3D (Three-Dimensional) similar physical testing device for simulating fault dislocation

A physical test and fault dislocation technology, applied in teaching models, educational tools, instruments, etc., can solve problems such as difficult to simulate the cantilever beam structure on the upper wall, small deformation of the test soil, and influence on the accuracy of test data, etc., to avoid Three-dimensional box effect, the effect of improving accuracy, improving standardization and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The physical simulation test method of the three-dimensional similar physical test device for simulating fault dislocation of the present invention is as follows:

[0076] S1: Prepare similar materials for the simulation test, determine the similarity ratio, and prepare other related instruments and equipment, including strain gauges, optical fibers, Brillouin distributed optical fiber testers, three-dimensional static deformation measuring instruments, and high-definition cameras. And both the strain gauge and the optical fiber are set in the test soil;

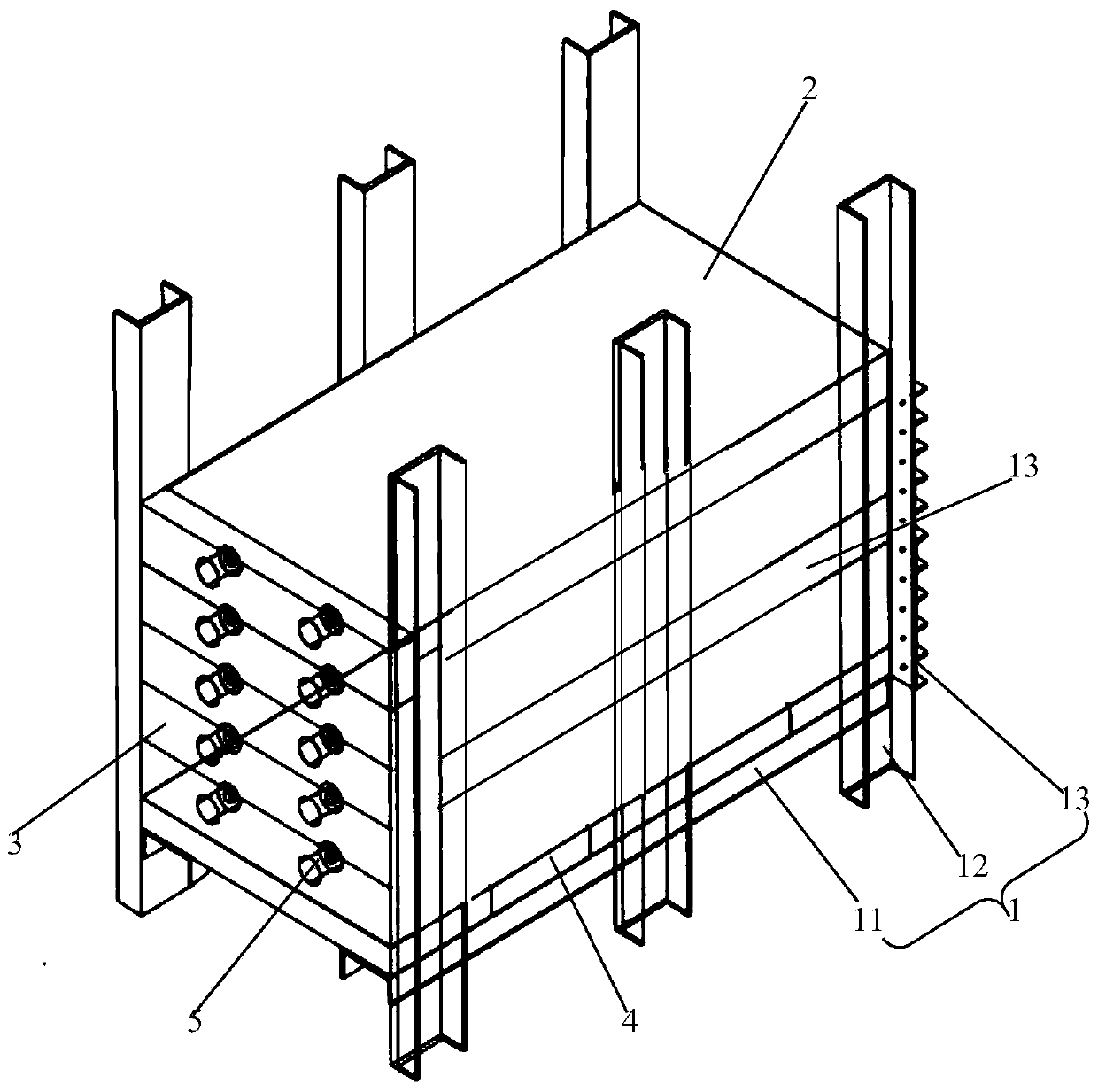

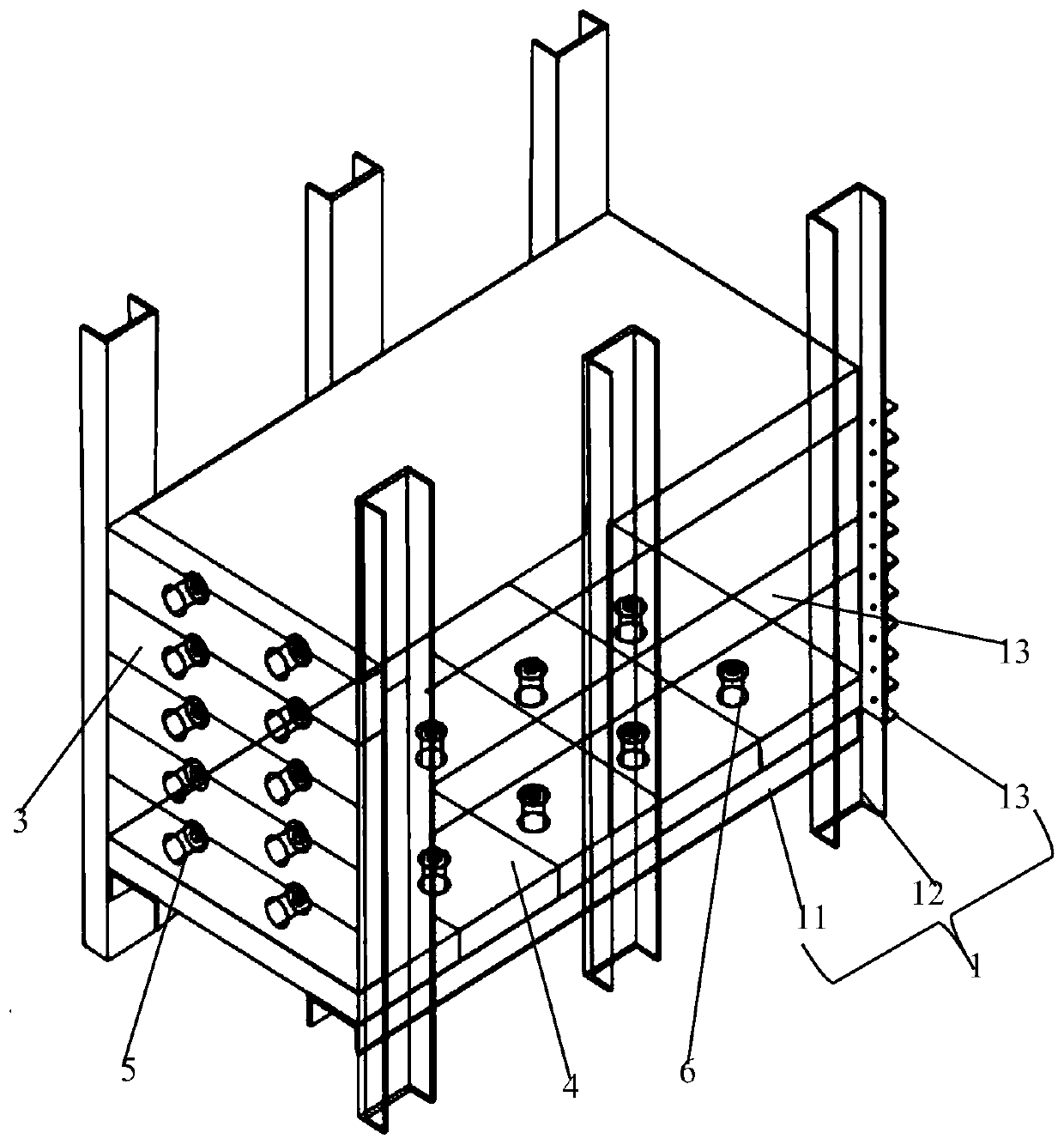

[0077] S2: Set up the test frame 1, set the scale marking structure on the column 12 and the baffle plate 13 in the test frame 1, and provide data calculation support for judging the fault direction, inclination and fault dip;

