsEngineeringCcd camera

The invention discloses a screen printer and a contraposition method for the same. The screen printer comprises a screen printer body; the screen printer body is provided with a computer and an XYtheta platform, wherein the computer is electrically connected with the XYtheta platform and can drive the XYtheta platform to move in the X-axis direction, the Y-axis direction and the theta-axis direction; a to-be-printed product placing part is arranged on the upper side of the XYtheta platform; the screen printer body further comprises a light source, a bracket and at least two CCD cameras, wherein the light source is arranged in the XYtheta platform; a light transmitting hole is formed on the edge of the to-be-printed product placing part on the XYtheta platform; the CCD cameras are mounted on the bracket; the camera shots of the two CCD cameras just face the light transmitting hole to enable light emitted by the light source to transmit the light transmission hole to reach the camera shots of the two CCD cameras; and signal output ends of the two CCD cameras are electrically connected with the computer. The two CCD cameras are adopted to conduct the contraposition. The screen printer has the advantages of simple structure, easiness in manufacturing, high contraposition speed and accuracy in contraposition.

Owner:东莞市嘉腾仪器仪表有限公司

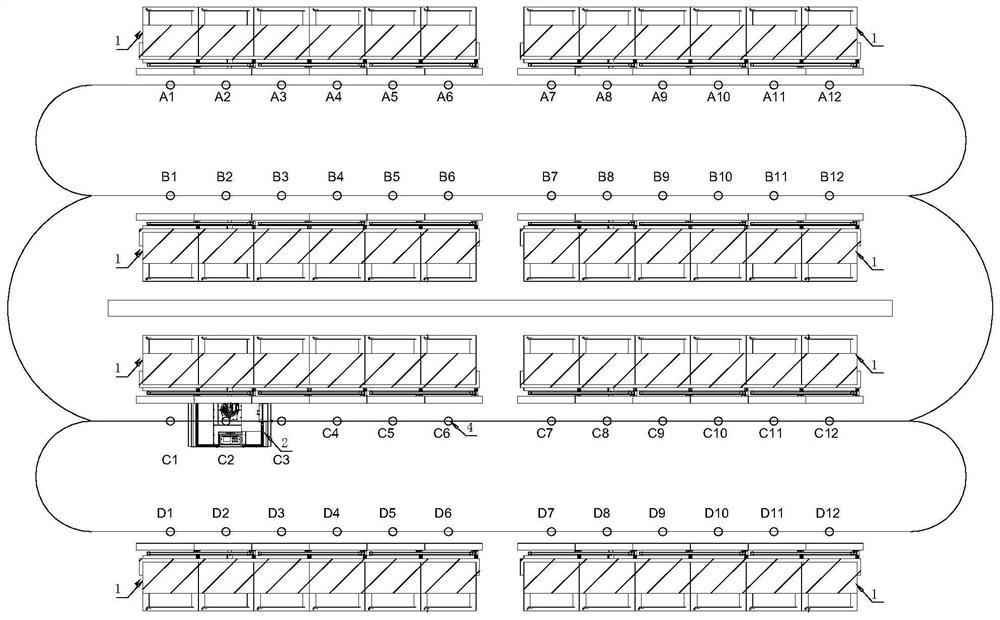

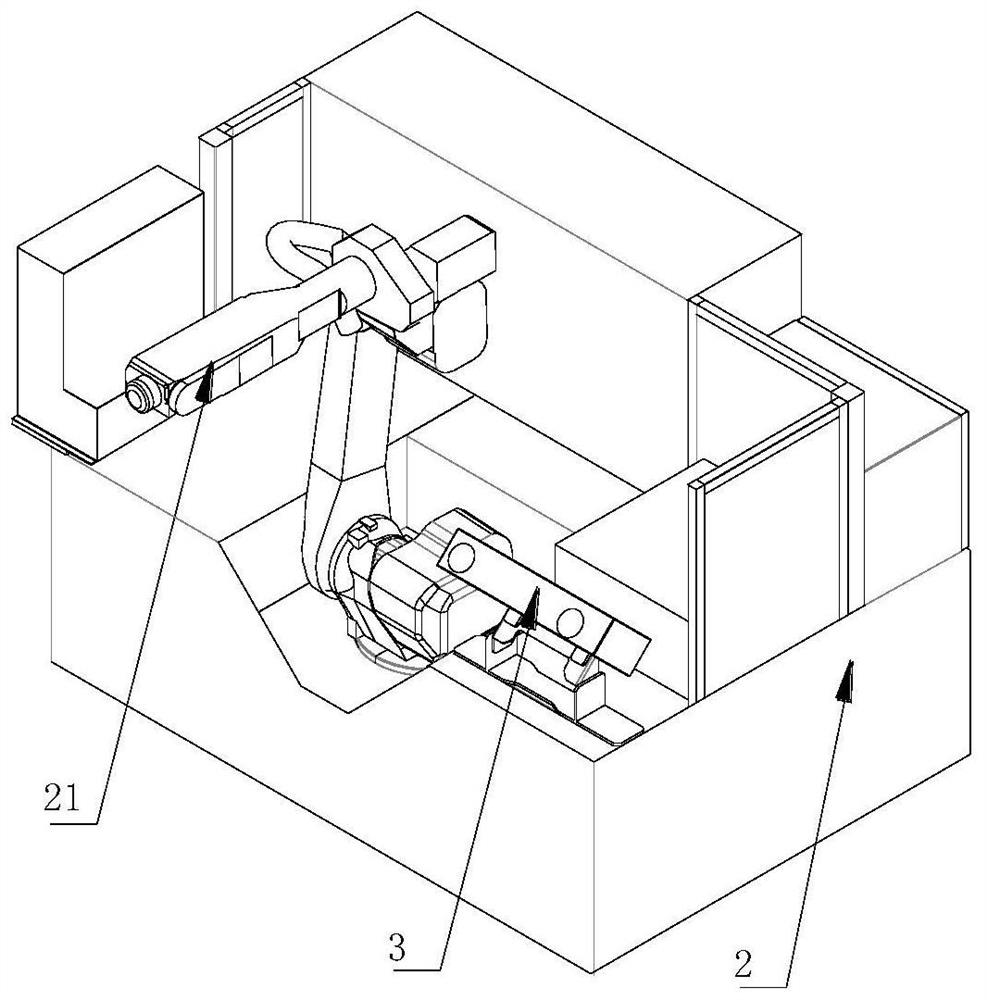

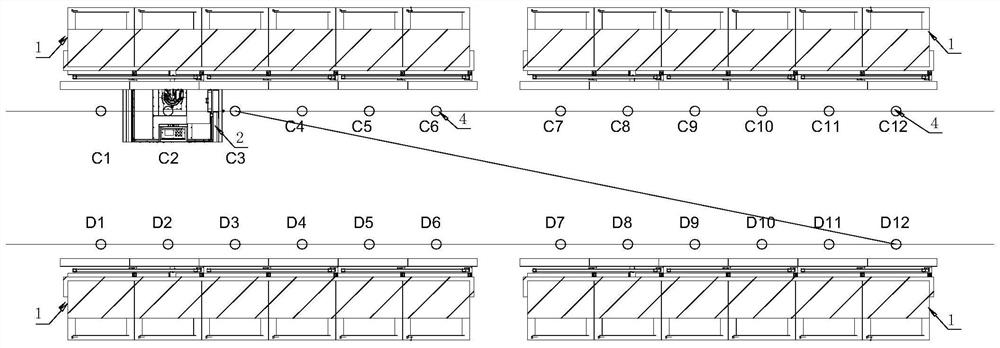

Automatic plate cleaning system

The invention discloses an automatic plate cleaning system which is used for clearing up a spinning jet on chemical fiber equipment. The automatic plate cleaning system comprises a walkable plate cleaning vehicle with a cleaning device, a 3D visual shooting positioning system, a navigation system, a call control system and the like. According to the automatic plate cleaning system, the plate cleaning vehicle is called through the call control system corresponding to the chemical fiber equipment, the plate cleaning vehicle is guided by a ground positioning magnet and a sensing device on the plate cleaning vehicle to automatically select an optimal route to reach a preset position, a spinneret plate is shot through the 3D visual shooting positioning system, the relative position of the spinneret plate is obtained, and therefore a cleaning device on the plate cleaning vehicle is precisely guided to reach the preset spinneret plate position to clean the spinneret plate. According to the automatic plate cleaning system, the cleaning device on the plate cleaning vehicle can be precisely aligned to the spinneret plate through the 3D visual shooting positioning system, the navigation system is formed by the positioning magnet on the ground surface and the sensing device on the plate cleaning vehicle together, the plate cleaning vehicle can automatically select the optimal and shortestroute to walk on, and therefore time is saved, and the efficiency is improved.

