A kind of tile making glazing equipment

A kind of equipment and tile technology, applied in the field of glazing equipment, can solve the problems of low glazing efficiency and high operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

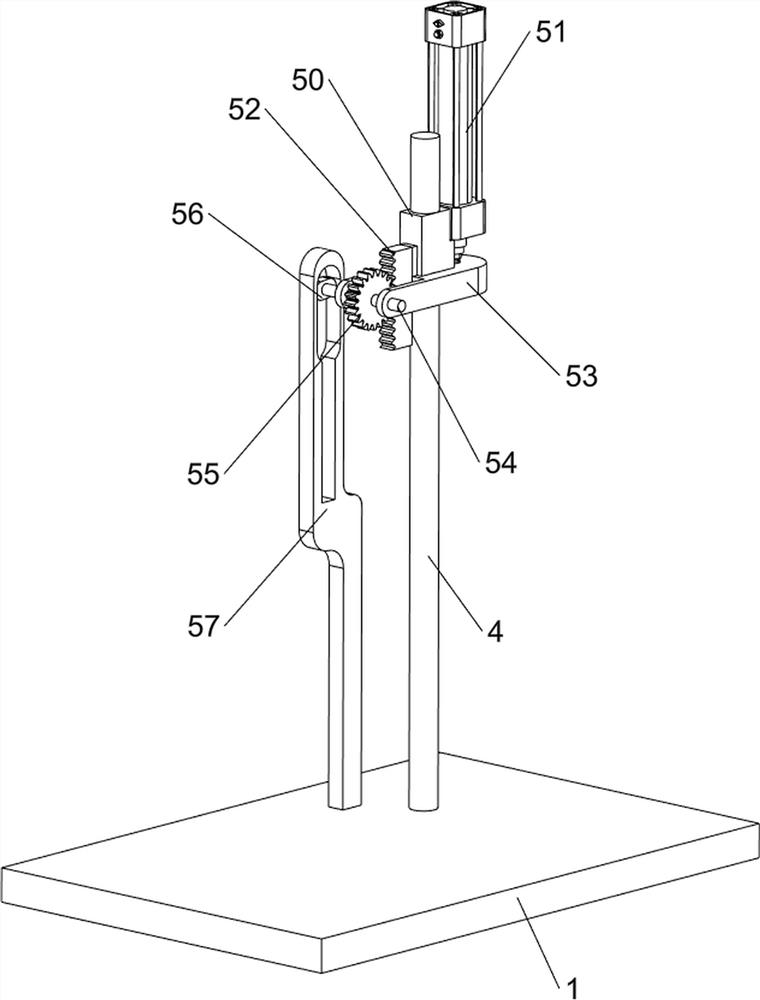

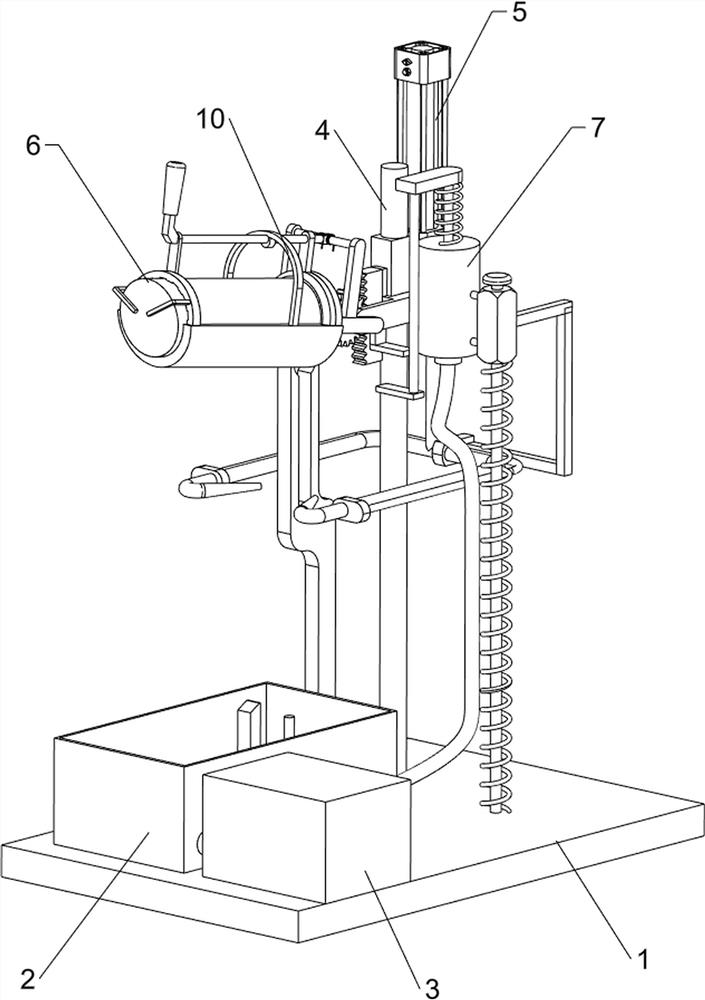

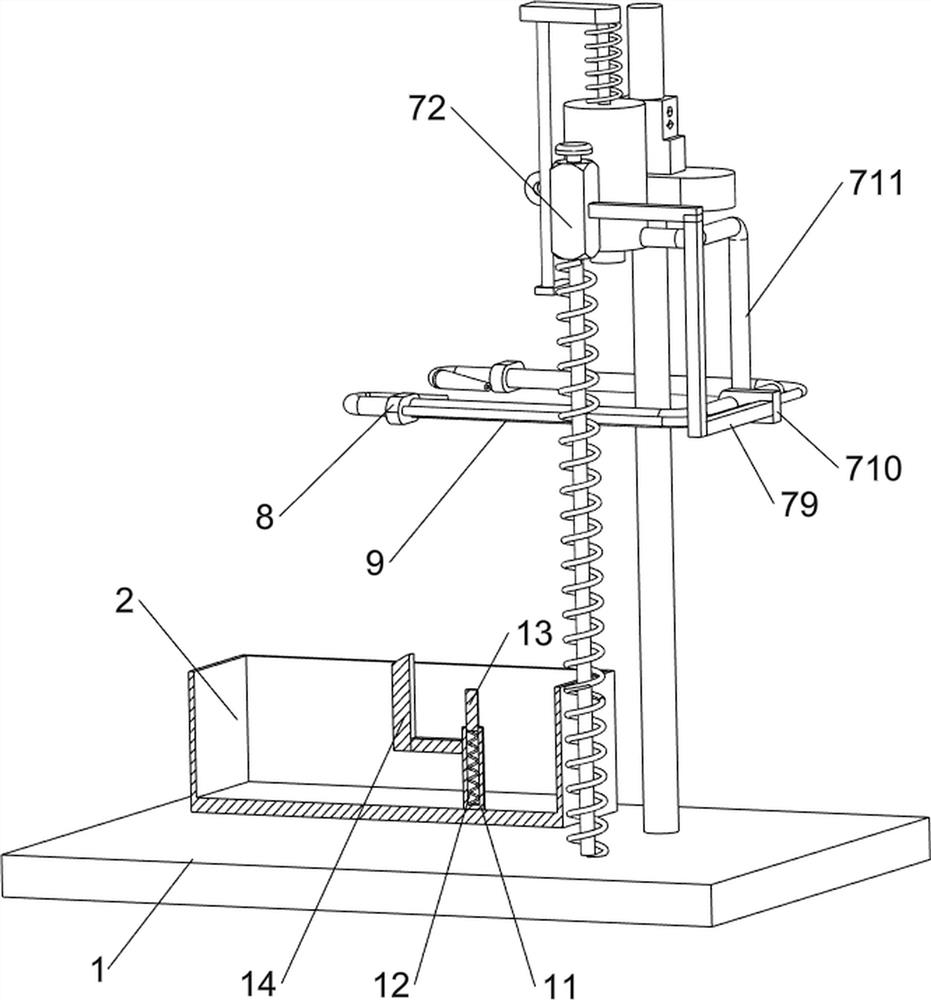

[0023] A tile making glazing equipment, such as Figure 1-5 As shown, it includes a bottom plate 1, a glazing box 2, a connecting pipe 20, a glaze storage box 3, a first guide rod 4, a moving mechanism 5, a clamping mechanism 6 and a glazing mechanism 7, and the top left front side of the bottom plate 1 is fixedly connected with a Glazing box 2, a communication pipe 20 is provided on the right side of the glazing box 2, a glaze storage box 3 is provided on the right front side of the bottom plate 1, the glaze storage box 3 is connected with the communication pipe 20, and a first guide is provided on the left rear side of the top of the bottom plate 1 Rod 4, a moving mechanism 5 is provided between the first guide rod 4 and the bottom plate 1, a clamping mechanism 6 is provided on the first guide rod 4, and a glazing mechanism 7 is provided on the first guide rod 4.

[0024] When people need to use this equipment, first people pour the glaze into the glaze storage box 3, the gl...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 , image 3 and Figure 5 As shown, it also includes a second connecting block 8, a special-shaped bracket 9 and a U-shaped block 10, and a second connecting block 8 is fixedly connected to the left and right symmetrically on the glaze spray pipe 711, and a special-shaped bracket 9 is arranged between the second connecting blocks 8. The special-shaped bracket 9 passes through the first connecting block 710 , and the pressing bar 65 is provided with a U-shaped block 10 , and the U-shaped block 10 is in contact with the placement plate 61 .

[0033] Since the glazing pipe 711 is a hose, the second connecting block 8 and the special-shaped bracket 9 can better support the glazing pipe 711, and at the same time, the U-shaped block 10 can protect the glazed tiles, so as to prevent the tiles from going upwards. When moving, the glaze spray pipe 711 wipes off the glaze on the tile.

[0034] It also includes a sliding sleeve 11, a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com