Inner glazing device for bowl-shaped ceramics

A ceramic and bowl-shaped technology is applied in the field of glazing devices, which can solve problems such as affecting the quality of glazing of bowl-shaped ceramics, and achieve the effects of convenient glazing, prevention of displacement, and convenient use of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

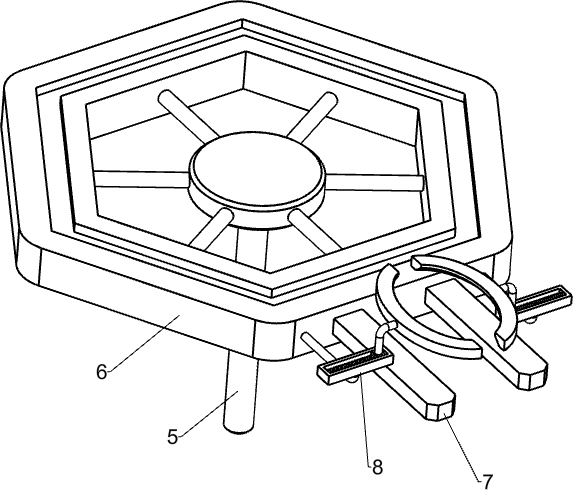

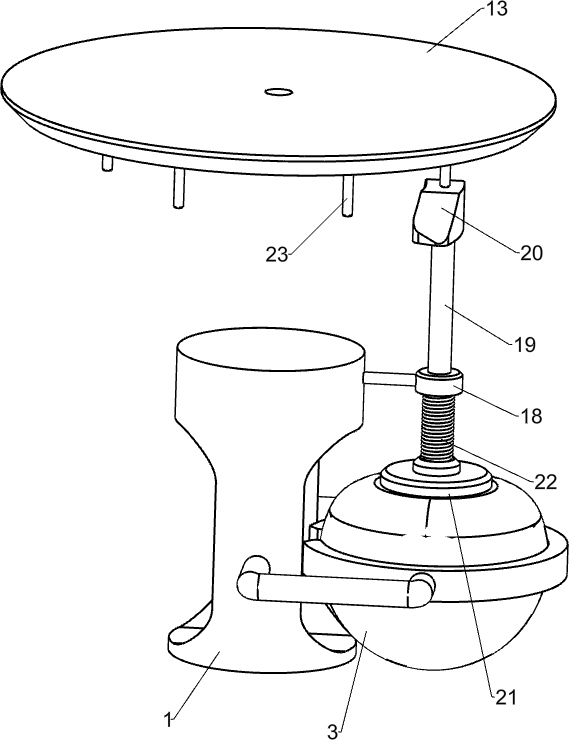

[0022] An internal glazing device for bowl-shaped ceramics such as Figure 1-4 As shown, it includes a support frame 1, a liquid storage frame 2, an air bag 3, a power assembly, and a placement and fixing assembly. The airbag 3 has a pipeline on the airbag 3, and the pipeline is in the liquid storage frame 2. The power assembly powered by the motor is installed on the top right side of the support frame 1, and the power assembly is installed on the top of the power assembly. Performs fixed placement and fixation of components.

[0023] When it is necessary to use the device for glazing bowl-shaped ceramics, first pour the glaze into the liquid storage frame 2, then place the bowl-shaped ceramics upside down on the placement and fixing assembly, and then control the power assembly to start working to drive the placement and fixing The assembly and the bowl-shaped ceramics on it are rotated. When the bowl-shaped ceramics rotates to the top of the air bag 3 pipeline, step on the...

Embodiment 2

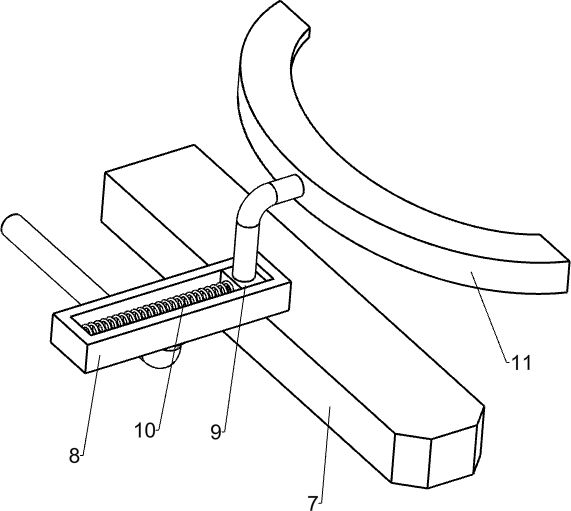

[0029] On the basis of Example 1, such as Figure 5-7 As shown, it also includes a first special-shaped rod 12, a disc 13, a wedge block 14, a second special-shaped rod 15, a second spring 16 and a swash plate 17, and a first special-shaped rod 12 is welded between the front and rear sides of the right side of the liquid storage frame 2. The special-shaped rod 12, the lower part of the rotary rod 5 is keyed to the disc 13, and the top of the disc 13 is welded with wedge-shaped blocks 14 at even intervals. The middle part of the first special-shaped rod 12 is slidingly provided with the second special-shaped rod 15. The second spring 16 is connected between the first special-shaped rod 12, the second special-shaped rod 15 cooperates with the wedge block 14, and the front and rear sides of the second special-shaped rod 15 are welded with slant plates 17, and the swash plate 17 and the arc clamp Plate 11 fits.

[0030] When the rotating rod 5 rotates, it drives the disc 13 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com