Liquid piston compressor

A liquid piston and compressor technology, applied in the field of compressors, can solve the problems of reduced efficiency, short life, difficulty in heat dissipation, etc., and achieve the effect of improving efficiency and life, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

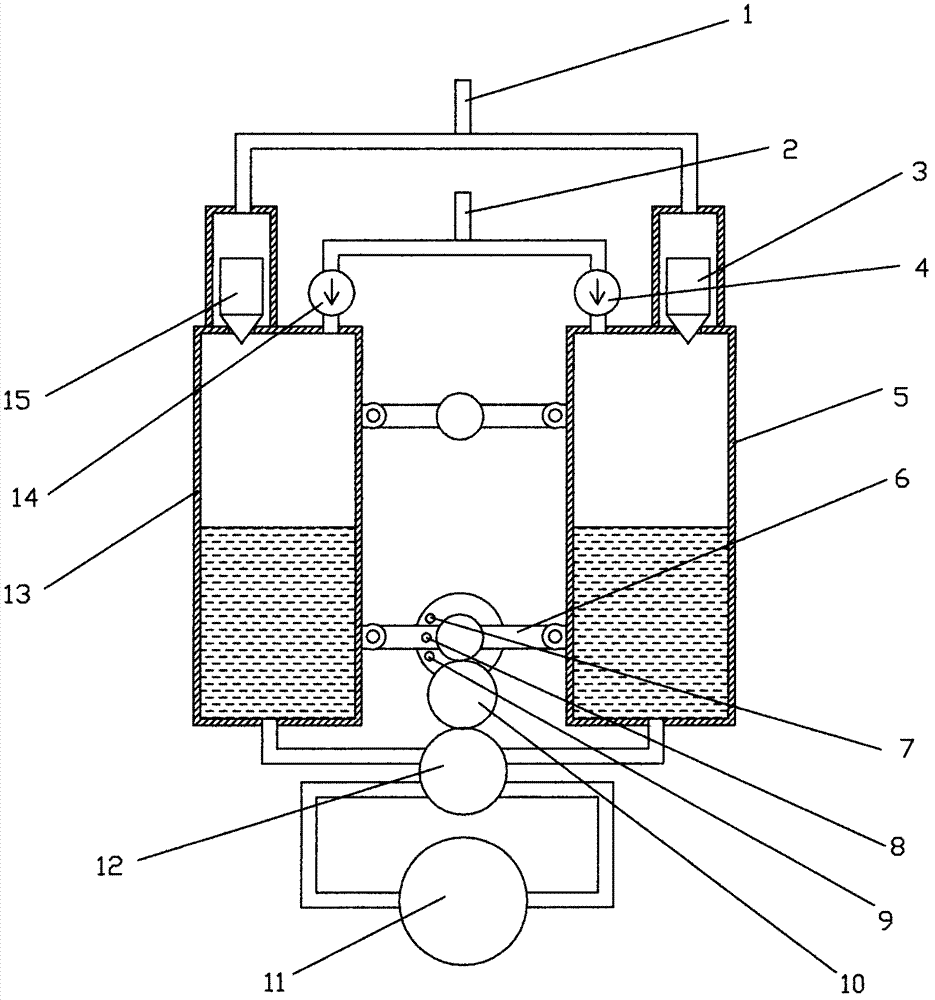

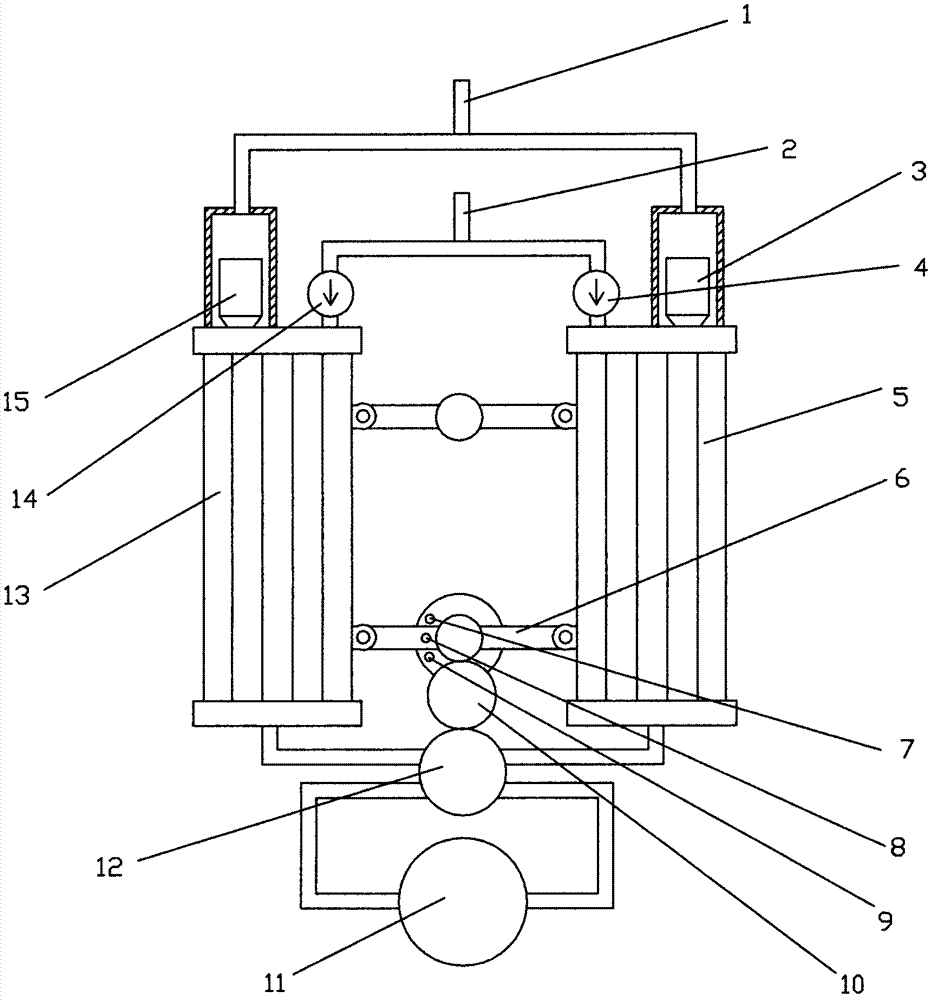

[0009] exist figure 1 Among them, the cylinder (5) and the cylinder (13) are respectively placed at both ends of the lever (6), and multiple levers (6) can be arranged in parallel to increase the stability of the system. (12) links to each other, and positioning bead (8) is arranged on the lever (6), and the hole corresponding to positioning bead (8) is respectively positioning hole (7) and positioning hole (9). Pressure transmission liquid is housed in the cylinder (5), the top of the cylinder (5) communicates with the air inlet (2) through the air intake check valve (4), and communicates with the exhaust port (1) through the buoyancy check valve (3), and the cylinder ( 5) The bottom is connected to the pump (11) through the reversing valve (12). Pressure transmission liquid is housed in the cylinder (13), the top of the cylinder (13) communicates with the air inlet (2) through the intake check valve (14), communicates with the exhaust port (1) through the buoyancy check val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com