Owner:芜湖锐冠智能装备有限公司

Solar cell secondary silk-screen printing and four-lens positioning integrated device

InactiveCN107160856AImprove conversion efficiencyAlignment speed is fastPrinting press partsScreen printingElectrical batteryDisplay device

The invention discloses an integrated device for secondary screen printing and four-eye positioning of solar cells, belonging to the field of solar cell screen printing, and an integrated device for secondary printing and four-eye positioning of solar cells, including an operating table and a support frame , large servo controller, camera, first small servo controller, first printing head, second printing head, first small servo controller, printing platform, first slide rail, second slide rail, display and host computer; The four-eye camera is controlled by a large servo controller, and the printing platform adjusts the angle to make the positioning of the solar cell precise. The first printing head and the second printing head are controlled by a small servo controller, and the printing of the solar cell is realized through the slide track; The device is combined with machine vision and motion control, the whole process is fully automated, and the alignment speed is fast. At the same time, two printing machines are integrated to complete the secondary printing of solar cells, increase the conversion efficiency of solar cells, achieve efficient production, and effectively reduce production. cost.

Owner:ZHENJIANG SYD TECH CO LTD

Printing method capable of quickly aligning glass substrate with screen

The invention relates to a printing method capable of quickly aligning a glass substrate with a screen, which is characterized by comprising the following steps: firstly, drawing a frame diagram (4) at the center of a table (2) of a silk screen printing machine with an oil pen; secondly, putting a glass substrate in the corresponding position according to the position of the frame diagram (4), and vacuumizing to fix the glass substrate; thirdly, manually adjusting the screen frame according to the position of the frame diagram (4) observed from the hollow part of the screen until the diagram (4) is at the center of a screen diagram (3), and fixing the screen; fourthly, feeding slurry to print an experimental substrate, and manually adjusting the position of the glass substrate according to the error; and fifthly, after the position of the glass substrate is determined, making a mark with the oil pen. The invention has the advantage of high alignment efficiency, can not pollute or damage the screen, and is convenient and quick.

