Patents

Literature

30results about How to "Easy to glaze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

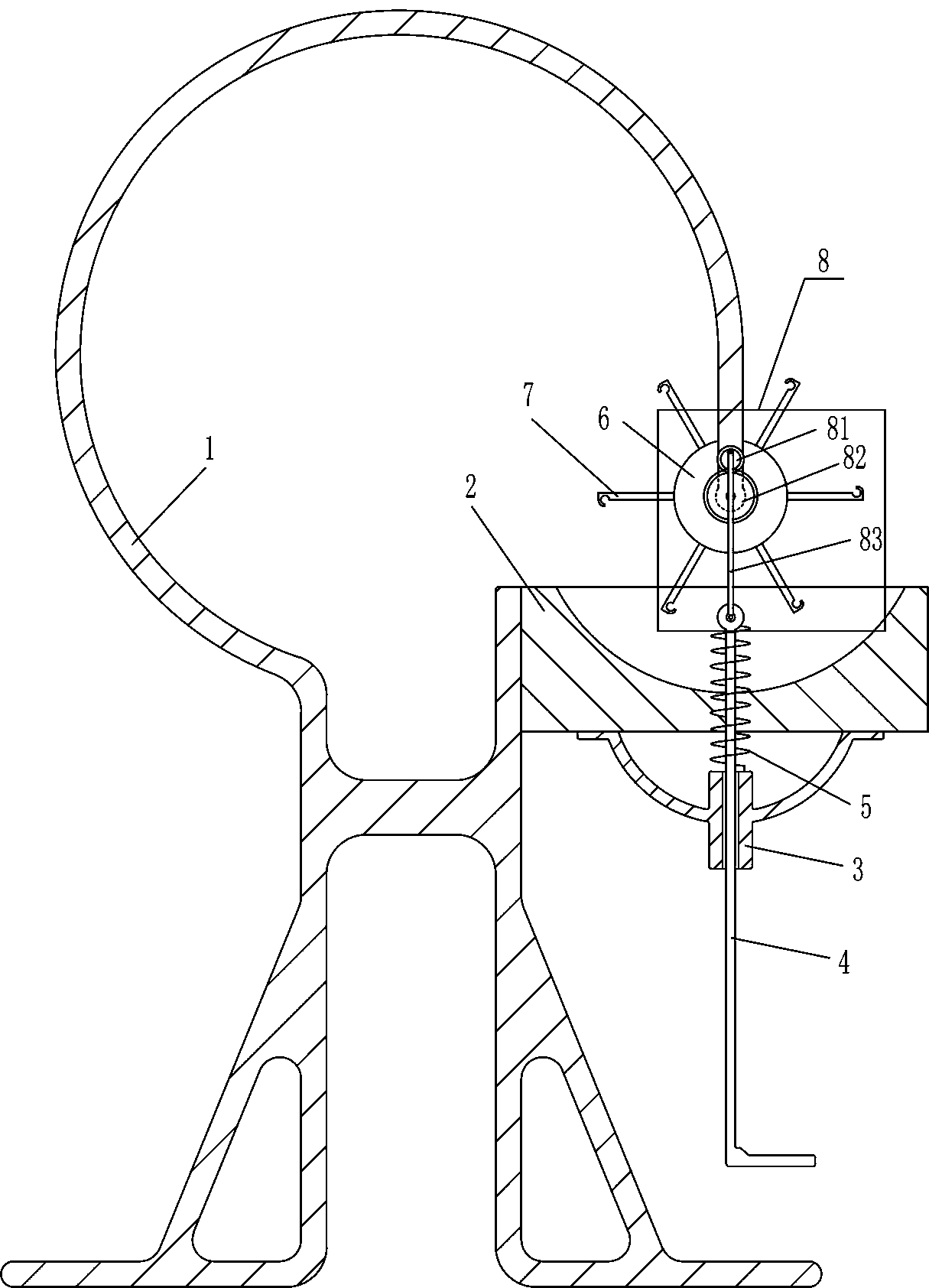

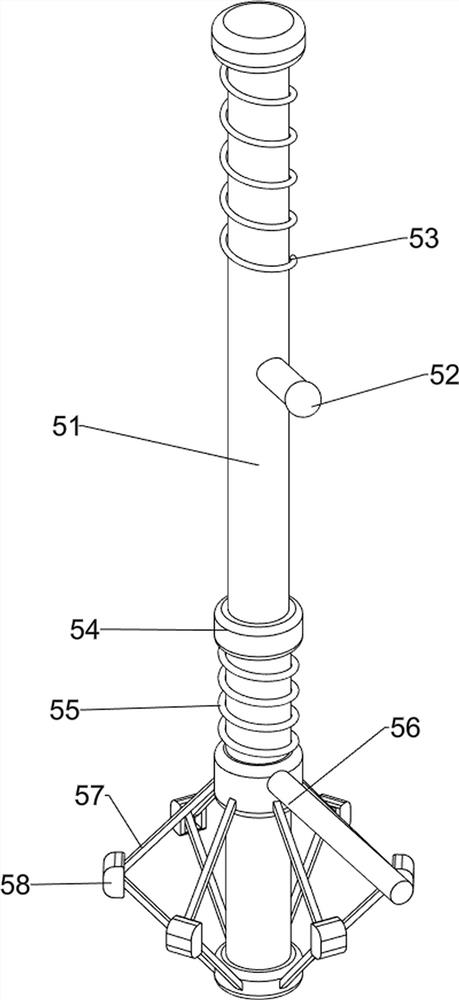

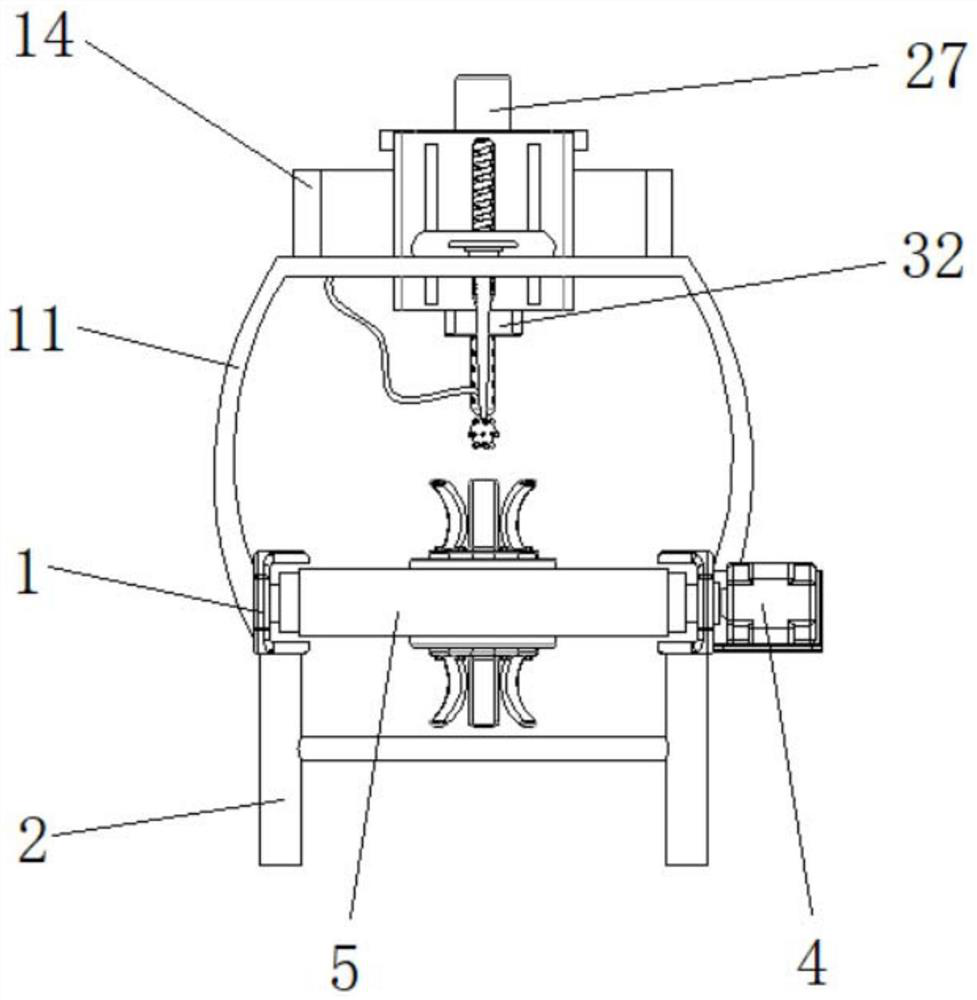

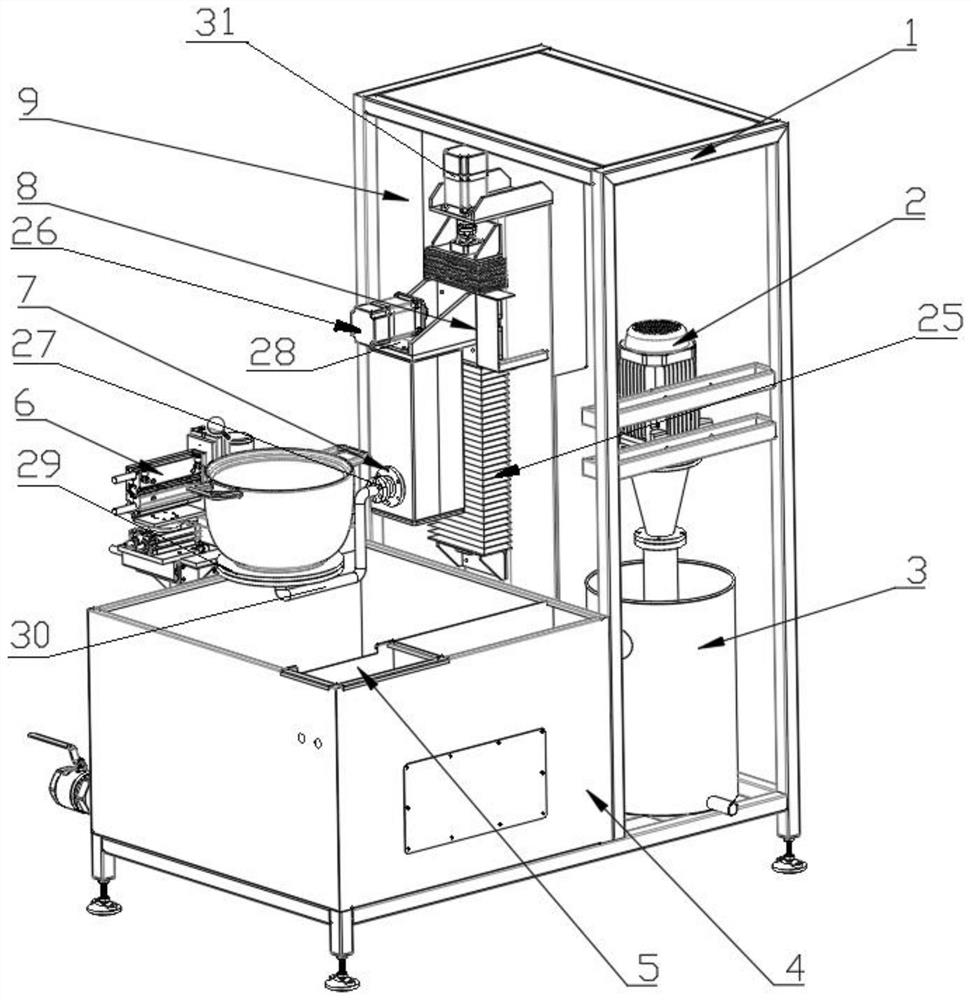

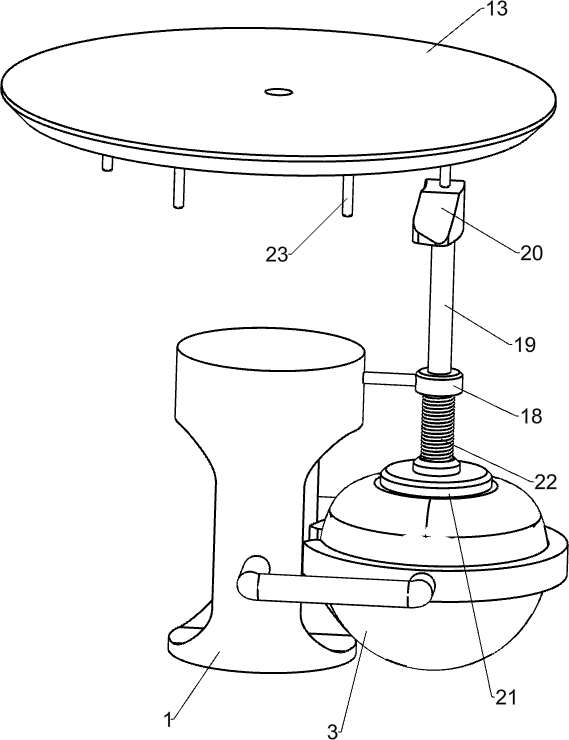

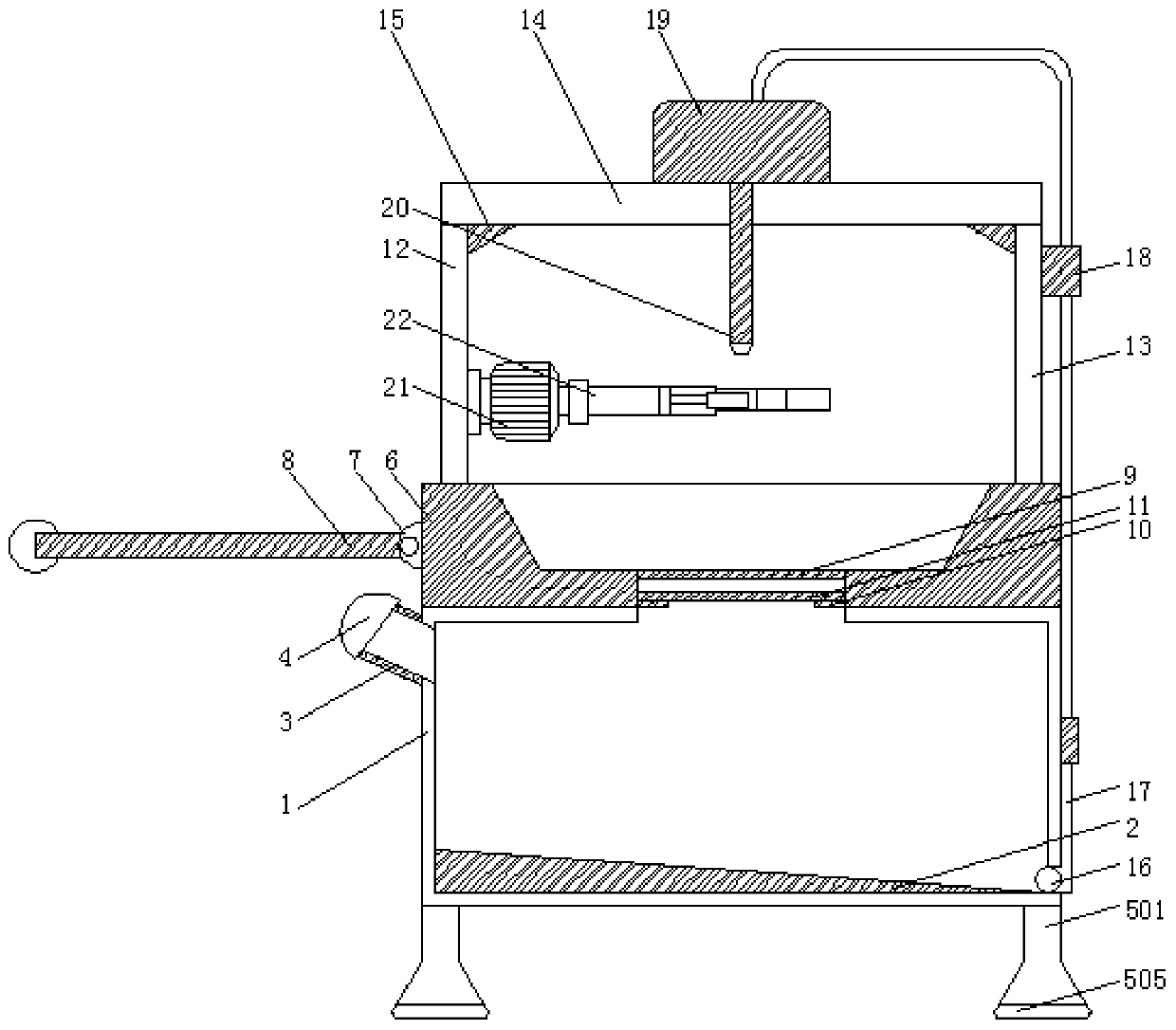

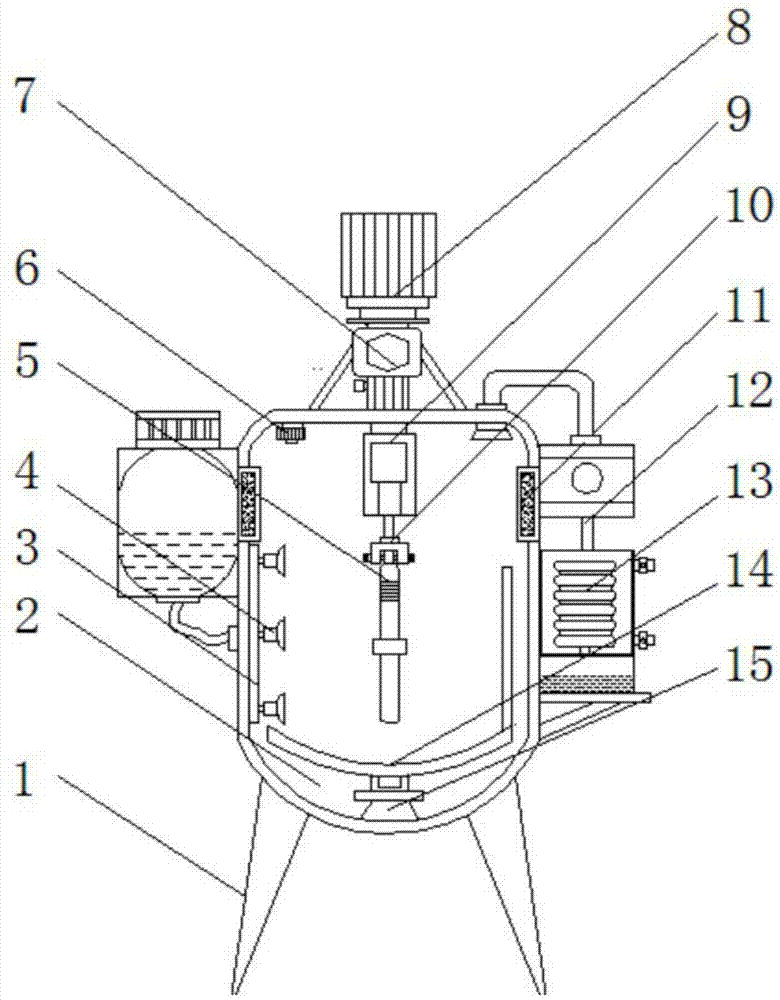

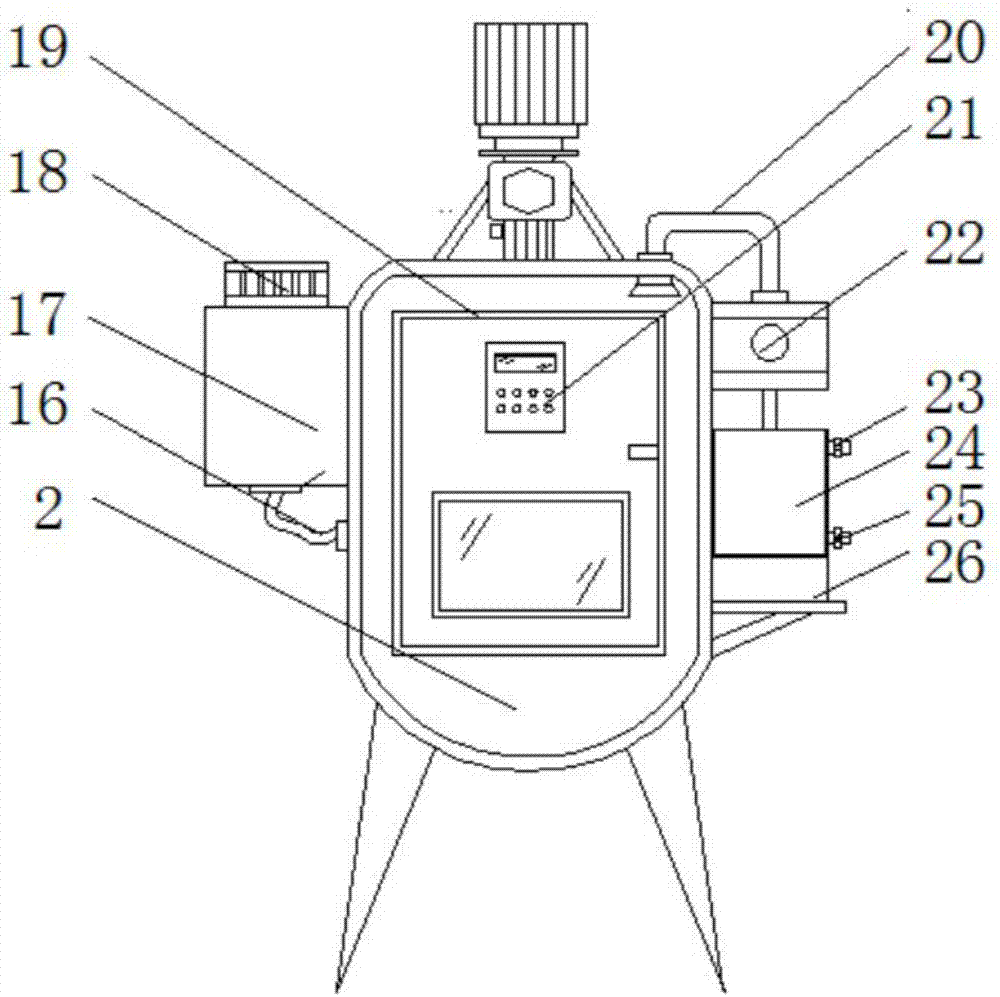

Ceramic bottle internal glaze spraying equipment for process ceramic production

ActiveCN111113649AAchieve insertionUniform spray treatmentCeramic shaping apparatusGlazeElectric machinery