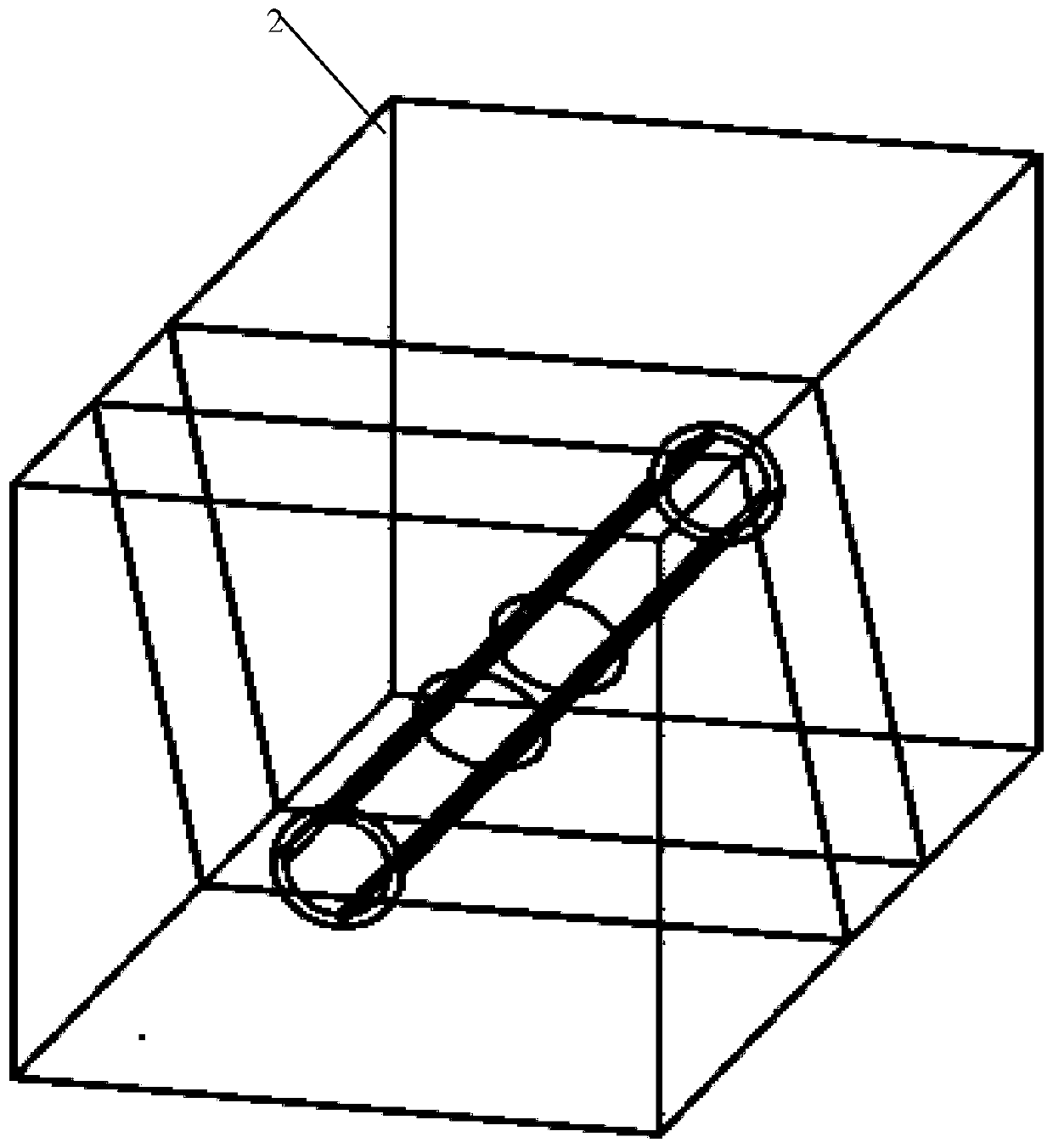

[0078] S3: Set the test model block 2 in the test frame 1, and the test model block 2 includes a transparent acrylic plate rectangular box and test soil, the test soil is filled in the transpa...

Embodiment 2

[0084] The physical simulation test method of the three-dimensional similar physical test device for simulating fault dislocation of the present invention is as follows:

[0085] S1: Prepare similar materials for the simulation test, determine the similarity ratio, and prepare other related instruments and equipment, including strain gauges, optical fibers, Brillouin distributed optical fiber testers, three-dimensional static deformation measuring instruments, and high-definition cameras. And both the strain gauge and the optical fiber are set in the test soil;

[0086] S2: Set up the test frame 1, set the scale marking structure on the column 12 and the baffle plate 13 in the test frame 1, and provide data calculation support for judging the fault direction, inclination and fault dip;

[0087] S3: Set the test model block 2 in the test frame 1, and the test model block 2 includes a transparent acrylic plate rectangular box and test soil, the test soil is filled in the transpa...

Embodiment 3

[0093] The physical simulation test method of the three-dimensional similar physical test device for simulating fault dislocation of the present invention is as follows:

[0094] S1: Prepare similar materials for the simulation test, determine the similarity ratio, and prepare other related instruments and equipment, including strain gauges, optical fibers, Brillouin distributed optical fiber testers, three-dimensional static deformation measuring instruments, and high-definition cameras. And both the strain gauge and the optical fiber are set in the test soil;

[0095] S2: Set up the test frame 1, set the scale marking structure on the column 12 and the baffle plate 13 in the test frame 1, and provide data calculation support for judging the fault direction, inclination and fault dip;

[0096] S3: Set the test model block 2 in the test frame 1, and the test model block 2 includes a transparent acrylic plate rectangular box and test soil, the test soil is filled in the transpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com