Process for installing reamer transmission shafts of cutter-suction dredge

A cutter suction dredger and installation process technology, applied to mechanically driven excavators/dredgers, etc., can solve the problems of unsatisfactory work effect, high technical difficulty, complicated installation process, etc., and achieve good work effect and easy operation. Easy to operate and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

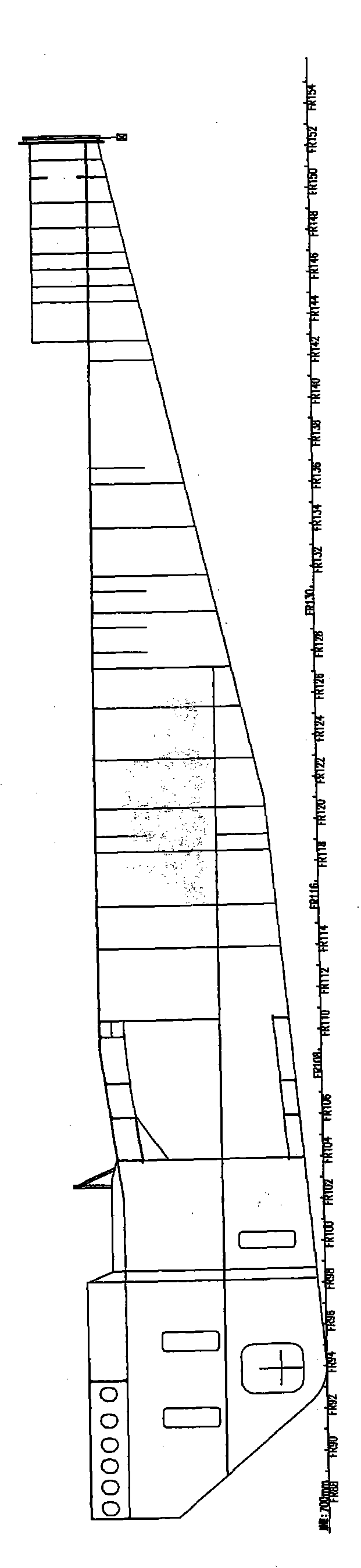

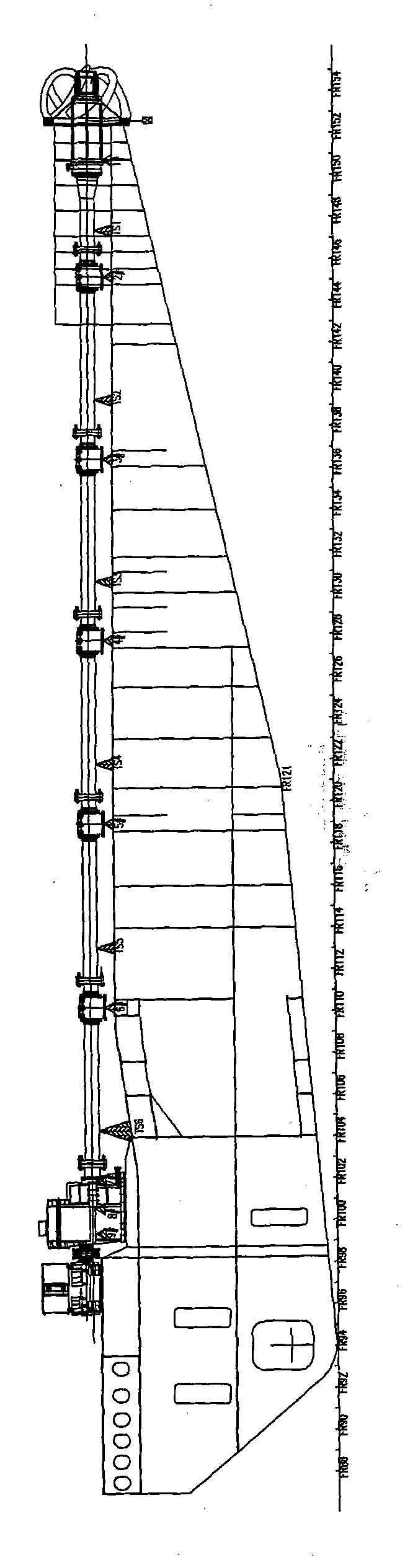

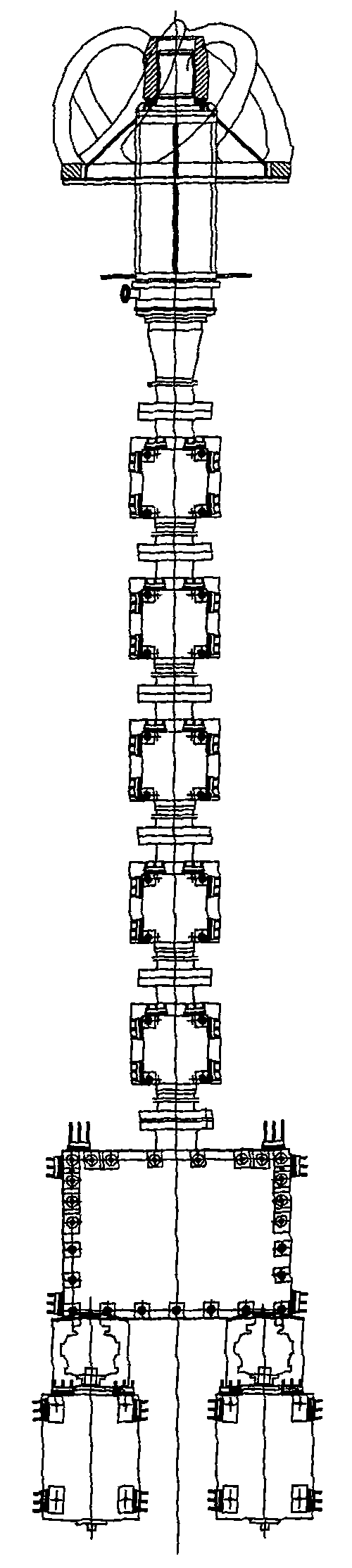

[0062] The ship's reamer is driven by two electric motors through a high-elastic friction clutch, a gear box, a long shaft supported by "Sailong" water-lubricated composite material bearings, and a reamer shaft supported by "Sailong" water-lubricated composite material bearings. The knife gearbox is mounted on top near the trunnion of the bridge.

[0063] The reamer shaft system consists of 5 intermediate shafts, 5 intermediate bearings, a reamer bearing, water-sealed cooling and lubricating device, reaming pin sleeve, screw bearing pressure ring, combustion ring, seals, etc. Intermediate bearings and reamer bearings use "Sailong" water-lubricated composite material bearings.

[0064] The 2055mm bearing seat is assembled and welded after being pulled, calibrated, and bored underwater, and the "Sailong" water-lubricated composite bearing is installed. The motor, high elastic friction clutch, gear box, etc. are hoisted on the bridge frame on the berth for temporary support and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com