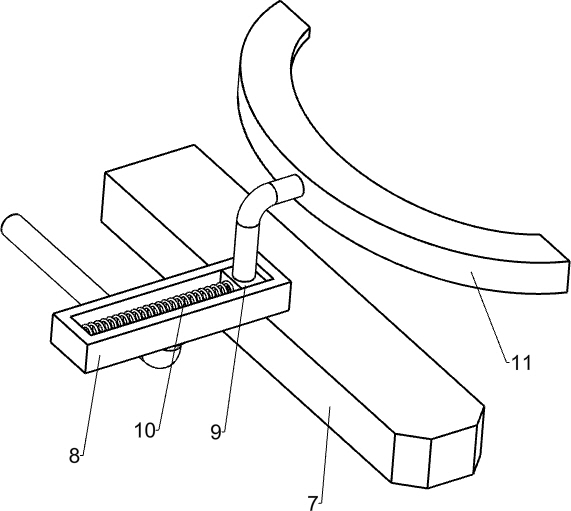

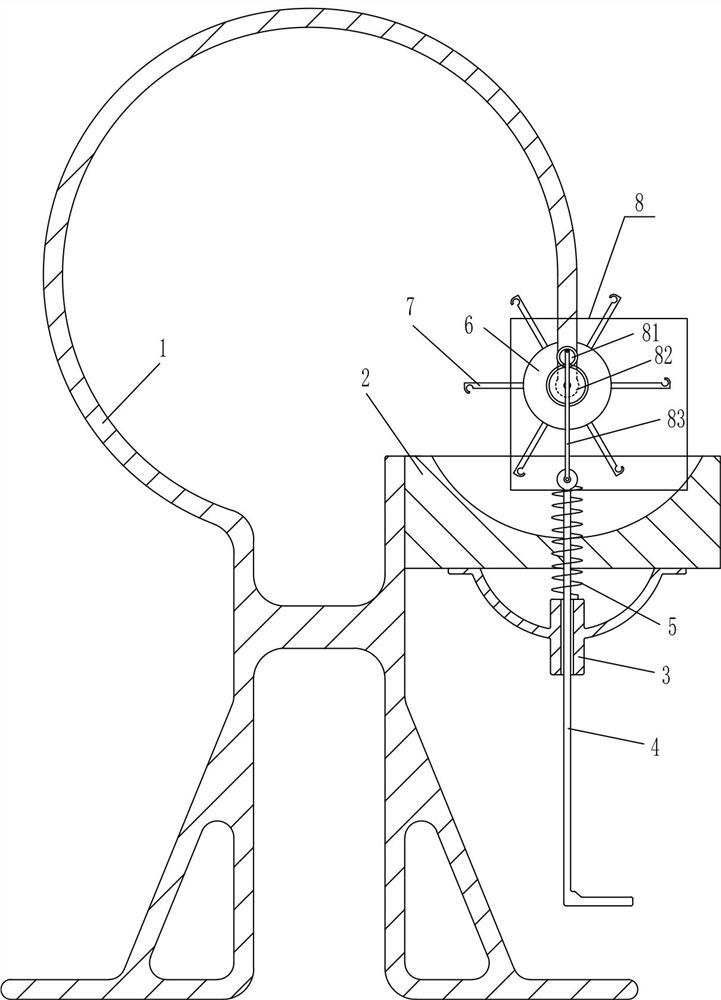

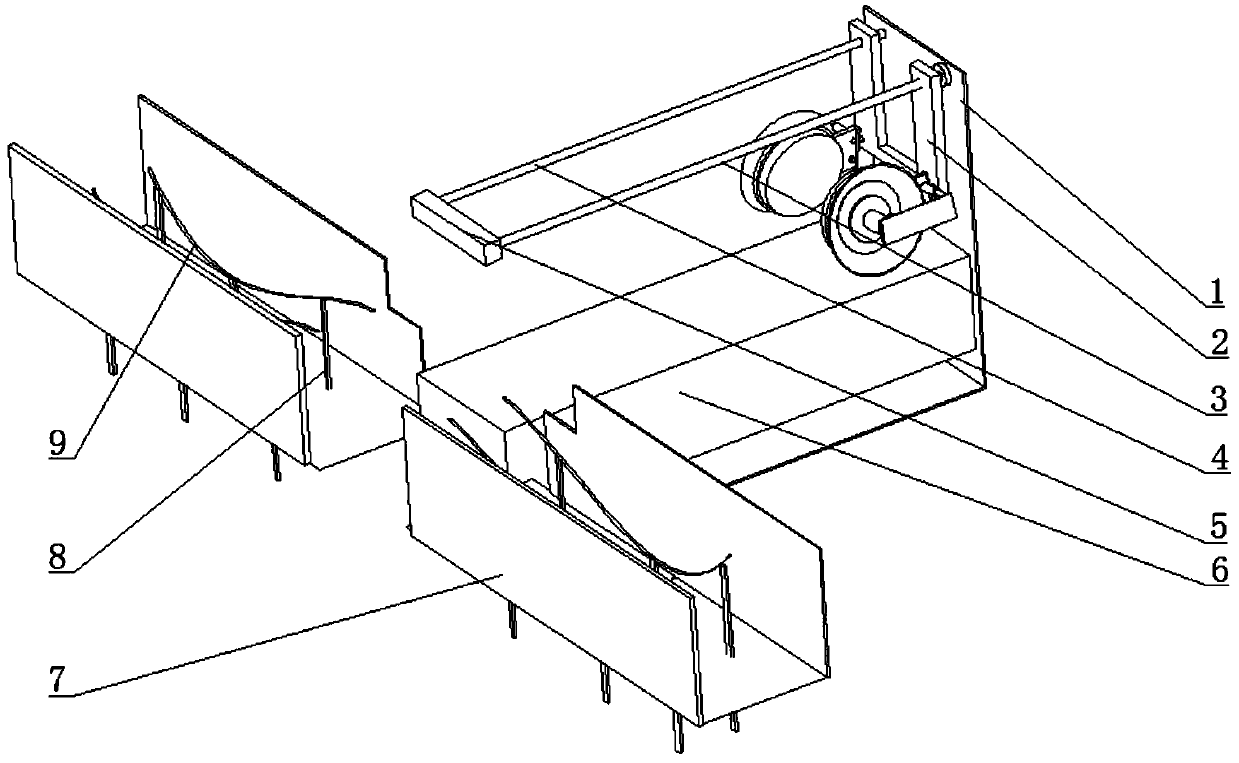

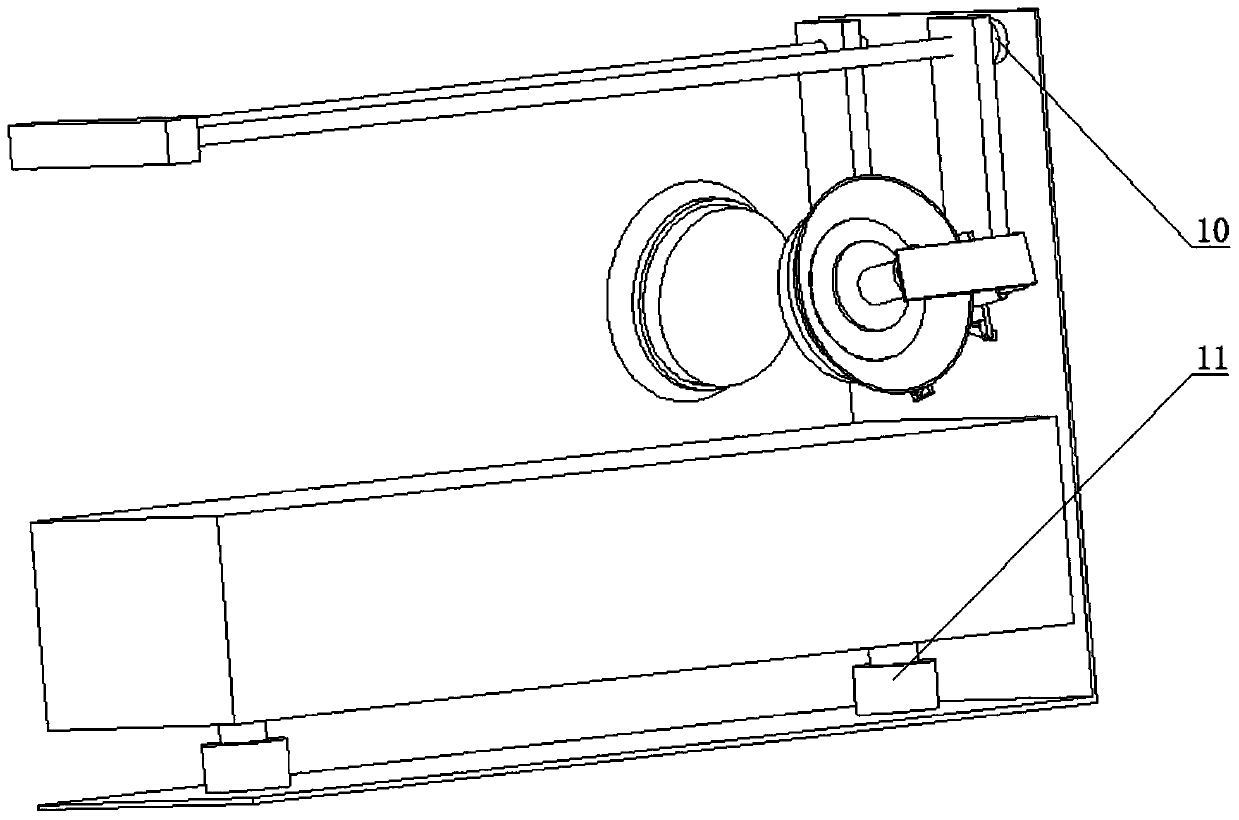

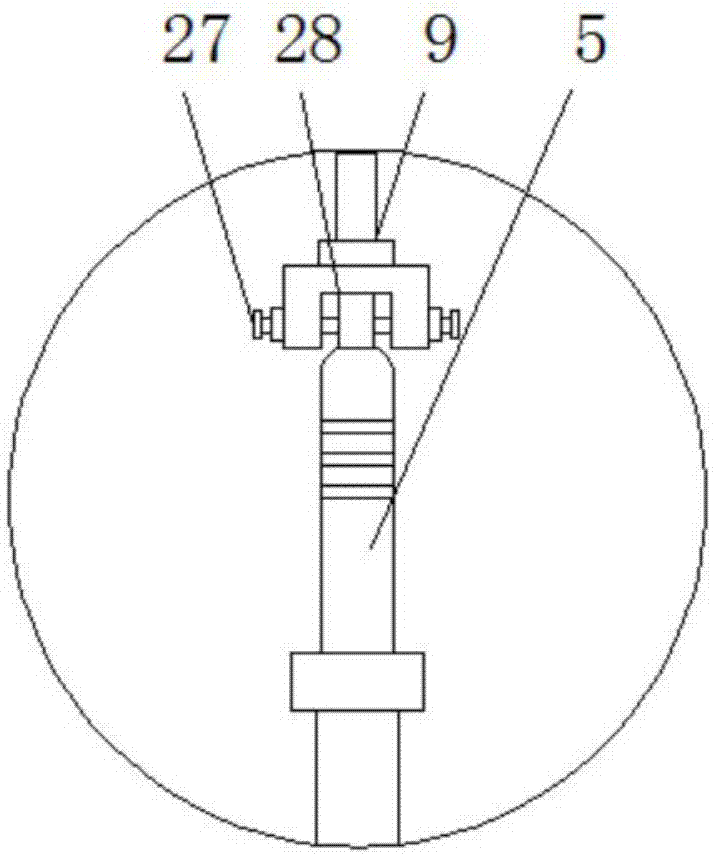

The invention belongs to the technical field of glaze spraying equipment, in particular to ceramic bottle internal glaze spraying equipment for process ceramic production. The ceramic bottle internalglaze spraying equipment comprises a protection support plate, wherein supporting legs are arranged at the bottom of the protection support plate, and an L-shaped supporting plate is arranged on one side of the protection support plate; a first motor is arranged at the top of the L-shaped supporting plate, and the output end of the first motor penetrates through the protection support plate. A ceramic bottle internal glaze spraying mechanism is arranged, on the one hand, storage and placement of glaze for glazing the surface of a ceramic bottle can be achieved through a material storage box, paint can be conveniently provided for glazing and spraying on the internal surface of the ceramic bottle, and meanwhile, the material storage box is used for storing the glaze so that the working amount of repeated adding of the glaze by an operator can be relieved; and on the other hand, a guide supporting cylinder can be conveniently inserted into the interior of the ceramic bottle through the mode that a transmission screw is adopted to move up and down for adjustment, and uniform glaze spraying treatment is carried out on the inner wall of the ceramic bottle by using a spherical glaze spraying joint.

Owner:广东金润源陶瓷股份有限公司

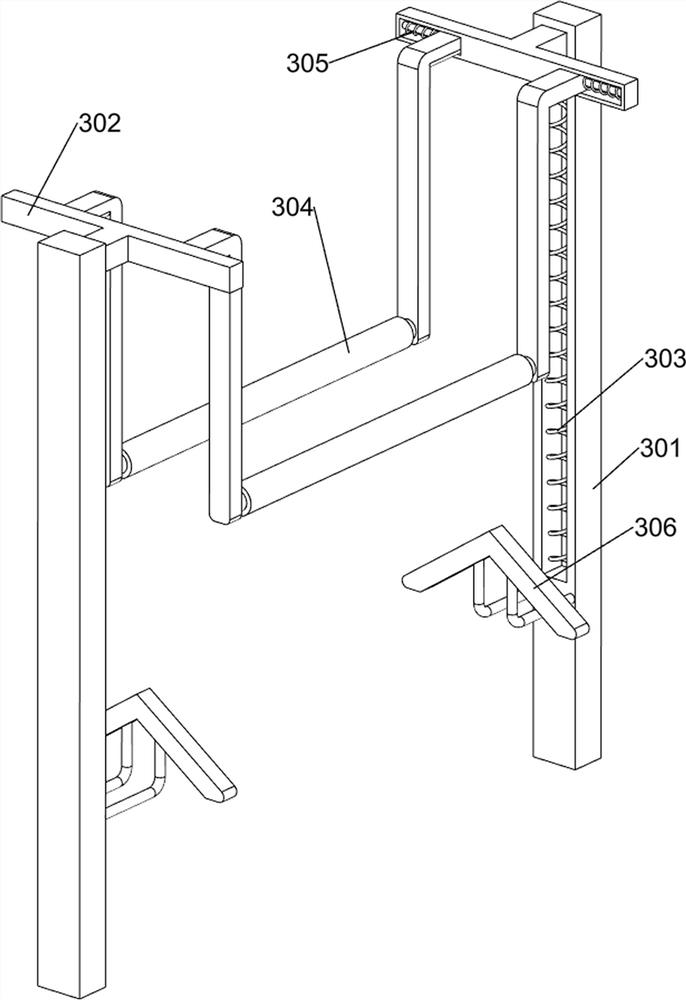

Glazing device for building cup manufacturing

The invention relates to a glazing device, in particular to a glazing device for building cup manufacturing, and aims to provide the glazing device which is used for building cup manufacturing, can realize sufficient glazing and can fix building cups. The glazing device for building cup manufacturing comprises two first supporting frames, a material carrying frame arranged between the upper parts of the first supporting frames, placing assemblies arranged on the first supporting frames, and clamping assemblies arranged on the placing assemblies. The effects that glazing can be fully carried out and the building cups can be fixed are achieved; the inner walls of the building cups are glazed through a spraying assembly, the whole building cups are immersed in the glaze liquid, and thus it can be guaranteed that the building cups are fully glazed.

