Water exploration testing device for horizontal well in offshore oilfield and dynamic dividing and positioning method of water exploration testing device

An offshore oilfield and water testing technology, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., can solve the problems of inability to accurately separate and locate water, and achieve the effect of solving inaccurate positioning and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

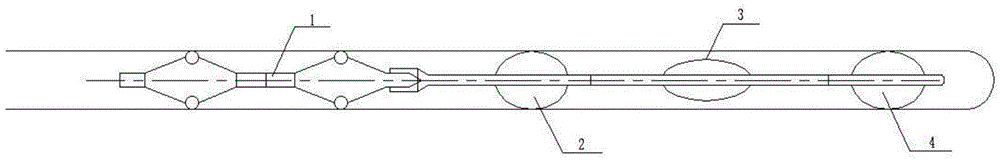

[0021] as attached figure 1 As shown, a water-seeking test device for horizontal wells in offshore oilfields is composed of a device body. The device body includes a downhole crawler 1 arranged in a pipe string and in contact with the inner wall of the pipe string. The upper end of the downhole crawler 1 is A lower separator 2 is connected, and the lower separator 2 is connected with a water content testing instrument 3 , and the water content testing instrument 3 is connected with an upper separator 4 .

[0022] The method for dynamic separation and positioning using the water finding test device of the present invention comprises the following steps:

[0023] 1. Prepare and assemble the above-mentioned water finding test device;

[0024] 2. Run into the water-finding test device: put the water-finding test device of the present invention into the well, and freely l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com