Glazing device for strung spoons

The technology of string spoon and transmission device is applied in the field of string spoon glazing device, which can solve the problems of long soaking time, insufficient soaking time to affect the effect of ceramic spoon glazing, inability to soak ceramic spoon, etc., so as to achieve the effect of convenient glazing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

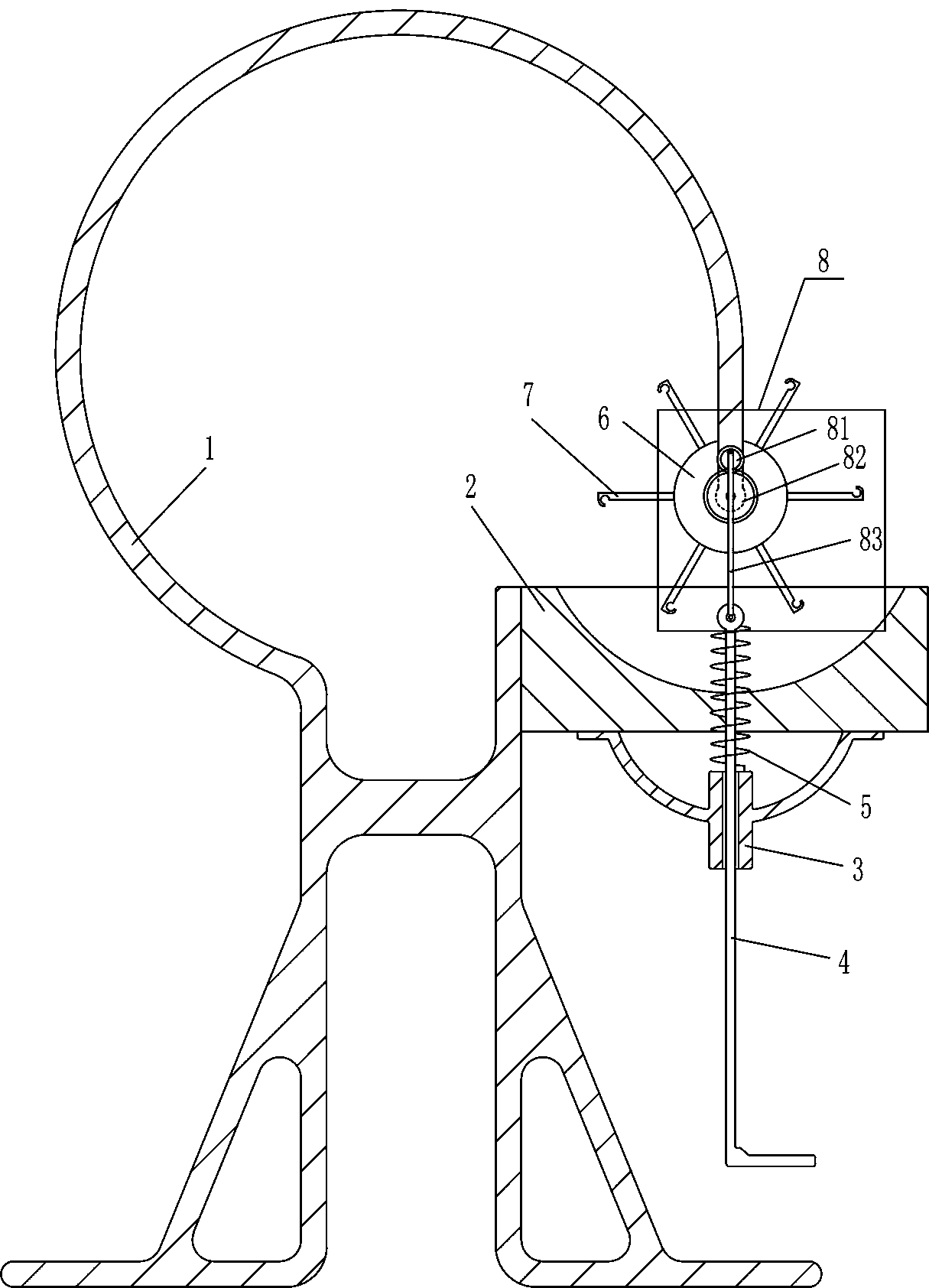

[0019] A skewer glazing device, such as figure 1 As shown, it includes a bracket 1, a material storage box 2, a first sliding sleeve 3, a pedal 4, a return spring 5, a turntable 6, a hook 7 and a transmission device 8, and the right side of the middle part of the bracket 1 is fixedly connected with a material storage box 2, The bottom of the material storage box 2 is fixedly connected with a first sliding sleeve 3, and a pedal 4 is slidably connected in the first sliding sleeve 3. The upper part of the pedal 4 is covered with a return spring 5, and the two ends of the return spring 5 are connected with the first sliding sleeve respectively. The upper part of 3 is fixedly connected with the upper part of pedal 4, and the rear side of the right part of support 1 is rotatably connected