Owner:刘顶军

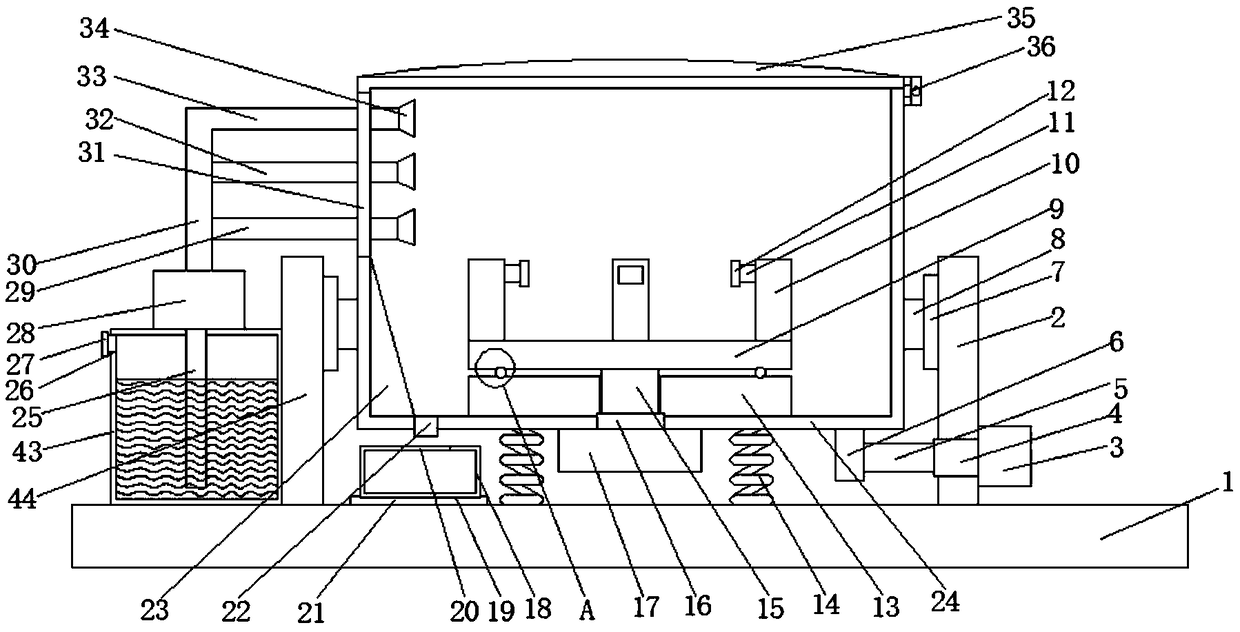

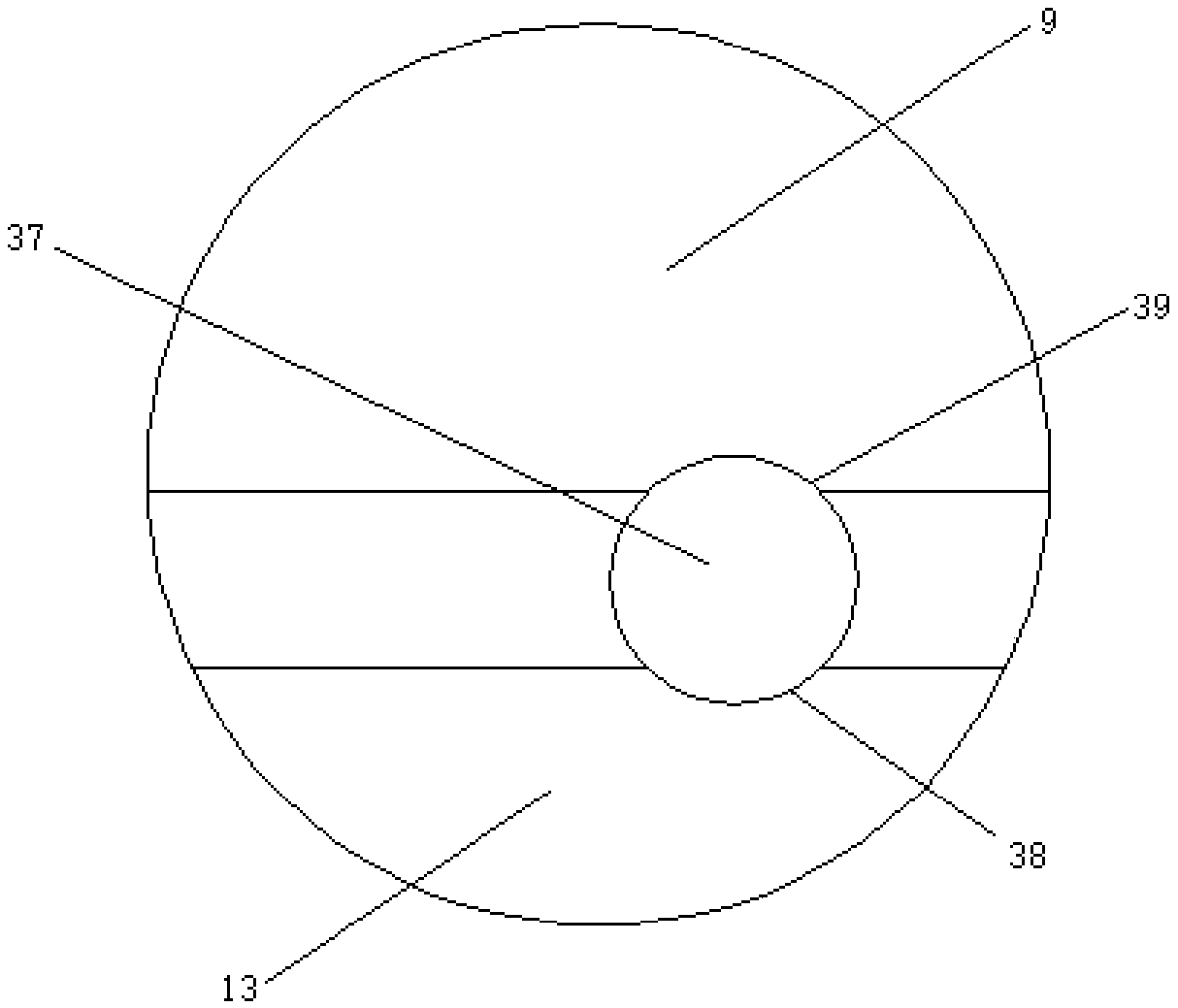

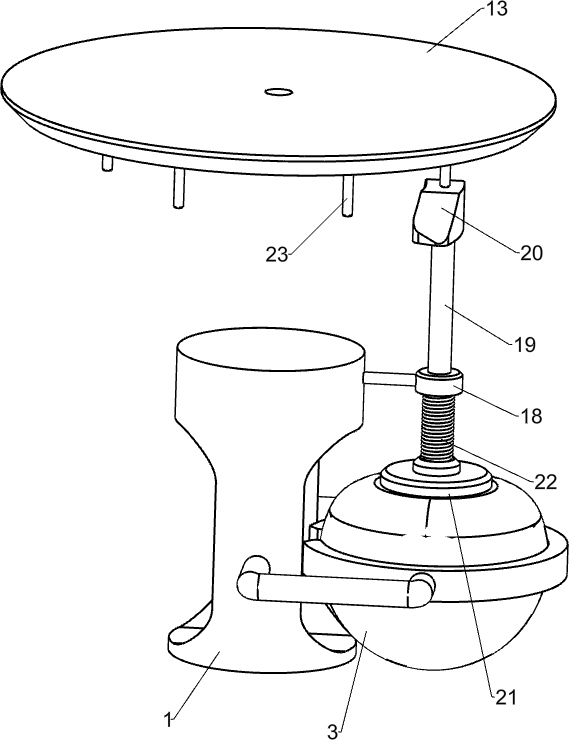

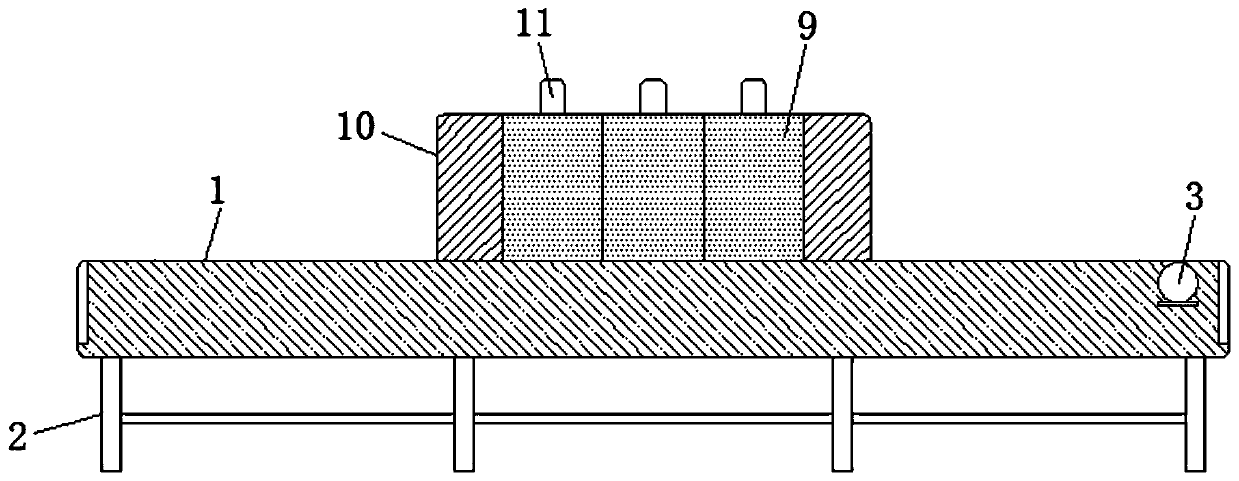

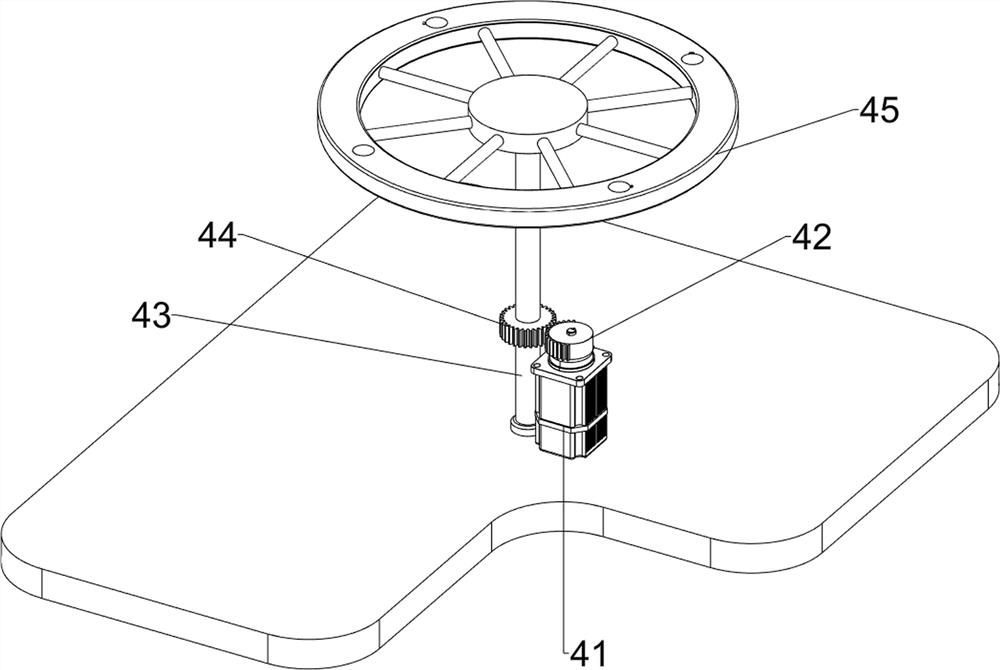

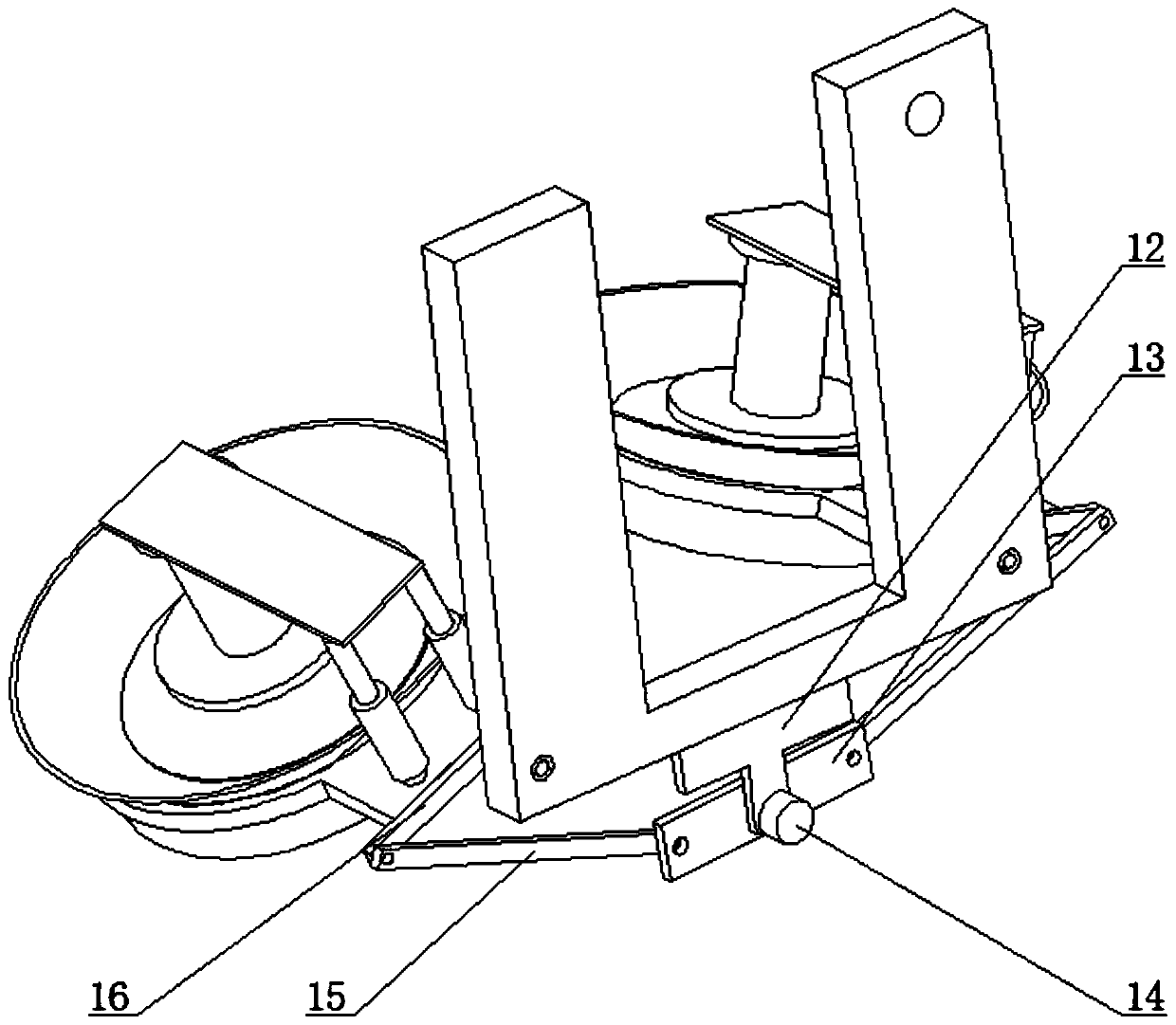

Centrifugal vibrating type multi-point-location daily ceramic glazing machine

The invention provides a centrifugal vibrating type multi-point-location daily ceramic glazing machine, and relates to the field of ceramic glazing. The centrifugal vibrating type multi-point-locationdaily ceramic glazing machine comprises a pedestal, wherein left and right sides of the top of the pedestal are separately connected with a second supporting plate and a first supporting plate; upperparts of opposite surfaces of the first supporting plate and the second supporting plate are connected with slide plates; and ends, away from the supporting plates, of the two slide plates are connected with slide rods. According to the centrifugal vibrating type multi-point-location daily ceramic glazing machine provided by the invention, a glaze pumping shaft is used for pumping glaze, and glaze is sprayed through a first branch tube, a second branch tube and a third branch tube; a first motor, a first rotary shaft, an eccentric wheel and a glazing box are connected, so that the glazing boxvibrates up and down; and a second motor, a second rotary shaft and a placing plate are connected, so that the placing plate rotates to generate centrifugal force, and therefore, ceramic glazing on the placing plate is more uniform and more convenient, and the inconvenient ceramic glazing problem and the uneven ceramic glazing problem are solved.

Owner:大埔县馨明园陶瓷有限公司

Porcelain glaze and preparation method thereof

InactiveCN106495481AGlaze surface hardness is highImprove wear resistancePotassium feldsparSilica fume

The invention belongs to the field of porcelains and relates to porcelain glaze and a preparation method thereof. The porcelain glaze comprises 25 to 30 parts of potassium feldspar, 20 to 30 parts of bentonite, 5 to 8 parts of molybdenum trioxide, 5 to 10 parts of wollastonite, 0.5 to 0.8 parts of chromium oxide, 6 to 10 parts of quartz, 3 to 5 parts of dolomite, 5 to 8 parts of calcium carbonate, 4 to 8 parts of flint clay, 0.7 to 0.8 parts of sodium tripolyphosphate, and 1 to 3 parts of silicon carbide powder. The preparation method comprises pulverization, ball milling and blending. The porcelain product made by the preparation method does not contain lead, has high hardness of a glaze surface, high wear resistance and high strength, is not deformed easily, and has a good blank-glaze combination degree and good heat stability because of sintering at a high temperature.

