Ceramic glazing and soaking device

A technology of ceramics and immersion box, which is applied in the field of ceramic processing and can solve the problems of difficulty in immersion and glazing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

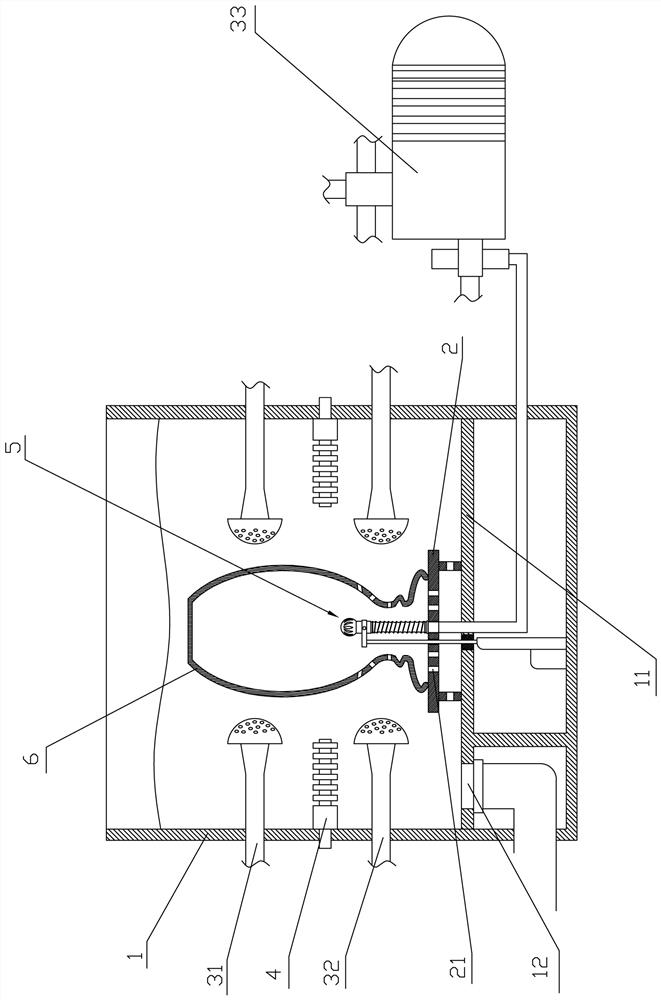

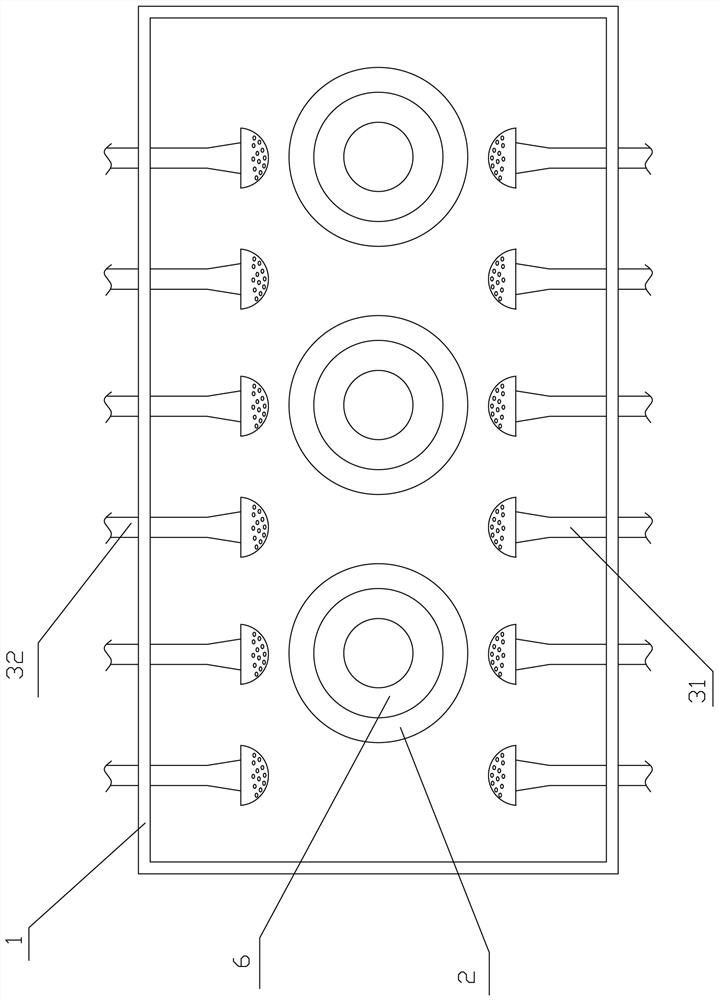

[0025] refer to Figure 1 to Figure 3 , a ceramic glazing soaking device, including a soaking box 1 for holding glaze water, a partition 11 and a drain 12 for discharging glaze water are arranged in the soaking box 1. A plurality of workbenches 2 for placing ceramics 6 are provided at intervals on the partition 11 . The pottery 6 is buckled upside down on the workbench 2, and several water inlet holes 21 are hollowed out on the workbench 2, through which glaze water can pour into the pottery 6 through the water inlet holes 21. Soaking case 1 inner side wall is provided with several nozzles facing ceramics 6, and nozzles are water-absorbing nozzles 31 and water-spraying nozzles 32, and water-spraying nozzles and water-spraying nozzles 32 are connected with the water inlet and the water outlet of a water pump 33 respectively, and this implementation is through the water-absorbing nozzles 31. The water spray nozzle 32 and the water pump 33 constitute the glaze water circulation ...