Owner:NANJING PANDA ELECTRONICS

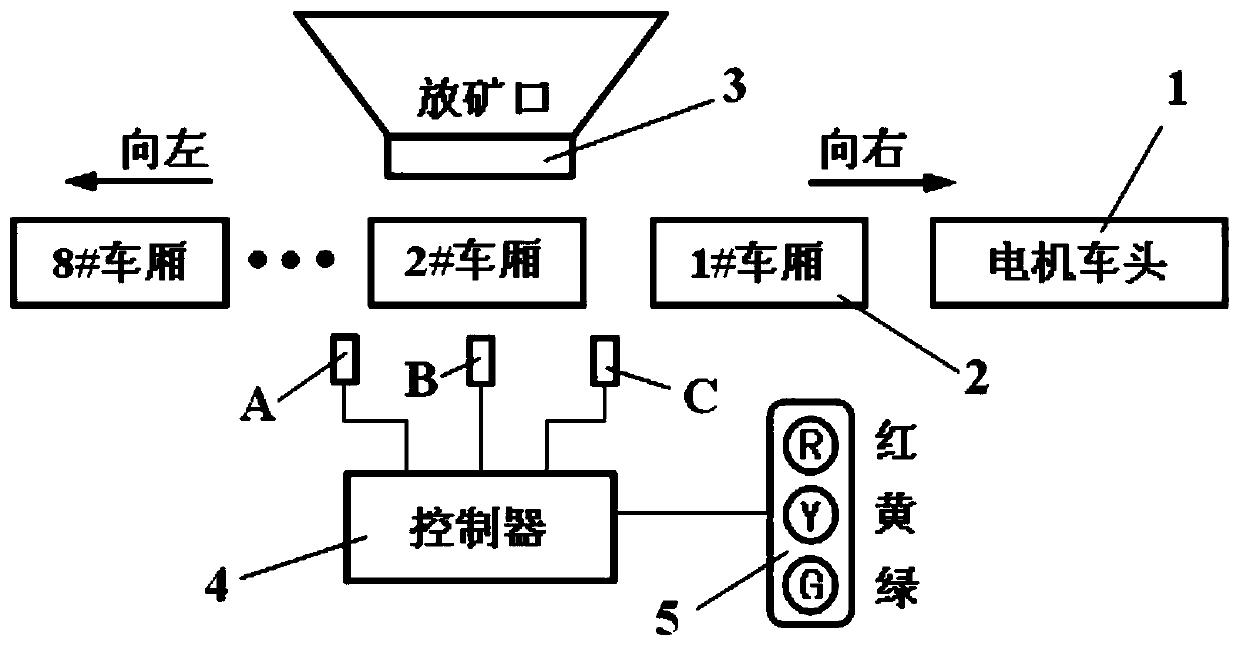

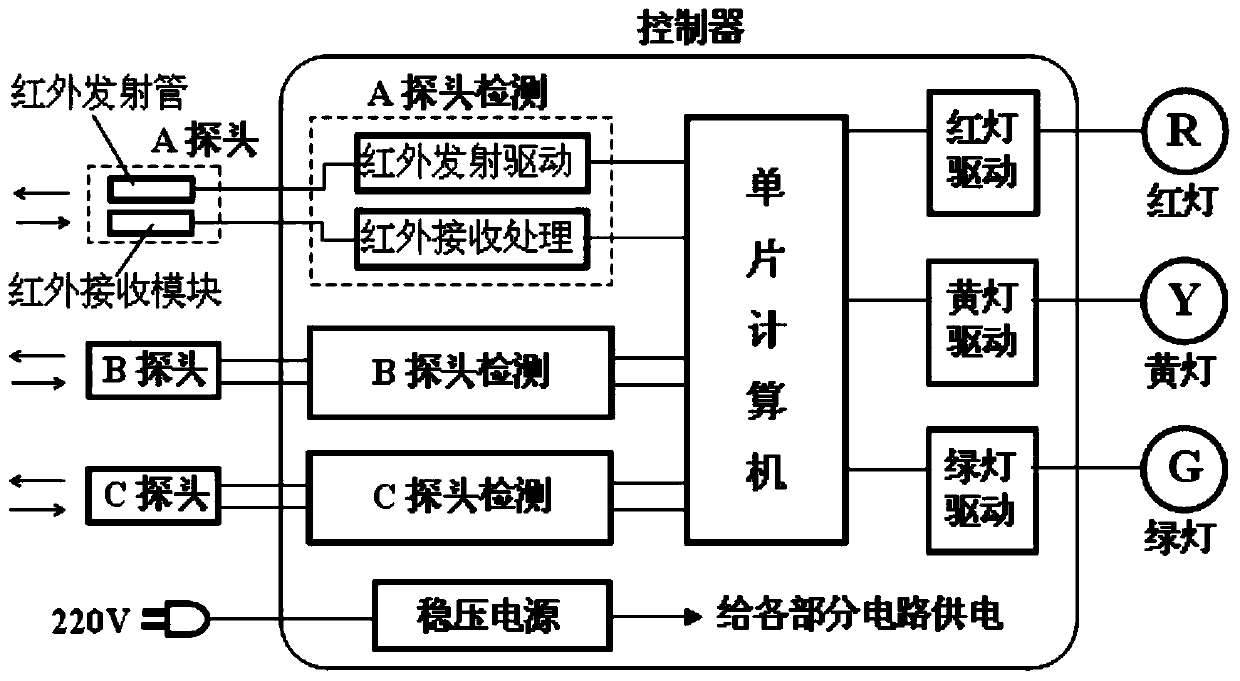

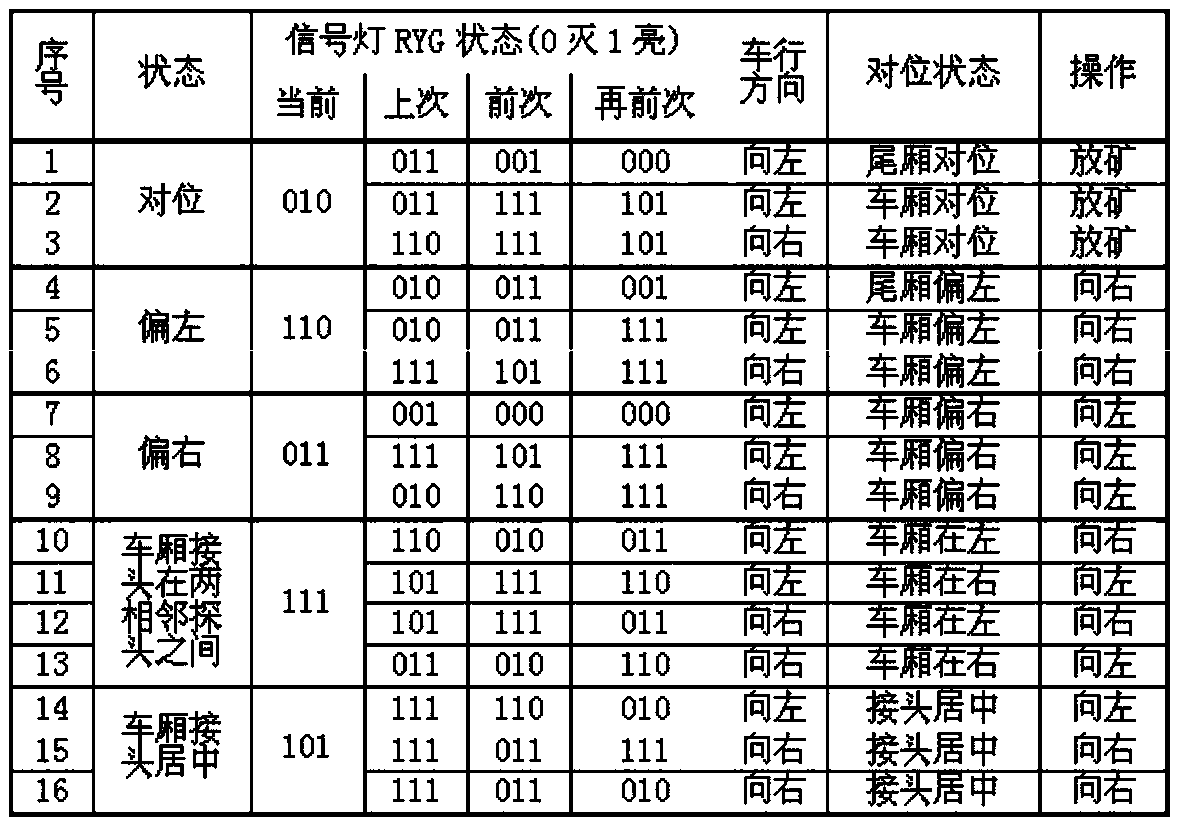

Electric locomotive signal indicator

InactiveCN110843858AAlignment speed is fastImprove loading efficiencySignalling indicators on vehicleMine carsEngineeringSignal light

The invention provides an electric locomotive signal indicator. The electric locomotive signal indicator comprises a controller, three infrared probes A, B and C connected with the input end of the controller and red, yellow and green tri-color signal lamps connected with the output end of the controller; each infrared probe comprises an infrared transmitting tube and an infrared receiving modulewhich are located inside; the controller comprises a single chip computer, three infrared probe detection circuits A, B and C, three signal lamp drive circuits and a stabilized voltage source supply circuit; the three reflective infrared probes are mounted on the outer side of a millhole railway, the probe B is located in the relative position in the middle of an aligning carriage, and the probesA and C are located in the relative positions of two ends of the aligning carriage; and each infrared probe detection circuit comprises an infrared transmitting drive circuit and an infrared receivingprocessing circuit. The electric locomotive signal indicator is simple in structure, convenient to mount, safe, reliable, economical and practical, and aligning speed of an ore loading carriage of anelectric locomotive can be greatly increased. The electric locomotive signal indicator can be applied to ore loading carriage alignment of the electric locomotive, ore unloading carriage alignment ofthe electric locomotive and other occasions needing aligning operation.