Owner:崔松伟

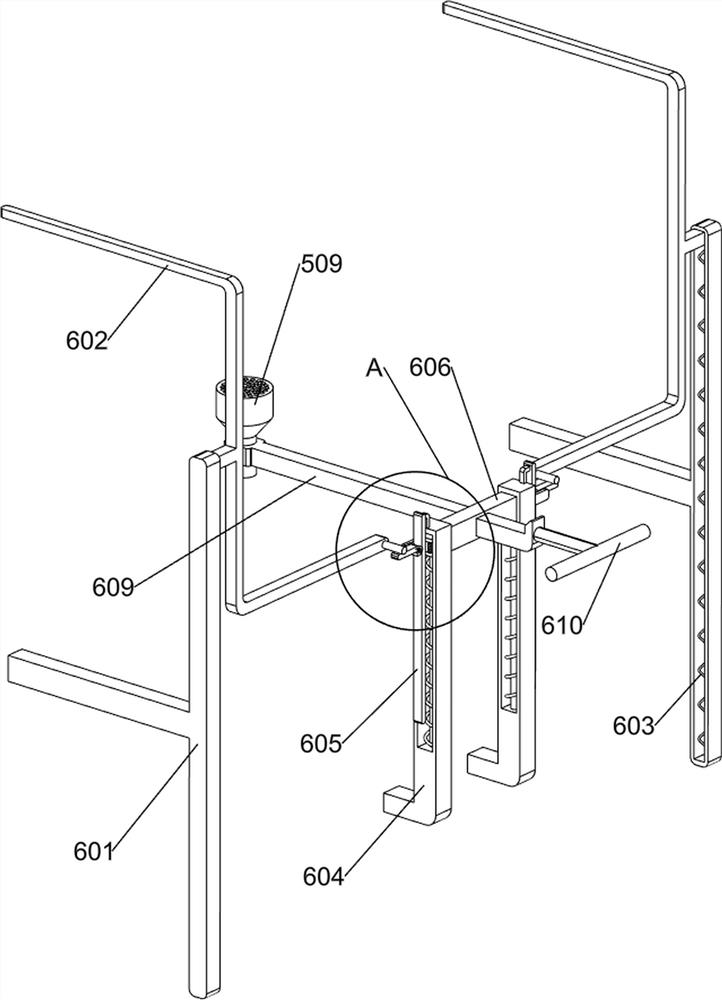

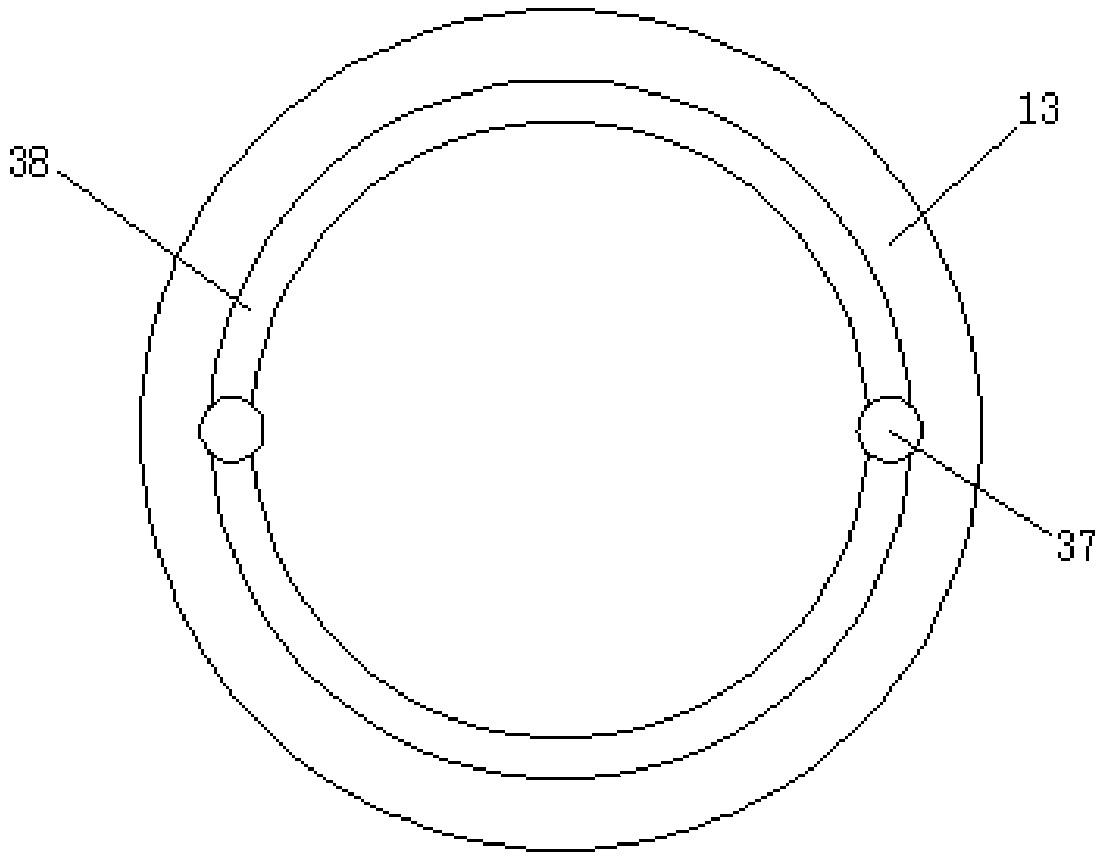

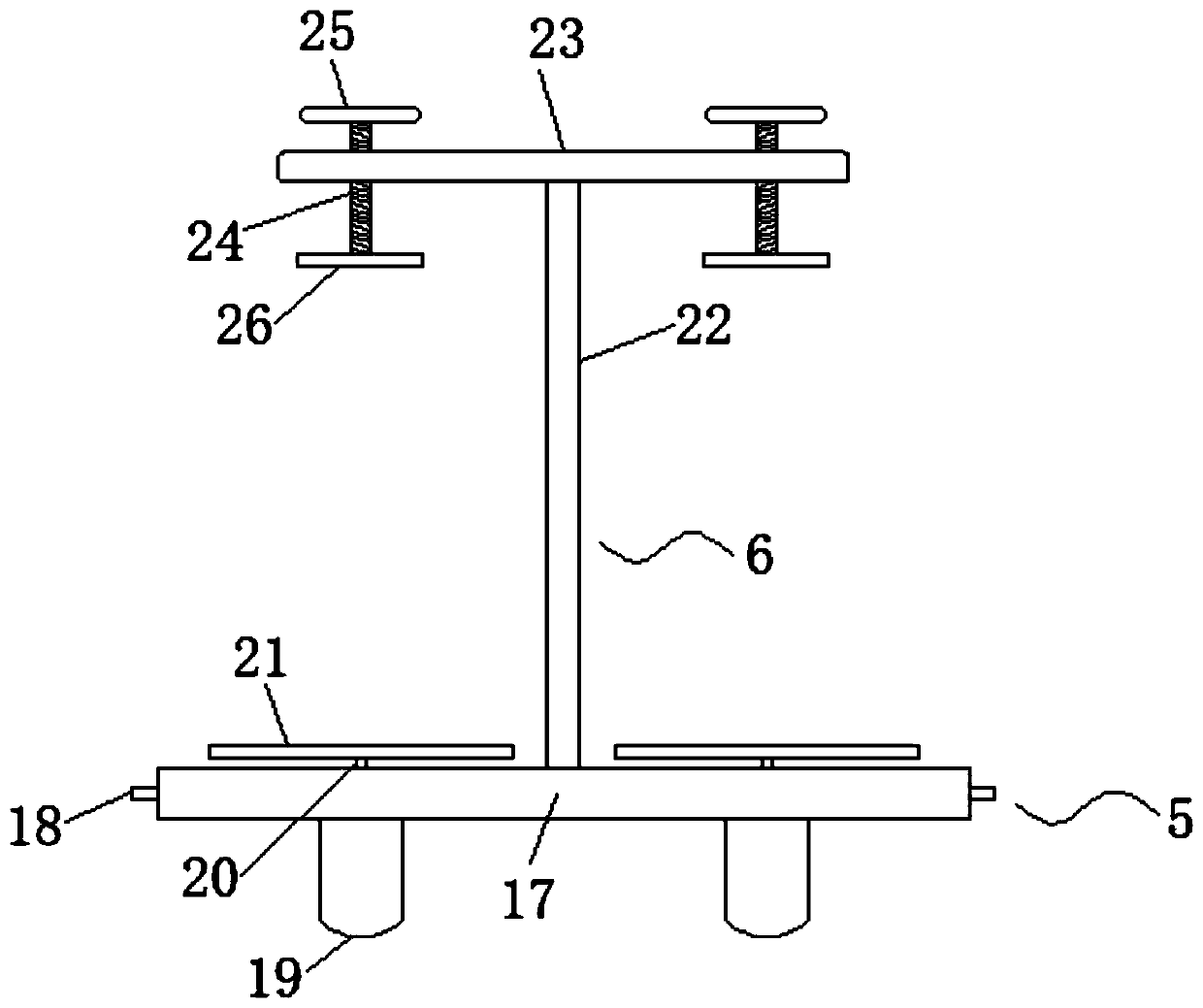

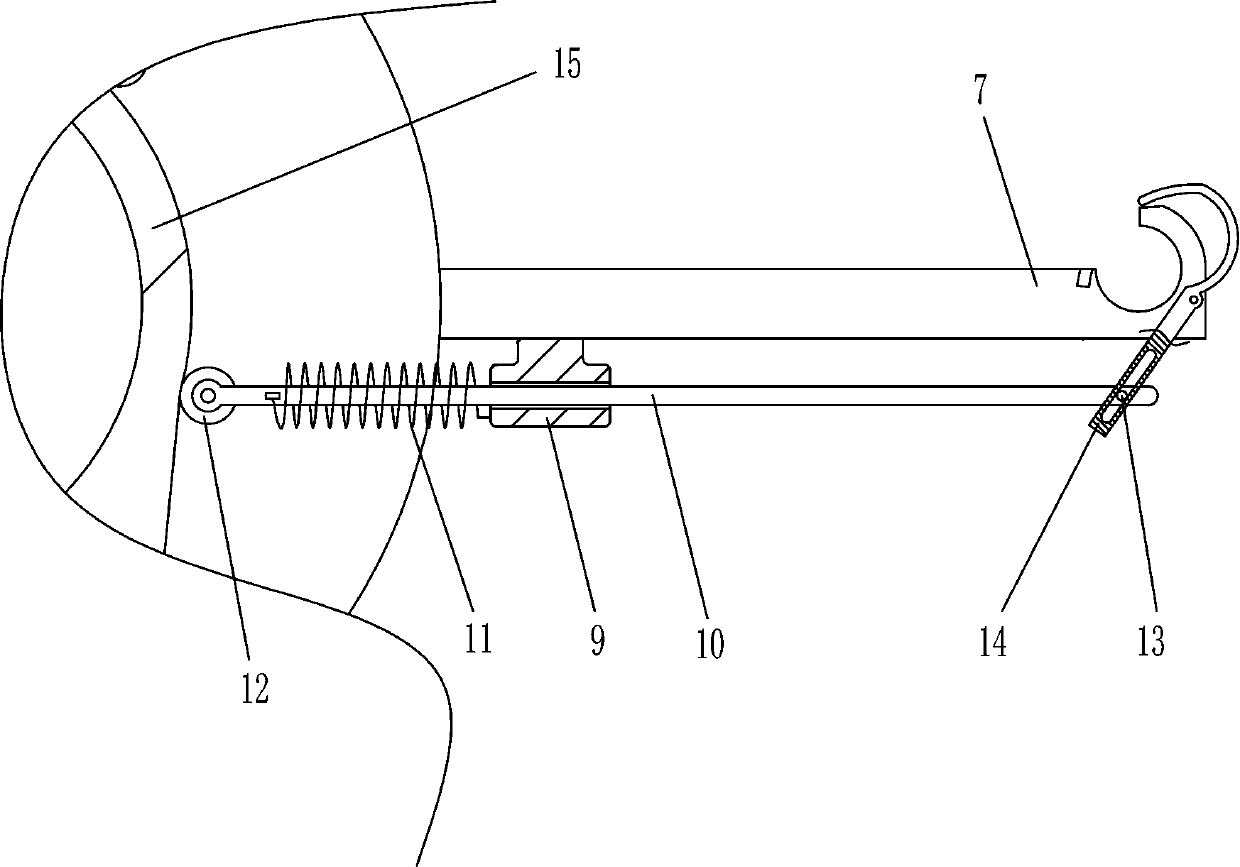

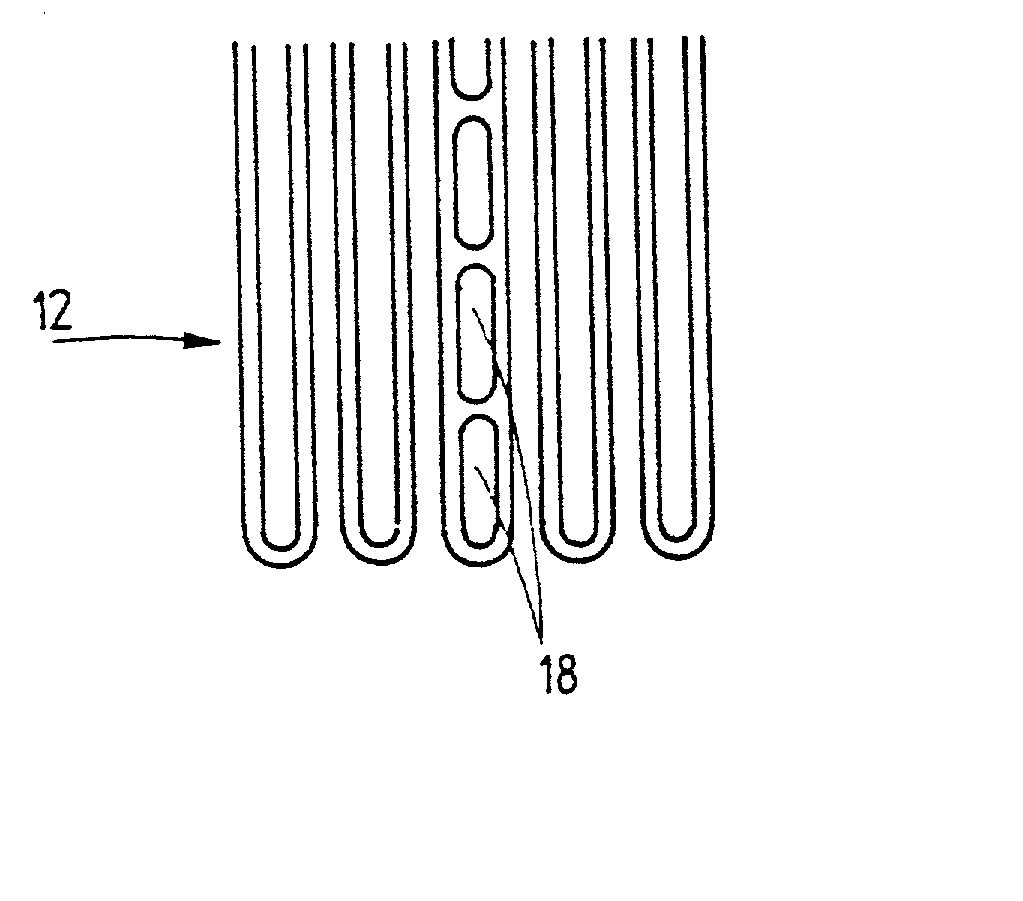

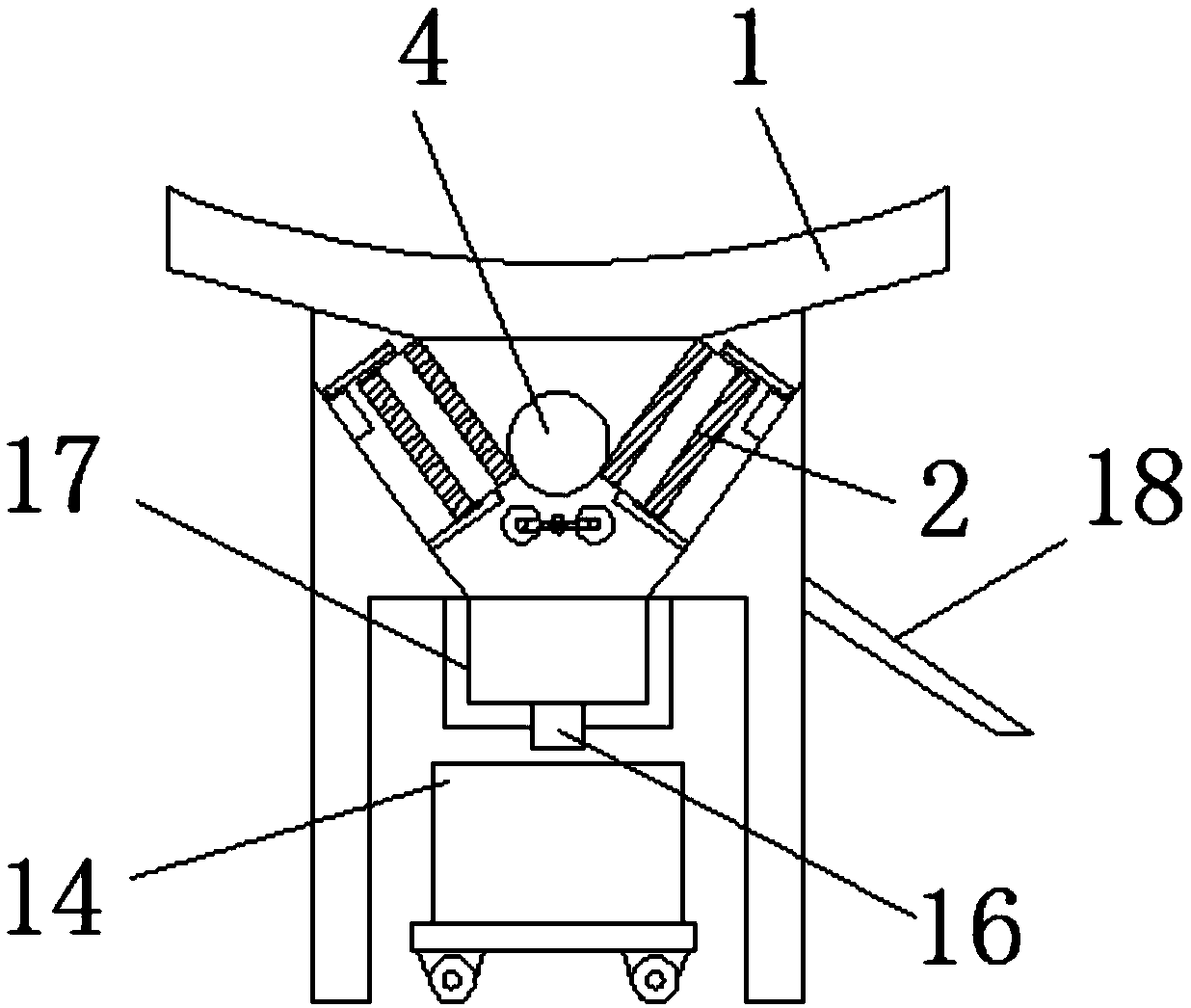

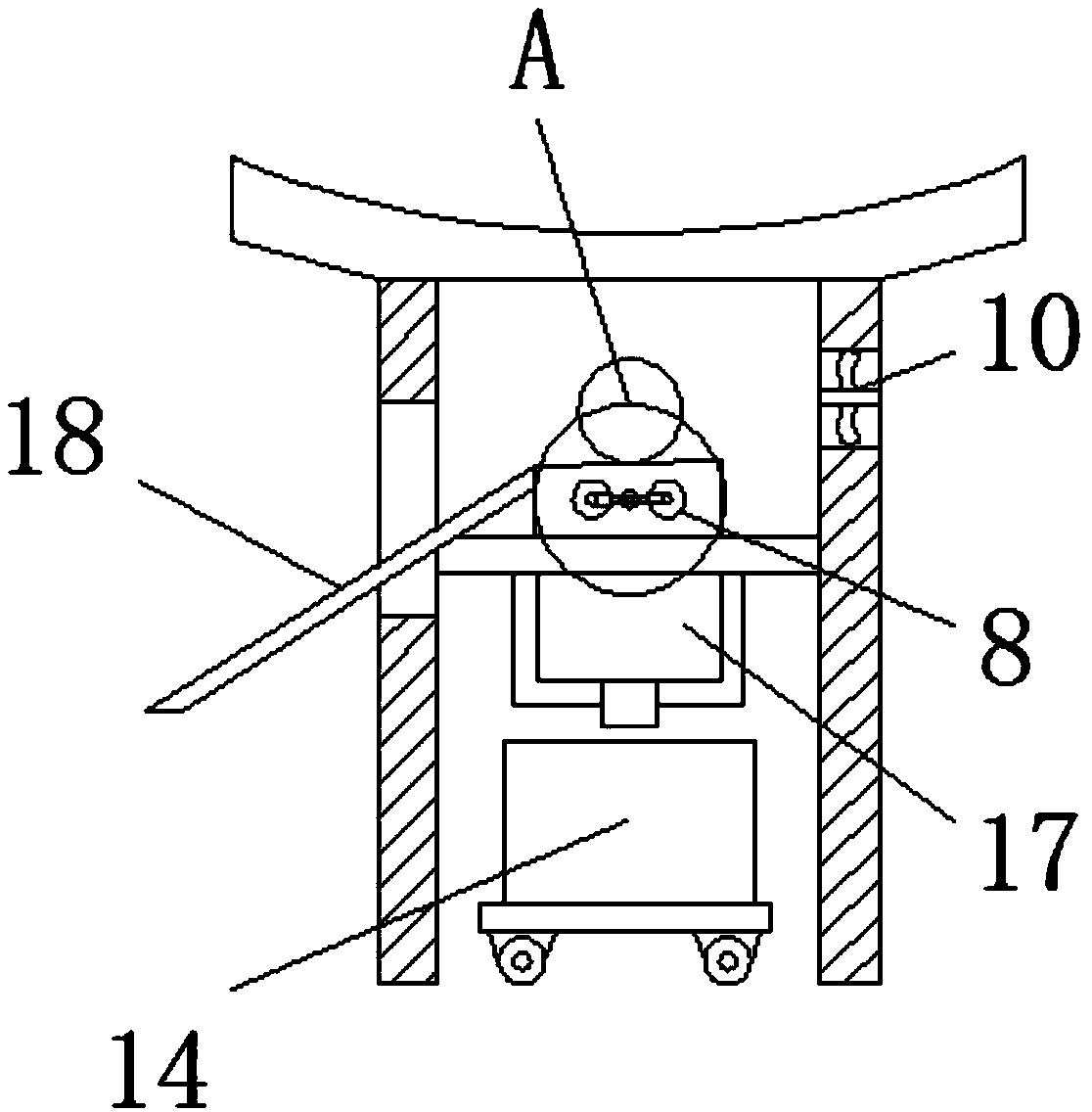

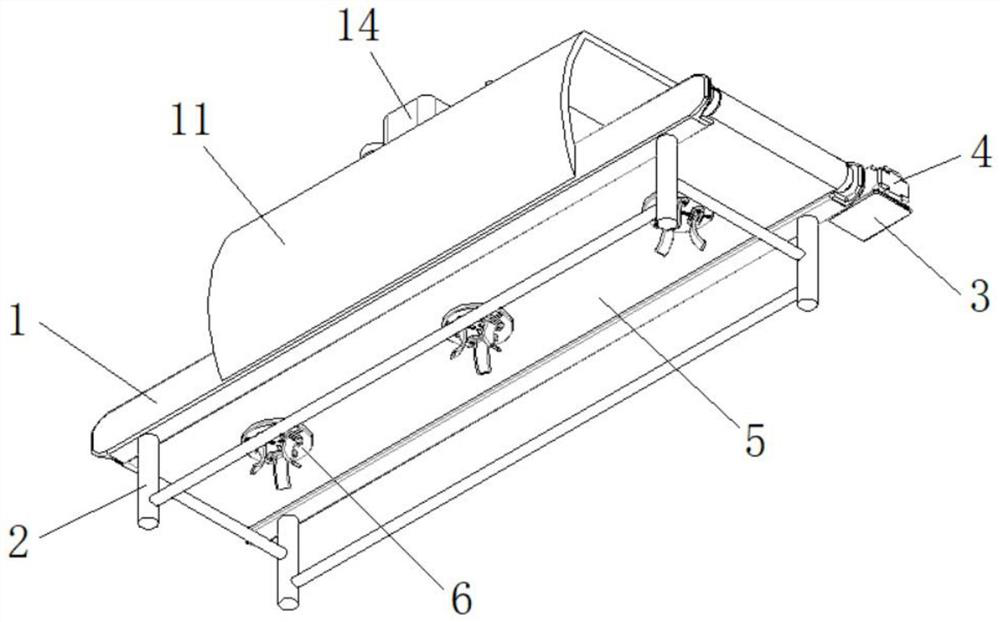

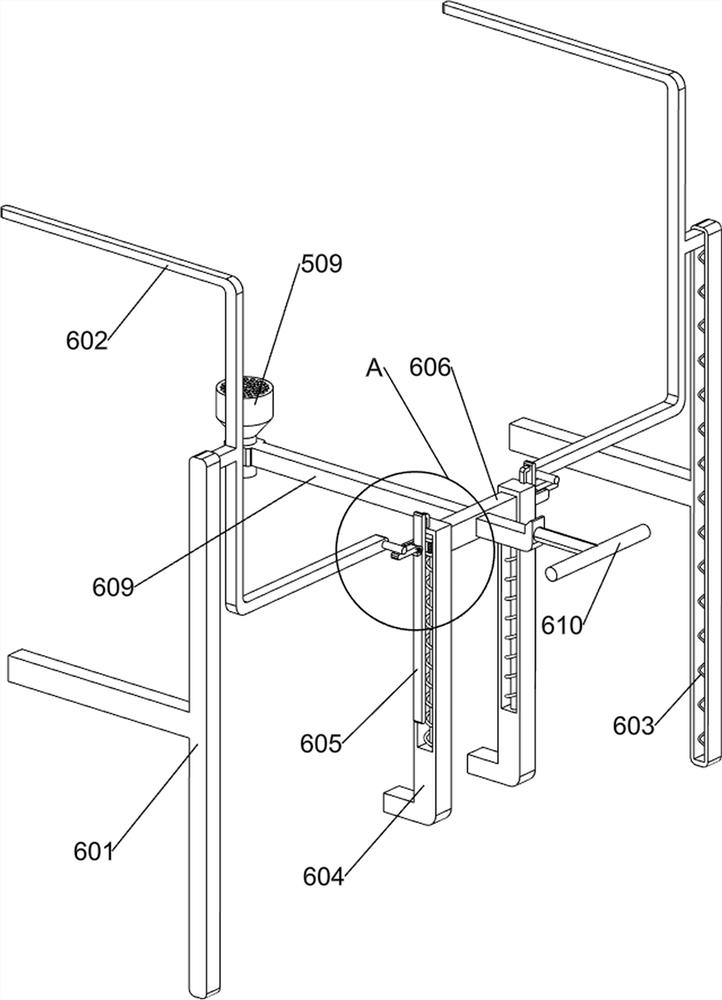

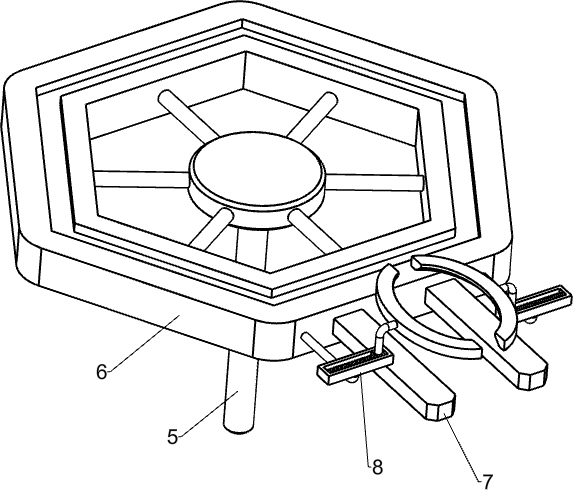

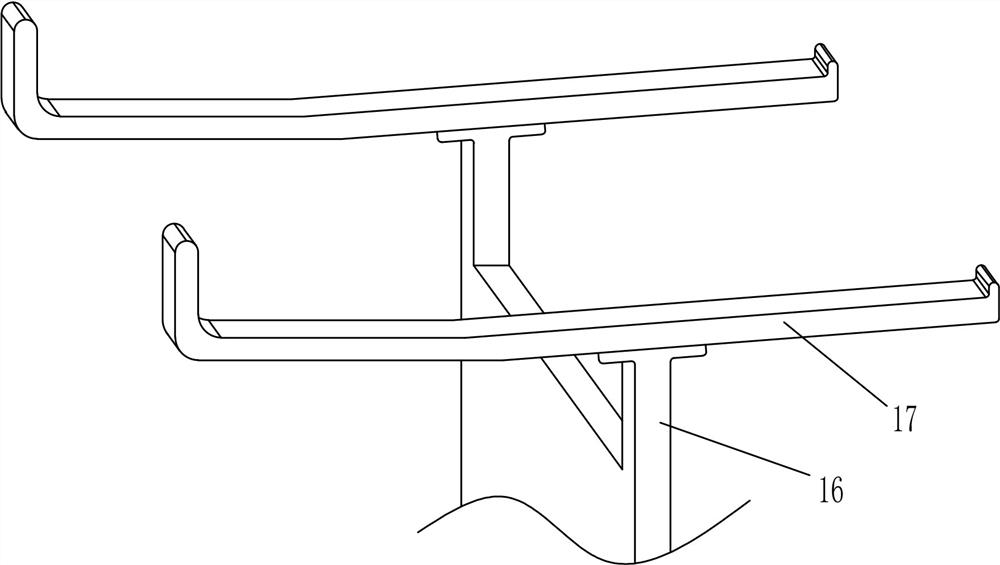

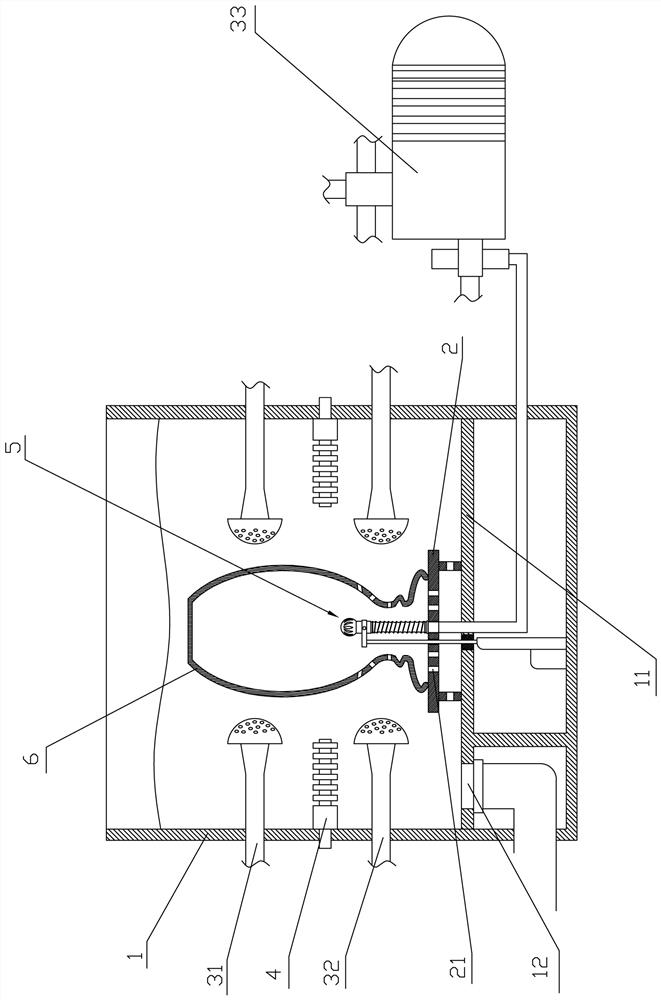

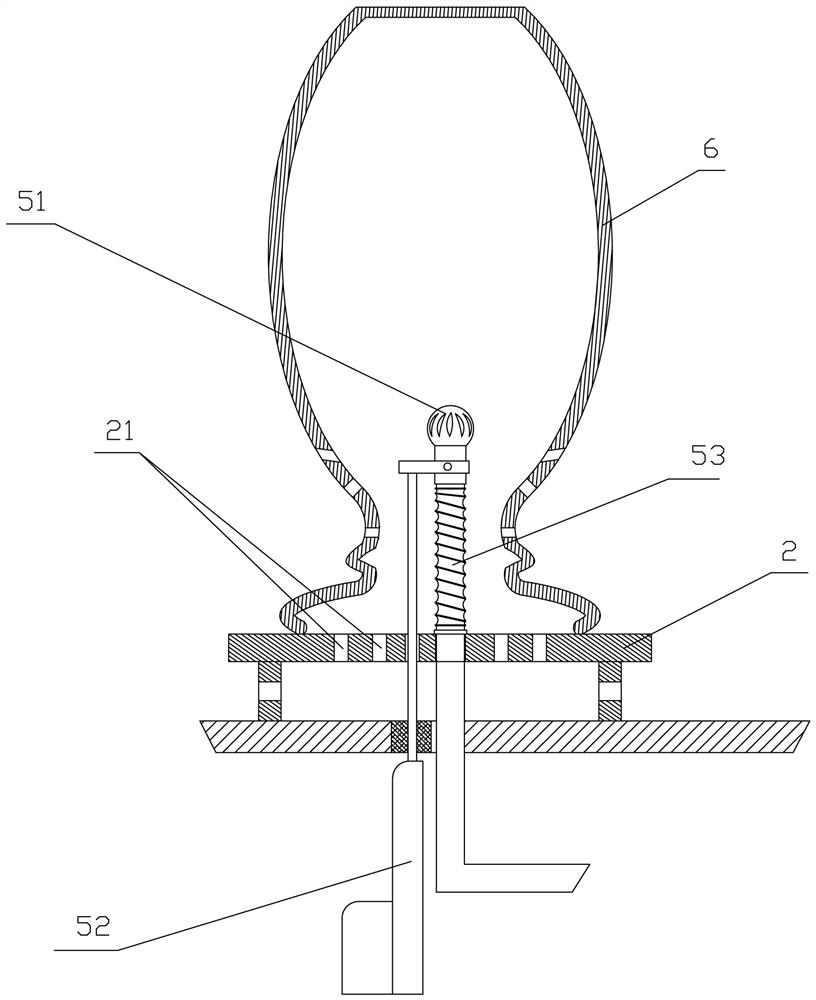

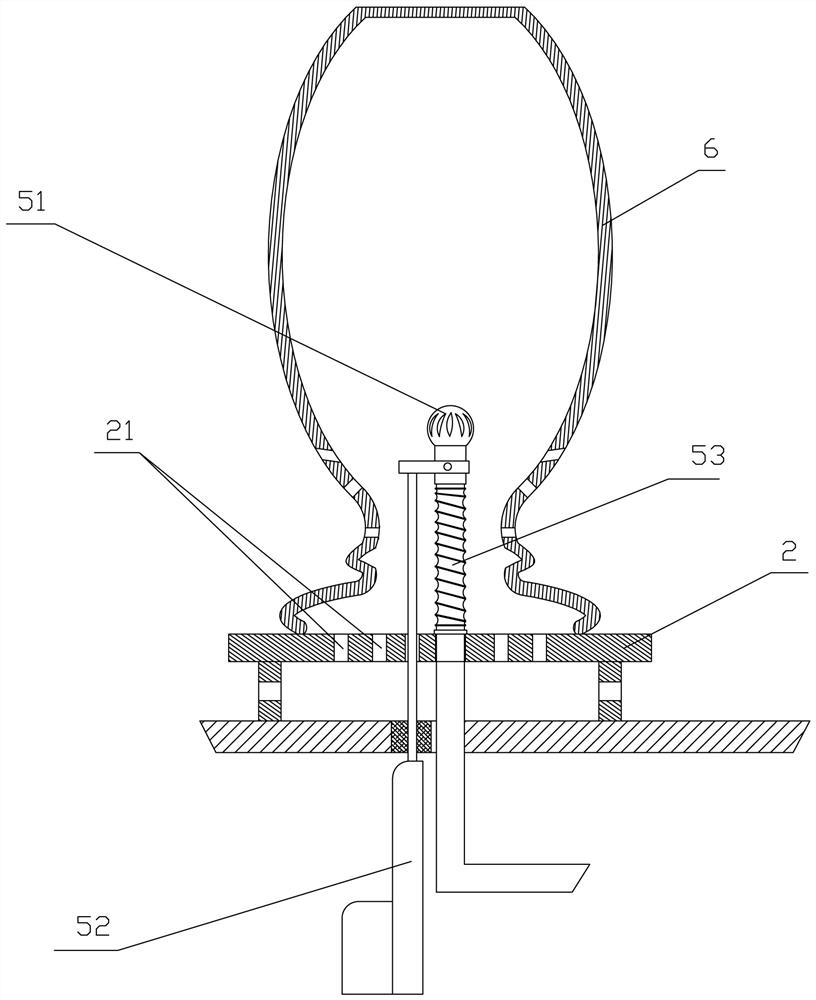

Inner glazing device for bowl-shaped ceramics

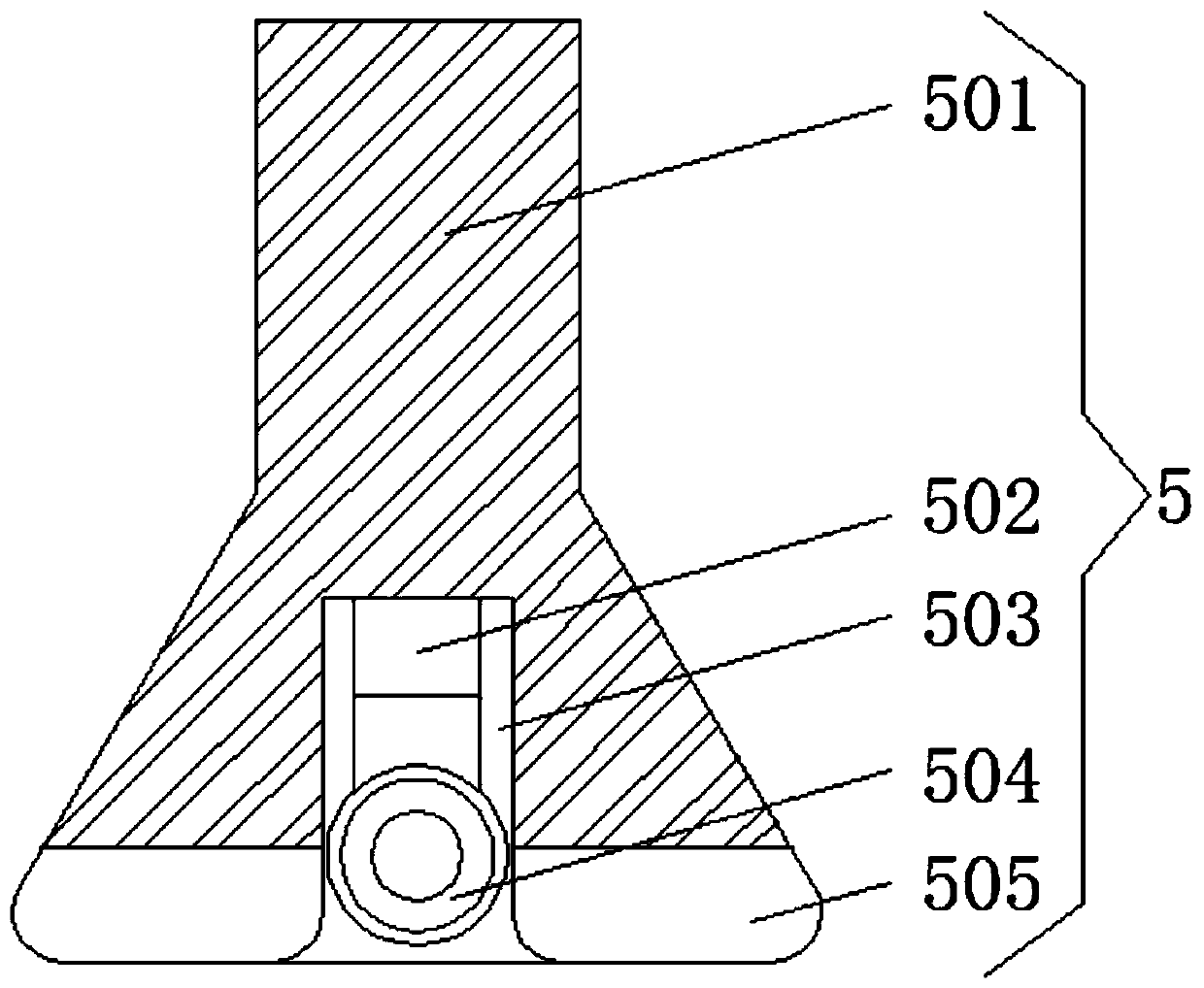

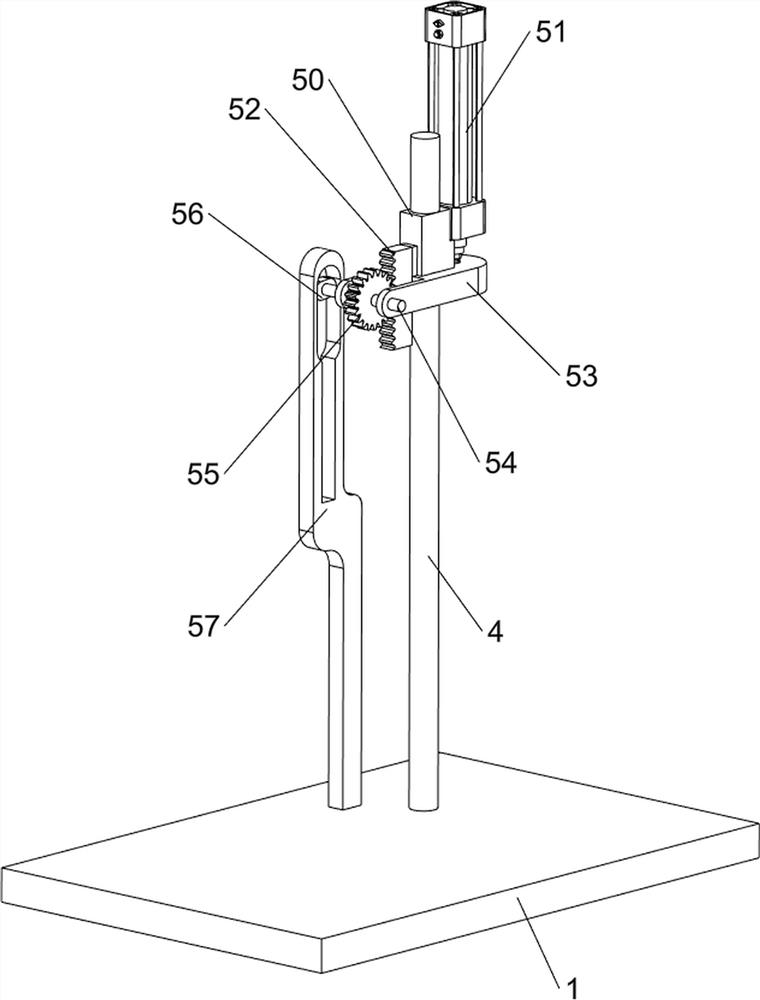

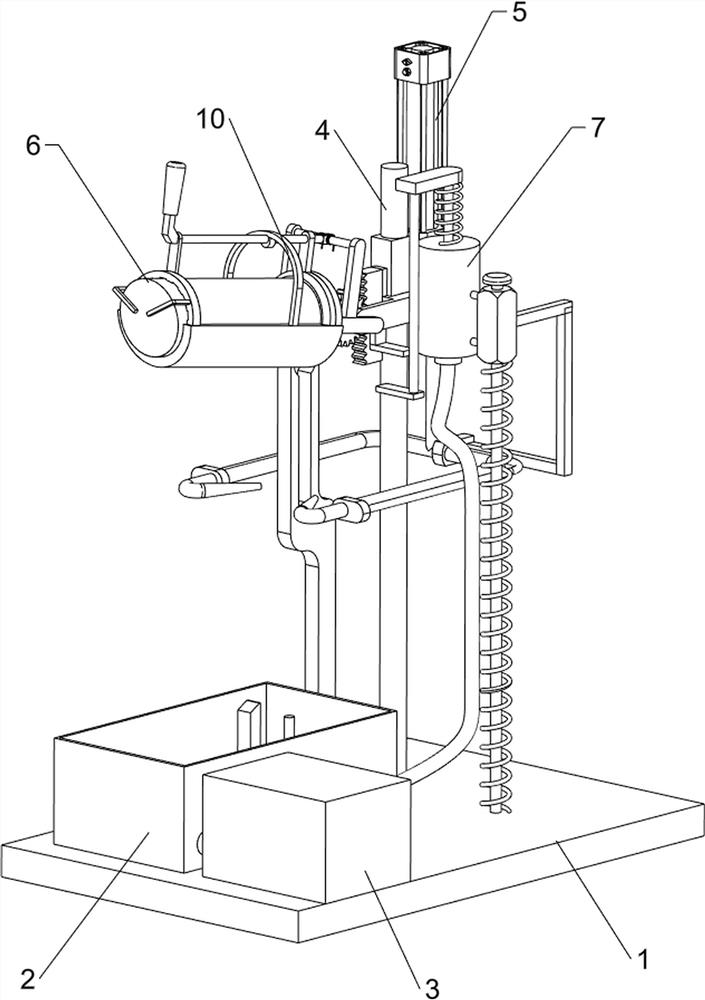

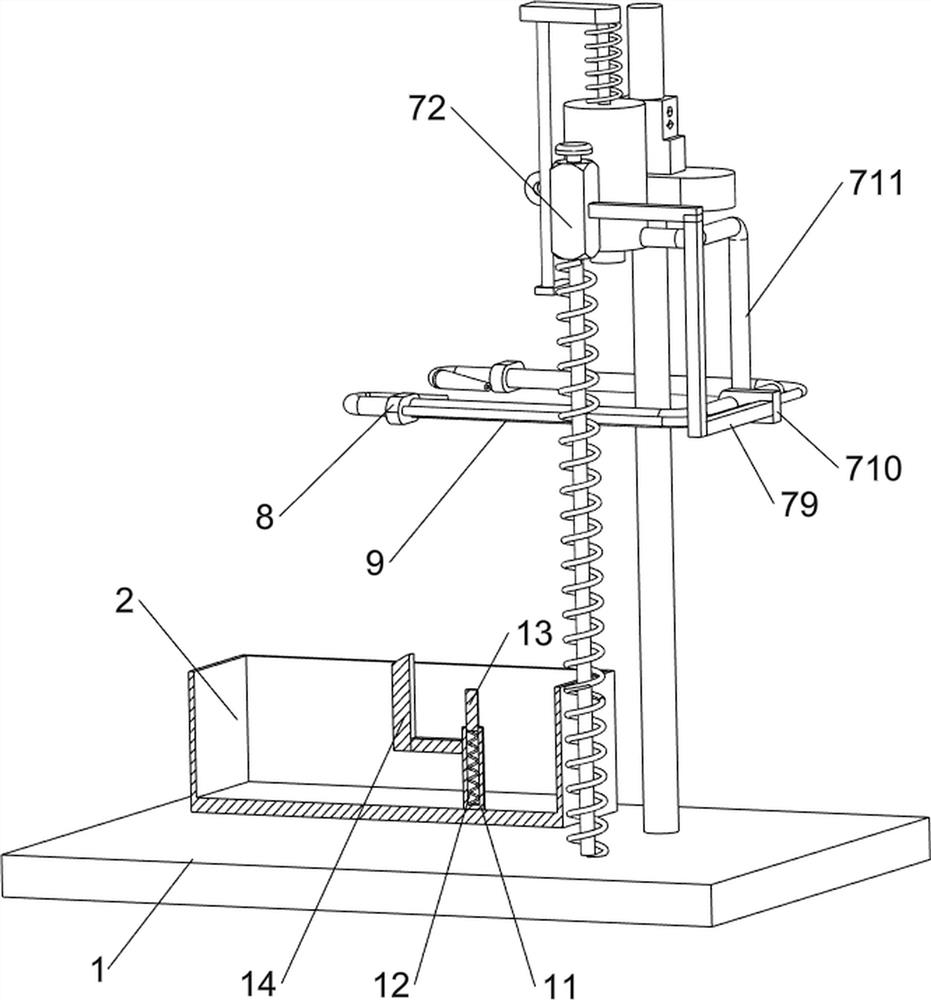

ActiveCN111633795AEasy to glazeAvoid displacementCeramic shaping apparatusElectric machineryEngineering

The invention relates to a glazing device, in particular to an inner glazing device for bowl-shaped ceramics. According to the technical aim to be achieved, the inner glazing device for the bowl-shaped ceramics is used for glazing the interior of the bowl-shaped ceramics evenly, and meanwhile the people cannot be influenced. The inner glazing device for the bowl-shaped ceramics comprises a supporting frame, a liquid storage frame, an airbag and a power assembly, the liquid storage frame is mounted on the supporting frame, the airbag is mounted on the supporting frame, and the power assembly ismounted on the supporting frame and provides power through a motor for working. According to the inner glazing device for the bowl-shaped ceramics, the gear motor can drive the bowl-shaped ceramics to rotate, the bowl-shaped ceramics are glazed conveniently, the bowl-shaped ceramics can be fixed through arc-shaped clamping plates, and the bowl-shaped ceramics can be prevented from doing displacement; and by means of inclined plates, the arc-shaped clamping plates can be automatically opened, the bowl-shaped ceramics are automatically fixed, and equipment use is more convenient.

Owner:陈长春

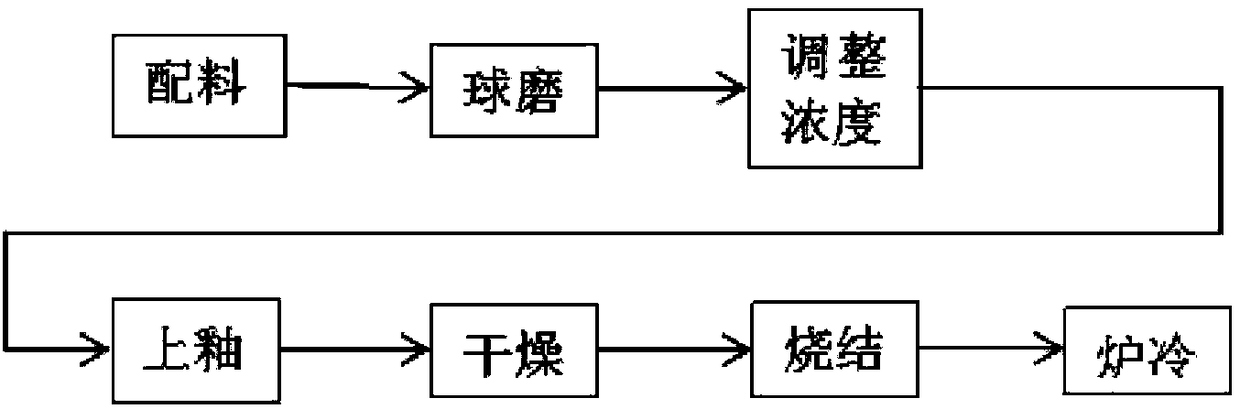

Jun porcelain sintering process

InactiveCN106336203AEnlarged stomataStrong glaze absorption abilityClaywaresFree coolingRoom temperature