with turntable 6, and the outside of turntable 6 has ring arrays 7 in front and rear, and the front side of turntable 6 is connected with transmission device 8, pedal 4 The top of the top is connec...

Embodiment 2

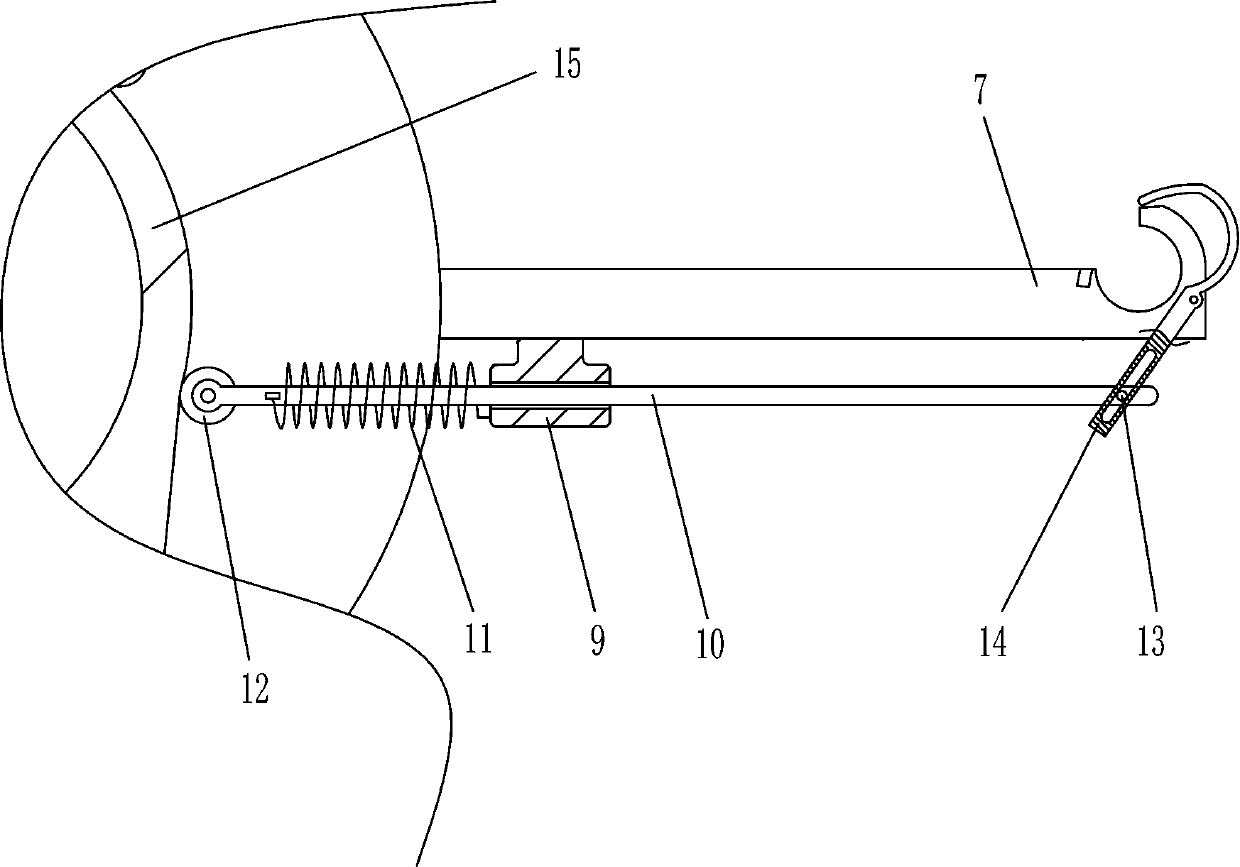

[0024] On the basis of Example 1, such as figure 2 Shown, also include fixing mechanism and cam 15, the bottom of each hook 7 is all provided with fixing mechanism, the right part of support 1 is fixedly connected with cam 15, and cam 15 is the same circle center position with rotating disk 6, and fixing mechanism includes the first Two sliding sleeves 9, the first sliding bar 10, the first spring 11, the first roller 12, the pin bar 13 and the swing bar 14, the bottom of each hook 7 is fixedly connected with the second sliding sleeve 9, the second sliding sleeve 9 The inner sliding type is connected with the first slide bar 10, and the inner end of the first slide bar 10 is covered with the first spring 11, and the two ends of the first spring 11 are connected with one side of the second slide sleeve 9 and the first slide bar 10 respectively. The inner end is fixedly connected, the inner end of the first slide bar 10 is rotatably connected with the first roller 12, the outer...