Owner:湘潭市宇通牵引电气有限公司

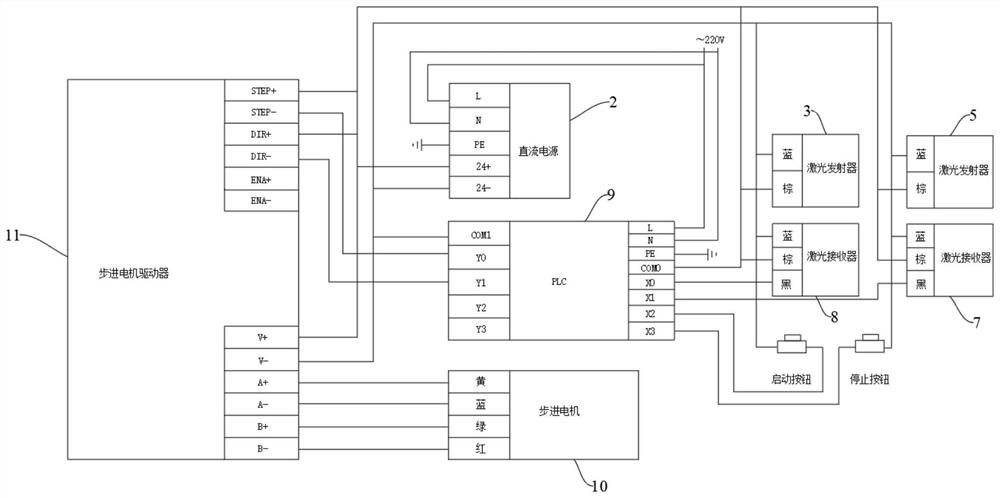

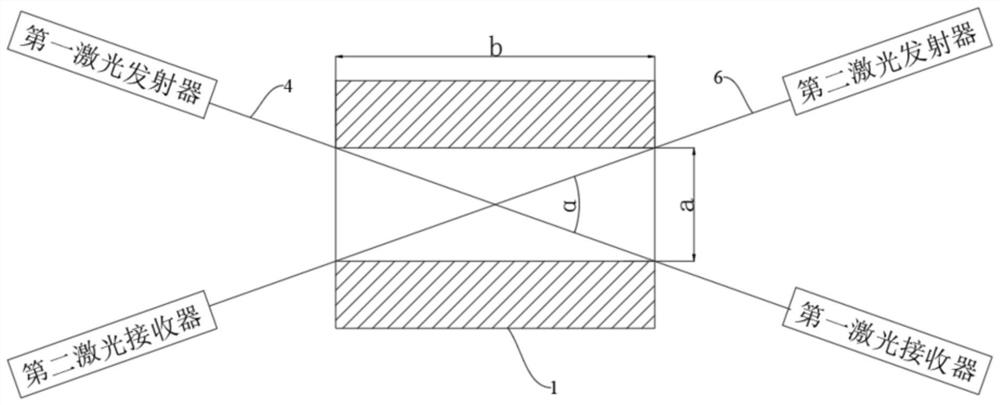

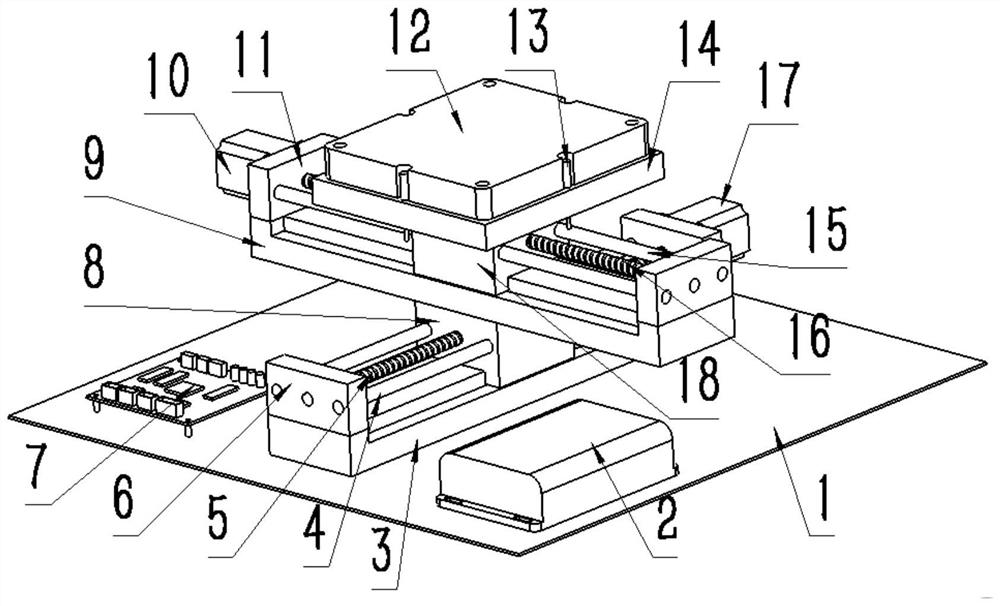

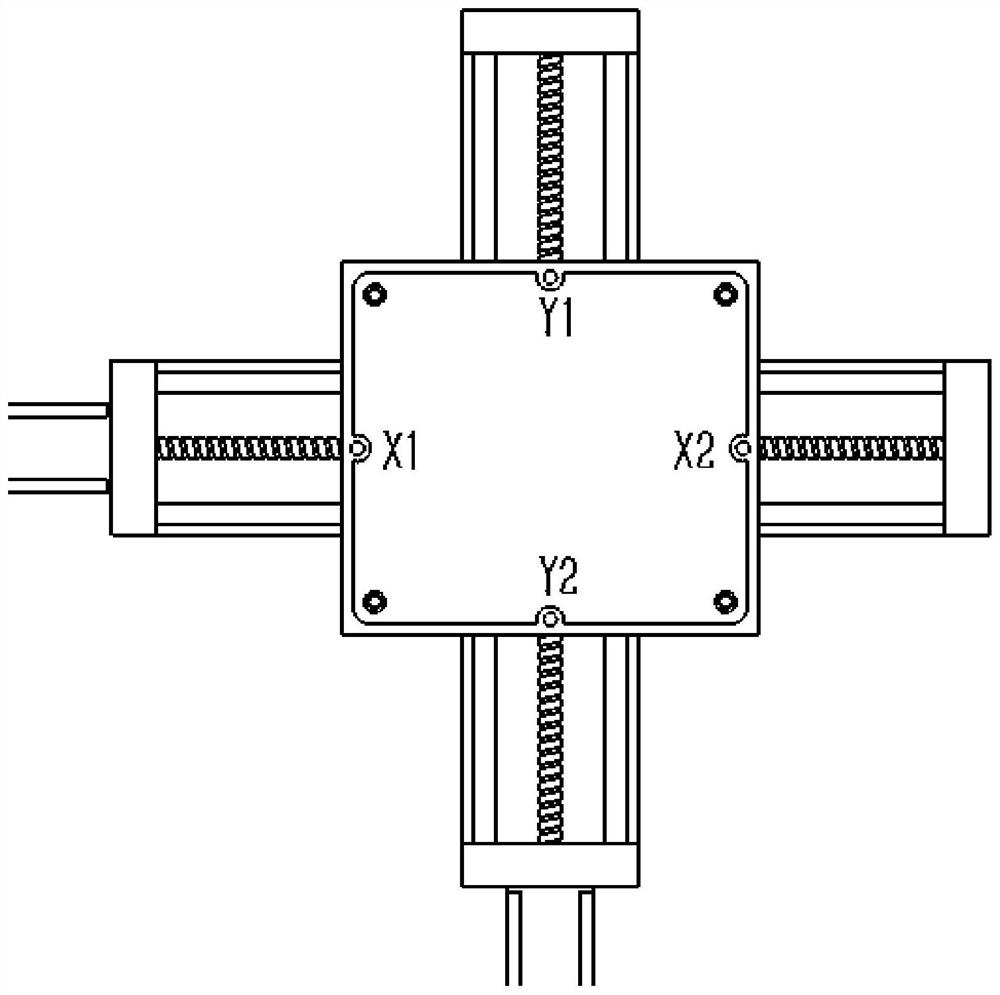

Automatic alignment method and device using optical alignment

ActiveCN113977479ASimple structureReduce wearFinal product manufactureWork holdersTransceiverLight beam

The invention belongs to the field of manufacturing and processing, and particularly relates to an automatic alignment method and device using optical alignment. The device comprises a workpiece to be aligned and an optical transceiver module. The optical transceiver module comprises a first transmitting end, a second transmitting end, a first receiving end and a second receiving end which are all arranged on the same horizontal plane. A first reference point, a second reference point, a third reference point and a fourth reference point are calibrated on the workpiece. The first reference point, the second reference point, the third reference point and the fourth reference point are all located on a horizontal plane. The workpiece is rotated on the horizontal plane, a light beam between the first transmitting end and the first receiving end passes through the first reference point and the second reference point, a light beam between the second transmitting end and the second receiving end passes through the third reference point and the fourth reference point, and alignment operation is completed. Optical automatic alignment is adopted, the alignment efficiency and precision are improved, and abrasion of the workpiece in the alignment process is reduced.

Owner:石嘴山工贸职业技术学院

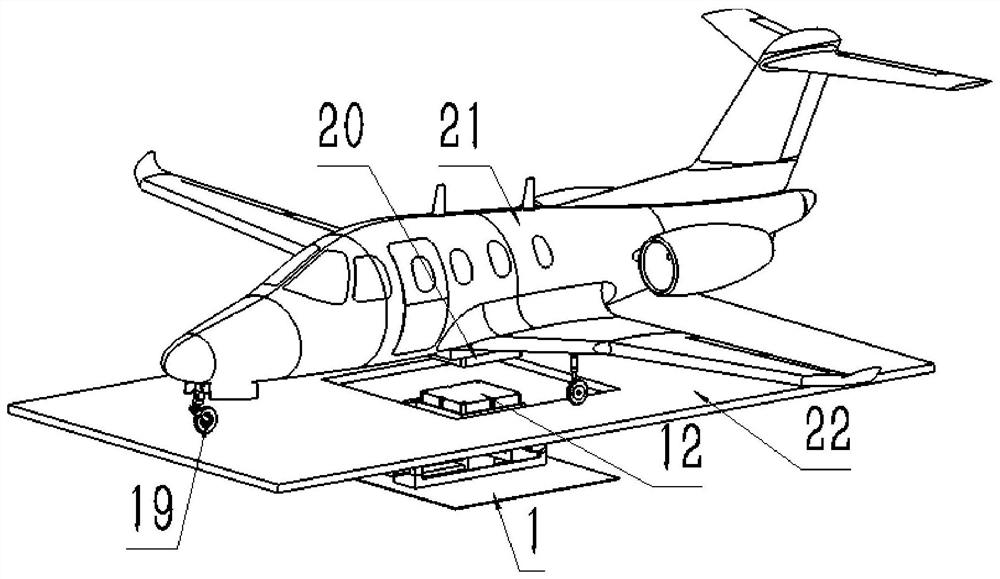

Electric aircraft wireless charging system and charging alignment method

PendingCN112895926AEnable wireless chargingNo leakageCharging stationsElectric vehicle charging technologyWireless transmissionElectric aircraft

The invention discloses an electric aircraft wireless charging system and a charging alignment method. The system comprises a battery and a receiving host which are arranged in the electric aircraft, the wireless charging transmitting device can charge the electric aircraft, a receiving wire coil is mounted on the electric aircraft, and the wireless charging transmitting device comprises a transmitting host capable of inputting alternating current and a transmitting wire coil capable of transmitting energy to the receiving wire coil. The transmitting host can transmit energy to the receiving wire coil in a resonant wireless mode through the transmitting wire coil, the receiving wire coil is connected with the receiving host, and the receiving host is connected with the battery and can charge the battery through the receiving host. The electric aircraft wireless charging system has the advantages that the wireless charging of the electric aircraft is realized, the phenomena of electric leakage and poor contact are avoided, the protection grade is high, and the electric aircraft can be charged outdoors and is not influenced by weather; automation of the whole charging alignment process is achieved, accurate positioning of a wireless charging transmitting wire coil and a wireless charging receiving wire coil is guaranteed, the charging efficiency reaches the highest, and manual intervention is not needed.