The invention relates to a jun porcelain sintering process. The jun porcelain sintering process comprises the steps of bisque firing, glazing and glaze firing. The bisque firing step comprises the following sub-steps that 1, green body inspection is performed: finished green bodies to be put in a kiln is inspected according to the standard, and the qualified can be put in the kiln after inspection; 2, kiln charging is performed: the qualified finished green bodies are loaded on a supported kiln car shed plate according to different categories in a classified mode; 3, access to the kin is performed: a charged kiln car is slowly pushed into the kiln at a constant speed, and a kiln door is closed; 4, firing is performed: the temperature in the kiln gradually rises from normal temperature to 900 DEG C within 4 hours, and then fire is ceased; 5, cooling is performed: the temperature in the kiln is naturally reduced to 100 DEG C, then the kiln door is opened to avoid the phenomenon that the green body suddenly cracks due to too quick temperature reduction, the kiln car is pulled out at the moment, and the fired green body is taken. The jun porcelain sintering process has the advantages of being reasonable in technological process, low in production cost and high in finished product pass percent.

Owner:温书强

Preparation method for colored sand glaze ceramic tile

The invention discloses a preparation method for a colored sand glaze ceramic tile. The tile is prepared from 70-80 parts of quartz sand, 2-4 parts of potash feldspar, 3-5 parts of kaolin, 4-6 parts of carboxymethyl cellulose sodium and 11-15 parts of pigment. According to the preparation method, the quartz sand is taken as a main raw material, a certain amount of carboxymethyl cellulose sodium isadded to improve a suspension property of glaze slip, and the defect of constant stirring in the glazing process of an original preparation process is solved, the method applied to bathroom floor tiles not only is simple and convenient to glaze, but also has skidproof and decorative effects. Because the raw material cost is low, the sintering temperature is not high, the product has more color varieties, the color is bright, firm, enduring, resistant in scratch, fadeless and resistant in a high temperature, and the method has significant economic benefits and social benefits.

