Edging device and edging technology for insulating boards

A technology for insulation boards and cutting devices, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., which can solve the problems of high physical hazards for operators, increased processing costs of insulation boards, unstable dimensions of insulation boards, etc., and achieve cutting speed Fast, high accuracy, less action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

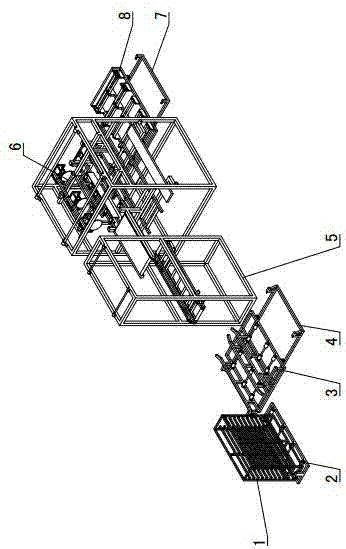

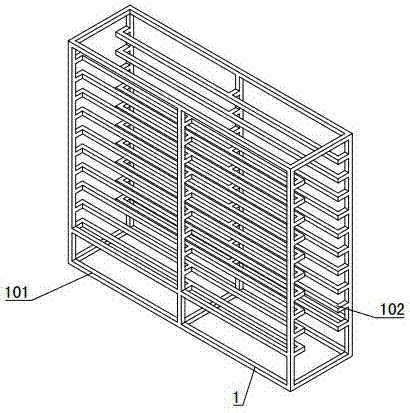

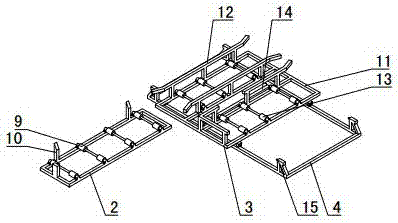

[0042] Figure 1~13 It is the best embodiment of the present invention. Figure 1~13 The present invention will be further explained.

[0043] An edge-aligning device for an insulation board includes a cutting device 6, a conveying device, and a stacking device 21. A cutting platform 22 is provided on the lower side of the cutting device 6, and the conveying device is provided on the feeding side of the cutting platform 22 and the bottom of the cutting platform 22 For the discharge side, the stacking device 21 is arranged on the lower side of the cutting platform 22 so as to be liftable. The conveying device of the insulation board aligning device completes the work of conveying the insulation board to the cutting platform 22. The cutting device 6 cooperates with the cutting platform 22 to cut the insulation board, and the cut insulation board is stacked on the stacking device 21 , Thus replacing manual labor, realizing automated cutting, fast edge-aligning speed, high accuracy, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com