Embodiment 3

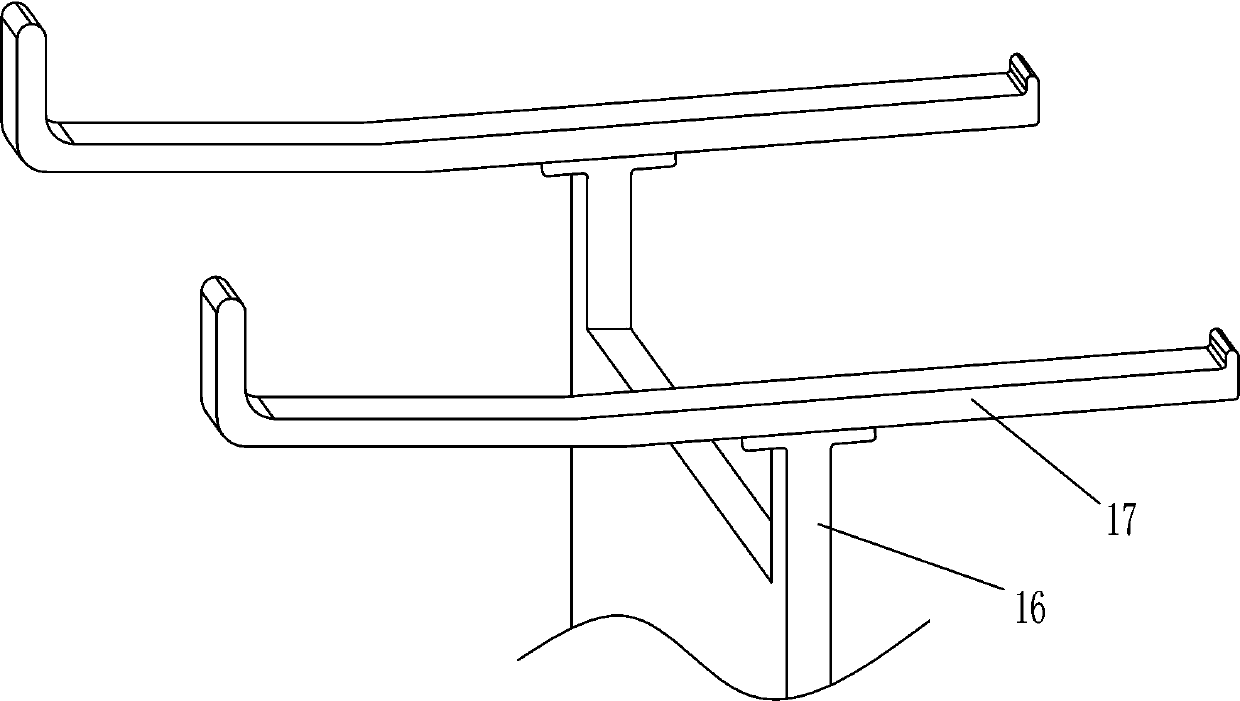

[0027] On the basis of Example 2, such as Figure 3-4 As shown, it also includes a second slide bar 16, a support plate 17, a second spring 18, a second roller 19 and a first bump 20, and the middle part of the bracket 1 is slidably connected with the second slide bar 16, and the second slide bar The front and rear ends of the top of 16 are fixedly connected with support plates 17, and the right part of the second slide bar 16 is covered with a second spring 18, and the left and right ends of the second spring 18 are connected with the right side of the support 1 and the second slide bar 16 respectively. The right part is fixedly connected, and the rear right part of the second slide bar 16 is rotatably connected with a second roller 19 , and the left side of the pedal 4 is fixedly connected with a first lug 20 , and the first lug 20 is in contact with the second roller 19 .

[0028]When the ceramic spoon is glazed, the pedal 4 moves down and squeezes the second roller 19 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com