Owner:江苏航空职业技术学院

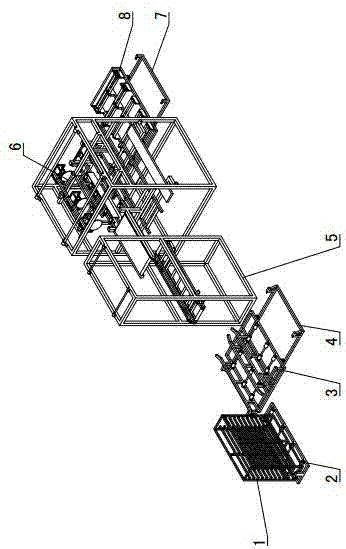

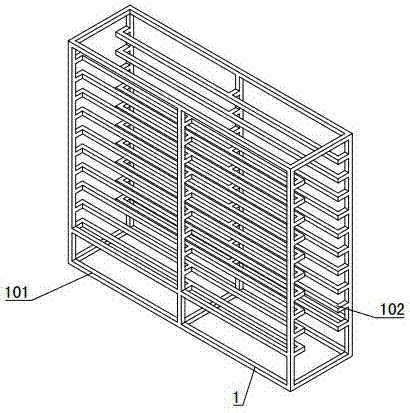

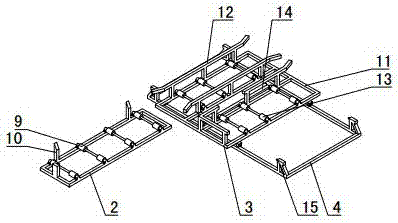

Edging device and edging technology for insulating boards

PendingCN107310019AImprove pass rateAvoid breakingAuxillary shaping apparatusEngineeringMechanical engineering

The invention discloses an edging device and an edging technology for insulating boards, and belongs to the technical field of production of the insulating boards. The edging device comprises a cutting device (6), a conveying device and a stacking device (21), wherein a cutting platform (22) is arranged on the lower side of the cutting device (6); the conveying device is arranged on the feeding side of the cutting platform (22); the bottom of the cutting platform (22) is the discharge side; and the stacking device (21) is arranged on the lower side of the cutting platform (22) in a liftable manner. According to the edging device for the insulating boards, manual labor is replaced, automatic cutting is achieved, edging speed is high, accuracy is high, and the qualification rate of the cut insulating boards is high; and the stacking device is arranged on the lower side of the cutting platform in a liftable manner, so that the insulating boards can be prevented from being broken during stacking, and the situation that operation of the cutting platform is hindered due to the fact that too much insulating boards are stacked can be avoided. The edging technology is simple in operation, and automatic one-by-one cutting for the insulating boards is completely automatic.

Owner:淄博雅安建材有限公司

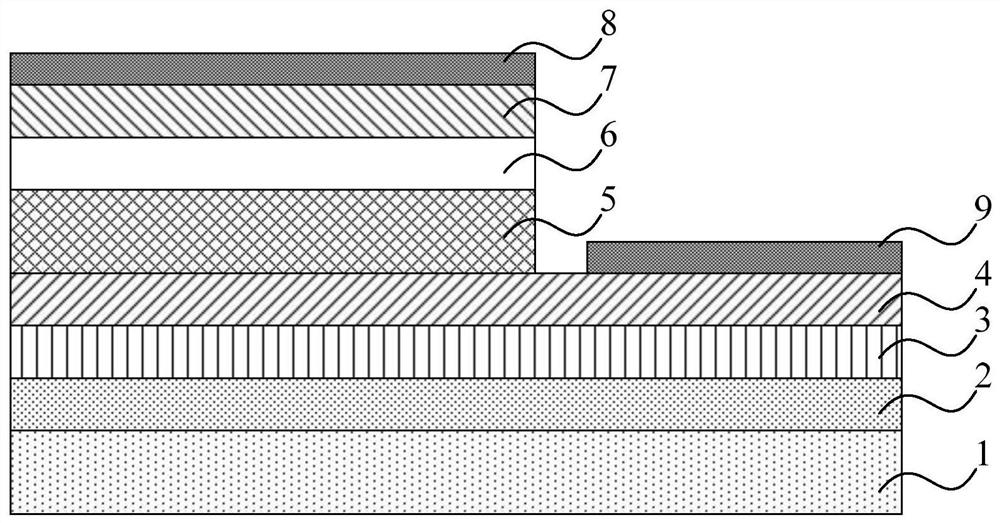

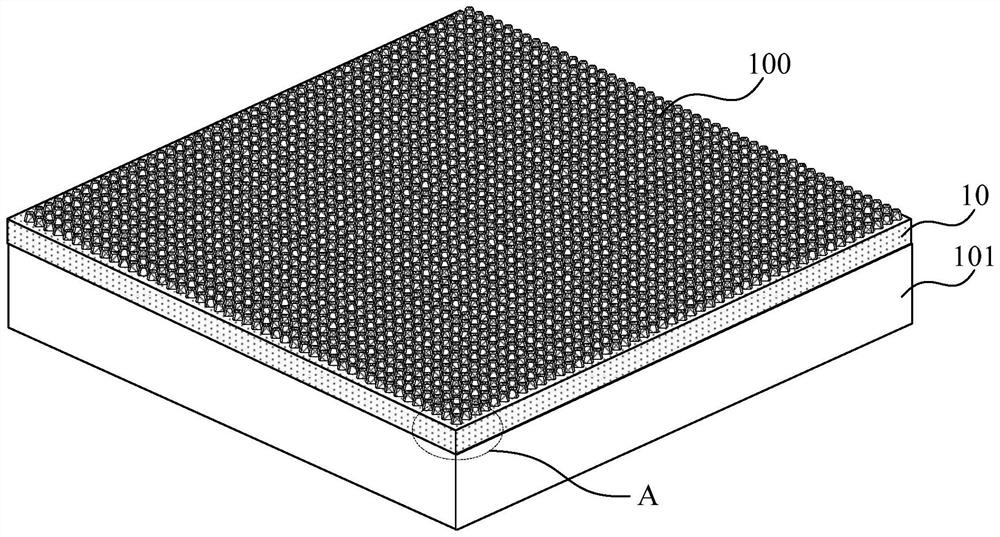

Preparation method of micro-led display panel and micro-led display panel

ActiveCN109994579BGood electrical contactAchieve normal displaySolid-state devicesSemiconductor devicesLED displayElectrical connection

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

A roll continuous sheet cutting method based on CCD image recognition die-cutting machine

ActiveCN108972675BGuaranteed accuracyReduce biasMetal working apparatusMechanical engineeringCharge couple device

The invention discloses a coiled continuous sheet cutting method based on a CCD (charge coupled device) image recognition die-cutting machine. Coordinates of a first identifier and second identifier are quickly recognized by making full use of cooperation of a first CCD image recognition module and a second CCD image recognition module; the coordinates are compared with preset coordinate, and analyzing is performed to obtain deviation data of current sheets; calculating is performed according to the deviation data of the current sheets to obtain alignment parameters; an alignment module can quickly acquire the alignment parameters and adjust positions of the current sheets according to the alignment parameters, and then, the current sheets may reach a die-cutting position to take cutting;a control module corrects single pull length according to the alignment parameters and controls a drum drawing module to draw each coiled continuous sheet. The die-cutting machine herein can perform aligning quickly to finish single cutting at the premise of precision guaranteed; cutting speed of continuous cutting can be further increased.

