Bowl and dish edge glaze smearing method and device for porcelain processing

A technique for porcelain and rims, which is applied to the field of glaze coating on the rims of bowls and plates for porcelain processing, can solve the problems of unstable manual operation, uneven glazing, poor finished product effect, etc., so as to improve work efficiency and work quality, and facilitate glazing. , the effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

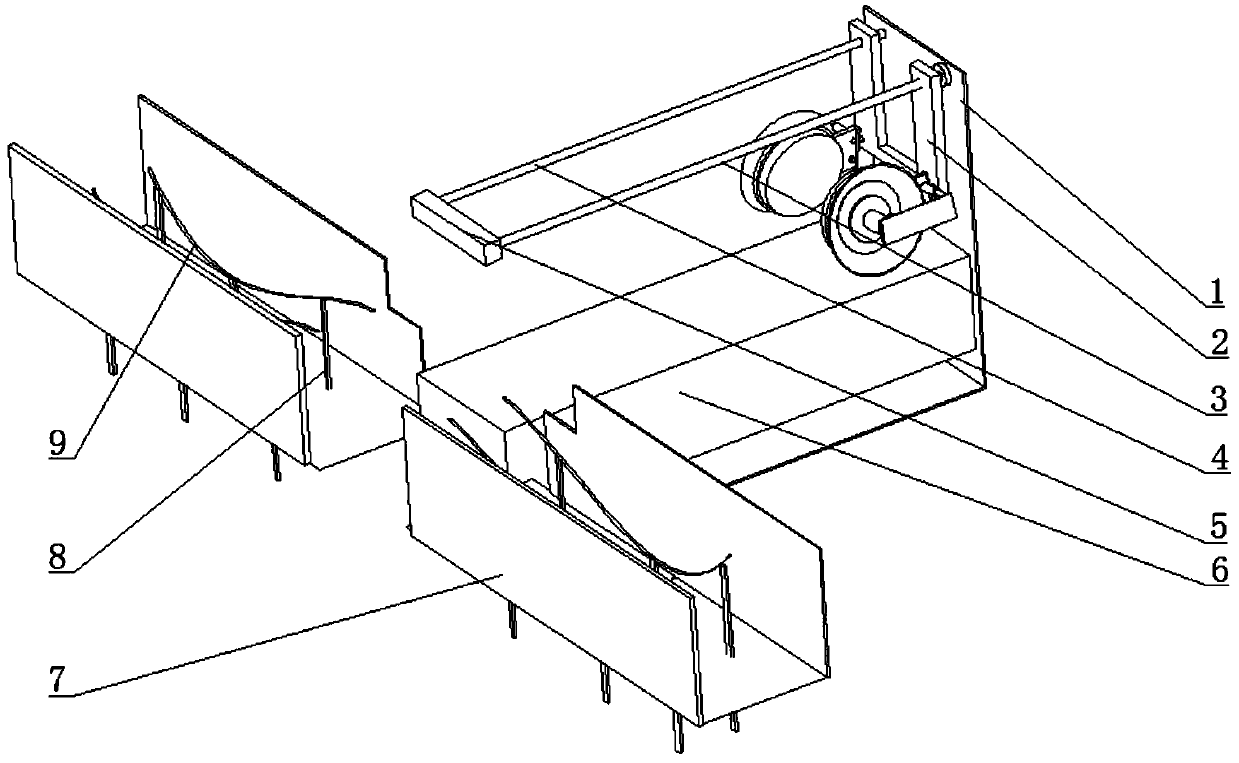

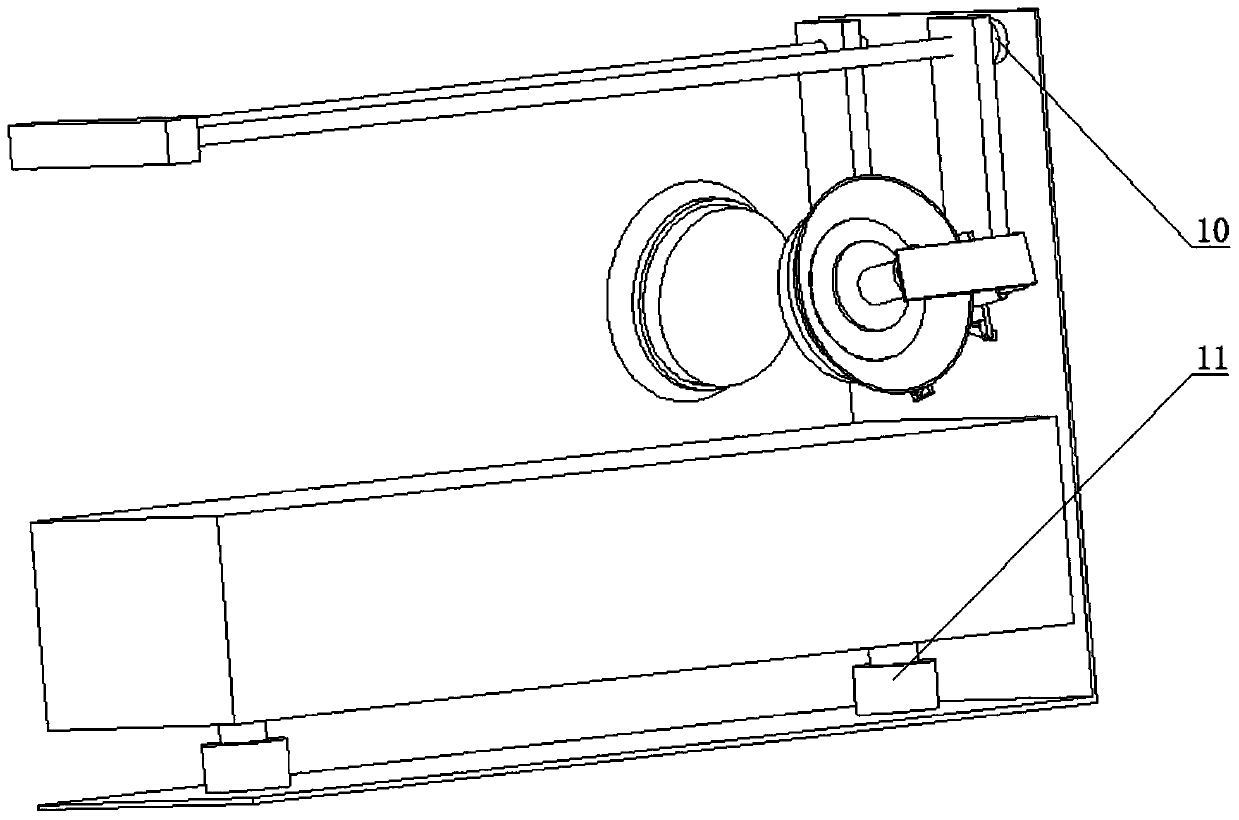

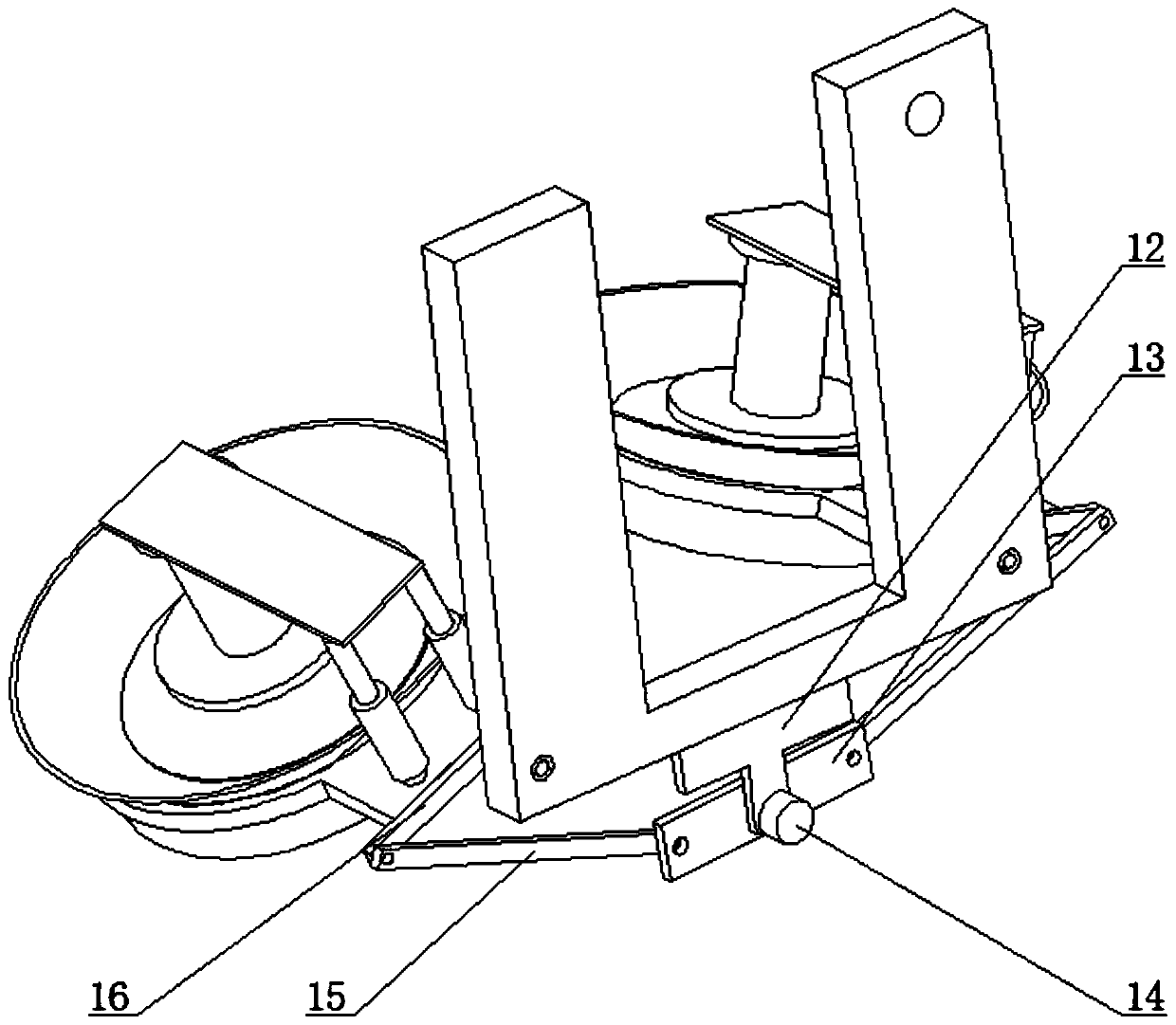

[0036] Such as Figure 1-Figure 9 Shown, the present invention comprises the following steps:

[0037] Step 1: apply glaze paint on the glaze paint table 6;

[0038] Step 2: In the initial state, the cylinder 2 21 is fully extended, the U plate 2 is close to the L-shaped plate 1, the circular plate 25 is far away from the circular groove 26, and the square plate 20 is slightly inclined to the outside, and the bowl plate 18 is placed on the circular plate 25 Between the circular groove 26, open the controller, the controller opens the cylinder two 21, and the cylinder two 21 drives the square plate 20, the small bearing 19 and the circular plate 25 to move, so that the The disc 18 is clamped by the circular plate 25 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com