Owner:FUJIAN UNIV OF TECH

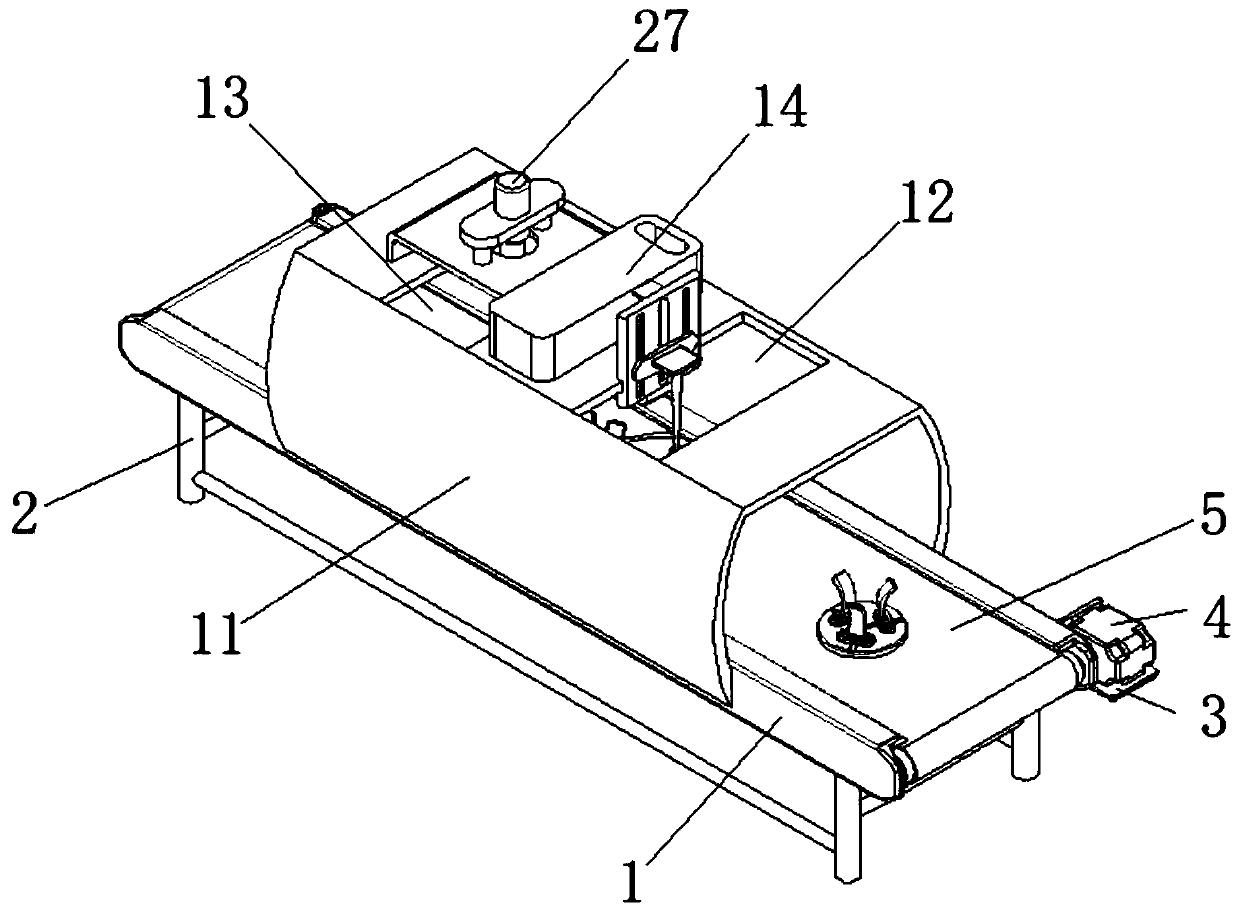

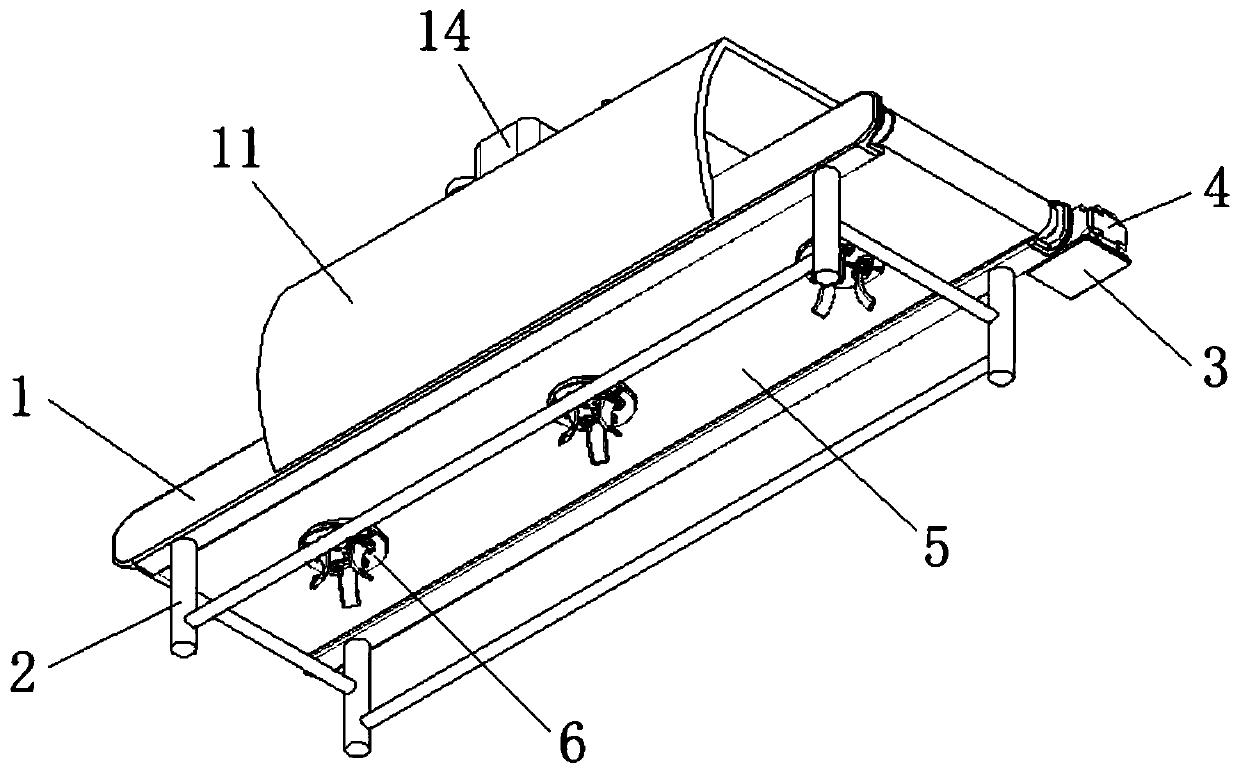

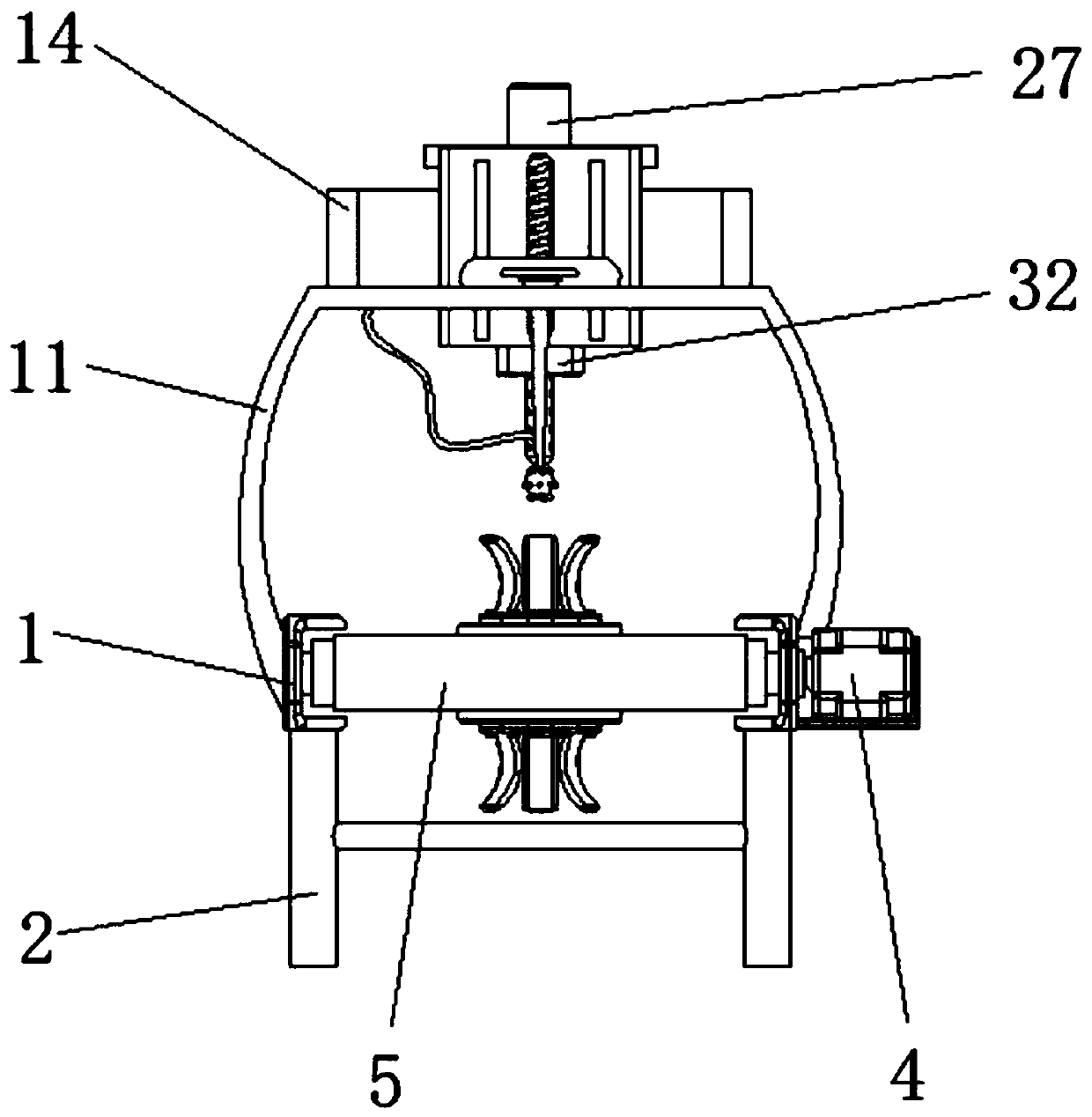

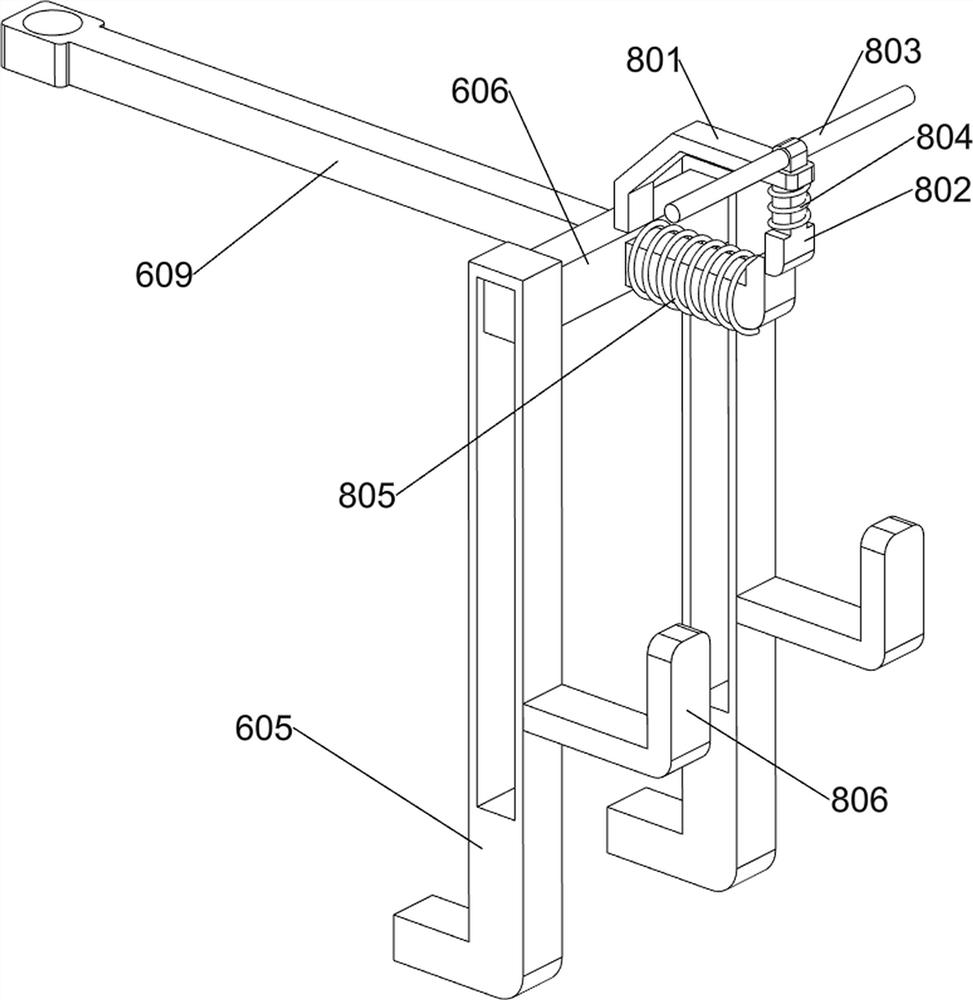

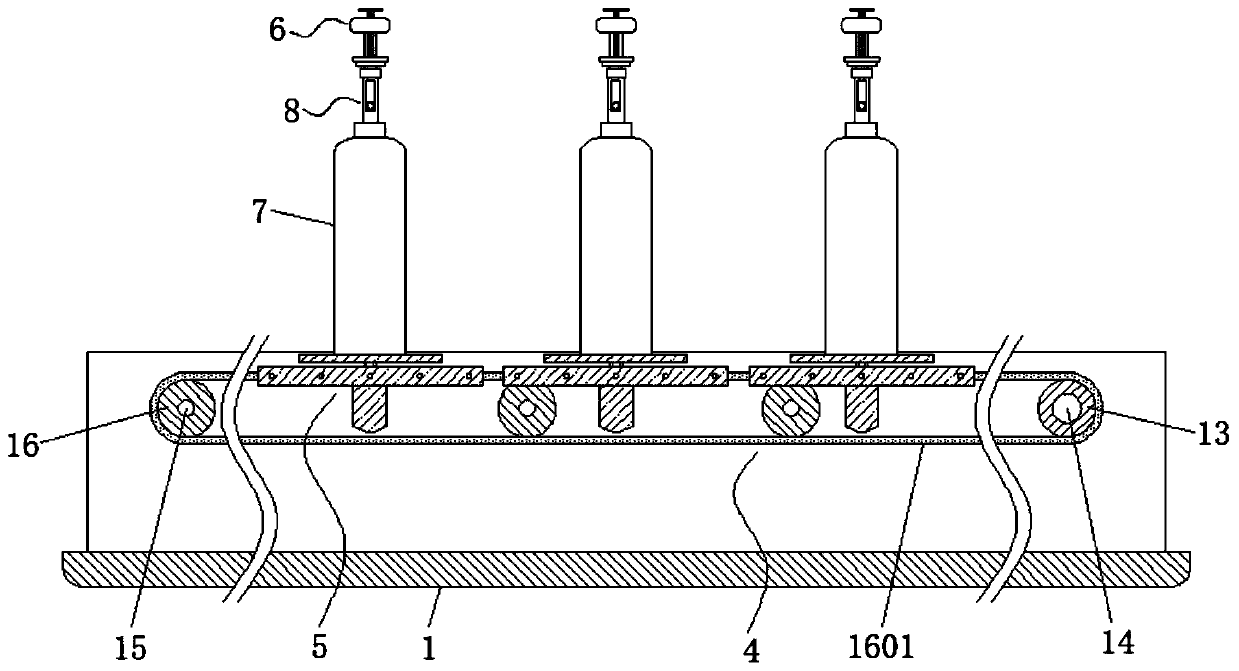

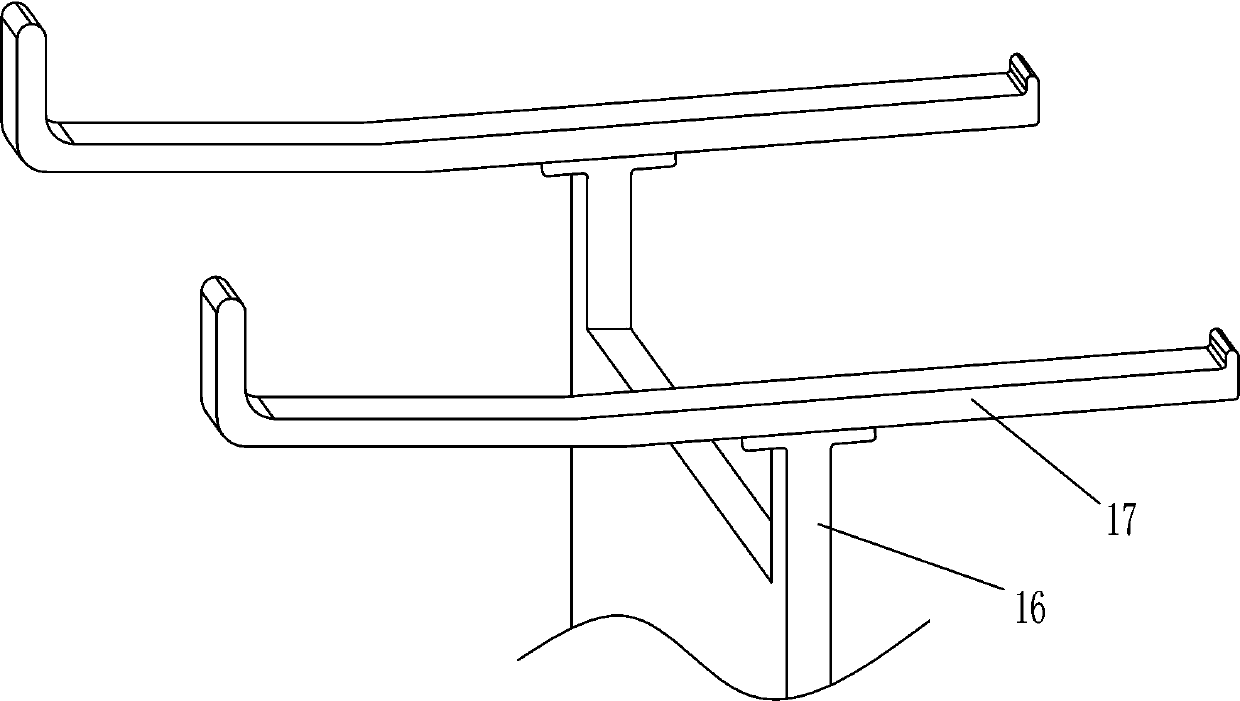

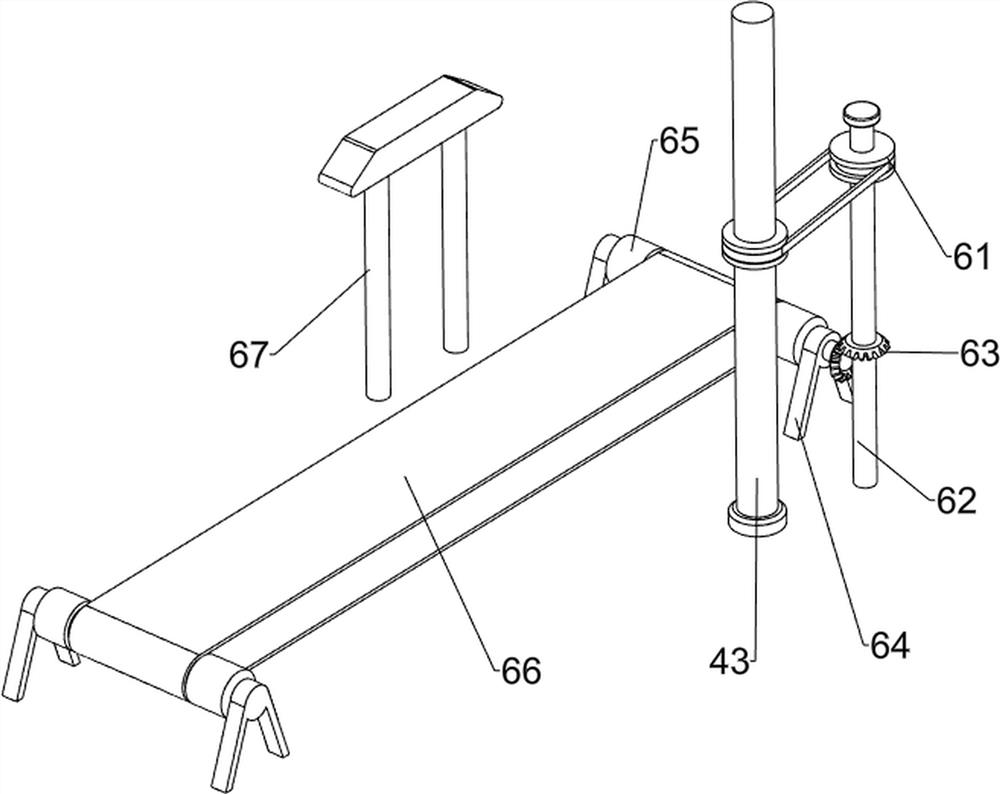

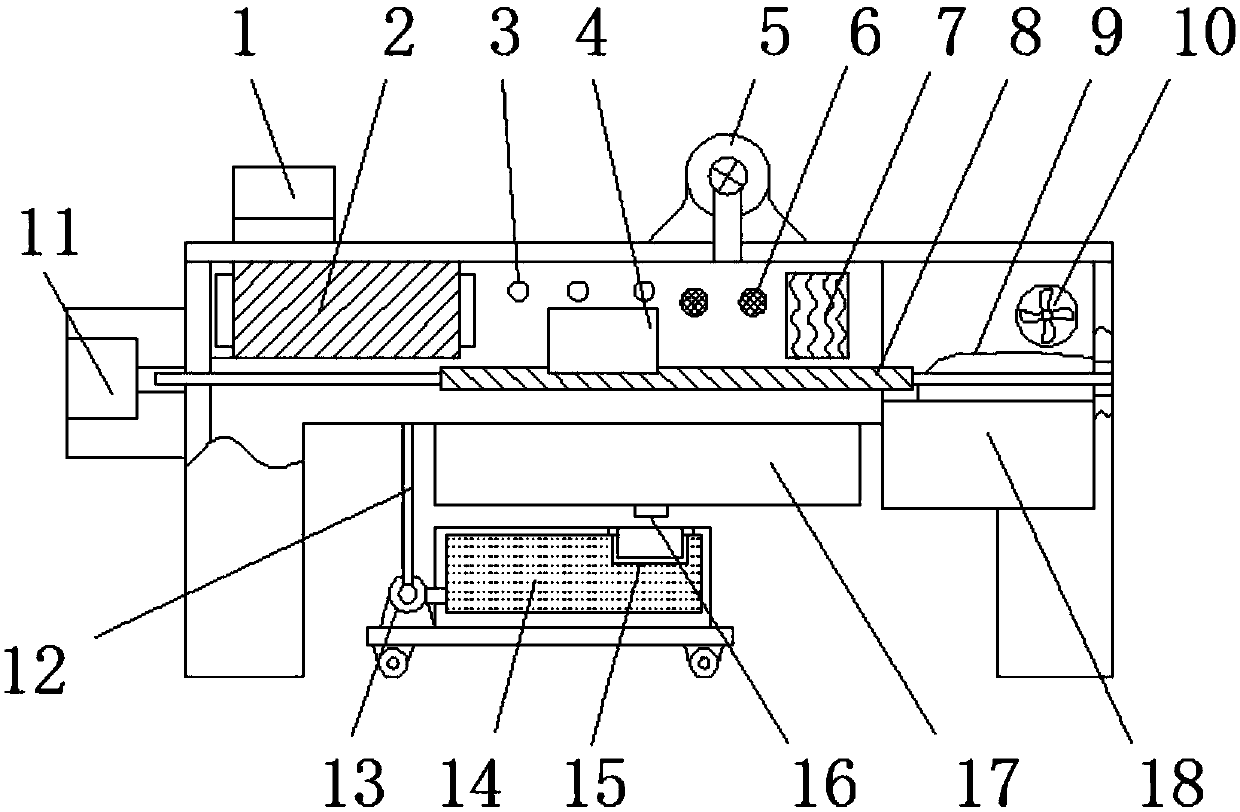

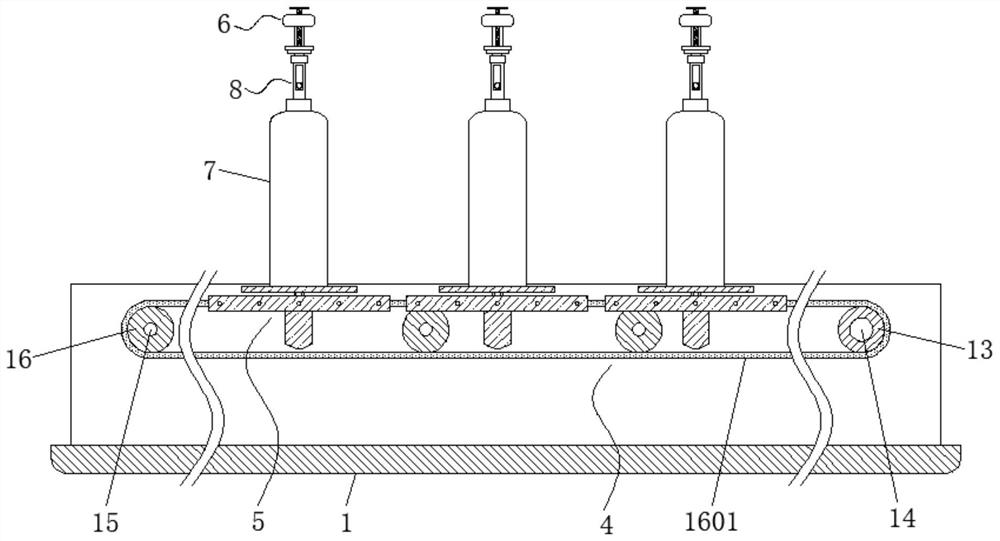

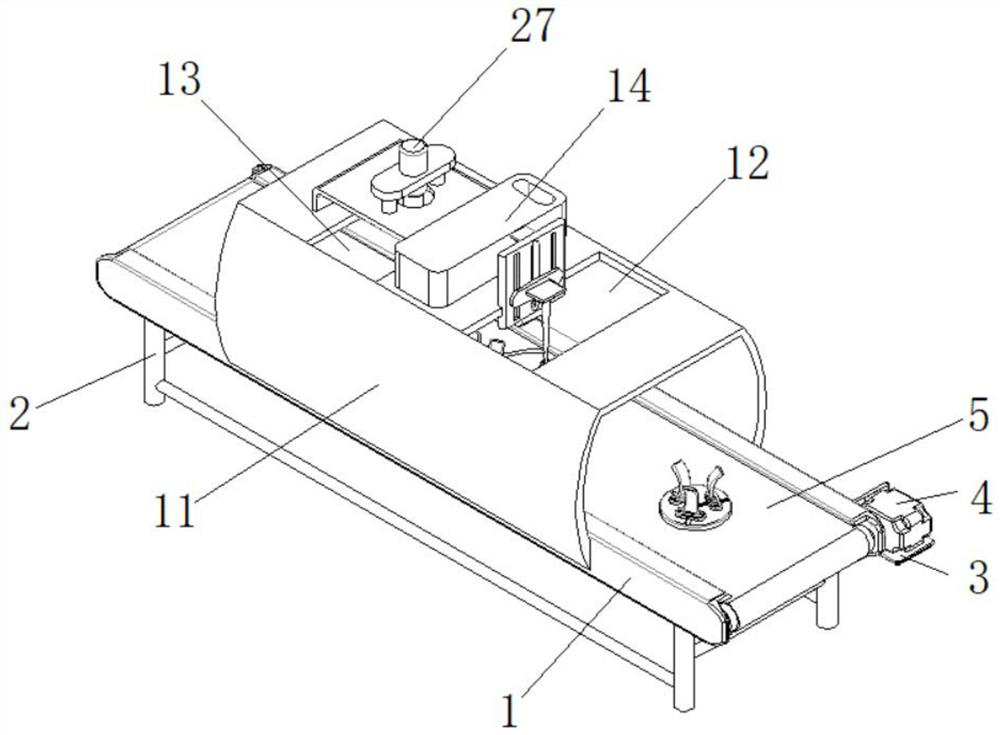

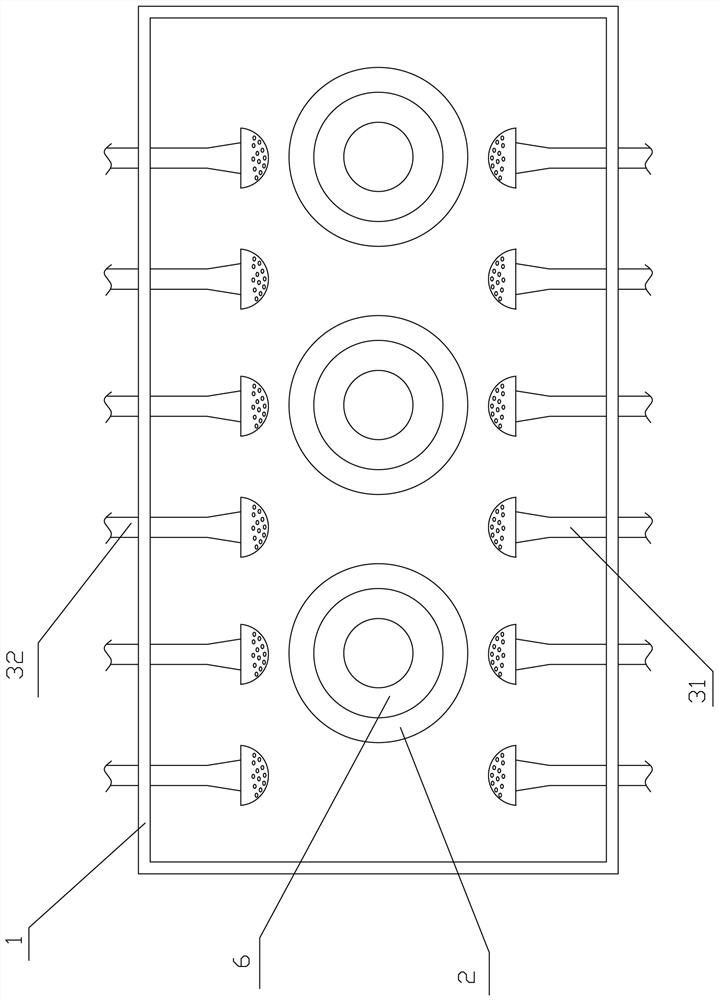

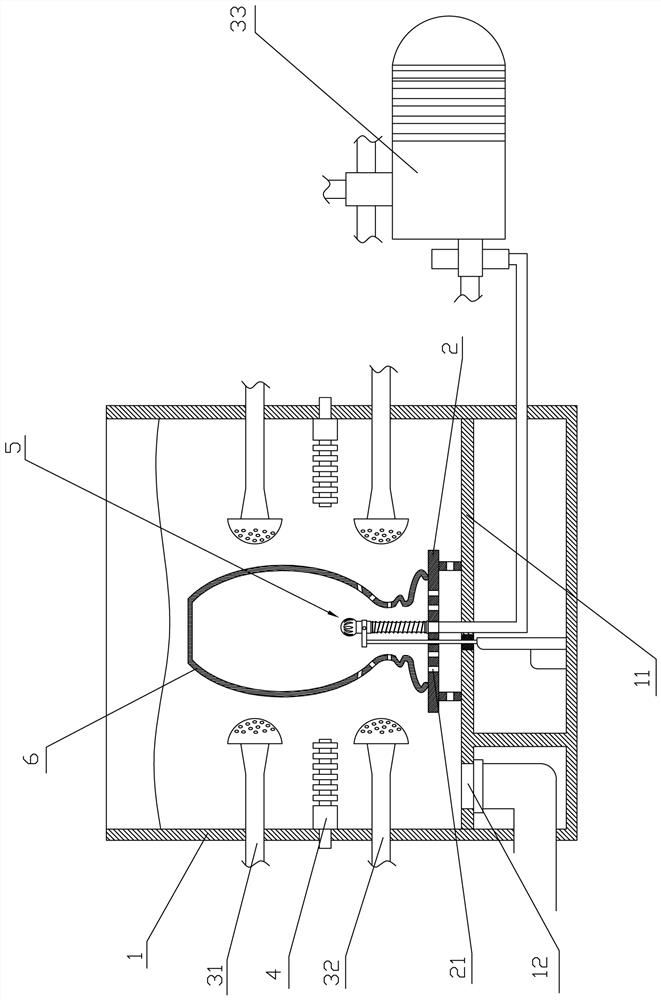

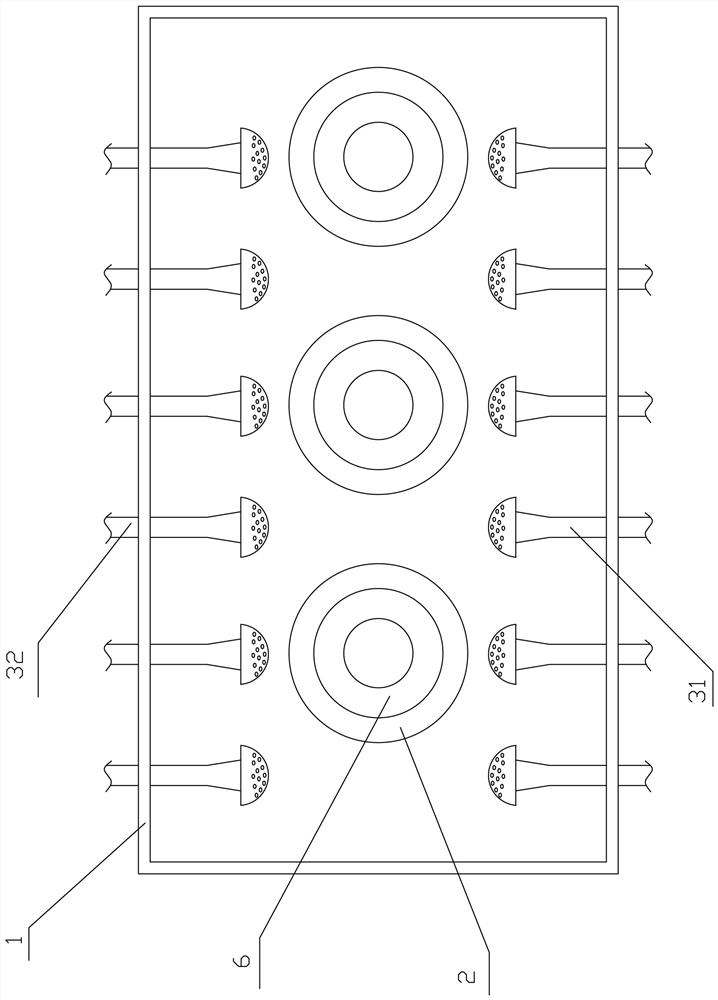

Efficient ceramic glazing device

ActiveCN110341030AEfficient glazingSimple glazeCeramic shaping apparatusUltimate tensile strengthMaterials science

The invention relates to the technical field of ceramic glazing devices, discloses an efficient ceramic glazing device, and solves the problems that the existing manual glazing is high in labor intensity, low in production efficiency, complex and inconvenient, and seriously damages the body health of operators. The efficient ceramic glazing device comprises a conveying groove plate, wherein supporting legs are fixedly arranged at the bottom of the conveying groove plate, a first motor is fixedly arranged at one end of the surface of the conveying groove plate, a conveying mechanism is arrangedinside the conveying groove plate, three rotating mechanisms are arranged in the middle of the conveying mechanism, the middle parts of the three rotating mechanisms are provided with fixing mechanisms correspondingly, and two sides of the top of each of the three rotating mechanisms are provided with ceramic blanks correspondingly. According to the efficient ceramic glazing device, the efficientglazing can be carried out on the blank during use, and the glazing process is simple, convenient, stable and effective; and meanwhile, the blank is not in contact with the operators during glazing,so that the body health of the operators is guaranteed.

