Alignment method for paperhanging paper and binding article

A technique for adhesives and paper mounting, which is applied in the fields of paper pasting and decorative art, and can solve the problems of correcting the deviation between the mounting paper and the carton, and the adhesives are not aligned and unqualified, so as to achieve fast alignment and alignment High-precision, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

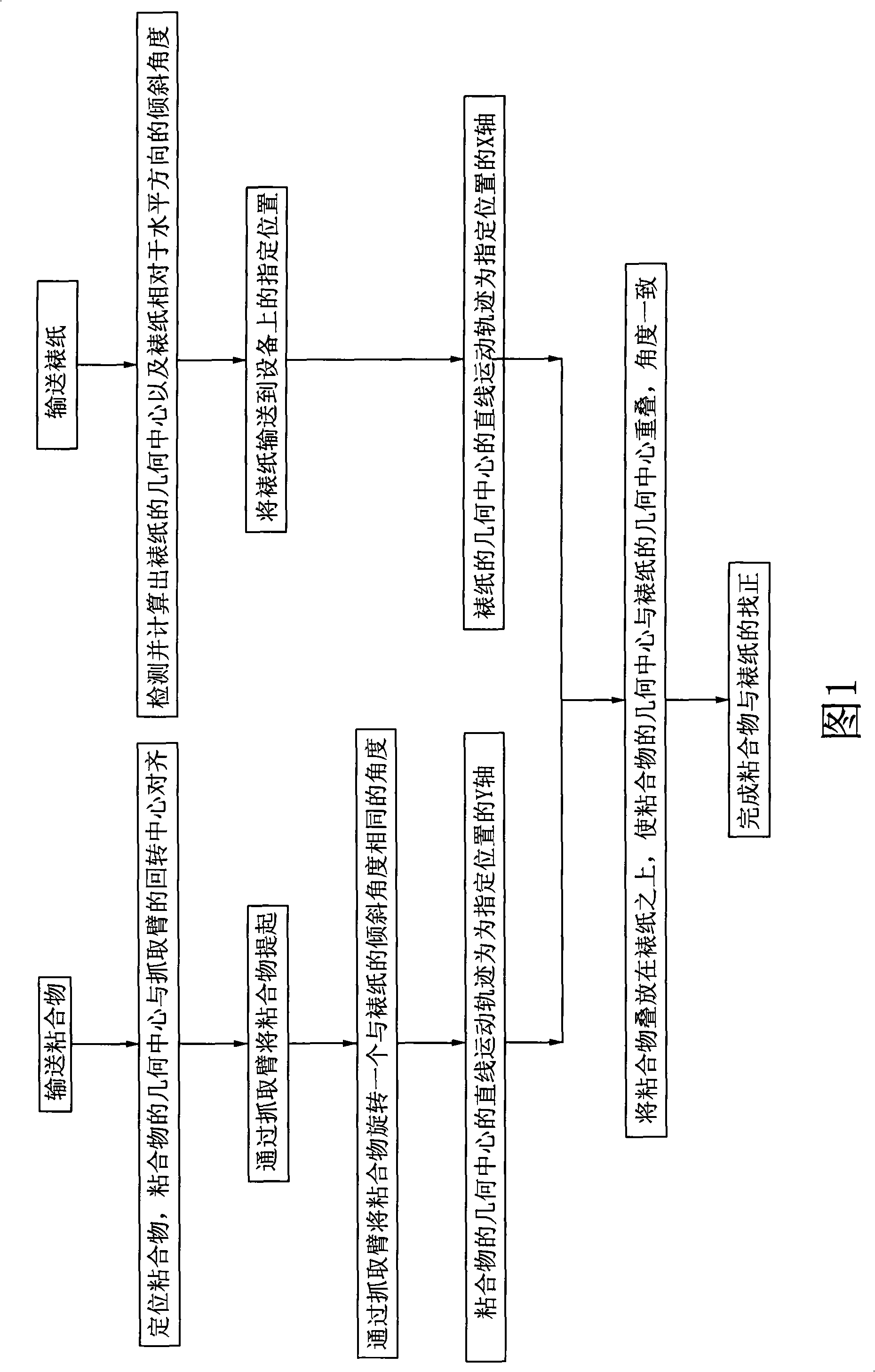

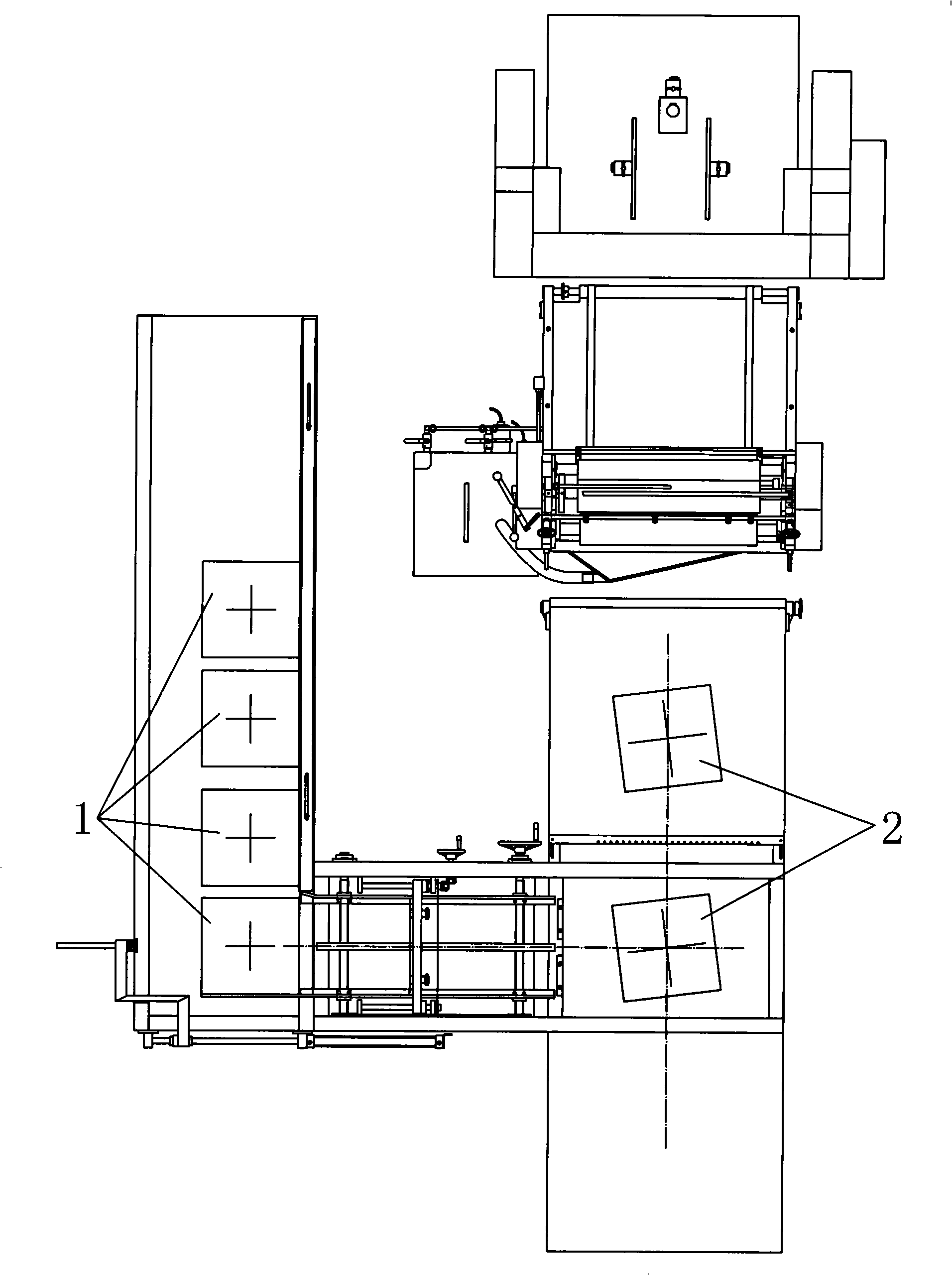

[0030] The alignment method of mounting paper and adhesive, embodiment sees accompanying drawing 1 and 2, and it comprises transporting mounting paper, conveying adhesive, adhesive is stacked on the mounting paper, specifically as follows:

[0031] A. The process of conveying and mounting paper includes:

[0032] The conveyor belt transports the mounting paper, and there is a geometric center on the mounting paper;

[0033] Detect and calculate the inclination angle of the mounting paper relative to the horizontal direction;

[0034] Transport the mounted paper to the designated position on the equipment;

[0035] B. The process of conveying adhesives includes:

[0036] The conveyor belt transports the adhesive, which has a geometric center;

[0037] Locate the adhesive and determine the geometric center of the adhesive;

[0038] The adhesive is lifted by the grabbing arm, and the center of rotation of the grabbing arm is aligned with the geometric center of the adhesive; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com