Method for automatically aligning pins of small liquid crystal display board plate and IC board

A liquid crystal display, automatic alignment technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of cumbersome alignment, long preparation time, low product quality, etc., to achieve wide application prospects, fast alignment speed, Good alignment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

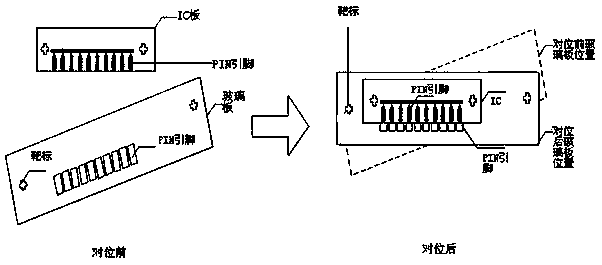

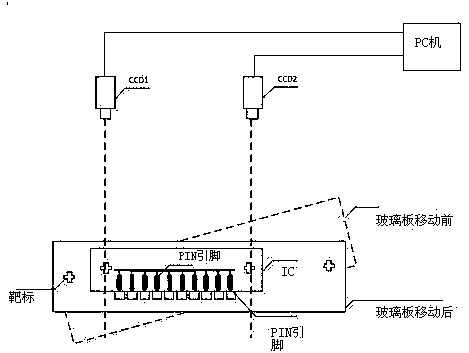

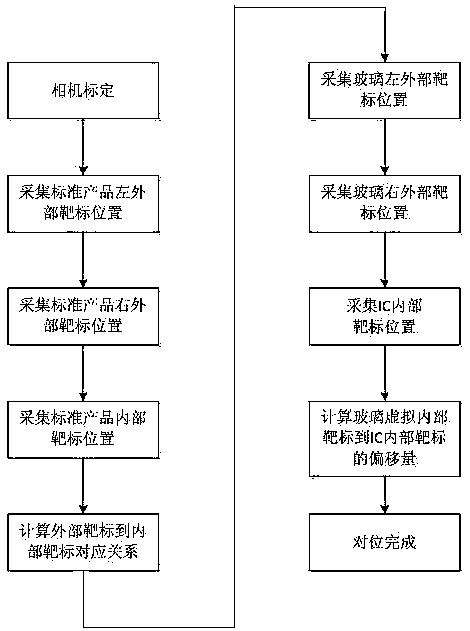

[0024] figure 2 , 3 , 4, 5, 6, 7, 8, 9, and 10, an automatic alignment method for the pins of a small liquid crystal display glass plate and an IC plate, using two CCD industrial cameras, a PC and an internal calculation The control software and the electric alignment platform are used as tools and software for automatic alignment, which are divided into the following steps to realize the alignment. 1. Use the PC control software to calibrate the positions of the two cameras respectively, and determine that the camera coordinates are converted into world coordinates The corresponding relationship, the coordinates are displayed on the screen of the PC; 2. Production preparation, place a standard product that has been aligned and pressed with a piece of glass plate and IC board pins on the electric alignment platform, and collect them respectively through two CCD industrial cameras The left outer target and right outer target of the glass plate of the standard product and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com