Owner:XUCHANG UNIV

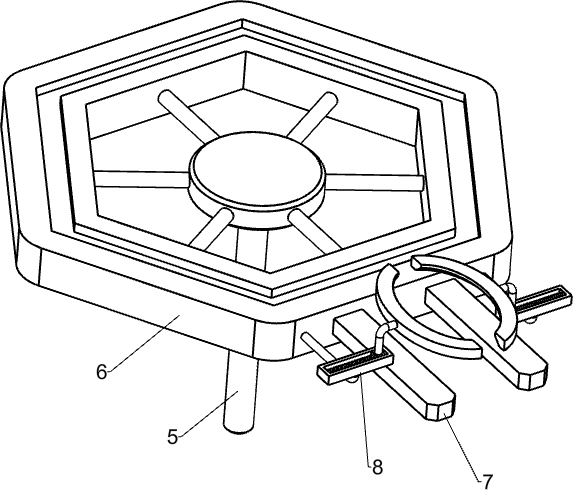

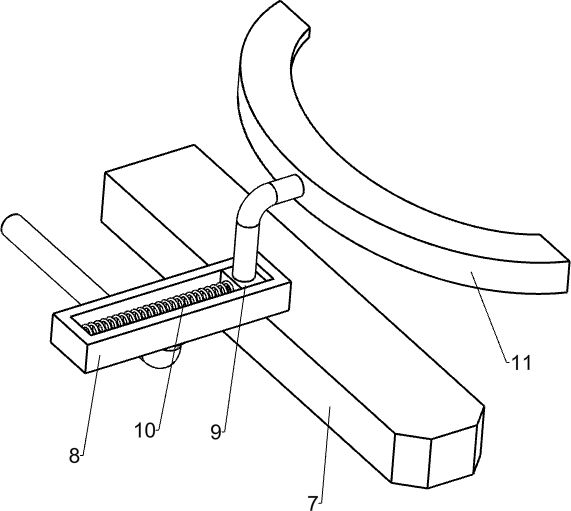

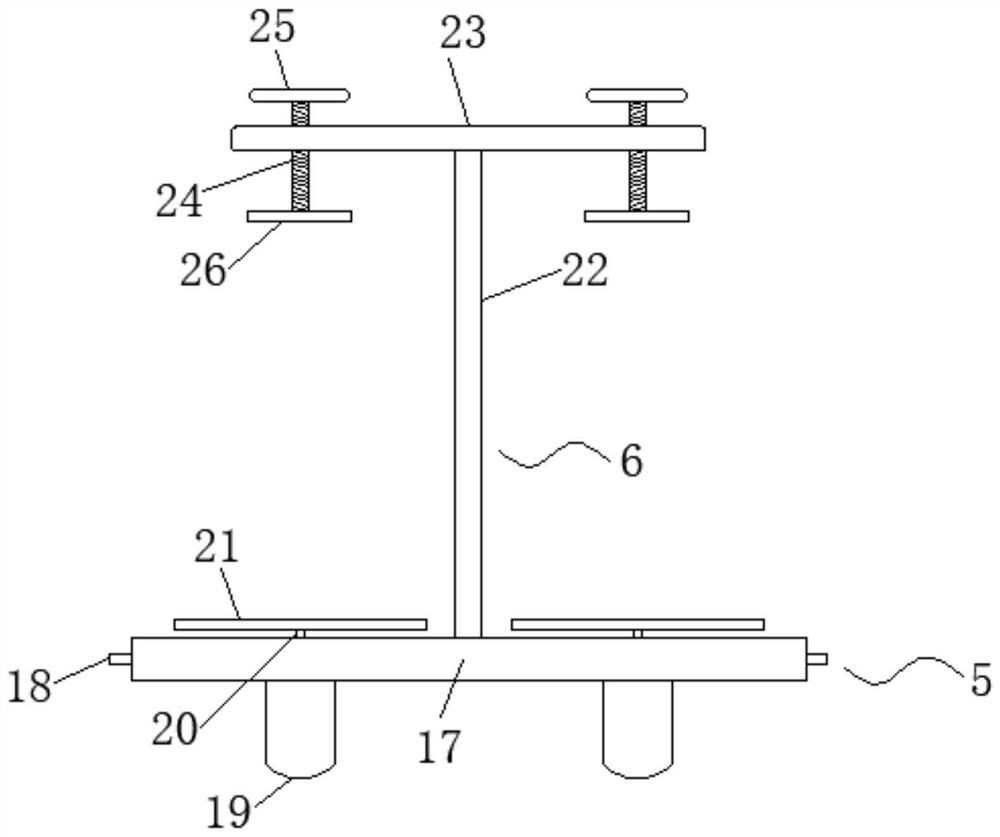

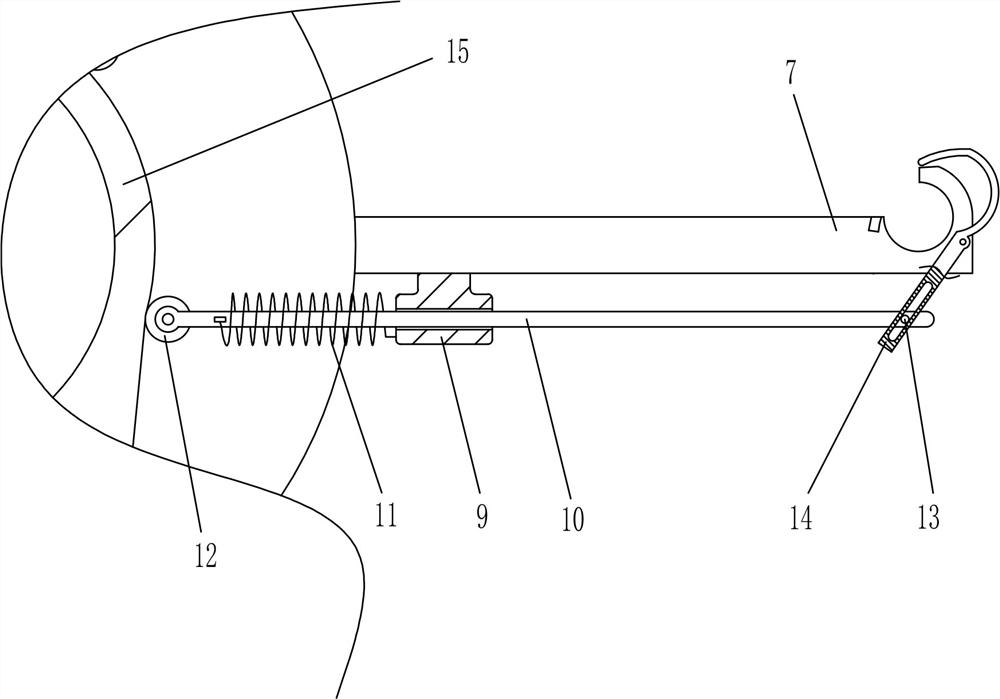

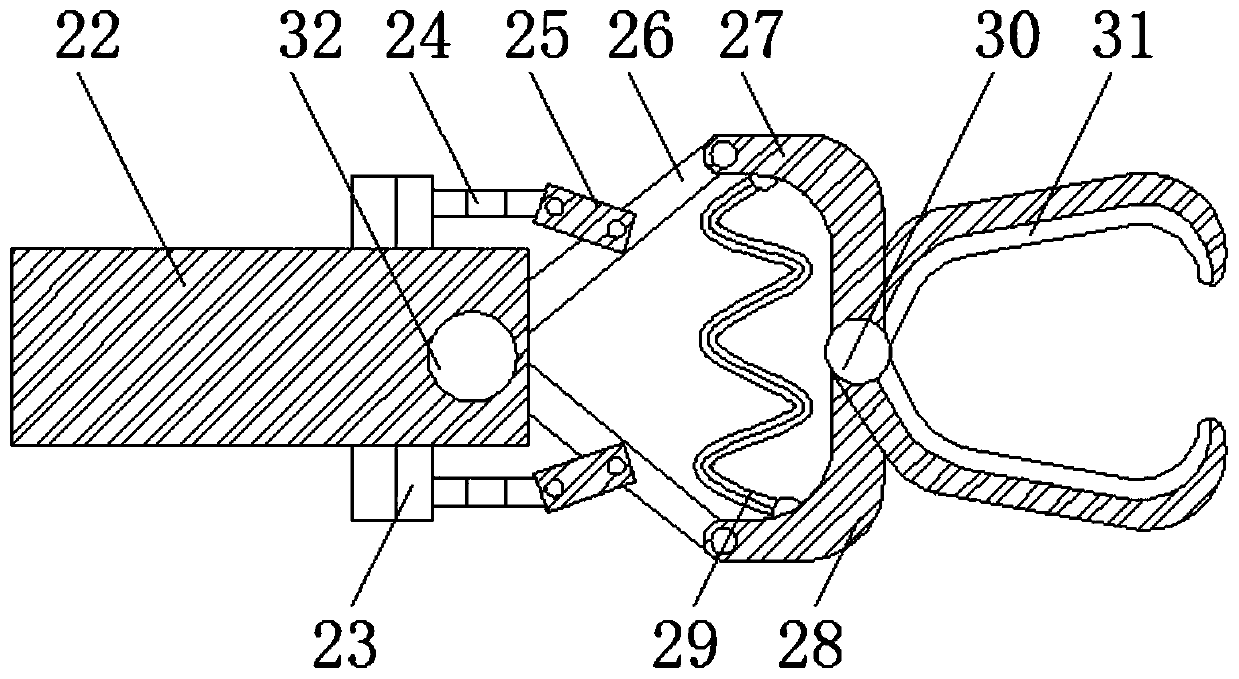

Glazing device for strung spoons

The invention relates to a glazing device, in particular to a glazing device for strung spoons. According to the glazing device for the strung spoons, the glazing operation of ceramic spoons is simple, and the soaking time of the ceramic spoons in dye can be controlled. The glazing device for the strung spoons comprises a support, a storage box and the like; and the storage box is fixedly connected with the right side of the middle of the support. According to the glazing device, the ceramic spoons on a rotating disc is driven to rotate by adopting a pedal mode, the ceramic spoons can be rotated into the storage box, and the ceramic spoons are covered with coating, so that the glazing function on the ceramic spoons is completed; and a first slide bar is extruded through the protruding partof a cam, the ceramic spoons on hooks are fixed with a swinging rod, and the placed ceramic spoons fall into the storage box, so that the ceramic spoons are glazed more conveniently.

Owner:梁泽冲

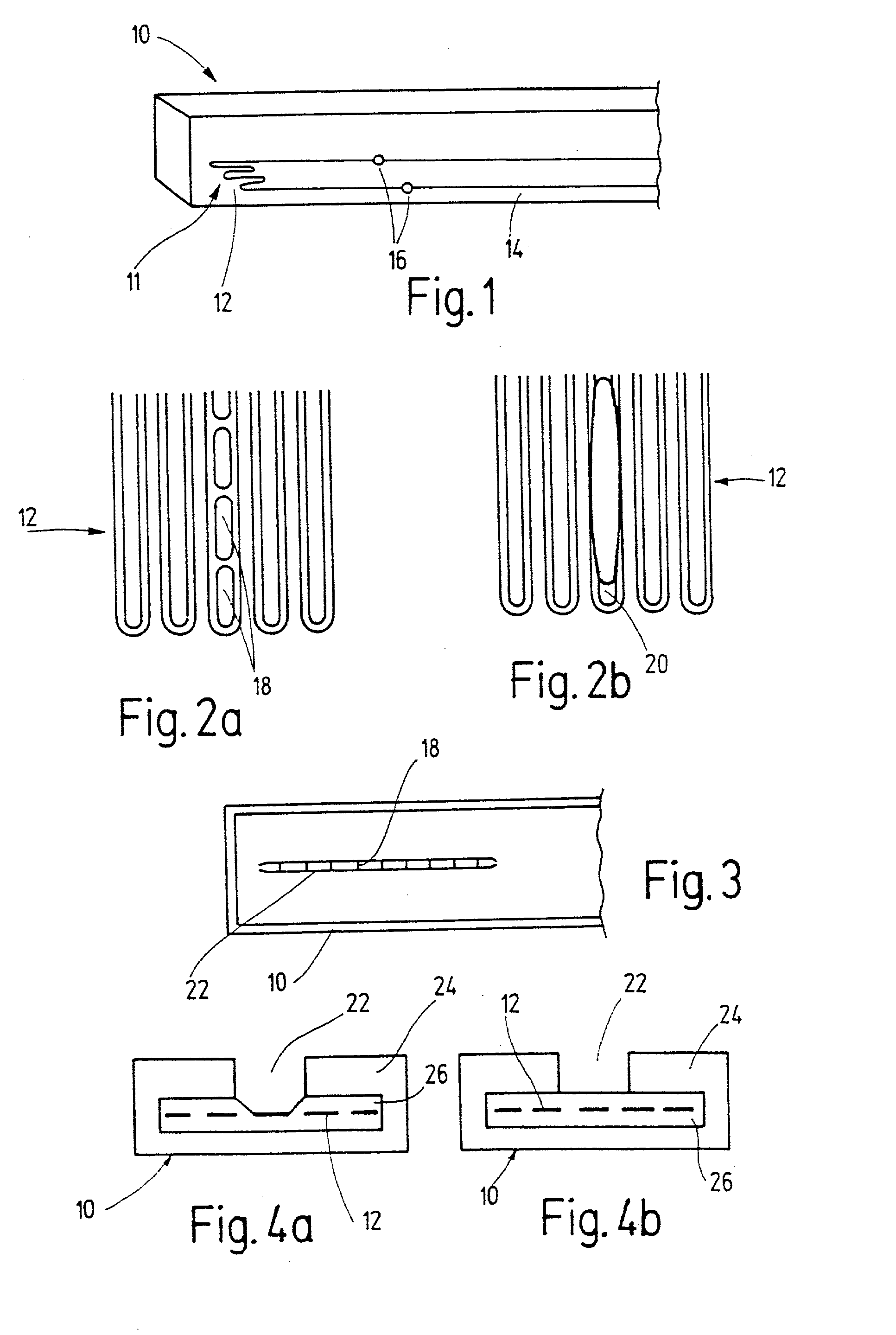

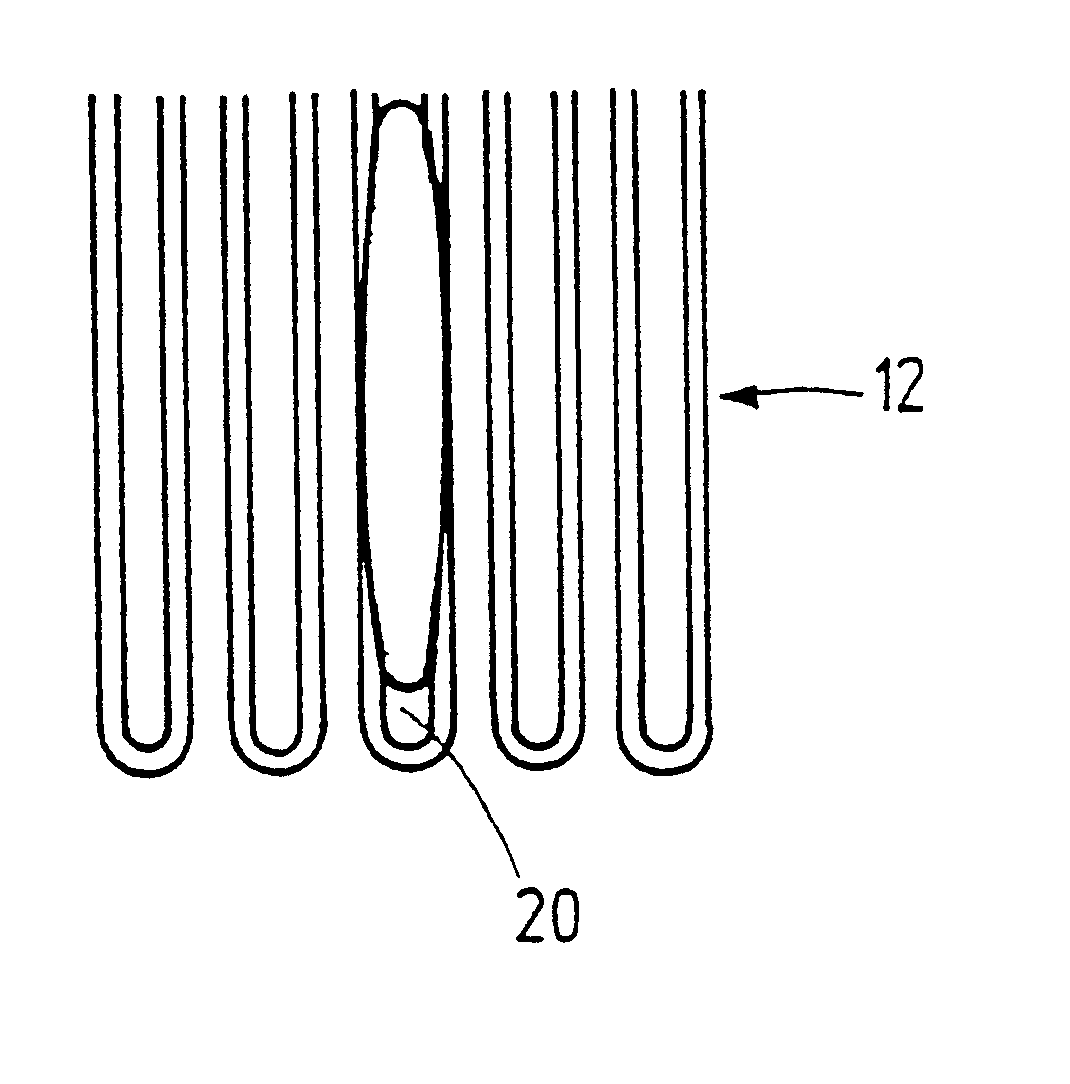

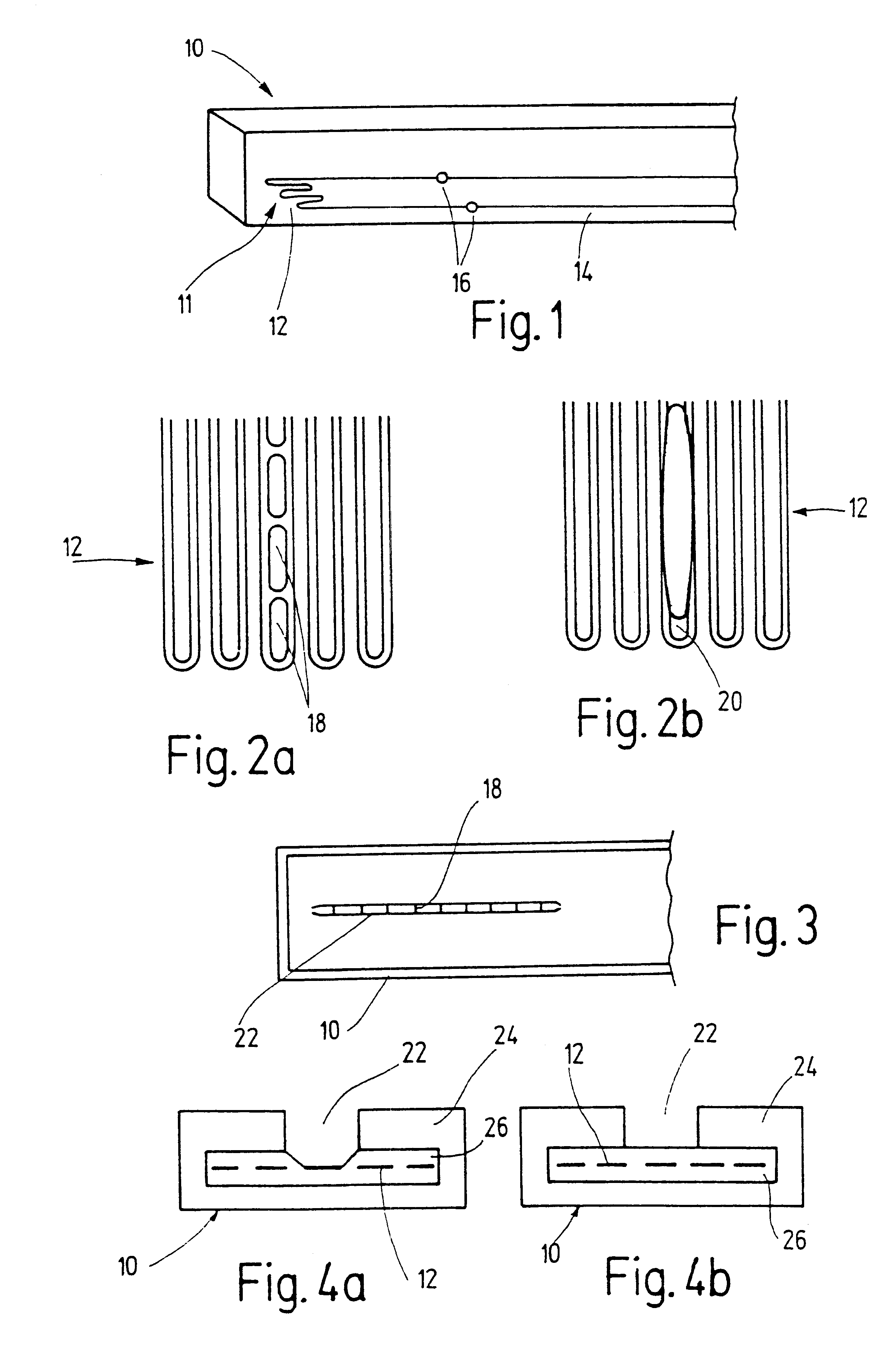

Ceramic layer system and method for producing a ceramic heating device

InactiveUS20030076218A1Easy to glazeTransparent/reflecting heating arrangementsMaterial resistanceCeramic compositeMetallurgy

A ceramic composite having at least one electrical resistor run integrated into the ceramic composite, with the composite including at least one layer that covers the resistor run toward the outside. The layer covering the resistor run has at least one opening through which the resistor run can be trimmed.

Owner:ROBERT BOSCH GMBH

Preparation method of Jun porcelain with natural cracks

InactiveCN107602083AUnable to achieve the effect of natural cracksInhibit sheddingClaywaresThree stageRoom temperature

A preparation method of Jun porcelain with natural cracks comprises specific steps as follows: step 1, a dried biscuit is placed in a kiln for primary firing and a base is obtained; step 2, a layer ofbiscuit material which is 0.1-0.2 cm thick is attached to the surface of the base, and the base is placed in the kiln again for secondary firing; step 3, the base subjected to secondary firing is taken out and placed in a constant-temperature and constant-pressure container after being cooled to 200 DEG C, kept at the constant temperature for 1-2 h, taken out and naturally cooled to the room temperature; step 4, the base subjected to secondary firing is glazed and the glazed base is dried again; step 5, the glazed base is placed in the kiln to be fired, and three stages of glaze firing are performed during firing. The biscuit is subjected to a series of biscuit firing and glaze firing, the strength of the biscuit of Jun porcelain is improved, glazing of the biscuit is facilitated, unevenconcave-convex surfaces occur due to existence of natural cracks on surfaces, and the Jun porcelain is brighter in color gradation due to difference between heating degrees during heating.

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

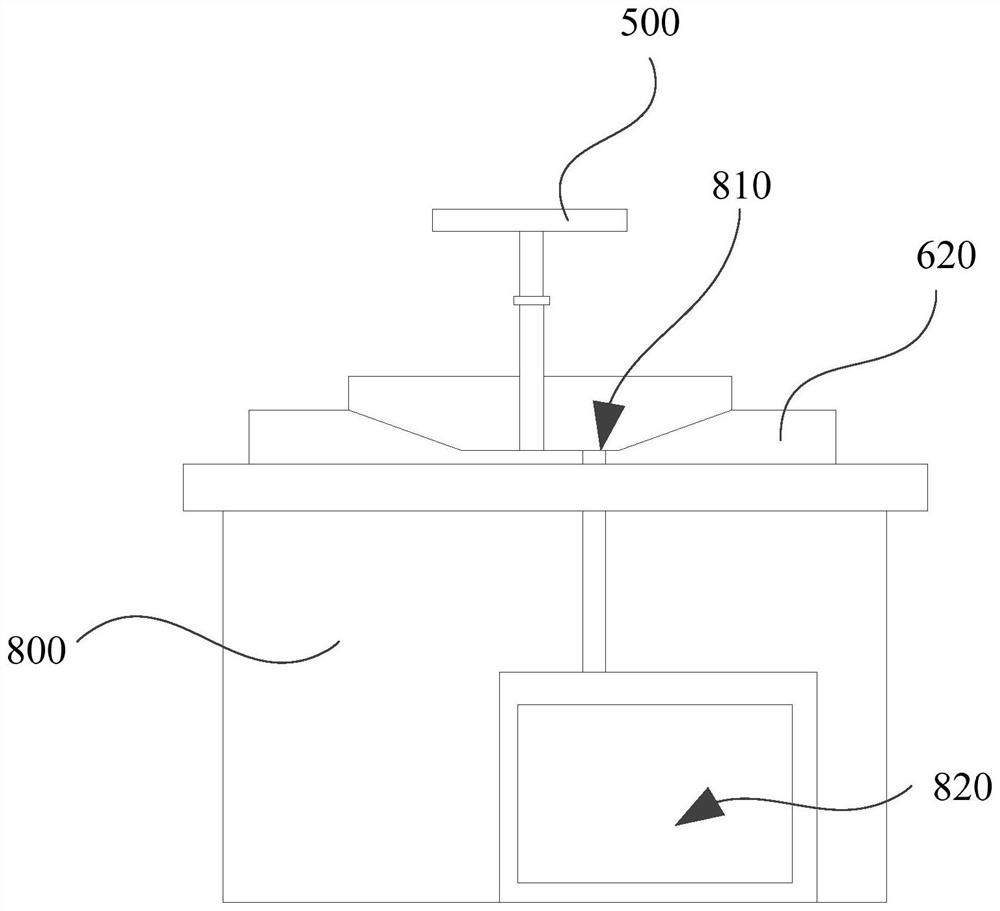

A device for glazing the outer wall of porcelain bowls used in the ceramic industry

ActiveCN112123534BEasy to moveEasy to glazeCeramic shaping apparatusEngineeringMechanical engineering

Owner:广东新来陶瓷有限责任公司

Turnover type glazing device for insulator

The present invention discloses a turnover type glazing device for an insulator, which comprises a feed port, a blower, a storage box and a rolling shaft. A conveyor belt is installed below the feed port; an aerosol nozzle is arranged on the right side of the conveyor belt; the insulator is arranged below the aerosol nozzle; a blow opening is mounted on the right side of the insulator; a spiral transmission shaft is mounted below a heating plate; a fan is mounted above the rear side of a blanking table; a motor is mounted on the right end of the spiral transmission shaft; a water pump is mounted on the left side of the storage box; a filter screen is mounted above the right side of the storage box; a liquid discharge port is mounted above the filter screen; a glaze collecting groove is arranged above the liquid discharge port; a discharging plate is mounted in front of the right side of the glaze collecting groove; and the rolling shaft is located on the inside of the spiral transmission shaft. The turnover type glazing device for the insulator is provided with the glaze collecting groove which can collect the dripping glaze and is used in combination with the liquid discharge portand the filter screen, thereby the environmental protection of the device is increased.

Owner:吴水燕

A high-efficiency ceramic glaze sealing device

ActiveCN110341030BEfficient glazingSimple glazeCeramic shaping apparatusElectric machineryEngineering

The invention relates to the technical field of ceramic glazing devices, discloses an efficient ceramic glazing device, and solves the problems that the existing manual glazing is high in labor intensity, low in production efficiency, complex and inconvenient, and seriously damages the body health of operators. The efficient ceramic glazing device comprises a conveying groove plate, wherein supporting legs are fixedly arranged at the bottom of the conveying groove plate, a first motor is fixedly arranged at one end of the surface of the conveying groove plate, a conveying mechanism is arrangedinside the conveying groove plate, three rotating mechanisms are arranged in the middle of the conveying mechanism, the middle parts of the three rotating mechanisms are provided with fixing mechanisms correspondingly, and two sides of the top of each of the three rotating mechanisms are provided with ceramic blanks correspondingly. According to the efficient ceramic glazing device, the efficientglazing can be carried out on the blank during use, and the glazing process is simple, convenient, stable and effective; and meanwhile, the blank is not in contact with the operators during glazing,so that the body health of the operators is guaranteed.