Owner:深圳市四元数数控技术有限公司

Alignment Fixture and Alignment Method for Complicated Housing Installation State

Owner:XIAN AERO ENGINE CONTROLS

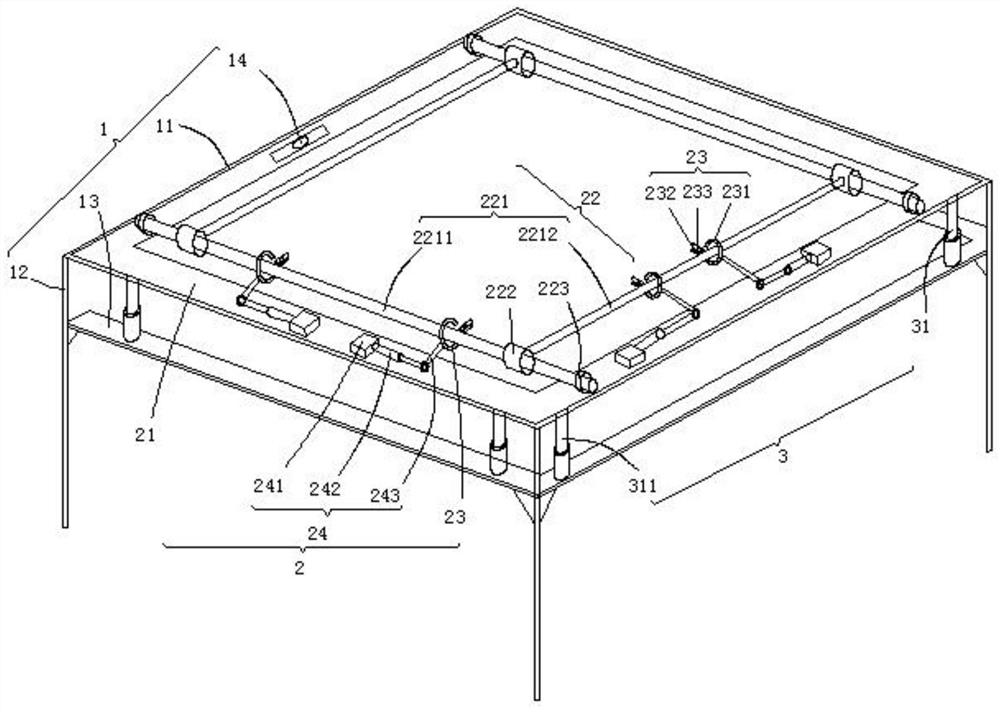

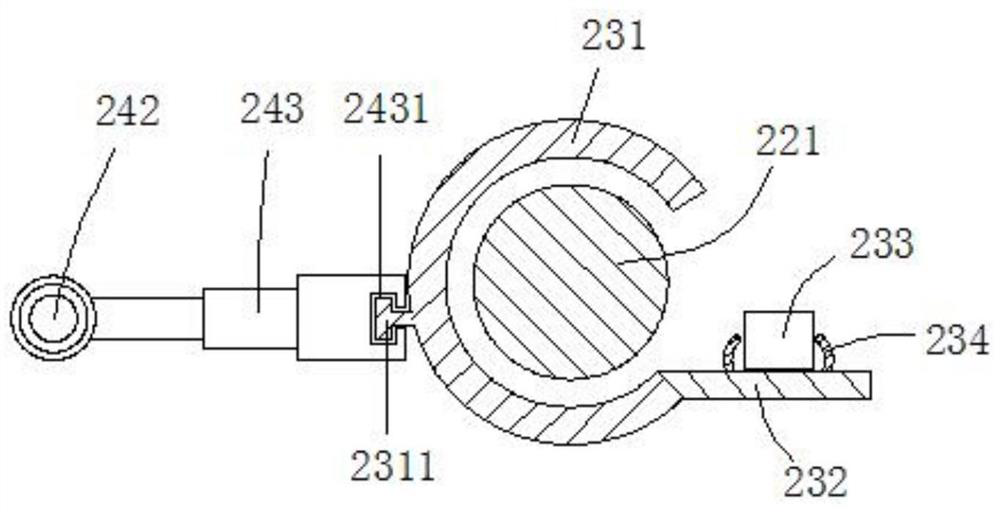

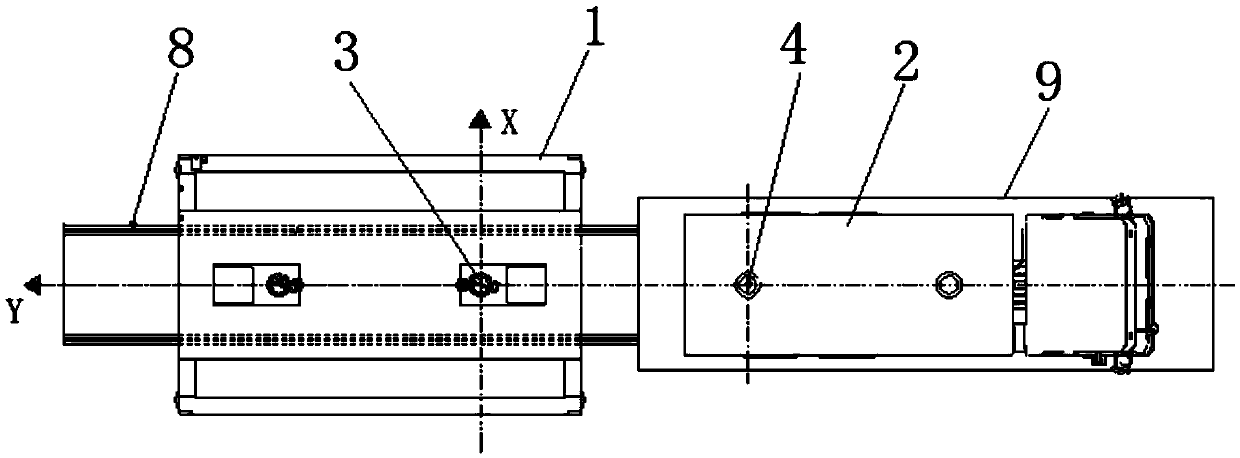

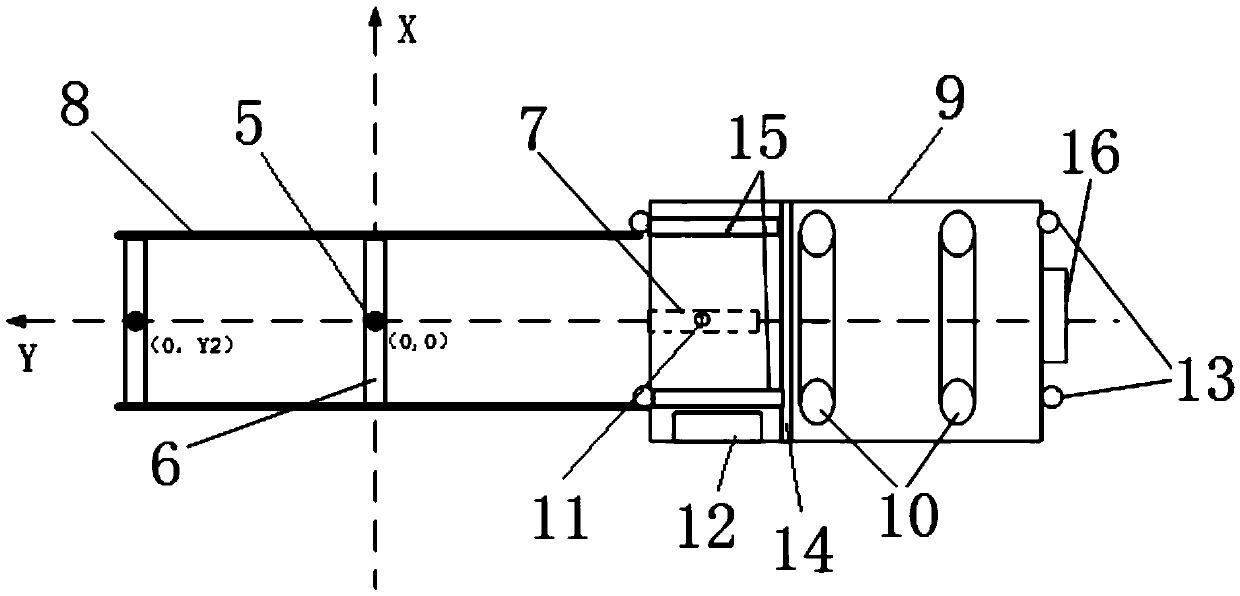

A dry-mixed mortar transport vehicle and a bulk head automatic alignment method and device

