Parallel confocal detection system and method

A detection system and detection method technology, applied in the field of confocal imaging, can solve problems that affect measurement accuracy and cannot achieve flexible measurement, and achieve the effects of increasing scanning speed, realizing flexible measurement, and solving mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

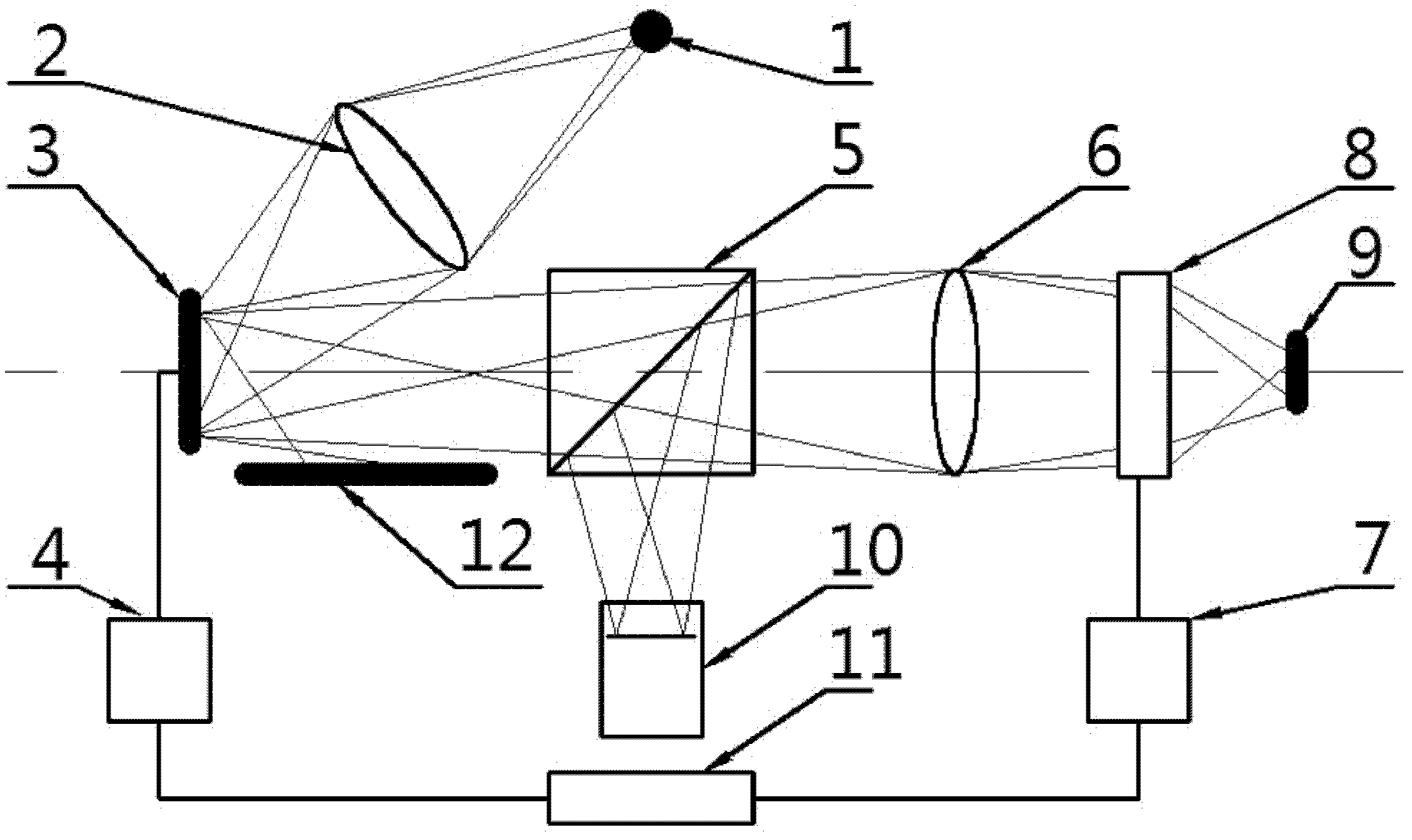

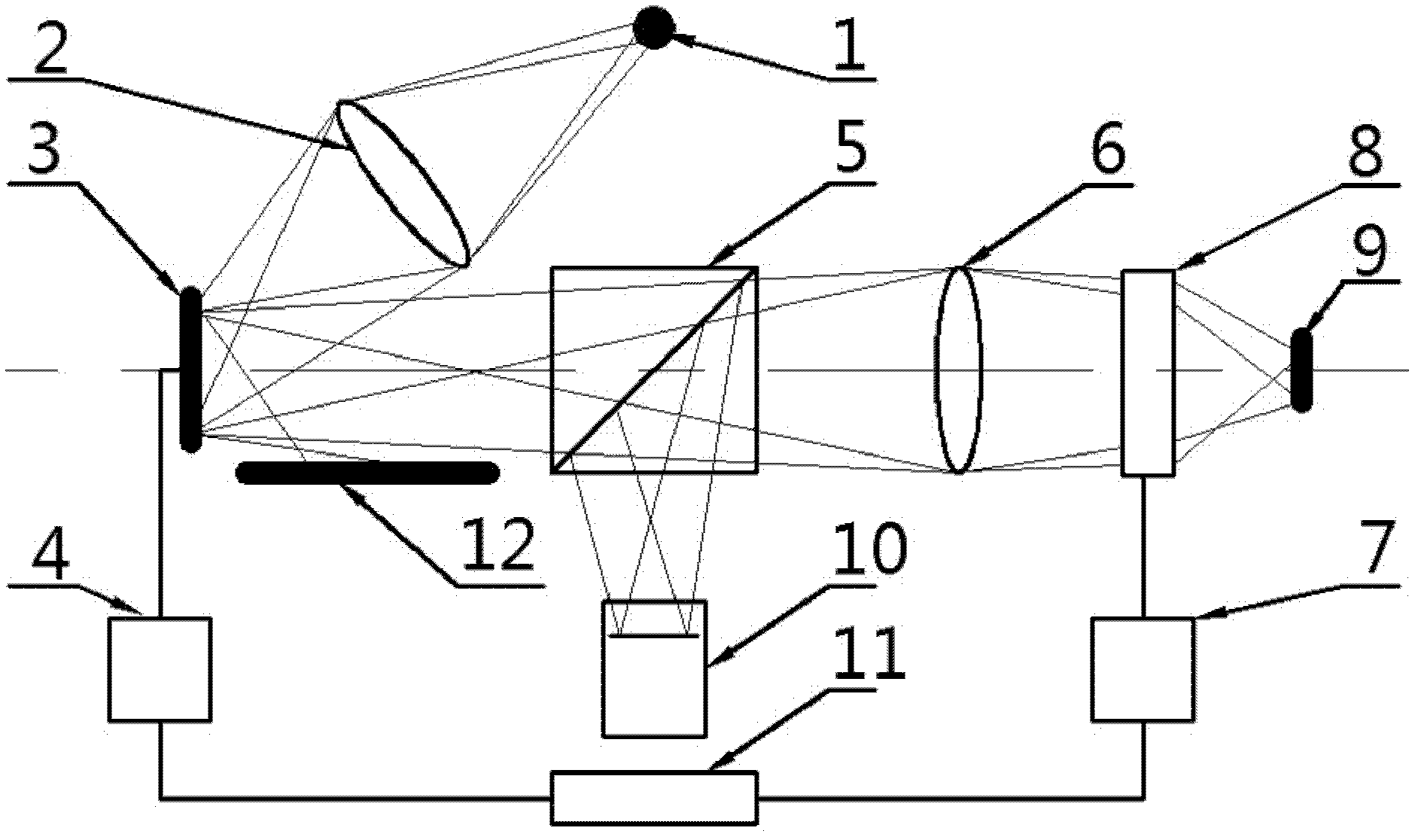

[0021] see figure 1 , the present invention discloses a parallel confocal detection system, said system comprising: a monochromatic LED light source 1, a condenser lens 2, a digital micromirror 3, a control board 4, two lenses 6, a beam splitter 5, an electronically controlled variable focus lens 8. Detection pinhole, light intensity detector 10, voltage controller 7, PC11, absorption plate 12.

[0022] The light emitted by the monochromatic LED light source 1 is irradiated onto the surface of the digital micromirror DMD 3 through the condenser lens 2, and the digital micromirror DMD 3 is modulated by the control board 4 to form a pinhole array, and first passes through the non-polarization beam splitter 5, (parts do not pass through The light of the beam splitter 5 is absorbed by the absorbing plate 12, which does not affect the received light intensity of the light intensity array detector CCD / CMOS 10) and then passes through the lens barrel lens 6 to become a parallel light...

Embodiment 2

[0026] A parallel confocal detection method of the above-mentioned parallel confocal detection system, the method specifically includes the following steps:

[0027] 1) The light emitted by the monochromatic LED light source is irradiated to the surface of the digital micromirror through the light collecting mirror. The light source is modulated by the digital micromirror to form a pinhole array, and then becomes a parallel beam through the lens. The zoom lens, the focused surface of the measured object, the light reflected by the measured object passes through the zoom lens, the beam splitter, and the lens detection pinhole, and is incident on the light intensity array detector, and the light intensity is recorded by the PC;

[0028] 2) The PC controls the voltage applied to the electronically controlled variable focus lens through the voltage controller, so that the focal length of the variable focus lens is changed by a small value Δf, and Δf is less than 1um. At this time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com