Owner:XUCHANG UNIV

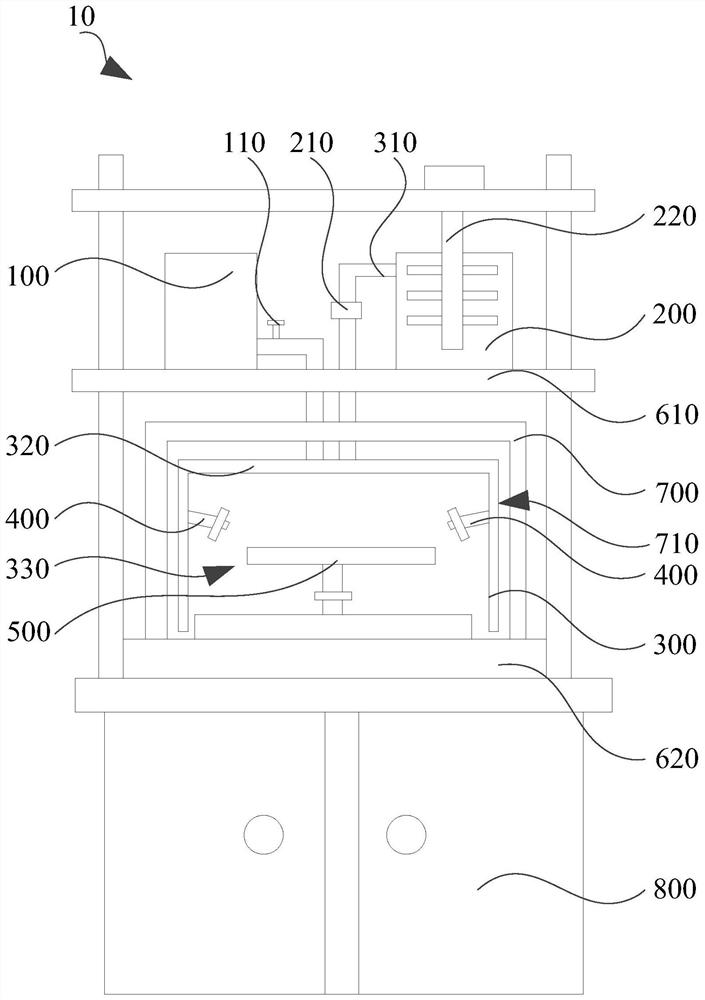

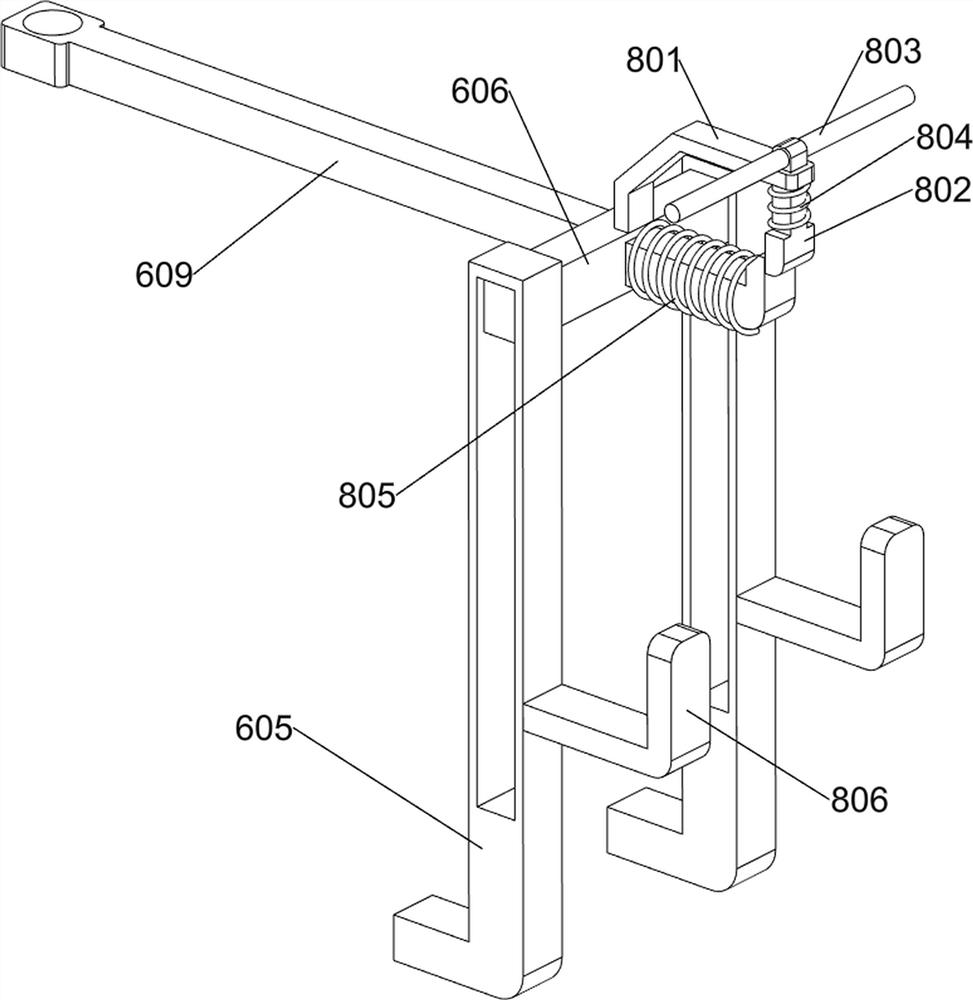

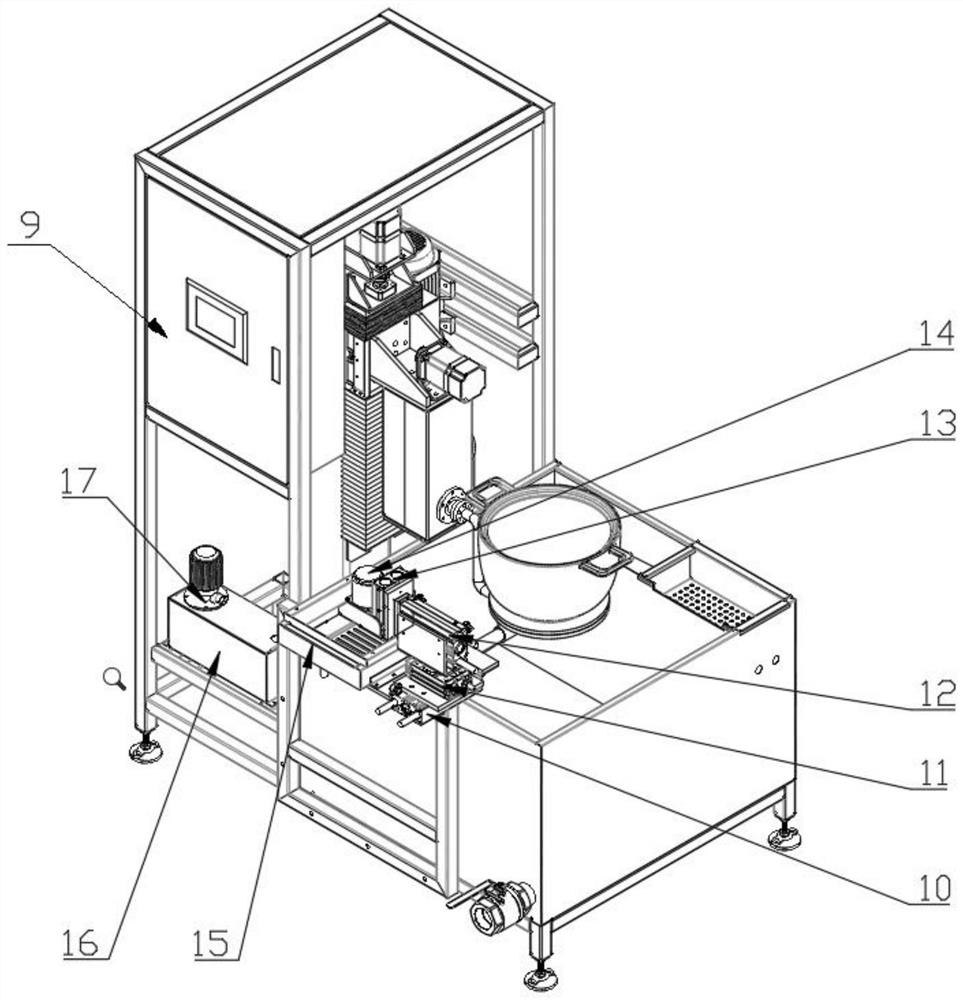

Jewelry glazing detection system and glazing equipment

PendingCN113146815AGuaranteed attachment stabilityHigh structural integrationAuxillary shaping apparatusMechanical engineeringEngineering

The invention relates to a jewelry glazing detection system and glazing equipment. The jewelry glazing detection system comprises the glazing equipment, a detection element and a host. The glazing equipment comprises a cleaning part, a storage part and a spraying pipe, a first accommodating cavity is formed in the cleaning part, and the first accommodating cavity is used for accommodating cleaning liquid. A second accommodating cavity is formed in the storage part and is used for accommodating glaze liquid. A spraying channel is formed in the spraying pipe, a first connecting opening, a second connecting opening and a spraying opening which communicate with the spraying channel are formed in the spraying pipe, the first accommodating cavity communicates with the spraying channel through the first connecting opening, the second accommodating cavity communicates with the spraying channel through the second connecting opening, and the spraying opening is used for spraying out cleaning liquid or glaze liquid. The cleaning part and the storage part are connected to the same spraying pipe, so that the structural integration level of the glazing equipment is improved, and the miniaturization of the glazing equipment is facilitated.

Owner:GUANGDONG BAIYUN UNIV

A kind of equipment for spraying glaze inside the porcelain bottle used in the production of craft ceramics

ActiveCN111113649BAchieve insertionUniform spray treatmentCeramic shaping apparatusGlazeElectric machinery

Owner:广东金润源陶瓷股份有限公司

A glazing device for making a lamp

Owner:刘顶军

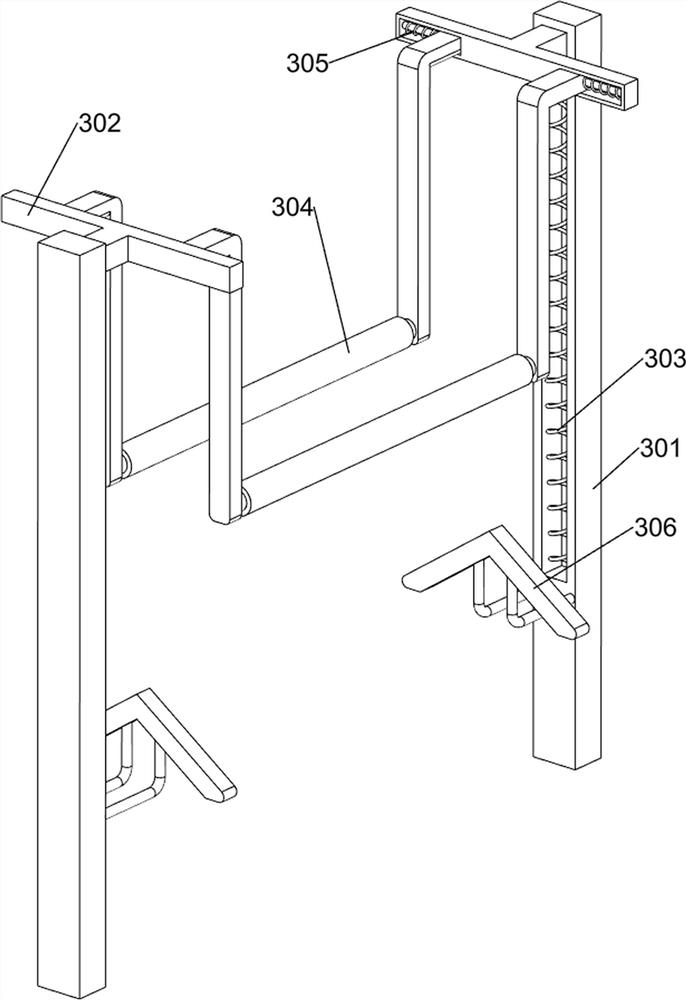

Large ceramic product glazing machine

PendingCN114055608AImprove work efficiencyReduce labor costsCeramic shaping apparatusGlazeElectric machinery

The invention discloses a large ceramic product glazing machine which comprises a rack, a glaze pool, a glaze circulating system, a lifting structure, an overturning structure, a cleaning structure and a sewage treatment structure, wherein the overturning structure comprises a vacuum suction pipe, a suction cup platform, a gear motor, a synchronous belt device and a vacuum generator; the cleaning structure comprises a wiping opening alignment air cylinder, a table placing air cylinder, a wiping surface alignment air cylinder, a high-low position air cylinder and a wiping surface driving motor; a glaze inlet pipe, a filtering pool and a glaze returning opening are further arranged in the glaze pool; and the glaze pool is divided into a glaze inlet area and a glaze returning area through a partition plate. The large ceramic product glazing machine solves the technical problems that no automatic equipment is provided for glazing large ceramic products and most work is manually operated, so that the working efficiency is greatly improved, the labor cost is saved, and the technical problems that the large ceramic products are difficult to transport and dip in glaze are solved.

Owner:河北斯罗米克科技股份有限公司

A skewer glazing device

Owner:梁泽冲

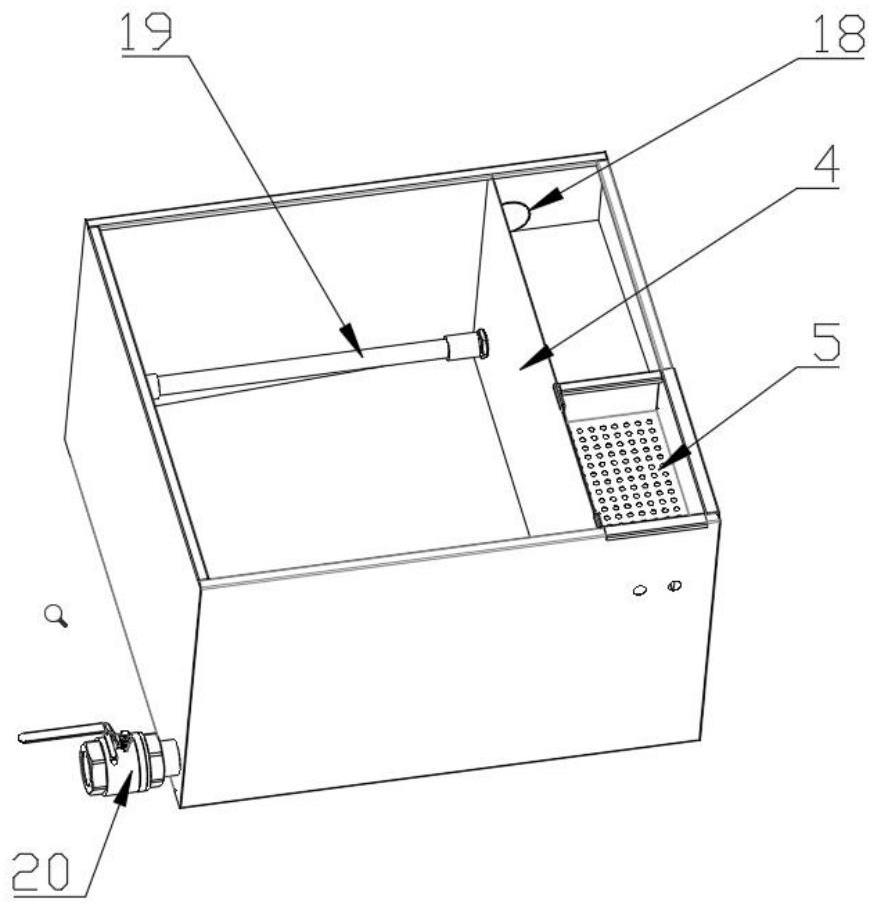

Ceramic glazing and soaking device

The invention relates to a ceramic glazing and soaking device. The device comprises a soaking tank used for containing glaze water, wherein a plurality of workbenches used for carrying ceramic are arranged in the soaking tank, a plurality of nozzles are arranged on the inner side wall of the soaking tank and face the ceramic, the nozzles include water suction nozzles and water spraying nozzles, the water suction nozzles and the water spraying nozzles are connected with a water inlet and a water outlet of a water pump respectively, and an internal flow power mechanism used for disturbing the flow of the glaze water in the ceramic is arranged in the ceramic. According to the device, glaze water flushing flow is formed in the soaking tank through the water suction nozzles, the water sprayingnozzles and the water pump to destroy a water curtain and bubbles formed by the glaze water on the surface of the ceramic, glaze water flushing flow is formed through the internal flow power mechanismto destroy a water curtain and bubbles at the inner side of the ceramic, and therefore both the interior and the exterior of the ceramic can be comprehensively soaked and glazed.

Owner:FUJIAN JIAMEI GRP

A preparation process of Jun porcelain with natural cracks

InactiveCN107602083BUnable to achieve the effect of natural cracksInhibit sheddingClaywaresKilnKiln burner

Owner:YUZHOU ZHENGYUJUN KILN CO LTD

A glazing device for processing daily-use ceramics

The invention discloses a glazing device for domestic ceramic processing and relates to the technical field of ceramic processing. The glazing device for domestic ceramic processing comprises a liquidbox, a bottom plate is fixedly connected to the bottom of the inner wall of the liquid box, a first slurry inlet pipe is arranged at the upper end of the left side of the liquid box, and supporting devices are arranged on the left side and the right side of the lower surface of the liquid box. A slurry tank body is fixedly connected with the upper end of the liquid box, a piston is arranged in the slurry tank body, and a filter net is placed on the slurry tank body and located below the piston. The glazing device for domestic ceramic processing is provided with a motor, a rotating rod, supporting blocks, automatic telescopic rods, connecting rods, supporting plates, a first clamping plate, a second clamping plate, a reset spring, a shaft core, non-slip mats and a circular shaft, so that the clamping effect is good when people glaze ceramic, the ceramic is not prone to falling, cost can be reduced for people, overturning is easy, and using is convenient for working people.

Owner:DABU FUDA CERAMICS

Glaze kerb stone and manufacturing method thereof

InactiveCN106336202AUniform compositionCompact structurePaving gutters/kerbsCeramic materials productionSlagTalc

The invention relates to the technical field of building materials for pavement, in particular to glaze kerb stone and a manufacturing method thereof. The problems that an existing forming process is simple, cracks easily appear in the drying process, the rejection rate is high, strength is not enough, and the technological sintering time is long are solved. The glaze kerb stone is prepared from, by weight, 4.5-5.5 parts of clay, 2.5-3.5 parts of metal smelting solid waste slag, 1.5 parts of feldspar, 0.5 part of talc and a proper amount of water. The preparation method includes the steps of smashing, mixing, green body forming, glazing and sintering, wherein mixing refers to kneading of smashed raw materials by means of a kneading machine, the kneaded raw materials are put in a rotting pond to be rot for 24-48 h, the yield during product drying is facilitated, dried green bodies are smooth in surface, glazing is convenient, and the production cycle of the product is shortened.

Owner:秦正彪

Bowl and dish edge glaze smearing method and device for porcelain processing

InactiveCN111285707ADecrease the tilt angleEasy to placeCeramic shaping apparatusEngineeringMechanical engineering

The invention discloses a bowl and dish edge glaze smearing method and device for porcelain processing; the method is characterized in that the method comprises the following steps: step 1, smearing aglaze coating table with a glaze coating; in an initial state, a second air cylinder completely stretches out, a U-shaped plate is close to an L-shaped plate, a circular plate is far away from a circular groove, a square plate slightly inclines outwards, bowls and dishes are placed between the circular plate and the circular groove, a controller is started, the second air cylinder is started by the controller, the second air cylinder drives the square plate, a small bearing and the circular plate to move, and the bowls and dishes are clamped by the circular plate and the circular groove. Theinvention relates to the technical field of melting and coloring, and in particular, relates to the bowl and dish edge glaze smearing method and device for porcelain processing. The bowl and dish edgeglaze can be convenient for smearing.

Owner:黄明忠

A ceramic glaze soaking device

The invention relates to a ceramic glazing soaking device, which comprises a soaking box for holding glaze water, a plurality of workbenches for placing ceramics are arranged in the soaking box, and several working tables for placing ceramics are arranged on the inner wall of the soaking box facing the ceramics. Nozzle, the nozzle is a water-absorbing nozzle and a water-spraying nozzle, the water-absorbing nozzle and the water-spraying nozzle are respectively connected to a water inlet and a water outlet of a water pump, and the internal flow mechanism for disturbing the flow of glaze water in the ceramic is provided in the ceramic . In the present invention, the water-absorbing nozzle, the water-spraying nozzle and the water pump are used to form the glaze water flushing flow in the soaking tank, destroying the water curtain and blisters formed by the glaze water on the ceramic surface, and forming the glaze water flushing flow through the internal flow mechanism, destroying the water curtain and blisters inside the ceramics , so that the inside and outside of the ceramic can be soaked and glazed in an all-round way.

Owner:FUJIAN JIAMEI GRP

Ceramic layer system and method for producing a ceramic heating device

InactiveUS6642835B2Easy to glazeTransparent/reflecting heating arrangementsMaterial resistanceCeramic compositeMetallurgy

A ceramic composite having at least one electrical resistor run integrated into the ceramic composite, with the composite including at least one layer that covers the resistor run toward the outside.The layer covering the resistor run has at least one opening through which the resistor run can be trimmed.

Owner:ROBERT BOSCH GMBH

Processing device of ignition needle of gas stove as household appliance

InactiveCN107538604AEasy to replaceEasy to controlAuxillary shaping apparatusHydraulic motorSpray nozzle

The invention relates to an ignition needle processing device for a gas stove of a household appliance, which comprises a tank body, a spraying device, a glaze liquid storage tank and a door body. The two ends of the bottom of the tank body are fixed with supporting columns, and one side of the tank body is installed with a A door body, a control panel is installed on one side of the door body, a base is fixed at the bottom of the inside of the tank, and a card slot is arranged on the top of the base, a material trough is fixed above the base, and the bottom of the material trough The middle position is fixed with a block that cooperates with the card slot. Both ends of the inside of the tank are provided with heating blocks. The top of the glaze liquid storage tank is equipped with a pressurizing device, and the bottom of the glaze liquid storage tank The spraying device is connected with the spraying device through the material guide pipe, and the spraying device is evenly equipped with spraying heads. The invention is equipped with a motor, a reducer and a hydraulic telescopic rod, and the motor drives the hydraulic telescopic rod to rotate, so that the main body of the ignition needle fixed at the bottom end of the hydraulic telescopic rod rotates, which facilitates more uniform glazing and better glazing effect.

Owner:王彩英

Oxidation resistance coating material for continuous casting function fire resistance material

The present invention belongs to the technical field of fire resistance materials, and mainly relates to an oxidation resistance coating material for a continuous casting function fire resistance material. According to the coating material, a carbon-containing material is coated with an oxidation resistance coating after forming, and the coated carbon-containing material is subjected to drying and sintering to obtain an oxidation resistance coating material, wherein a loose and porous structure is formed after coating and drying. The raw material components of the oxidation resistance coatingmaterial comprise, by mass, 25-30% of potassium feldspar, 12-17% of pyrophyllite, 47-53% of borax, 5-11% of silica, and a dispersing agent, wherein the weight of the dispersing agent is 0.1-0.25% of the total weight of the potassium feldspar, the pyrophyllite, the borax and the silica. The raw materials and the dispersing agent are mixed and uniformly stirred; the resulting mixture and a binder are placed in a ball mill according to a ratio of 2:1-1:1 to uniformly mix to form the coating material; the coating material is coated on the surface of the formed function fire resistance material toform the coating. The oxidation resistance coating material of the present invention does not peel and bubble during the sintering process along with the fire resistance material, and finally a smooth, uniform and compact glaze layer is formed on the surface of the carbon-containing fire resistance material, such that the purpose of prevention of the carbon-containing fire resistance material from oxidation is achieved.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

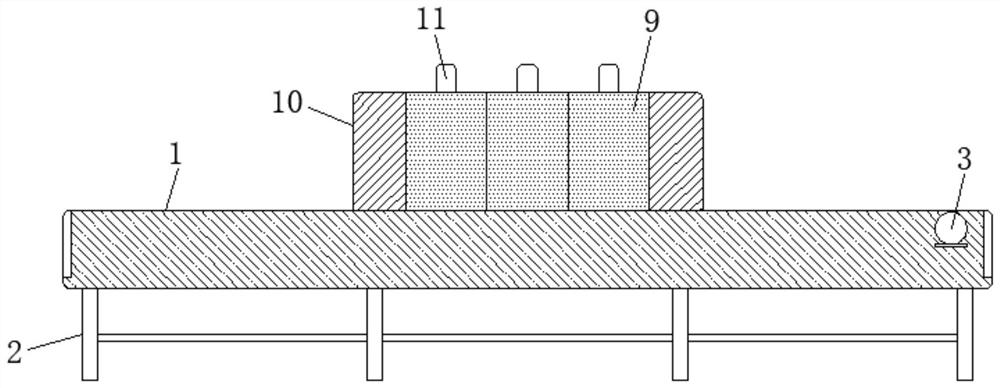

A kind of tile making glazing equipment

The invention relates to a glazing equipment, in particular to a glazing equipment for making tiles. Provided is a tile making and glazing equipment capable of automatic glazing, uniform and efficient glazing, and easy operation. A tile making and glazing equipment, comprising: a bottom plate, a glazing box is arranged on the top of the bottom plate; a communication pipe, a communication pipe is arranged on the glazing box; a glaze storage box, a glaze storage box is arranged on the top of the bottom plate, the glaze storage box and the communication pipe Connection; the first guide rod, the first guide rod is provided on the side of the top of the bottom plate close to the glaze box; the moving mechanism, the movement mechanism is provided between the first guide rod and the bottom plate; the clamping mechanism, the first guide rod is provided with clamping mechanism. The invention realizes the fixing of the tiles through the clamping mechanism, and then under the cooperation of the moving mechanism and the glazing mechanism, the uniform glazing of the tiles can be carried out stably and quickly. When the gear moves downward along the rack, the placing plate drives the The tiles are turned 90 degrees so that the tiles can be glazed better.

Owner:罗爱灵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com