ActiveCN103707797BImprove work efficiencyAlignment speed is fastConcrete transportationDischarging apparatusDrive motorAutomotive engineering

The invention relates to an automatic alignment method and an automatic alignment device for a dry-mixed mortar transporting vehicle and separate-packaging heads. The device comprises a finished product warehouse and the dry-mixed mortar transporting vehicle, wherein the separate-packaging heads are arranged on the finished product warehouse; material receiving openings corresponding to the separate-packaging heads are formed in the dry-mixed mortar transporting vehicle; a first detection line is arranged at positions of projection points of the separate-packaging heads on the ground in the finished product warehouse; a second detection line is arranged at positions corresponding to the material receiving openings in the dry-mixed mortar transporting vehicle; traveling rails are arranged in the finished product warehouse; a traveling trolley for carrying the dry-mixed mortar transporting vehicle is arranged on the traveling rails; position adjustment mechanisms for adjusting a relative position of the dry-mixed mortar transporting vehicle and the traveling trolley, a detection device for detecting the first detection line and the second detection line, a controller and a driving motor are arranged on the traveling trolley; the detection device is electrically connected with the controller; the controller is electrically connected with the position adjustment mechanisms and the driving motor; the driving motor is used for driving the traveling trolley. The automatic alignment method and the automatic alignment device can increase the speed for aligning the transporting vehicle to the separate-packaging heads.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