Embodiment 2

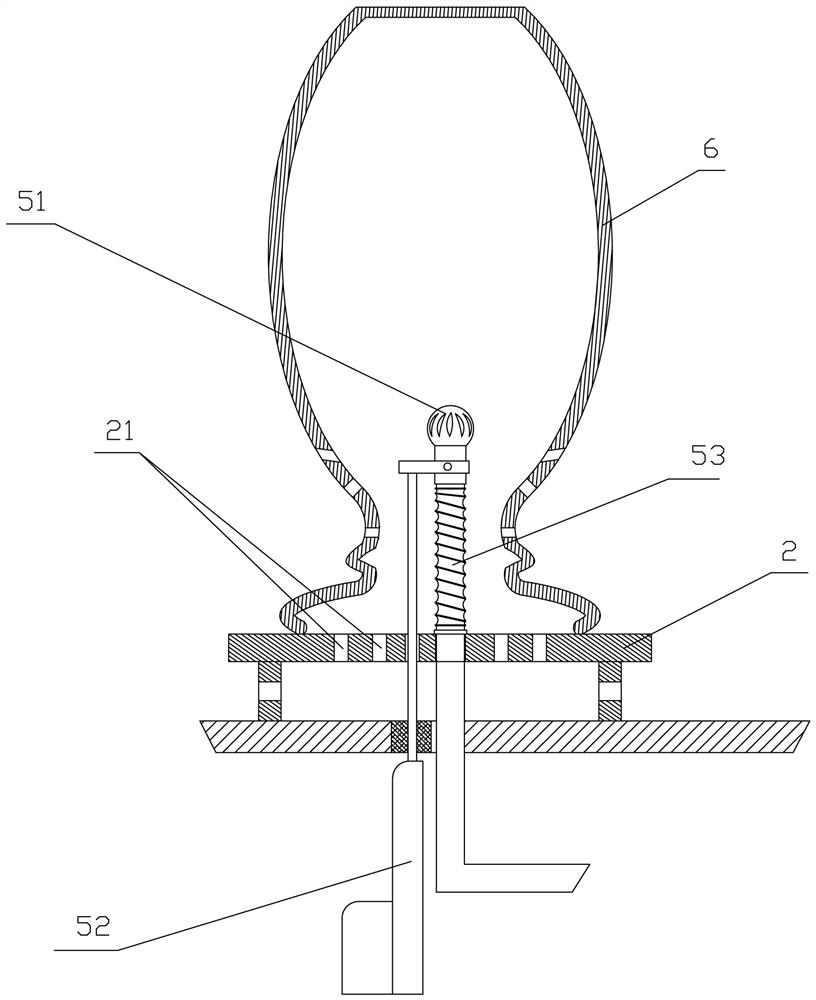

[0030] refer to Figure 4 and Figure 5 , the structure of this embodiment is basically the same as that of Embodiment 1, and will not be repeated here. The difference is that the internal flow power mechanism 5 includes a rotating shaft 54 extending into the ceramic 6 and a rotating shaft 54 for driving the rotating shaft 54 to rotate. The servo motor 55 is arranged under the partition 11 . A plurality of rotating fan blades 56 are arranged on the rotating shaft 54, and the rotating fan blades 56 are made of bendable plastic material.

[0031] refer to Figure 4 and Figure 5 , when the present invention is soaked and glazed ceramics 6, especially when ceramics with holes 6 is soaked and glazed, glaze water is poured into the soaking box 1, and the nozzle near the holes of ceramics with holes 6 is connected with the water inlet of water pump 33, for Water suction nozzle 31. The water pump 33 and the servo motor 55 run, the water flow in the soaking tank 1 forms a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com