Method for recording friction force of reciprocating type friction testing machine through position information

A technology of friction testing machine and position information, which is applied in the direction of measuring devices, mechanical devices, force/torque/power measuring instruments, etc., and can solve problems such as large friction force, poor data volume, small stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

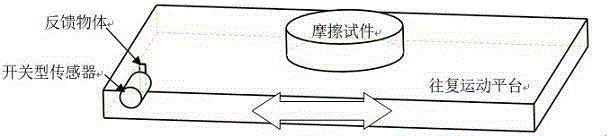

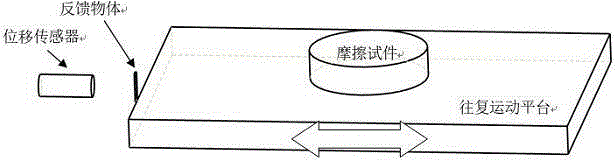

[0015] Such as figure 1 As shown, a method for recording the friction force of the reciprocating friction testing machine through position information, by judging the position information of the friction test piece, when the friction test piece passes the preset position, the friction data of the reciprocating friction testing machine are recorded in real time, specifically Proceed as follows:

[0016] 1) Install the feedback object on the designated position of the reciprocating motion platform with the friction test piece fixed, and then make the reciprocating motion platform reciprocate;

[0017] 2) Install the sensor at the designated position, connect it to the host computer, and control it through the host computer; when the feedback object on the reciprocating motion platform moves to the preset position corresponding to the sensor, the signal information transmitted by the sensor to the host computer is consistent with the preset position of the host computer. The inf...

Embodiment 2

[0019] This embodiment is basically the same as Embodiment 1, except that the sensor is an infrared photoelectric switch.

Embodiment 3

[0021] This embodiment is basically the same as Embodiment 1, except that the sensor is a laser photoelectric switch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com