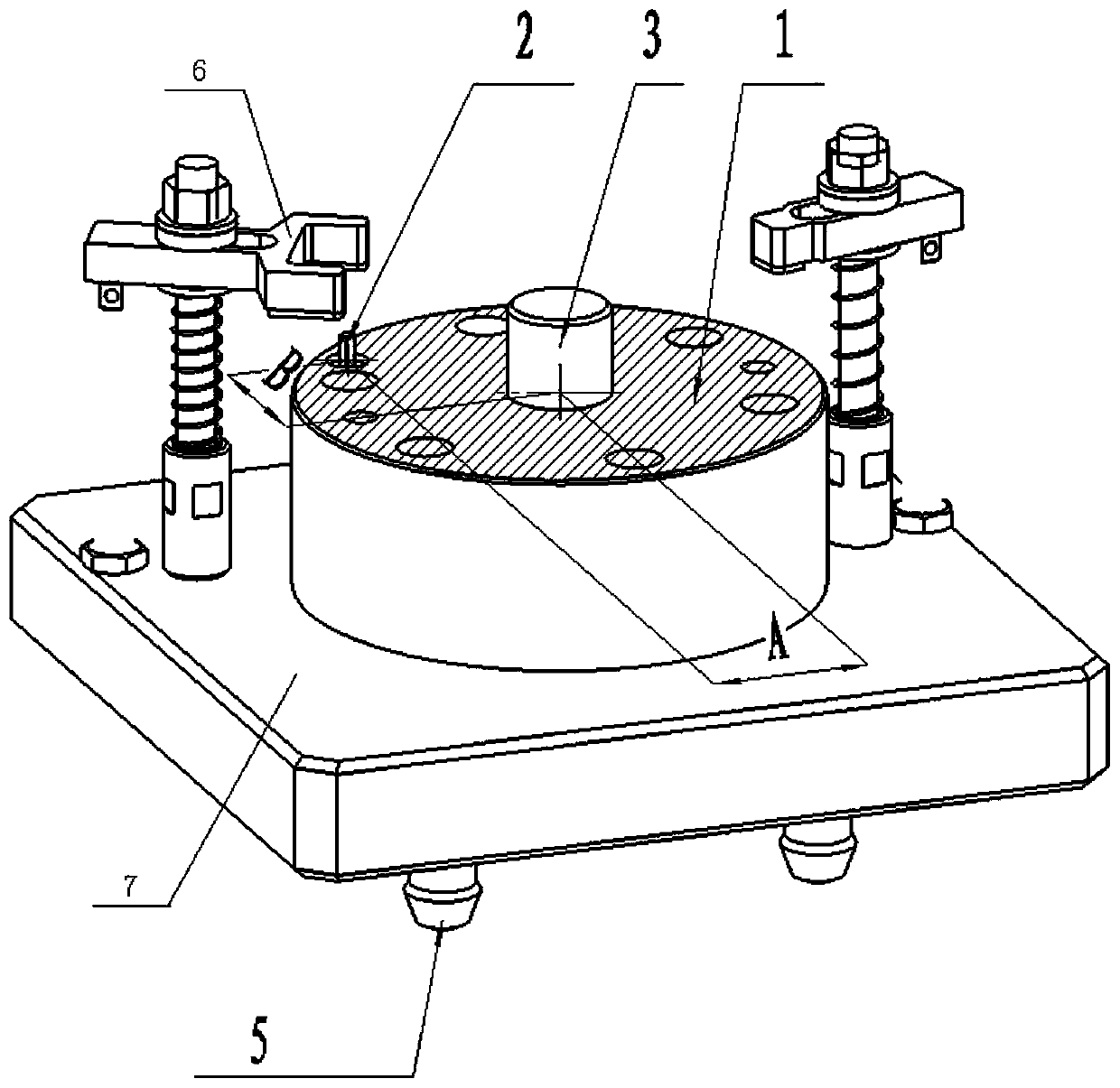

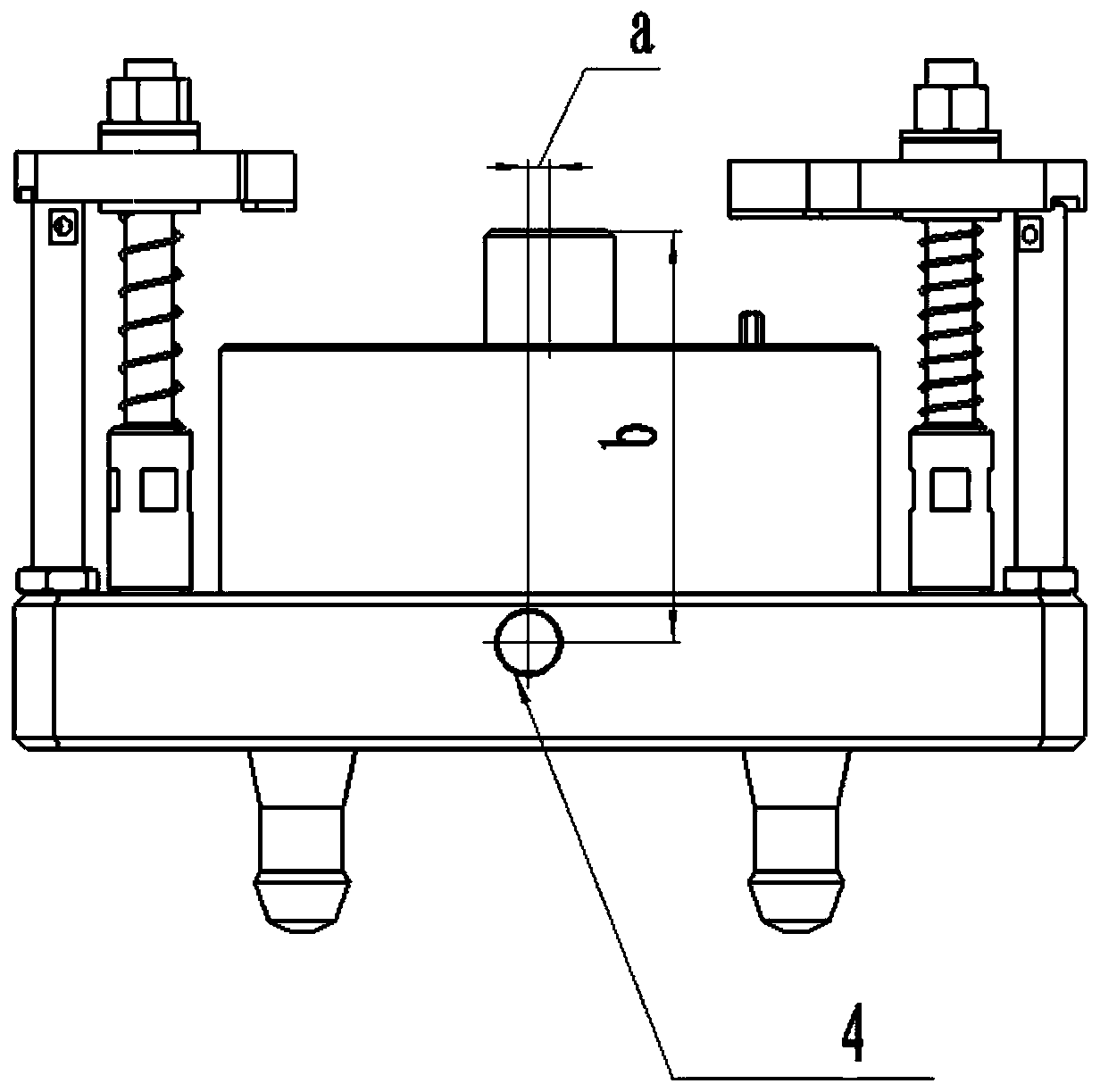

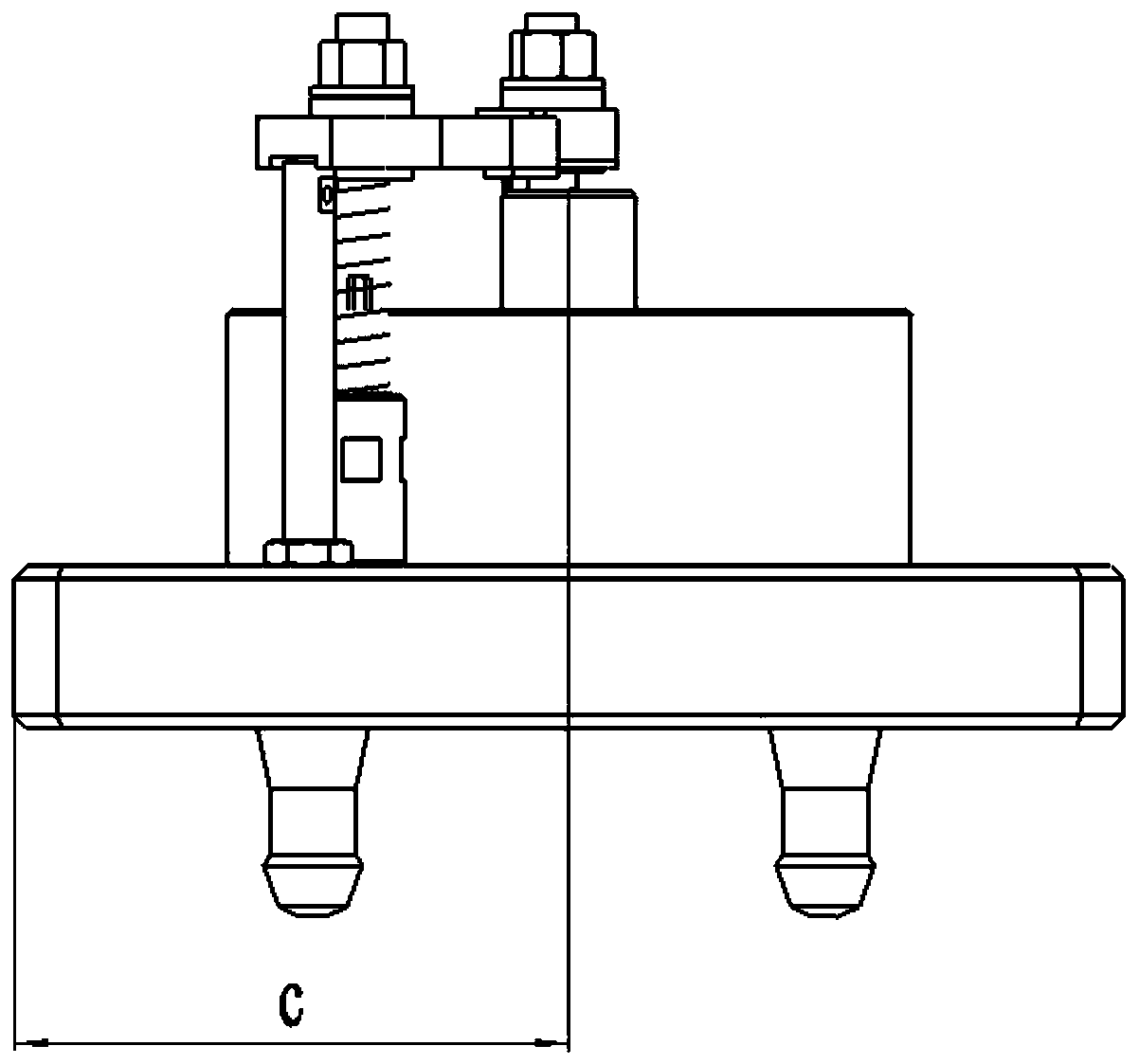

Alignment clamp for complex shell installation state and alignment method

The invention belongs to the field of machining, and relates to an alignment clamp for a complex shell installation state and an alignment method. The alignment clamp comprises a clamp body, a boss isarranged on the clamp body, and the upper surface of the boss is a positioning surface for placing a part to be aligned; an auxiliary positioning pin and a main positioning pin which are respectivelyvertical to the positioning surface are arranged on the positioning surface in parallel; an alignment hole is formed in the side wall of the boss; the distance between the alignment hole and the mainpositioning pin is constant; a clamping blind rivet is arranged on the lower surface of the clamp body; and a pressing plate used for fixing the part to be aligned is arranged on the upper surface ofthe clamp body. By means of the alignment clamp for the complex shell installation state and the alignment method, the universality is high, the alignment speed is high, and the alignment correctnesscan be improved.

Owner:XIAN AERO ENGINE CONTROLS

Method for automatically aligning pins of small liquid crystal display board plate and IC board

ActiveCN109001920AAlignment speed is fastAccurate operationNon-linear opticsLiquid-crystal displayControl software

The invention discloses a method for automatically aligning pins of a small liquid crystal display board plate and an IC board. Aligning is achieved through the following steps that 1, the corresponding relationship of converting of camera coordinates into world coordinates is determined through PC control software; 2, the positions of a left outer target and a right outer target of the standard product glass board and left and right targets, in the glass board, of the IC board are collected; 3, the corresponding relationship of the positions of the left outer target and the right outer targetof the standard product glass board and the left and right targets of the IC board are calculated; 4, actual production is conducted, specifically, the positions of the left outer target and the right outer target of the glass board and the left and right targets of the IC board are collected; and 5, the positions of a virtual left outer target and right outer target of the glass board, and the offset of the virtual left outer target and right outer target to the left and right targets of the IC board are calculated, according to the calculation results, calculation control software transmitsthe calculated offset, needed for aligning of the glass board signal input end pins and the pins of the IC board, of an electric aligning platform to the electric aligning platform, and the electricaligning platform drives the glass board to automatically move by a certain amount to complete the aligning program of the glass board signal input end pins and the pins of the IC board. The aligningspeed is high, and aligning is accurate.

Owner:上海视眸自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com