Reaction and separation integrated process and device for synthesizing poly-alpha-olefin (PAO)

An olefin and reaction technology, which is applied in the field of integrated reaction and separation process and device of lubricating base oil polyalphaolefin (PAO), can solve problems such as low production efficiency, slow filtration rate, and difficult separation of catalysts, so as to improve production High efficiency, fast and efficient separation, close contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

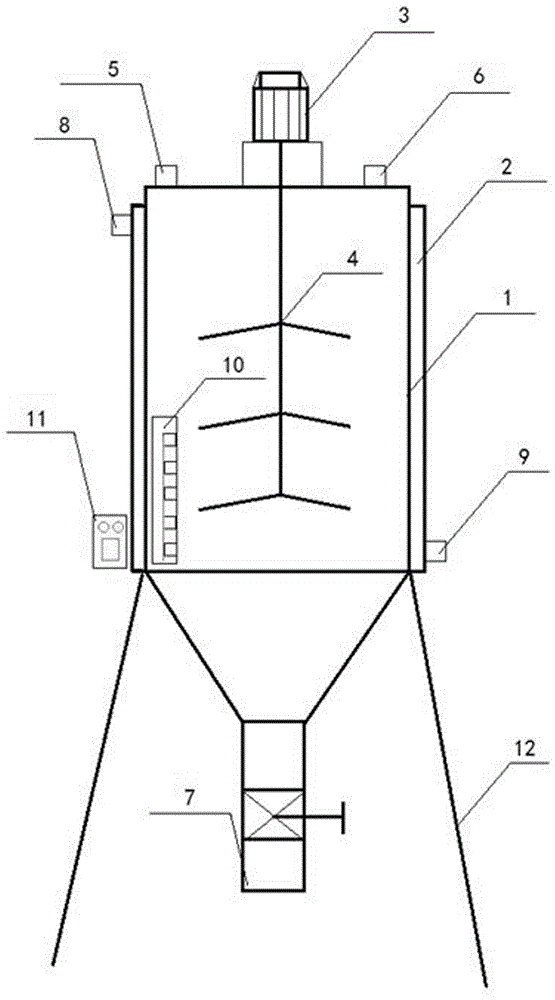

[0024] A reaction separation integrated device for synthesizing polyalpha-olefin (PAO), such as figure 1 As shown, it includes a reactor main body 1, a jacket 2 is provided outside the reactor main body 1, a heating / cooling medium outlet 8 is arranged at the upper end of the jacket 2, and a heating / cooling medium inlet 9 is arranged at the lower end; 1. An agitator 4 driven by a motor 3 is installed in the inner center, an electromagnetic chuck 10 is fixed on the inner wall of the reactor main body 1, and an electromagnetic chuck controller 11 is installed outside the reactor main body 1. The electromagnetic chuck controller 11 controls The opening and closing of the electromagnetic chuck 10; the top of the reactor main body 1 is provided with a feeding port 5 and a temperature measuring port 6, and the bottom is provided with a discharging port 7; the reactor main body 1 is located on the reactor support 12.

Embodiment 2

[0026] Take 1m 3 The jacketed stirring reaction kettle that the 1-decene solution adds, adds 5% (mass fraction) AlCl 3 +TiCl 4 / SiO 2 / NiFe 2 O 4 , turn on stirring, adjust the temperature to 80°C, control the reaction pressure to 0.1MPa, and after the reaction time is 3h, turn on the electromagnetic chuck controller, and magnetically separate AlCl 3 +TiCl 4 / SiO 2 / NiFe 2 O 4 The catalyst is then distilled to remove light components, and the PAO product is obtained after hydrogenation. Testing PAO products, the viscosity index is 130, and the kinematic viscosity at 100°C is 12mm 2 / s, the freezing point is 50°C.

Embodiment 3

[0028] Take 1m 3 The jacketed stirring reaction kettle that the 1-nonene solution was added, added 4% (mass fraction) AlCl 3 +TiCl 4 / SiO 2 / Fe 2 O 4 , turn on stirring, adjust the temperature to 75°C, control the reaction pressure at 0.5MPa, and after the reaction time is 5h, turn on the electromagnetic chuck controller, and magnetically separate AlCl 3 +TiCl 4 / SiO 2 / Fe 2 O 4 The catalyst is then distilled to remove light components, and the PAO product is obtained after hydrogenation. Testing PAO products, the viscosity index is 125, and the kinematic viscosity at 100°C is 10mm 2 / s, the freezing point is 45°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com