Standard centering device, engine test trolley and standard centering method

A centering device and engine technology, applied in the direction of engine testing, measuring devices, machine/structural component testing, etc., can solve problems such as low centering accuracy, poor test efficiency, broken transmission shaft, etc., and achieve high centering accuracy , Improve installation efficiency and maintain alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

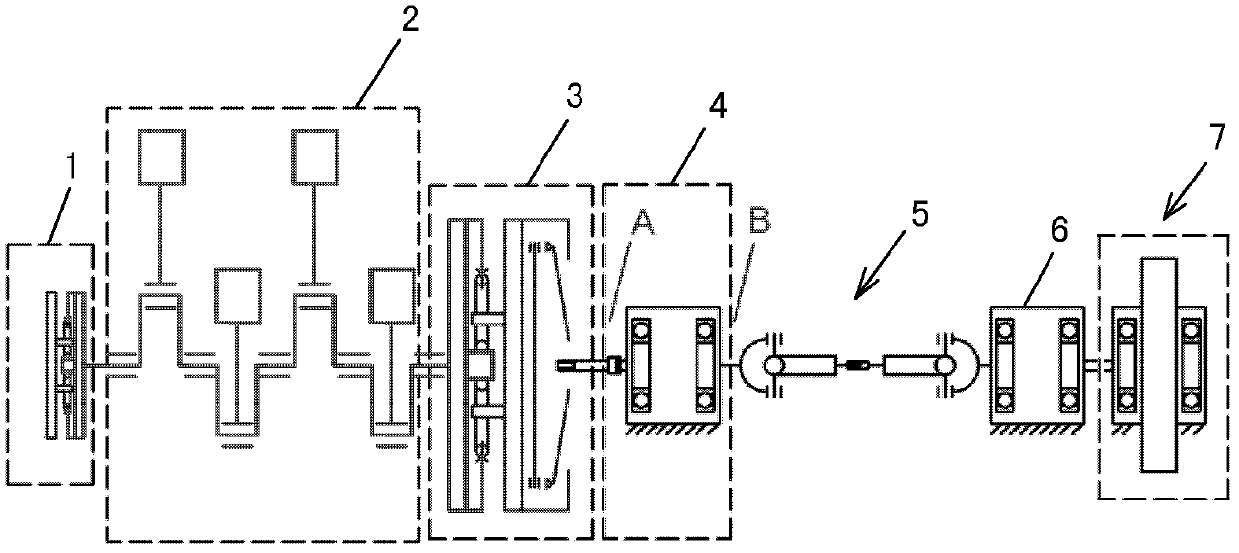

[0045] The bench test of the engine pre-development is very important. figure 1 The transmission system in the engine bench test is shown. The transmission system includes a crank pulley 1, an engine 2, a dual-mass flywheel 3, a first bearing assembly 4, a universal joint 5, a second bearing assembly 6, and a dynamometer 7 in sequence. The invention concerns the coaxiality of the shafting between the engine 2 and the dynamometer 7 . The technical scheme of the present invention can be applied to figure 1 Drivetrain shown.

