Ultra-elastic alloy slice mechanical arm

A superelastic alloy and manipulator technology, applied in the field of robotics, can solve the problems of restricting the research and popularization of serpentine manipulators, serious coupling of pull wire movement, and heavy driving mechanism, etc., to achieve improved control accuracy, simple structure, and motion accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further introduced below in conjunction with the accompanying drawings.

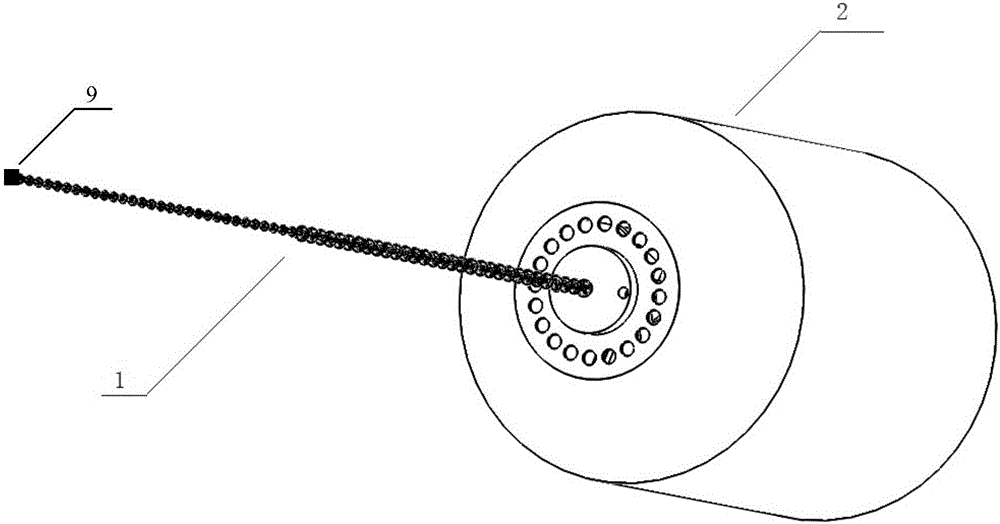

[0042] Such as figure 1 As shown, a superelastic alloy sheet mechanical arm is characterized in that it includes a mechanical arm joint body 1 and a driving mechanism 2 , and the mechanical arm joint body 1 and the driving mechanism 2 are mechanically connected by a pull wire 25 .

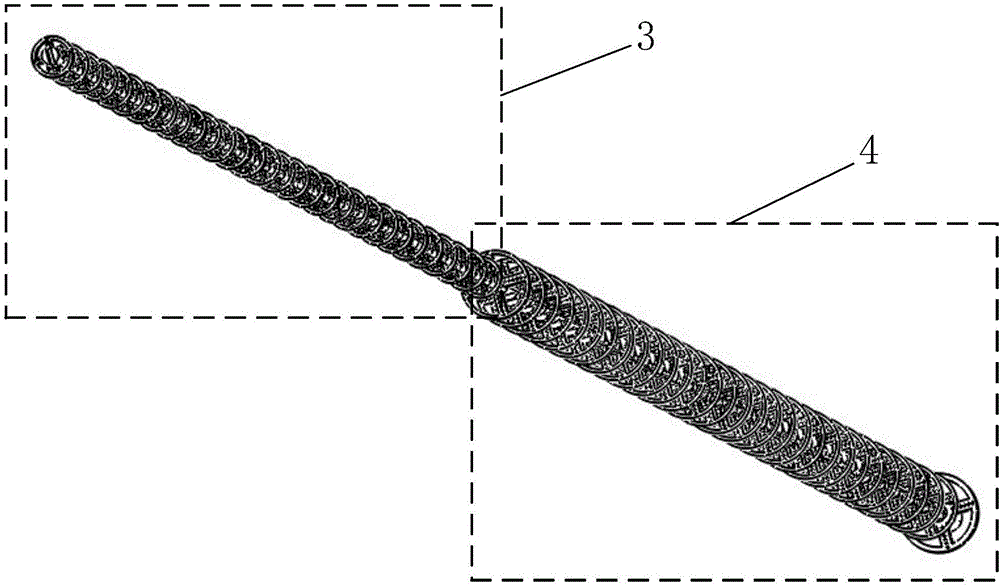

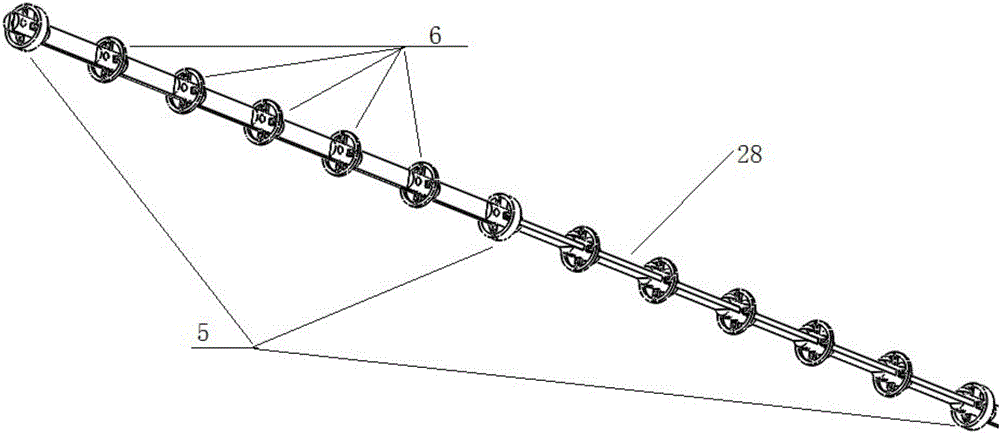

[0043] Such as Figure 2 to Figure 5 As shown, the joint body 1 of the mechanical arm includes a small joint body 3, a large joint body 4, a superelastic alloy sheet 28, a front-end camera 9 and a rivet 24; At the same time, in order to reduce the weight of the overall mechanical arm, a small joint body 3 with a smaller radius is used; the second half of the mechanical arm adopts a large joint body 4 with a larger radius due to the large number of backguys 25 passing through. Such as Figure 20 As shown, the front camera 9 can be replaced by other tools such as manipulators.

[0044] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com