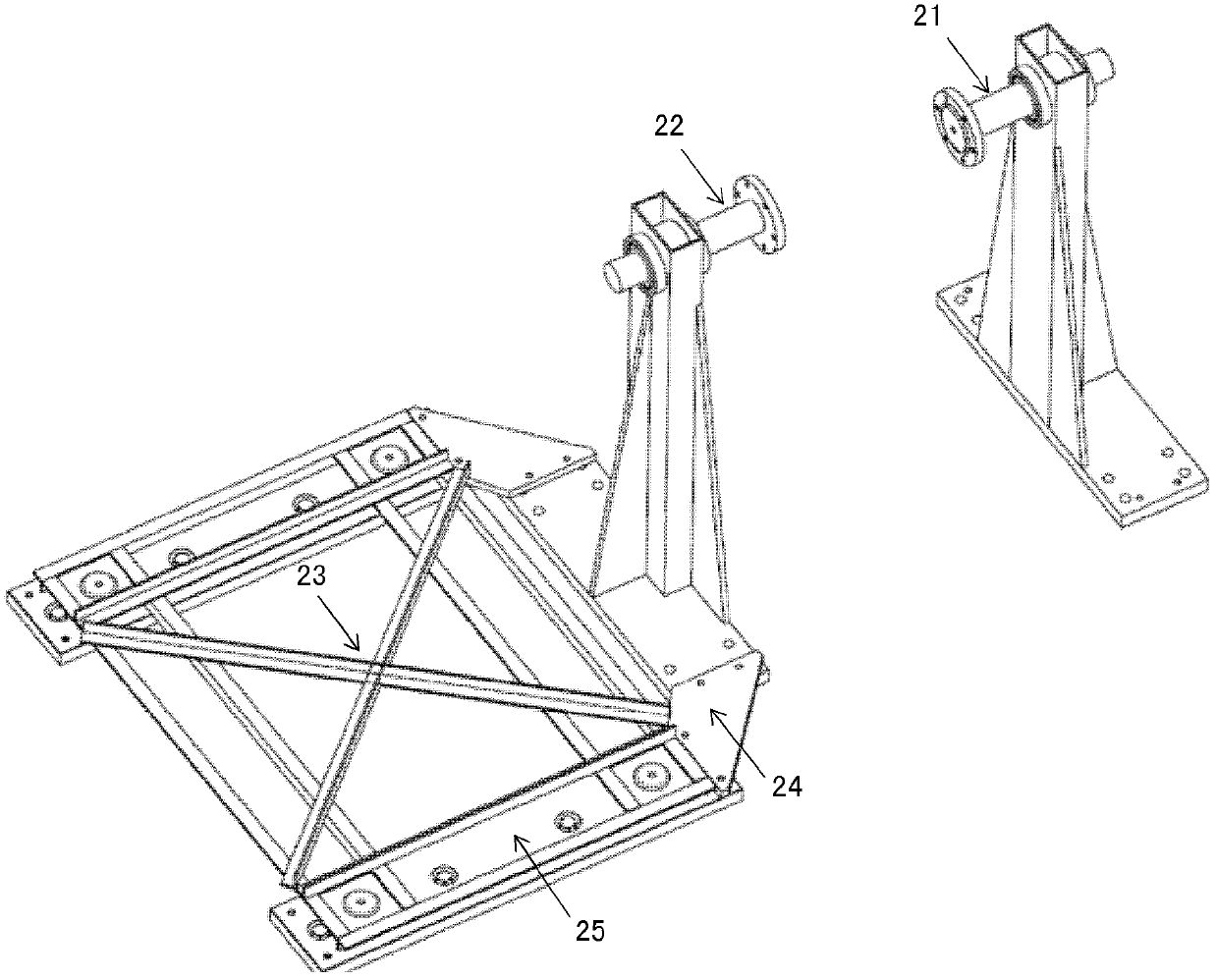

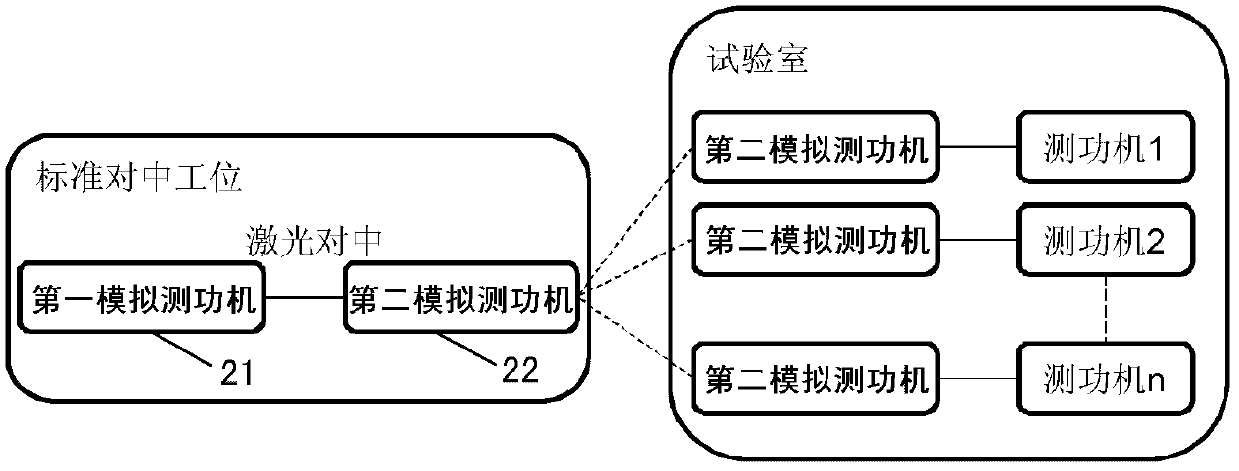

[0046] figure 2 A standard centering device according to an embodiment of the invention is shown. The standard alignment device is used to provide alignment standards between the engine trolley and the dynamometer. In one embodiment, the standard centering device is a standard laser centering station. The standard centering device includes a first simulated dynamometer 21 , a second simulated dynamometer 22 , a positioning cage 23 , a positioning con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com